Pyrolisis of Kapok (Ceiba pentandra) Pods Wastes as Sources of

Potassium Oxide (K

2

O)

Lilis Sukeksi

1,2

, Chandra Sitorus

1

and Andy Junianto Sidabutar

1

1

Department of Chemical Engineering, Faculty of Engineering, Universitas Sumatera Utara, Jl. Almamater Kampus USU,

Medan 20155, Indonesia

2

Natural Produk Base of Technology, Centre of Excellent, Universitas Sumatera Utara, Jl. Dr. T. Mansur No. 9 Kampus

USU, Medan 20155, Indonesia

Keywords: Waste, Utilized, Kapok Pods, Burned, Potassium Oxide.

Abstract: Nowadays, various combinations of agricultural waste and others material have been successfully made into

commercial products. Kapok pods can be processed into a source of potassium oxide which may have an

impact on the reduction of environment pollution caused by industrial kapok. The purposes of this works were

to determine the best of combustion time and temperature to produced potassium oxide from ash that made

from kapok pods. The kapok pods were dried at 110˚C for 24 hours to obtain the dry of kapok pods. Those

kapok pods were burned at 500˚C, 550˚C, 600˚C, and 650˚C by muffle furnace, with a burning time of 3, 4,

5, and 6 hours. The potassium that contained in ash had been extracted by distilled water for 24 hours. The

highest content of Potassium Oxide (K

2

O) resulting from the 3 hours of combustion at 500˚C was 35.91%.

Atomic Absorption Spectroscopy (AAS) was used to analyse the Potassium Oxide (K2O).

1 INTRODUCTION

Kapok tree (Ceiba pentandra) is a tropical tree comes

from South America and has spread to the rain forests

of West Africa and Southeast Asia from the Malay

Peninsula to the Indonesian archipelago (Mojica,

2002), (Chaiarrekij, 2011).

Kapok tree has many uses for humans, for

example wood is light and porous, so good for

carving, casket and canoeing. Delicate fibers can be

used as mattresses and pillows, and the seeds can be

used as bio diesel (Putri, 2012) (Bates, 2004), (Orwa,

2009). Other parts of the tree can also be used as a

drug for example by drinking a decoction of cured

skin can be useful as a diuretic, aphrodisiac, and to

treat headaches, as well as type II diabetes (rainforest-

alliance.org, 2018), (Wikipedia, Ceiba Pentandra,

2017).

Kapok plantations are common in Indonesia,

spreading from the region Lebak Wangi, Bandung,

Pati, Kudus, Jepara, in west and center of Java.

Meanwhile in East of Java are Tulung Agung, Blitar,

Pasuruan, and Banyuwangi area. According to the

estate agency, Pati is the most spacious area of kapok,

ranges about 15,020 hectares, meanwhile Kudus

reach about 4,000 hectares. Total area for the territory

development of Kapok in region Centre of Java

covering area of 95,107.17 hectares. This area can

produce kapok fiber 340 kg, seed 220 kg, pods or

shell 540 kg (Wibowo, 2012). Research conducted by

Anigo and others also says that the content of the

kapok pods is 57.87% of the total weight of the fruit

of the kapok. Obviously, it can be concluded that

industry generates waste kapok pods in bulk that can

pollute the environment. Therefore, it is necessary to

explore the potential of waste kapok pods can be

different types of products that have economic value.

In addition to economic value, the kapok tree can also

be used as a buffer against erosion, flood control, as

well as green plants that can also be used to conserve

natural resources. Indonesia is the largest producer of

kapok before World War I in the world, where the

biggest kapok production is from the island of Java.

Kapok plantations in Indonesia are owned by, private

and government plantation estates.

Agricultural waste is the result of agricultural

activities, may be in the form of chaff, straw, cob or

fiber (Abba, 2013). In recent time, industry must

move towards a green industry and sustainable

development, global warming and the depletion of

natural resources has occurred and will continue.

Kapok pods is kapok industrial waste that still

Sukeksi, L., Sitorus, C. and Sidabutar, A.

Pyrolisis of Kapok (Ceiba pentandra) Pods Wastes as Sources of Potassium Oxide (K2O).

