Exploration of Wayang Kulit (Indonesian Leather Puppet) Leather

Leftover Material for Jewelry

Annisa Intan Kumalasari and Eri Naharani Ustazah

Institut Teknologi Sepuluh Nopember, Jl. Raya ITS, Keputih, Kec. Sukolilo, Kota SBY, Jawa Timur, Indonesia

Keywords: wayang, jewelry, leather waste.

Abstract: Wayang Kulit, a traditional puppet shaped Indonesian art which has been made since the 8th century is now

recognized by UNESCO as World Master Piece of Oral and Intangible Heritage of Humanity. In the process,

the material of Wayang Kulit like cow and buffalo hides cannot be used up without leaving material waste,

up until now this waste material usually recreated into craft products. Both making process of the main

products and the waste materials use manual techniques, named Tatah Sungging. The experimental method

used in this study is laser cutting test on leather material, coloring test and mix material. The application of

laser cutting technology is intended to increase the processing productivity of waste material. The results of

this study are form style variants (aesthetics) and product quality variants..

1 INTRODUCTION

Wayang Kulit and Tatah Sungging. Wayang kulit has

been acknowledged by UNESCO as Masterpiece of

Oral and Intangible Heritage of Humanity

(Nurgiyantoro, 2011). Wayang kulit recognized as a

masterpiece because it has a high value for human

civilization, full of value, both reflected in the

characters, stories, and various other elements.

Wayang which generally tells the story of the

character of a hero who fights evil figures is favored

from generation to generation and has been embedded

in the minds of the people, showing how puppets have

important meanings and high value in Indonesian

society.

In addition to having an important meaning in

shaping the character of the nation, Wayang,

especially shadow puppets, gives importance to the

development of creative industries based on local

culture. In line with the national creative industry

roadmap, the Wayang Tatah Sungging industry

contributed significantly to exports by 18% according

to the year 2010 Disperindag data. Wayang kulit is a

product of strategic creative industries because it is

based on Indonesian local cultural values (local

cultural heritages of creative industries) that need

attention so that they still exist in this modernization

era (Murtiasri, 2015).

Tatah Sungging is an icon of Central Javanese

crafts that has a number of 70 small and medium

enterprises (SME) that spreads in Sukoharjo,

Wonogiri, Klaten and Magelang. The Sonorejo

Urban Community has the largest number of Tatah

Sungging SME with 20 SMEs who makes Wayang

Kulit and craft products.

The exploration of leftover leather material into

jewelry products is supported by the phenomenon of

the use of materials that are not commonly used as

jewelry. Like contemporary jewelry products made

from cow intestine by Korean-originated Munich –

based artist Eunmi Chun in a jewelry exhibition titled

Flora & Fauna (Ornamentum, 2014). These unusual

jewelry turns out to be an exclusive and limited

edition urban contemporary jewelry.

The expressive character of urban society is

indicated by their style in clothing and the accessories

they wears. The existence of urban jewelry products

can be a medium for visualizing the image and

expression of its users.

2 PROBLEM STATEMENT

Like the case study in Kampung Wayang, Kepuhsari,

Wonogiri - Central Java. There are a total of 78

crafters of wayang kulit in this village which produce

as much as 1 kg leather leftover daily. Hence 78 kg of

Kumalasari, A. and Ustazah, E.

Exploration of Wayang Kulit (Indonesian Leather Puppet) Leather Leftover Material for Jewelry.

DOI: 10.5220/0008556701670171

In Proceedings of the 1st International Conference on Interdisciplinary Arts and Humanities (ICONARTIES 2019), pages 167-171

ISBN: 978-989-758-450-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

167

skin left over from production per day is produced by

this village and if projected within 1 month there will

be 2.3 tons of leather material left over from

production. Therefore, the problem can be formulated

as follows. 1) It is necessary to develop the rest of the

wayang leather production material in the form of

exclusive products in the form of jewelery as a

medium of expression for urban society. 2)

Processing of existing puppet skin waste material is

done manually by craftsmen..

3 RESEARCH OBJECTIVE

In the future this research is expected by the authors

to be useful for, 1) As an alternative choice for

fashion products for the people who want to lift the

exclusivity of wayang leather waste products without

losing traditional and historical elements from

wayang kulit. 2) As an alternative method for

utilizing puppet skin waste for wayang waste leather

entrepreneurs in Indonesia. 3) As a form of culture

appreciation and increasing awareness of urban

people about the prestige value of wayang kulit in the

form of media expression that can be used daily.

