Synthesis Succinic Galactomannan from Galactomannan Arenga

pinnata Merr. and Succinic Anhydride using Microwave Method

Juliati Br. Tarigan*, Mutiara H. Siregar

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Jl. Bioteknologi No.

1 Kampus USU, Medan, Indonesia

Keywords: Arenga pinnata Merr., endosperm, Galactomannan, Succinic Galactomannan, Microwave.

Abstract: The synthesis succinic galactomannan has been conducted through esterification reaction of galactomannan

Arenga pinnata and succinic anhydride using sodium bicarbonate as catalyst under the radiation of

microwave. The experiment divided by two steps which first step was the extraction of galactomannan from

Arenga pinnata rendering yield of 4.20% and have confirmed by spectroscopy Fourier Transform Infrared

(FT-IR). The second step was esterification with succinic anhydride using NaHCO3 as catalyst under the

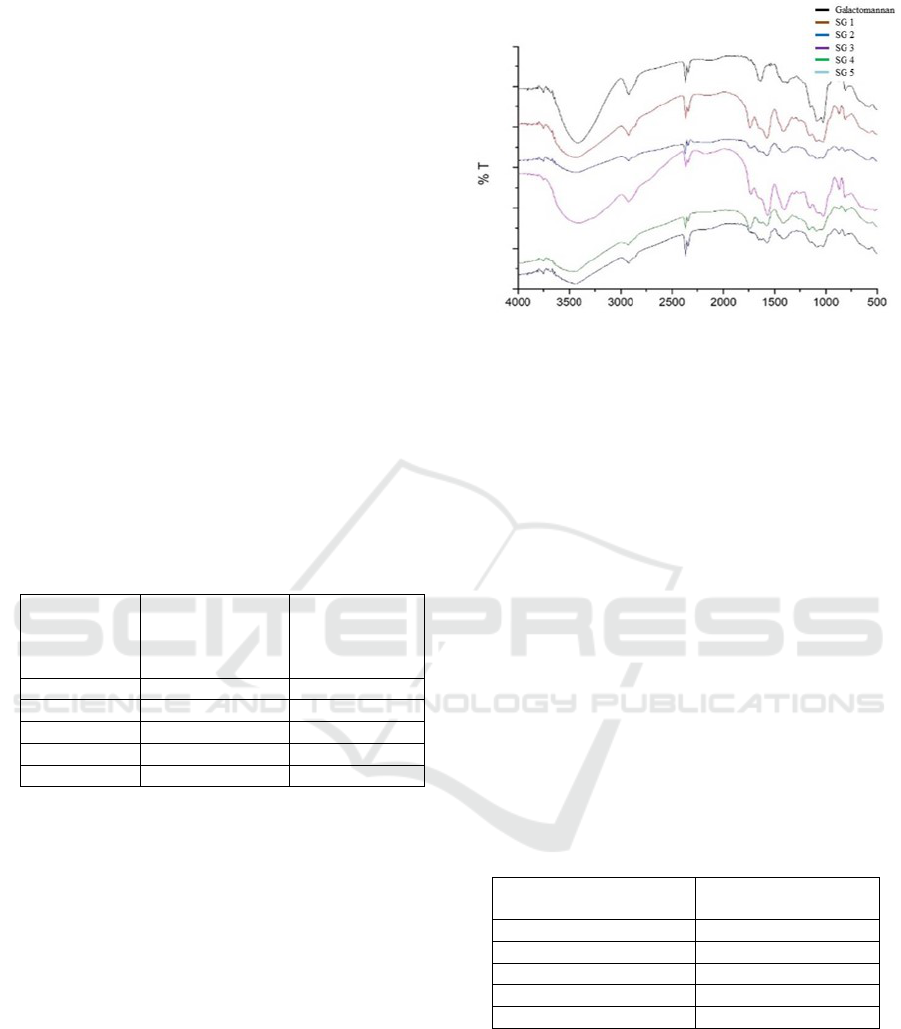

radiation of microwave for 3, 5, 7, 9 and 11 min. Spectroscopy FT-IR showed the stretching vibration of the

carbonyl group (C=O) of the ester at a wavelength of 1735 cm-1 which established the formation of succinic

galactomannan. The substitution degree of succinic galactomannan determined by titration method obtained

the maximum value at 1.527 for 9 min radiation time. The scanning electron microscopy (SEM) images

showed that succinic galactomannan has rough surface morphology than galactomannan Arenga pinnata.