DOI: 10.5220/0008552202290234

In Proceedings of the International Conference on Natural Resources and Technology (ICONART 2019), pages 229-234

ISBN: 978-989-758-404-6

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

229

containing potassium 20% -25% (Purbasari, 2008).

The potassium compounds contained in the kapok

pods, can be manufactured into useful products, such

as raw materials for the manufacture of soap and

shampoo (Chekuboyina, 2012).

Pyrolysis is a process of thermo chemical that can

be done on the conversion of biomass which has a low

density or organic materials into the biomass has a

high energy. Pyrolysis involves the heating of organic

material to temperatures over 400 ° C in the absence

of oxygen. At this temperature, organic material

normally decompose generating steam phase and

phase residual solid (bio char). On cooling the steam

pyrolysis, polar compounds with high molecular

weight condensed as a liquid (bio-oil) while the

molecular weight volatile compounds remains low in

the gas phase (Laird D. A., 2009).

The consider factors in conducting pyrolysis:

a. Temperature pyrolysis, which affect the resulting

product, it is caused the increase of the

temperature then the process will be more perfect.

b. Time of pyrolysis, the longer the pyrolysis time

will improve the results of liquid and gas, whereas

the solid of results generated will decrease.

c. Moisture content of materials, if the moisture

content higher cause the time used will be longer

so that more energy is needed.

d. The size of the material, when the bigger size of

material, the equipment used is greater.

The steps that must be done to get the minerals

that formed in the ash during combustion is still

unclear, but for obvious reasons it is assumed that the

conversion of mineral changed based on the

temperature of combustion. Carbonate is formed at

low temperatures while the ashes will be formed at

high temperatures in an atmosphere containing

oxygen, which is the main form of metal oxides. At

high temperatures, potassium oxides formed will

react with other elements to form chemical bonds, in

the same situation would occur dissociation of

sodium and potassium oxide compounds and will

undergo rapid vaporization. While at low

temperatures, the heat will move to the surface of

KOH, will then form K2CO3.

Soda Q is extracts combustion results from the

Kapok pods. There are several stages of process to

manufacture Soda Q maximum. The stages are

extraction, evaporation, and crystallization. Soda Q

generally contains 50.78% K

2

CO

3

, 26.27% Na

2

CO

3

,

and 4.37% NaOH (Wibowo, 2012).

This study will evaluate the effect of temperature

and time pirolis on the quality and amount of K

2

O

produced. Temperatures used in the pyrolysis process

are 500, 550, 600 and 650 C, while the burning time

are 3, 4 and 5 hours.

2 METHODOLOGY

2.1 Raw Materials and Equipment’s

The materials used in this research are the skin or

pods of the fruit of the kapok (Ceiba Pentandra),

aquadest, acetic acid (CH

3

COOH), and

phenolphthalein indicator.

The instrument used was a muffle furnace as

burner sample, oven as a drying to calculate the

moisture content, porcelain bowls as a sample

container while burning, analytical balance to

measure the mass of the material, a beaker glass as a

container to extract the ashes, a measuring cup to

measure the volume of the solution.

2.2 Procedure of Making the Ashes

In the process of making the ashes, first step, the

kapok pods was inserted into the oven at a

temperature of 110˚C for 24 hours in order to reduce

the moisture content. Then the kapok pods was

weighed as much as 20 g, and was inserted into the

muffle furnace combustion, with temperature and

time that have been determined.

2.3 Determination of Normality

To determine the normality of aqueous alkaline

extracts by the method of titration of acid base. 1 gr

ash dissolved in 30 ml aquadest and soaked for 24

hours, the solution is then filtered using filter paper

and the filtrate accommodated in an erlenmeyer flask.

Then do a titration using acetic acid (CH

3

COOH) 0.1

N by adding phenolphthalein as an indicator. The

normality from the extract can be calculated from the

total volume of titration.

2.4 Determination of pH

1 gr ash dissolved in 30 ml of aquadest and soaked for

20 minutes, the solution is then filtered using filter

paper and the filtrate was accommodated in a beaker

glass. Then the pH of each extract was measured

using a pH meter.