4 LITERATURE STUDIES

Definition of Rawhide Material. Rawhide or raw

skin is the skin of native animals that have not gone

through the process of tanning or chemical processes.

Similar to parchment, it has a lighter color than the

skin through vegetable tanning. Before used, rawhide

skin is prepared by removing all feathers, meat, fat or

blood on the skin and then stretched and dried (UGM,

2012). The original character of raw leather is hard,

stiff, slightly patterned and translucent. But it can be

flexed through repeated bending and stretching

processes. If necessary, oil coating or lubrication can

be carried out on the surface of the skin to make it

waterproof. Raw leather material commonly used to

make puppets comes from cow skin, buffalo and goat.

Definition of Split Leather Material. Split skin

is the skin of a buffalo or cow that has gone through

a chemical process, then split using a splitter machine

into two or more parts. The split parts are nerf (grain

split), flesh split and middle split. The split skin

process can produce more sheets of skin, making the

price cheaper than raw skin (Susilawati, 1992). Split

skin has two sides, on average has a smooth surface

and on the other hand is more rough due to skin fibers

that are "split forcibly" during the splitting process.

Split skin has more flexible character than raw skin,

more translucent. This skin is more sensitive to

temperature, easily curved or rolled when exposed to

heat or humidity.

Definition of Jewelry. Jewelry, small jewelry and

goldsmith items, are used as decorative items that are

worn for personal jewelry both body and clothing.

Made of precious materials (precious metals: gold,

silver, platinum, gemstones, ivory) decorated with

various techniques and characterized by artistic

execution. Including indigenous ornaments, primitive

ornaments with colorful stones, horns, bones, and

others. Jewelry has been known in all historical

periods and in all cultures that define the social role

of jewelry along with a number of basic forms.

Initially it was a function of an object, especially that

used to decorate clothes such as pins, buckles and

pins (Clarke, 2010).

Coloring Technique and Leather Finishing.

Basically the wayang coloring technique uses white

wall paint mixed with color pigments and PVAC

glue. While the Gold coloring usually uses gold foil.

Varnish or neutral waterbase topcoat used for

finishing.

Laser Cutting. Laser (Light Amplification by

Stimulated Emission of Radiation) technology that

uses lasers to cut material and is usually applied to

manufacturing industries. Laser cutting works by

directing a high-power laser to cut material and use

the computer to direct it. Industrial laser cutting has

been designed to concentrate a high amount of energy

into a small place. Usually laser cutting rays are

around 0.003-0.006 inches in diameter when using a

laser with a short wavelength. Following are the types

of lasers and their uses, 1) Laser CO2

Used to cut, make boring, and carve. 2) Neodymium

(Nd). Used to make boring, it takes big energy with

low reps. 3) Laser Neodymium Yttrium-

Aluminum-Garnet (Nd-YAG). Very high power is

used to make boring and engrave.

Here are the capabilities of the laser cutting:

1) Marking. The laser beam damages the surface of

the material so that it leaves a mark in the form of a

scratch according to the pattern image designed.

2) Engraving. Plasma laser light scratches the surface

of the material with different depths so as to produce

carved shapes or images or motifs that match the

pattern images that are designed.

3) Perforating/Punching/Cutting. Plasma laser light is

used to hollow out material with the shape according

to the design pattern that is designed.

ICONARTIES 2019 - 1st International Conference on Interdisciplinary Arts and Humanities

168

5 RESEARCH METHODS

The method of this research data collection is done

through, 1) Literature Studies, 2) Survey, 3) Deep

Interview, 4) Experiment. The experiments carried

out in this study were using the application of laser

cutting technology, coloring experiments and mix

material.

6 EXPERIMENTS

Laser Cutting Test 1. In this laser cutting author

used the orceLASER FL-1310 machine using 22-25

speed 18 power, with pattern that arranged with

varied distances ranging from 0.1 mm, 0.3 mm, 0.5

mm, 0.7 mm to 1 mm.

