Evaluation of Separator Performance in a Vermiculture Based

Microbial Fuel Cell Assembly (VBMFC) with Eudrilus Eugeniae

Kristopher Ray S. Pamintuan

1,2,

Catherine Jill D. Brillas

1

, Ronalyn R. Inagan

1

1

School of Chemical, Biological, and Materials Engineering and Sciences, Mapua University, Muralla St., Intramuros,

Manila, Philippines 1002

2

Center for Renewable Bioenergy Research, Mapua University, Muralla St., Intramuros, Manila, Philippines 1002

Keywords: Vermiculture, microbial fuel cells, Eudrilus eugeniae, waste management

Abstract: Vermiculture-based Microbial Fuel Cells (VBMFC) generate electricity by using earthworms as catalysts that

speed up the degradation of bulk organic substrates, leaving simpler compounds for exoelectrogenic

bacteria to feast on. In this type of set-up, renewable electricity is generated while simultaneously reducing

the volume of solid waste. Eudrilus eugeniae, commonly known as African nightcrawler, was used as the

model earthworm for this study. The worms were fed with a total of 1.854 kg of watermelon peels. These

peels act as the substrate for the bacteria to metabolize and generate electricity. The main objective of the

study is to determine what type of separator would yield a higher power output. Results show that the

control system (no separator) produced the highest maximum voltage of 40.5 mV. On the other hand,

VBMFCs with clay membranes had the highest average voltage of 9.68 mV. Polarization curves were used

to measure the optimal current, maximum power density, and internal resistance of the three systems. The

control system had the largest optimum current density of 1.23 mA/m2 and the highest maximum power

density of 0.056 mW/m2. On the other hand, vessel that had cotton cloth as separator had a better current

density and maximum power density than the vessel with clay membrane, which offered the most

resistance. Overall, the absence of a separator seems to benefit power generation, as well as helping to offset

the cost of construction as the membrane separator often is the most expensive part of the set-up.

1. INTRODUCTION

The energy demand in the world right now continues

to increase and it prompts an increased usage of

fossil fuels, consequently trigerring environmental

pollution. The dependence on fossil fuels, such as oil

and gas, is not sustainable in view of the fact that it

is limited, its supply is decreasing, and it poses

negative effects on the environment. As a result of

this, many researches are focused on alternative,

renewable, and also carbon neutral energy sources

which are necessary for the sustainability of the

environment and economy [1].

The global community recognized that solid

waste management is an issue that requires serious

attention. The aggressive pursuit for economic

growth, by developing countries like the Philippines,

has resulted in the manufacture, distribution and use

of products and generation of wastes that contributes

to enhanced environmental degradation [2]. In the

past years, the Microbial Fuel Cell (MFC)

technology has gained the attention of the scientific

community due to its attractive quality of being able

to cleam wastewater while generating electricity [3].

MFC are devices in which bacteria generate

electrical power by oxidizing simple compounds

such as dissolved organic matter in wastewater. This

technology depicts a new and promising approach

for power generation. MFCs not only clean

wastewater, but they also transform organics in the

wastewater into energy that can be useful. With the

world’s finite supply of fossil fuels and the impact of

fossil fuels on climate change, the ability of MFC

technology to generate renewable and also carbon

neutral energy has cause huge interest globally.

MFCs have been broadly seen as a standout amongst

the most promising alternative sources of renewable

energy [4].

The success of MFCs do not come without

limitations. For one, it mainly relies on wastewater

for its source of energy. To solve solid waste

management issues, the MFC needs to be modified

to accommodate soil-based decomposition. With

that, the concept of a Vermiculture-based Microbial

Ray S. Pamintuan, K., Jill D. Brillas, C. and R. Inagan, R.

Evaluation of Separator Performance in a Vermiculture Based Microbial Fuel Cell Assembly (VBMFC) with Eudr ilus Eugeniae.

DOI: 10.5220/0008656700410045

In Proceedings of the International Conference on Future Environment Pollution and Prevention (ICFEPP 2019), pages 41-45

ISBN: 978-989-758-394-0

Copyright

c

2019 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

41

Fuel Cell (VBMFC) was born. In this set-up, solid

biodegradable waste is fed to earthworms, much like

in vermiculture. The worm castings then become a

prime nutrient source for bacteria to consume and

generate electricity with carefully-placed electrodes.