2.5 Determination of Ash Yield

In the process of making the ashes, kapok pods were

inserted into the oven at a temperature of 110˚C over

ICONART 2019 - International Conference on Natural Resources and Technology

230

the past 24 hours to reduce the moisture content. Then

the kapok pods weighed as much as 20 g, inserted into

the muffle furnace with the time and temperature

which has been specified. Results of the combustion

ash was weighed and ash yield can be calculated by

the equation:

Ash Yield = ( M2 / M1) × 100 % ………… .(1)

Where:

M1 : weight of the initial sample (g)

M2 : weight of the end sample or ash (g)

Then the ash yield as a sampling was taken as 1

gr and it would be analyzed to determine the levels of

K

2

O using an Atomic Absorption Spectrophotometer

(AAS).

3 RESULT AND DISCUSSIONS

3.1 Moisture Content of Kapok Pods

Utilization of kapok pods as alkaline source can be

done in 2 stages, the first step was process reduction

moisture content of the kapok pods and the second

was process pyrolysis kapok pods using the muffle

furnace. On the process of reduction of moisture

content, the kapok pods are dried in the oven until the

kapok pods become dry and until the fixed weight.

Moisture content of the kapok pods down to 90%

from the initial weight, with drying time 24 hours in

the oven.

Some researcher have examined about the

moisture content of kapok pods and they said that

moisture content significant influence the nature of

biomass that would serve as a source of energy

especially its influence the heat generated value. The

higher moisture content resulting in the more low

value biomass heat. This is due to more heat is needed

to remove the water in the biomass to be steam so the

remaining energy will be smaller in the fuel

(Haygreen and Bowyer 1996). Good biomass for

energy is to have a low moisture content, its because

at the time of the burning they not a lot of smoke

(Hendra dan Wirnani 2003). Putra has reported that

kapok pods moisture content at dry air around of

9.54-14.04% (Putra, 2014; Hendra D, 2003;

Haygreen, 1996).

3.2 Influence of Combustion

Temperature of Dry Kapok Pods to

the Normality (N)

The results obtained from the combustion

experiments, was extracted using aquadest as a

solvent, and soaking for 24 hours, then filtered with

filter paper and the filtrate was analyzed using

titration method by acid to determine the

concentration of base that conceived from the results

of the combustion. The influence of the temperature

of combustion versus normality extract from the

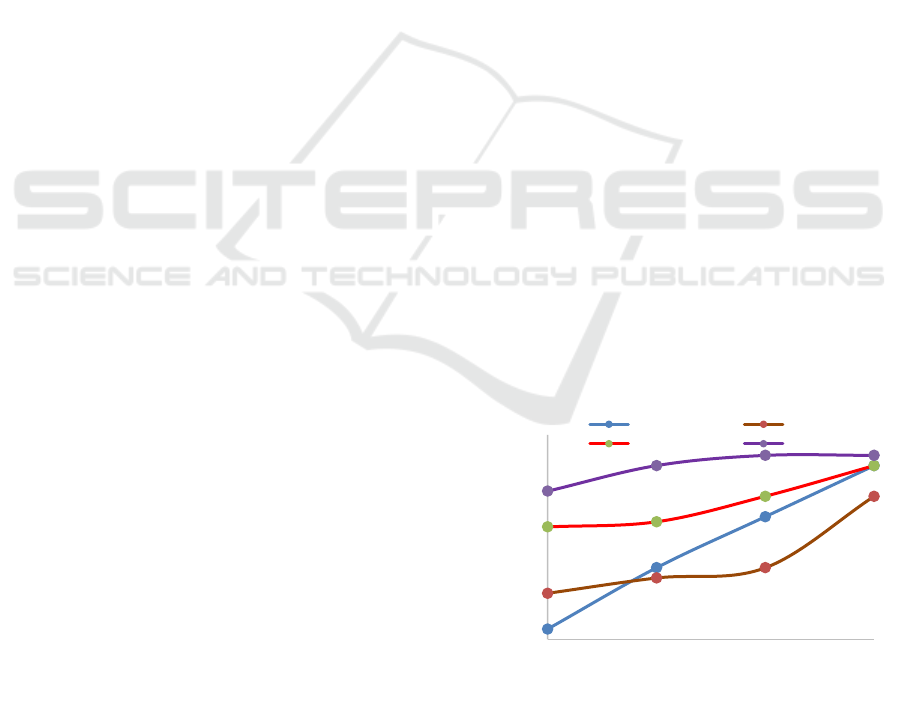

ashes can be seen in Figure 1.