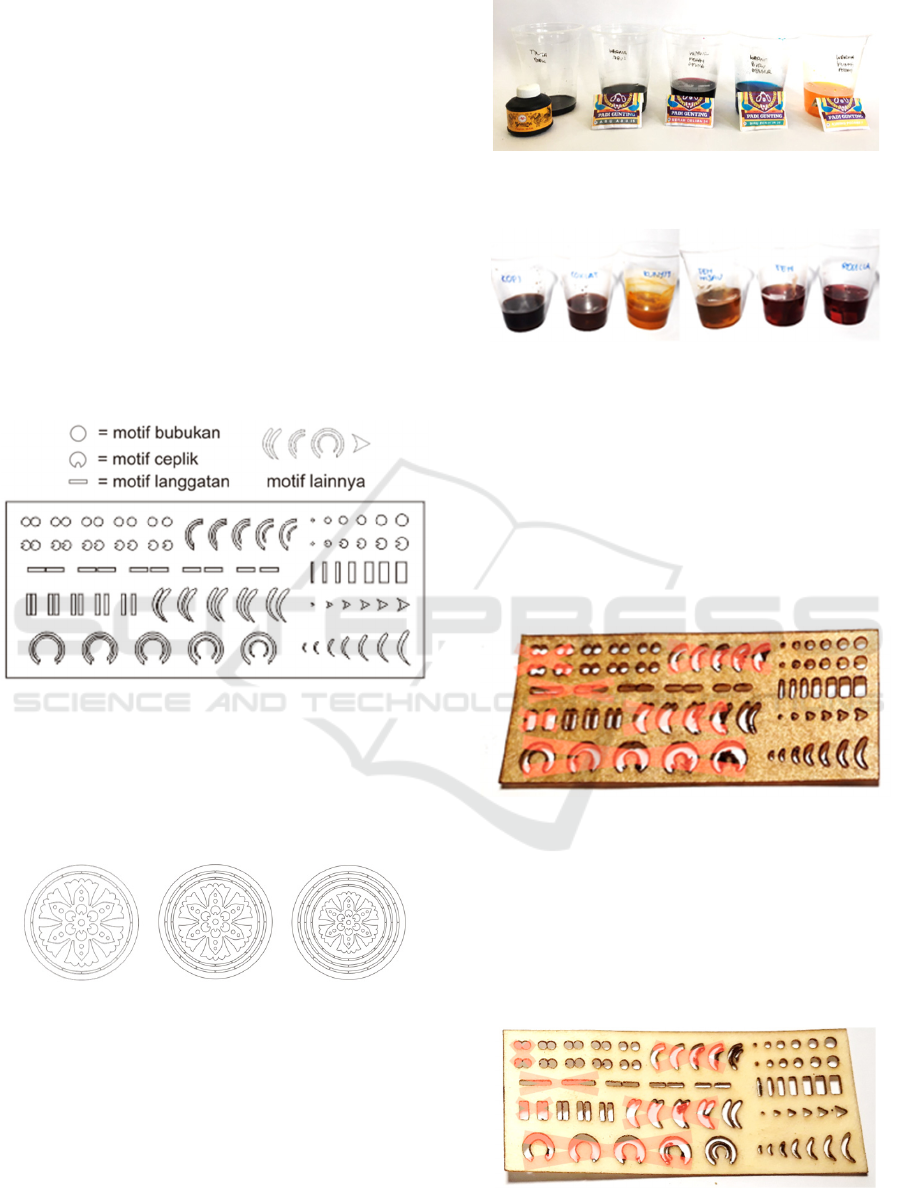

Figure 1. Vector Design Pattern for Laser Cutting Test 1

Laser Cutting Test 2. In the next stage, laser

cutting tests were carried out by using the selected

pattern of Tatah Sungging arranged in the form of a

mandala with the following design,

Figure 2. Design Pattern for Laser Cutting Test 2

Coloring Test. The coloring test carried out on

this experiment is using a wet staining technique

using chemical and natural dyes.

Figure 3. Chemical (Textile) Dyes Coloring

Figure 4. Natural Coloring

Mix Material Test. This experiment trials mixing

leather material with silver.

7 RESULT AND DISCUSSION

Result of Laser Cutting Test 1. Following figure is

the result of laser cutting test on rawhide material and

split leather,

Figure 5. Laser Cut Result (Rawhide

)

In Rawhide:

1) The smallest distance needed for making

appropriate bubukan, ceplik and langgatan pattern

on rawhide is 0.5 mm

2) For the circular shape, the distance between

each circle or radius should be bigger than 1mm

Figure 6. Laser Cut Result (Split Leather)

Exploration of Wayang Kulit (Indonesian Leather Puppet) Leather Leftover Material for Jewelry

169

In Split Leather:

1) The smallest distance needed for making

appropriate bubukan and ceplik pattern is 0.3 mm

2) For langgatan pattern there should be at least

0.5 mm distance in each pattern

3) For the circular shape, the distance between

each circle or radius should be at least 1mm

Result of Laser Cutting Test 2. Following figure

is the result of 2nd laser cutting test on rawhide

material and split leather,

Gambar 7. Hasil Uji 2 Cutting Laser Mandala

Discussion:

1) Cutting laser result with the 1st mandala

pattern turns out that it can be executed in detail

even though it is small in size (25 mm).