Desirable qualities for a VBMFC would be high

power generation, low internal resistance, and low

cost, much like in MFCs. Earthworm selection is

also to be considered. Commonly, Red wigglers

(Eisenia fetida) are thought to be the most adaptable

of all the vermicomposting worms, but comparing it

with other worms in terms of selected parameters

(e.g. size, time of maturity, incubation time, ideal

working temperature, etc.), the African nightcrawler

seems more capable. In laboratory tests, E. eugeniae

outperformed E. fetida at in tests

utilizing cattle manure as the feedstock. Also, some

assert that E. eugeniae also slightly sensitive to

handling and disturbance. It appears that it is not

usual for E. eugeniae to start roving after disturbance

or even clear reasons at all. That being said, E.

eugeniae appear to be the most popular choice

among vermicomposters due to its quick growth and

bigger size compared to E. fetida [5].

There are still some ongoing studies on ways to

collect electricity from different variants of MFC

like Plant-Microbial Fuel Cells (PMFCs) [6] and

Constructed-Wetland Microbial Fuel Cells

(CWMFCs). However, there are no studies that

explore VBMFCs for their power generation and

waste management capabilities. In terms of its

operation, it is similar to an MFC but differs on the

substrate. Conventionally, MFCs include a

membrane separator to segregate charges in the

anode and cathode compartments. However,

commercially available membranes are costly, and it

is generally attractive for MFC technology to be

low-cost. Thus, alternative materials are to be

sought. The objective of this study is to determine

the performance of cotton cloth and clay as

membrane separators in VBMFC using E. euginae

as decomposer. In addition, polarization curves will

be used to measure the optimal current, maximum

power, and internal resistance of the VBMFCs.

2 METHODOLOGY

2.1 VBMFC Design

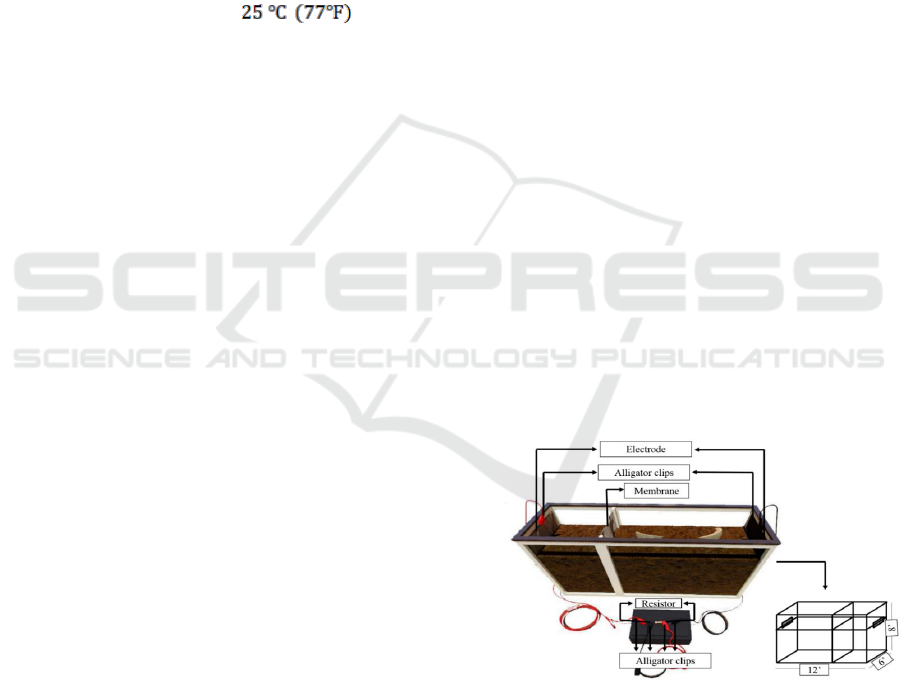

The VBMFC assembly is shown in Figure 1.