From Figure 1, it can be seen that at the same of

extraction time, increasing the temperature of

combustion will increase the normality of extracts

from the ash. Similarly, with increasing of extraction

time, normality obtained is also increasing. Extract

lye from ashes are alkaline hydroxide, this can be

explained as K

2

O or Na

2

O is formed on the burning

of material a plant and dissolves in the water during

extraction, become a hydroxide. It can be said that the

order of K

2

O or Na

2

O formed by the combustion of

pure metals (K or Na) in the air, where K or Na in

plant material bound in his organic matrix (Babayemi

J. O., 2010).

In addition, the ability of ash to dissolves is a

function amount of alkali metal compounds and

others salts can dissolve more (such as chloride and

sulphate of K and Na) that contained in the ashes, its

depend on the type of plants that burned. The

components that are not soluble in the ash contain

silicates and other metals are insoluble in water.

When the ash dissolved in water, only the carbonate

and sulfate and chloride may be of

Figure 1: Influence of Time and Temperature of

Combustion (˚C) versus Normality (N).

0,045

0,047

0,049

0,051

0,053

0,055

0,057

0,059

0,061

0,063

0,065

500 550 600 650

3 hours 4 hours

5 hours 6 hours

Temperature of Combustion (˚C)

Normality

(N)

Pyrolisis of Kapok (Ceiba pentandra) Pods Wastes as Sources of Potassium Oxide (K2O)

231

In addition, the ability of ash to dissolves is a

function amount of alkali metal compounds and

others salts can dissolve more (such as chloride and

sulphate of K and Na) that contained in the ashes, its

depend on the type of plants that burned. The

components that are not soluble in the ash contain

silicates and other metals are insoluble in water.

When the ash dissolved in water, only the carbonate

and sulfate and chloride may be of alkali metals in

solution, includes a small portion of other metals that

insoluble or a little soluble (Babayemi J. O., 2010).