2) Although large in size, the 2nd and 3rd pattern

mandala design have weaknesses in the cutting

edge. Proven by the failure of the cut on each

design. There needs to be a wider distance

between the holes so as not to break when finished

cutting.

Coloring Test Result. These are the coloring test

results using chemical dyes (textile dyes), the color

results are vivid bright and easily absorbed by the

both rawhide and split leather material under 1 hour.

Figure 8. Chemical Coloring Test Result

Whereas for coloring with natural ingredients

(coffee, tea, turmeric, rosella and chocolate) takes

longer than chemical dyes. The new color is seen after

repeated immersion for 2-3 hours, the resulting color

tends to be smooth pastel color. The following are the

results of coloring the skin using natural dyes.

Figure 9. Natural Coloring Test Result

Mix Material Test Result. In the mix material

test, author combining leather material with silver is

used. The selection of silver material was assessed

according to the jewelry design concept named

Lunarian. A series of jewelry inspired by the elegance

of the moon. The basic form of jewelry is also a

stylization and simplification of the formation of the

moon phase.

Figure 10. Moon Phase Shape Simplification

The following pictures documented the process of

making silver parts in jewelry, the technique is

framing the post laser cut leather leftover material.

The making begins by processing the silver plate into

parts of the frame and then uniting and finishing.

After that, then the skin is inserted and then assembly

the jewelry.

Figure 11. Jewelry Making Process

ICONARTIES 2019 - 1st International Conference on Interdisciplinary Arts and Humanities

170

8 CONCLUSIONS

Final Design Product Photography. This Following

figure is the prototype of Lunarian Jewelry, including

sets of earrings, necklace and headpiece.

Figure 12. Lunarian Jewelry Set

The use of laser cutting techniques can be used on

the skin of puppets, but it will produce charred effects

on the surface and edges of the skin. Adjustments

need to be made for each use of the new skin sheet

because of the lack of water content and skin

thickness. Coloring on the skin can be done using wet

coloring techniques (soak) using either chemical dyes

(textile dyes) or natural dyes. Chemical dyes will

produce more striking colors and have a shorter

coloring duration than natural dyes. Processing the

rest of the wayang kulit production into jewelry

products can be done and will further highlight the

character of the skin when compared with

combination materials that have contrasting

characteristics such as metal. Details of metal

processing techniques and methods. Application of

laser cutting technology can support standardization

and productivity.

ACKNOWLEDGEMENTS

Author A.I.K give thanks the Management

Secretariat of Kampung Wayang for being

theinterviewees, to Kampung Wayang, Kepuhsari,

Wonogiri Central Java for being the study case

location for this research, and supports from Basic

Design Laboratory Departement of Product design

Department Institut Teknologi Sepuluh Nopember

Surabaya.

REFERENCES

Clarke, M. C. (2010). Oxford Concise Dictionary of Art

Terms. British: Oxford University Press.

Eka Murtiasri, S. a. (2015). DIAN MAS, Volume 4, Nomor

2, Oktober 2015. Peningkatan Kualitas Produk Dan

Kompetensi Pengrajin Wayang Kulit Menuju Pasar

Sasaran Ekspor, 71-82.

Nurgiyantoro, B. (2011). Jurnal Pendidikan Karakter,

Tahun I, Nomor 1, Oktober 2011. Wayang dan

Pengembangan Karakter Bangsa, 17.

Ornamentum. (2014, September 20). Ornamentum:

Exhibitions: Eunmi Chun. Retrieved from

Ornamentum: http://www.ornamentumgallery

.com/exhibitions/eunmi-chun

Susilawati, S. S. (1992). Penelitian Kulit Belahan (Split

Leather) Untuk Barang Kulit atau Atasan Sepatu. In

Majalah Barang Kulit, Karet dan Plastik Vol. VIII No.

15 (pp. 31-39).

UGM, K. P. (2012). Kerajinan Kulit Tatah Sungging.

Retrieved from tatahsungging.wordpress.com:

https://tatahsungging.wordpress.com/produk/proses-

pembuatan.

Exploration of Wayang Kulit (Indonesian Leather Puppet) Leather Leftover Material for Jewelry

171