Polycarbonate plastic was cut and assembled into a

rectangular vessel measuring 12 inches by 6 inches

with a height of 8 inches. The edges were then

sealed with hot glue and duct tape. Two carbon fiber

sheets measuring 6 inches by 8 inches each were

attached to the inner opposite sides of the vessel to

act as electrodes. Alligator clips were latched into

the top part of the carbon fiber to attach them to

copper wires. The other ends of the connecting wire

were connected to an external 2000 ohms resistor to

continuously polarize the set-up. The experimental

separators were attached as seen in Fig. 1. Two types

of separators were tested against a control: clay and

cotton cloth. Both types of separators were cut to the

size of the set-up cross-section and attached to the

containers. Moist loam soil was used to fill the

container. Triplicates were prepared for every

experimental set-up.

2.2 Experimental Set-up

E. euginae was obtained from a vermiculture farm in

Manila, Philippines. 50 adult worms were placed in

the anodic compartment for set-ups with separators,

and were scattered in the control set-ups (without

separator). Since the worms are sensitive to light, all

set-ups were covered with dark-colored cloth to

maintain a dark environment without suffocating the

worms. Good moisture was maintained by daily

spraying of distilled water, taking care not to flood

the set-ups.

The worms were fed starting on their second day

on the containers with fresh watermelon peels. They

were fed ad libitum, although care was exercised to

not let the watermelon peels decompose before they

were consumed. 5-g portions of peels were added in

every container until it is consumed.

Figure 1. Vermicultue-based microbial fuel cell

(VBMFC) assembly

2.3 Data Acquisition and Analysis

The voltage of the VBMFC set-ups were manually

measured everyday against a 2000-ohm resistance,

for 25 days, using a digital multimeter (RS Pro

RS14). From the gathered data, power can be

ICFEPP 2019 - International conference on Future Environment Pollution and Prevention

42

determined ( ) as well as power density

( ). All parameters were plotted against

time to analyse their evolution as the assembly

matures. Polarization curves were generated at the

end of the experimental period.

3. RESULTS AND DISCUSSION

3.1 Voltage of VBMFCs

As seen on Fig. 2, the maximum average voltage for

the control was obtained on day 23 with a value of

0.405 V and the lowest average voltage on day 8

with a value of 0.001 V. For the cotton separator, the

maximum average voltage was obtained on day 17

with a value of 0.025 V and the lowest average

voltage on days 2 and 5 with a value of 0.001 V.

Lastly, for the clay separator set-up, the maximum

average voltage was obtained on day 18 with a value

of 0.0255 V and the lowest average voltage on days

2, 5 and 12 with a value of 0.001 V. These are

summarized in Table 1.

The maximum voltage of the control system is

significantly higher than the experimental cotton and

clay separators . In terms of the average

voltage, there is no significant difference between

the values from the control and the clay separator,

although both are significantly larger than that of the

cotton separator. For voltage readings, it can be seen

that using a clay separator or no separation at all is

more advantageous than using cotton.

There are some factors that may hinder the

VBMFC from generating its maximum potential

voltage, one of which is resistances, both inherent

and induced. In the operation of the VBMFCs, the

junctions between the electrodes and the connecting

wires are often sources of resistance from rusting.

Another factor to consider is the adaptation of

bacteria to the working environment and the

formation and destruction of exoelectrogenic biofilm

in the electrodes due to the constant movement of

earthworms.

3.2 Polarization

The constructed polarization curves are shown in

Fig. 3.

The control system had the highest optimum

current density of 1.227 mA/m

2

amongst the other

systems. Control system is a Single Chamber MFC

(SC-MFC) which does not incorporate the use of

membranes. In Ohms law, current is inversely

proportional to resistance. Therefore, higher current

occurs at lower internal resistances [7] .

(a)

(b)

(c)

Figure 2: Average voltage measured from the constructed

VBMFCs: control (a), cotton separator; (b), and clay

separator (c)

In another context, the control system had the

highest Maximum Power Point (MPP) obtained at

0.0560 mW/m

2

. The maximum output power of the

fuel cell is proportional to the square of the open-

circuit voltage and is inversely proportional to its

Evaluation of Separator Performance in a Vermiculture Based Microbial Fuel Cell Assembly (VBMFC) with Eudrilus Eugeniae

43

internal resistance. When the load resistance is equal

to the internal resistance, the output power of the

fuel cell is at the maximum. Thus, monitoring the

internal resistance of the microbial fuel cell

effectively is not only the necessary condition for

realizing the maximum power output, but also a key

action to ensure the health and performance of the

microbial fuel cell.