1 INTRODUCTION

Galactomannan is a polysaccharide which found

abundant and are specifically produced from beans.

One source of galactomannan in Indonesia is

“kolang – kaling” or Arenga pinnata endosperm

(APE). APE is a semi-mature, soft, chewy and

slightly clear white sugar palm endosperm which is

obtained after going through the processing process

(Kooiman, 1971). Galactomannan consists of two

types of sugar monomer units, namely mannose and

galactose. Mannose is the main component and

galactose is a minor component. The number of

galactose units in the polysaccharide is always

smaller than that of mannose (Mathur, 2011).

Comparison of galactose and mannose will affect the

properties of the galactomannan. The advantages of

galactomannan are the chain of galactose branches

which is polar and mannose (straight chains) is

nonpolar. The molecular weights of galactomannan

from APE are diverse and vary from 6000 to 17000

(Kooiman, 1971). Galactomannan has a structure (1-

4) -β-D-mannopyranose as a straight chain and unit

(1-6) -α-D-galactopyranose as its branch (Dey,

1978). Galactomannan has been extracted from

sugar palm seeds using ethanol and water followed

by centrifugation to separate the precipitate.

Galactomannan content was obtained at 4.58% and

is feasible to eat (Tarigan, 2014). To improve

galactomannan properties can be done by modifying

the compound using chemical reagents. One way is

to convert galactomannan to its ester form.

Esterification reactions of polysaccharides are

very common and have been used to modify and

increase the functional properties of derivate

polysaccharide. Succinic esters of Arabic gum have

been used as stabilizers of emulsions and used in

microencapsulation processes (Sarkar and Singhal,

2011). Dong and Tian (1999) have been successfully

synthesized palmitic ester of guar galactomannan

and used as emulsion stabilizers. Prashanth et al.

(2006) have synthesized galactomannan esters using

succinic anhydride, acetic anhydride and n-octenyl

succinate anhydride using catalyst sodium

bicarbonate at a temperature of 28˚C, 40˚C, 60˚C for

2 hours. Sarkar and Singhal (2011) demonstrated the

synthesis of guar gum esters with n-octenyl

succinate anhydrous using sodium bicarbonate as a

catalyst at a temperature of 60˚C, 75˚C, 90˚C for 3

hours. Previous researchers have modified

galactomannan compounds through acetylation

using acetic anhydride using sulfuric acid catalysts

under reflux conditions at 50˚C for 6 hours. In

Tarigan, J. and Siregar, M.

Synthesis Succinic Galactomannan from Galactomannan Arenga pinnata Merr. and Succinic Anhydride using Microwave Method.

DOI: 10.5220/0008854200690073

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 69-73

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

69

general, the reaction of polysaccharide ester

production is carried out prolonged reaction time.

Therefore it is necessary to find out a novel method

to produce polysaccharide ester in short reaction

time. Microwave has been known could enhance

organic reaction and shorten reaction time producing

a high yield of product (Mohd Fuad et al., 2019).

Based on that, the aim of this study was to

synthesis succinic galactomannan from the reaction

of galactomannan with succinic anhydride using

sodium bicarbonate as a catalyst under microwave

irradiation. The succinic galactomannan esters

obtained were analyzed for functional group changes

by FT-IR spectrophotometer, SEM and the degree of

substitution by titration.

2 MATERIALS AND METHODS

2.1 Materials

“Kolang-kaling” was bought from a local traditional

market in Medan – Indonesia. All chemicals used in

this study were purchased from local chemical

dealers and have been used without any purification.

2.2 Methods

2.2.1 Extraction Galactomannan from APE

The APE which has been cleaned and chopped as

much as 100 grams is mashed with a blender by

adding 1000 mL of distilled water and stored in the

refrigerator for 24 hours. Then, it was centrifuged at

an average speed of 8500 rpm for 50 minutes.

Ethanol is added to the supernatant with a volume

ratio of 1: 2 and stored in a refrigerator for 24 hours.

The precipitate formed is then soaked using ethanol

and dried in a desiccator.

2.2.2 Synthesis Succinic Galactomannan

One gram of galactomannan was added with 0.5

gram of sodium bicarbonate and 2 mL of ethanol.