3.3 Influence of Time and Temperature

of Combustion to the pH of Ash

The results obtained from the pyrolysis experiment

were extracted using aquadest as a solvent, and then

the filtrate was filtered and analyzed to measure the

pH of ash.The influence of burning temperature

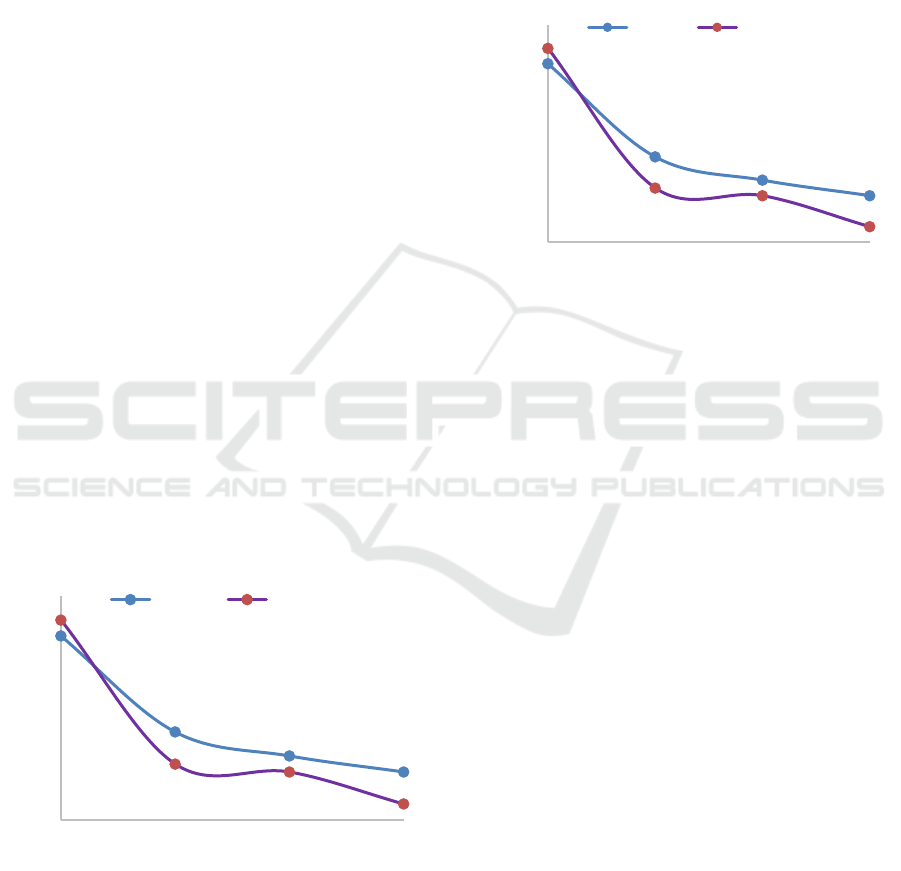

versus the pH of ash can be seen in Figure 2.

From the Figure 2 it can be seen that the increase

combustion temperature generate an increasing of

pH. Carbonate formed at low temperatures, while ash

formed at high temperature in the state of atmospheric

oxygen which is the main form of metal oxides. With

the formation of alkaline carbonate compound as well

as alkali oxides in ash water added, the mixture will

become the alkaline solution (Misra, 1993).

Similarly, by increasing the burning time will also

increase the pH of the resulting solution. This is due

to the longer burning time, will increase the amount

of alkali is formed, thereby increasing the pH of the

solution.

Figure 2: Influence of Time and Temperature Combustion

versus the pH of ash.

3.4 Influence of Extraction Time and

Temperature Combustion to the

Ash Yield

The influence of extraction time and temperature

combustion can be seen in Figure 3 below. Ash

combustion results were weighted, to calculate the

yield or rendemen of ash by using the Formula 1

Figure 3: Influence of Time and Temperature Combustion

Versus the Ash Yield.

From Figure 3 it can be seen that the addition of

the combustion temperature generate reduce yield of

ash, so was against the addition of the combustion

time generate yield ash decrease. The cause of the low

yield in this ash because of the reaction of carbon with

water vapor increasing with increasing temperature

and the length time of the combustion, so the carbon

reacts to become CO

2

and H

2

be a lot, otherwise will

produced the less amount of ash (Siahaan, 2013). The

results of this study in accordance with previous

research that has done on burning coconut shell, in

which increasing temperature and combustion time,

the results yield burning decrease (Tirono, 2011).