Table 1. Maximum and average voltage of

VBMFC

System

V

max

(mV)

V

ave

(mV)

Control

40.5

8.89

Cotton cloth membrane

25

5.36

Clay membrane

25.5

9.68

Table 2. Maximum Power and Optimum

Current Density of VBMFC

Syste

m

Int

ernal

Resista

nce (Ω)

Optimu

m current

density

(mA/m2)

Maximum

power

density

(mW/m

2

)

Contro

l

12

40

1.227

0.0560

Cotton

cloth

28

74

0.338

0.0030

Clay

54

93

0.247

0.0009

On the other hand, the vessel with cotton cloth as

membrane had a better current density and

maximum power than the vessel with clay

membrane. These dual chamber MFC corporates

membranes that allows internal ionic fluxes but

prevents mixing of anodic reducing solution and

cathodic oxidant. This membrane, however, is one

of the principal cost factors in an MFC plant and

increases the cell’s internal resistance [8]. Other

factors that contributes to lesser conductivity and

power are ohmic losses, activation losses and

microbial losses. Ohmic losses can be reduced by

minimizing the electrode spacing, using a membrane

with a low resistivity and checking thoroughly all

contacts. Low activation losses can be achieved by

increasing the electrode surface area, improving

electrode catalysis, increasing the operating

temperature, and through the establishment of an

enriched biofilm on the electrode.

4. CONCLUSIONS

This study has shown that electricity generation is

possible in a VBMFC, albeit its magnitude is still

small compared to other sources of energy. The set-

ups with no membrane separators exhibited the

highest voltage, current density, and power density,

along with the lowest internal resistance. With

regard to the two experimental separators, cotton

cloth exhibited less internal resistance and thus

would lead to higher power density compared to the

clay separator. All of these were confirmed by

polarization studies. The elimination of the

membrane separator would cut down significantly

on the building cost of VBMFCs.

(a)

(b)

Figure 3: Polarization curves of VBMFCs with

cotton separator (a), and clay separator (b)

It is therefore recommended for future studies to

further develop the VBMFC technology through

optimizations for electrode materials, substrate, type

of earthworm, and configurations.

ICFEPP 2019 - International conference on Future Environment Pollution and Prevention

44

REFERENCES

[1] M. S. Guney and Y. Tepe, “Classification and

assessment of energy storage systems,”

Renewable and Sustainable Energy Reviews, vol.

75. pp. 1187–1197, 2017.

[2] N. Hussain, S. Das, L. Goswami, P. Das, B.

Sahariah, and S. S. Bhattacharya, “Intensification

of vermitechnology for kitchen vegetable waste

and paddy straw employing earthworm

consortium: Assessment of maturity time,

microbial community structure, and economic

benefit,” J. Clean. Prod., vol. 182, pp. 414–426,

2018.

[3] C. Santoro, C. Arbizzani, B. Erable, and I.

Ieropoulos, “Microbial fuel cells: From

fundamentals to applications. A review,” J.

Power Sources, vol. 356, pp. 225–244, 2017.

[4] B. E. Logan et al., “Microbial fuel cells:

Methodology and technology,” Environmental

Science and Technology, vol. 40, no. 17. pp.

5181–5192, 2006.

[5] A. J. Reinecke and S. A. Viljoen, “Effects of

worm density on growth and cocoon production

of the african nightcrawler Eudrilus eugeniae

(Oligochaeta),” Eur. J. Soil Biol., vol. 29, no. 1,

pp. 29–34, 1993.

[6] K. R. S. Pamintuan, J. A. A. Clomera, K. V.

Garcia, G. R. Ravara, and E. J. G. Salamat,

“Stacking of aquatic plant-microbial fuel cells

growing water spinach (Ipomoea aquatica) and

water lettuce (Pistia stratiotes),” IOP Conf. Ser.

Earth Environ. Sci., vol. 191, 2018.

[7] L. P. Fan and J. J. Li, “Overviews on internal

resistance and its detection of microbial fuel

cells,” vol. 10, 2016.

[8] A. G. Capodaglio et al., “Microbial Fuel Cells

for Direct Electrical Energy Recovery from

Urban Wastewaters,” vol. 2013, 2013.

Evaluation of Separator Performance in a Vermiculture Based Microbial Fuel Cell Assembly (VBMFC) with Eudrilus Eugeniae

45