3.5 Influence of Extraction Time and

Temperature of Combustion to the

Concentration of K

2

O

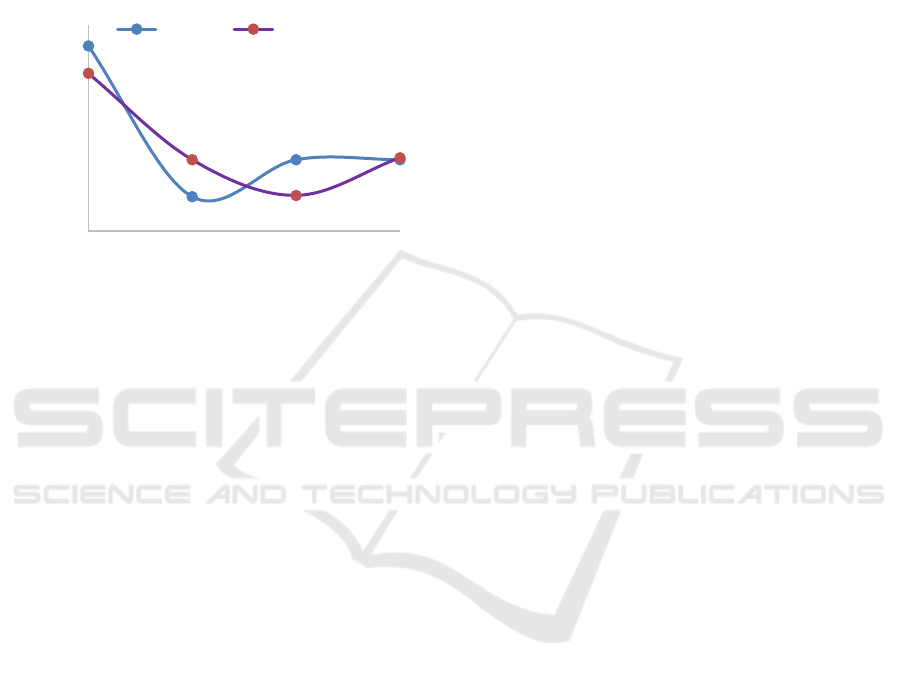

The resulting level of K2O from the ashes was

analyzed using Atomic Absorption

Spectrophotometer (AAS) can be seen in Figure 4.

Figure 4 shows the graph that the increase of

temperature of combustion significant influence to

the yield of K

2

O on the ash. Increase temperature will

decrease the yield of K

2

O, but the time of combustion

are not significant different such as at low

temperature or higher temperature. The higher the

time used at low temperature 500C the rendemen of

7,5

7,9

8,3

8,7

9,1

9,5

9,9

10,3

500 550 600 650

3 hours 6 hours

Temperature of Combustion (˚C)

Rendemen of Ash (%)

7,5

7,9

8,3

8,7

9,1

9,5

9,9

10,3

500 550 600 650

3 hours 6 hours

Temperature of Combustion (˚C)

Rendemen of Ash (%)

ICONART 2019 - International Conference on Natural Resources and Technology

232

K

2

O was lower. But at temperature combustion at

650 the rendemen both of sample for 3 hours and 6

hours time of combustion are same at 15.7% of

rendemen. It is caused not due to potassium is lost or

evaporates, however, the decrease in K

2

O levels may

occur with increase temperature, because the amount

other alkaline components increases with increasing

temperature at the longer time (Perry, 1999).

Figure 4: Influence of Time and Temperature Combustion

versus levels of K2O.

4 CONCLUSIONS

The conclusions from this research are the highest

yield of K

2

O from kapok pods on the pyrolysis

combustion for 3 hours at 500˚C with levels of K

2

O

of 35.91%. Pyrolysis process time 6 hours is better,

because the ash was obtained in the form of oxide.

While the process time is 3 hours the resulting ash

still contain abundance elements of carbonate.

Increase the temperature of pyrolysis will also

improve the normality and pH, as well as increasing

the time of pyrolisis also will raise the pH and

normality. Potassium content in ash kapok pods can

be used as a source of alkaline solution.

REFERENCES

Abba, H. A. 2013. Review of Agro Waste Plastic

Composites Production. Journal of Minerals and

Materials Characterization and Engineering, 1, 271-

279.

Babayemi, J. O. 2010. Evaluation of the Composition and

Chemistry of Ash and Potash from Various Plant

Materials-A Review. Journal of Applied Sciences, 10:

1820-1824.

Bates, D. M. 2004. Malvales. CD Version: Encyclopaedia

Britannica.

Brown, S. H. 2017. Ceiba pentandra. Horticulture Agent.

Florida, South West Florida: University of Florida.

Chaiarrekij, S. A. 2011. Kapok 1: Characteristics of Kapok

Fibre as A Potential Pulp Source for Paper Making.

Journal of Bioresources , 7 (1), 475-488.

Chekuboyina, R. K. 2012. Physico-Chemical

Characterization and Antimicrobial Activity of Ceiba

Pentandra (Kapok) Seed Oil. Journal Alt med studs, 2-

9.

Green, R. H. 1999. Perry's Chemical Engineer's Handbook.

New York: McGraw-Hill Companies, Inc.

Haygreen, J., G. 1996. Hasil Hutan dan Ilmu Kayu, Suatu

Pengantar.Hadikusumo SA, Penerjemah. In

Terjemahan dari: Forest Products and Wood Science:

an Introduction. Yogyakarta: Gadjah Mada University

Pr.

Hendra D., Winarni, I. 2003. Sifat Fisis dan Kimia Briket

Arang Campuran Limbah Kayu Gergajian dan Sebetan

Kayu. Jurnal Penelitian Hasil Hutan, 21(3), 211-226.

Anigo, K., M., Dauda, B., M., D., Sallau, A., B., and

Chindo, I., E., 2013. Chemical Composition of Kapok

(Ceibapentandra) Seed and Physicochemical Properties

of its Oil. Nigerian Journal of Basic and Applied

Science, 21(2): 105-108.

Kapok Tree (Ceiba Pentandra). (2012, September 13).

Retrieved June 29, 2017, from http://www.rainforest-

alliance.org/species/kapok-tree.

Laird, D., A. 2009. Review of the pyrolysis platform for

coproducing bio-oil and biochar†. Biofpr (Biofuels,

bioproducts and biorefining), 1-16.

Misra, M., K. 1993. Wood Ash Composition As a Function

of Furnace Temperature. Biomass and Bioenergy, 4(2)

113.

Mojica, E., R. 2002. Fiber of Kapok (Ceiba pentandra) as

Component of A Metal Sensor for Lead in Water

Samples. Philippines Journal of Crop Science, 27 (2),

37-42.

Ningrum, N., P. 2013. Pemanfaatan Minyak Goreng Bekas

dan Abu Kulit Buah Kapuk Randu (Soda Qie) Sebagai

Bahan Baku Pembuatan Sabun Organik Berbasis

Teknologi Ramah Lingkungan. Journal Teknologi

Kimia dan Industri, 2 (2), 275-285.

Orwa, C., M. 2009. Agroforestree Database: a Tree

Reference and Selection Guide Version 4.0. Kenya:

World Agroforestry Centre.

Perry, R., H. 1999. Chemical Engineers Handbook Physical

and Chemical Data (Vol. 7). Mc Graw Hill Company

Purbasari, A., S. 2008. Pembuatan Pupuk Kalium-Fosfat

dari Abu Kulit Kapok dan Tepung Fosfat secara

Granulasi . Jurnal Ilmiah Bidang Ilmu Kerekayasaan ,

29-2.

Putra, I., T. 2014. Karakteristik Kimia Kulit Buah Kapok

Randu sebagai Bahan Energi Massa .

Putri, E., M. 2012. Biodiesel Production from Kapok Seed

Oil (Ceiba Pentandra) through The Transesterification

process by using cao as catalyst. Global Journal of

Researches in Engineering Chemical Engineering, 12

(2), 6-11.

Rainforest-alliance.org. (2018, September). Retrieved from

https://www.rainforest-alliance.org/species/kapok-tree.

5

10

15

20

25

30

35

500 550 600 650

3 hours 6 hours

Temperature of Combustion (˚C)

Amounts of K

2

O (%)

Pyrolisis of Kapok (Ceiba pentandra) Pods Wastes as Sources of Potassium Oxide (K2O)

233

Siahaan, S., H., 2013. Penentuan Kondisi Optimum Suhu

dan Waktu Karbonisasi pada Pembuatan Arang dari

Sekan Padi. Jurnal Teknik Kimia, 2 (1).

Tirono, M., S. 2011. Efek Suhu pada Proses Pengarangan

Terhadap Nilai Kalor Arang Tempurung Kelapa. Jurnal

Neutrino, 3 (2).

Wibowo, W., A. 2012. Pengaruh Laju Alir Pelarut dan

Tinggi Tumpukan Bahan Terhadap Nilai Koefisien

Transfer Massa Volumetris Pada Proses Ekstraksi Soda

Ki dari Abu Klotok randu. Ekuilibrium , 11 (2), 57-61.

Wikipedia. 2017. Ceiba Pentandra. Retrieved from

https://en.wikipedia.org/wiki/Ceiba_pentandra.

Wikipedia. 2018. https://en.wikipedia.org/wiki/Ceiba_

pentandra.

Winanti, M., S. 2017. Pabrik Bio-Oil dari Jerami Padi

dengan Proses Pirolisis Cepat Teknologi Dynamotive.

Surabaya.

ICONART 2019 - International Conference on Natural Resources and Technology

234