Next, 2 g of succinic anhydride was added followed

by stirring for 20 minutes. Then the mixture is

heated in the microwave for 3 minutes. After that,

the mixture was added with 10 mL ethanol 50% and

then followed by neutralization using NaOH 2N.

The precipitate was washed with 75% ethanol and

then washed with ethanol. The precipitate was dried

in a desiccator (Prashanth et al., 2006).

2.2.3 Determination of Substitution Degree

One gram of succinic galactomannan was put in

Erlenmeyer and then added with 10 mL of water

containing 5 mL NaOH 0.5M followed by stirring

for 30 minutes at room temperature. The solution

then titrated with HCl 1N using phenolphthalein

indicators (Sarkar and Singhal, 2011). The value of

the degree of substitution can be calculated based on

the equation below.

(1)

(2)

Where W is substitution of succinic acid, V

blank

is

the HCl volume for the blank solution and V

sample

is

the HCl volume required for neutralizing the sample.

N is normality of HCl, M is molecular weight of

succinic acid.

3 RESULTS AND DISCUSSIONS

3.1 Extraction of Galactomannan from

APE

About 300 grams of APE was extracted using

distilled water and then centrifuged at a speed of

8500 rpm for 50 minutes and then the supernatant

was added ethanol 96% to formed precipitate which

was washed using ethanol. The galactomannan

extracted was 12.6205 grams (4.20%) which were

then characterized by FT-IR.

3.2 FT-IR analysis

The galactomannan obtained was analyzed using

FT-IR to determine the presence of functional

groups. The FT-IR results obtained are shown in

Figure 1.

Figure 1: F-IR spectra of galactomannan

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

70

The FT-IR spectrum of galactomannan showed

vibration peaks in the wavenumber area of 3410 cm

-

1

represent a stretching vibration of the -OH group

from polysaccharides. This is supported by

absorption bands at wave number 1635 cm

-1

which

showed vibrations –OH bending from water

absorption (Gong et al., 2012). The absorption band

at wave number 2924 cm

-1

shows the stretching of -

CH vibration, which is supported by the presence of

absorption bands at wave number 1381 cm

-1

represent the bending –CH vibrations (Singh et al.,

2009). The 871 cm

-1

band shows the characteristics

of β-D-mannopyranose bond in the polysaccharide

and in the 810 cm

-1

band shows the characteristics of

α-D-galactopyrannose bonds (Buriti et al., 2014).

3.3 Synthesis and Characterization

Succinic Galactomannan

The result obtained from the esterification

galactomannan with succinic acid anhydride is white

solids. The yields of succinic galactomannan are

shown in Table 1.

Table 1: The yield of succinic galactomannan

Reaction

Time

(min)

Weight of

Galactomannan

(g)

Weight of

Succinic

Galactomannan

(g)

3

1.0608

1.2884

5

1.0065

1.1765

7

1.0870

1.0289

9

1.0089

1.0023

11

1.0054

0.9473

The galactomannan reacted with succinic

anhydride produces succinic galactomannan which

has different weights. The decrease in weight of

succinic galactomannan produced was due to the

increasing reaction temperature during heating

which caused degradation of the polysaccharide

chain in the galactomannan. The degradation of the

polysaccharide chain causes a decrease in molecular

weight produced rendering increasing solubility

which during washing it dissolves. Prashanth et al.

(2006) stated that the molecular weight of gum

acetate (~1500 kDa with HPSEC) decreases when

the reaction takes place at a temperature of 60

o

C

compared to gum and other esters which are reacted

at low temperatures (~2000 kDa). Succinic

galactomannan from various reaction time obtained

was analyzed using FT-IR to determine the changes

in functional groups. The FT-IR results obtained are

shown in the following Figure 2.

Figure 2: FT-IR spectra of galactomannan and succinic

galactomannan in various time reaction

FT-IR was used to confirm the formation of succinic

galactomannan. The FT-IR spectrum showed the

absorption band appears at wavenumbers of 1730 -

1750 cm

-1

which is represent the stretching vibration

of C=O which and it is supported by absorption

bands at wave number of 1379 cm

-1

which shows the

CH bending vibration and the vibration stretching of

CO in the group of -O-(C=O)-CH3 at wavelength of

1245 - 1250 cm

-1

. The changes of wavelength from

1024 to 1031 cm

-1

shows the vibration stretching of

C-O-C on galactomannan to galactomannan ester

(Prashanth et al., 2006).

3.4 The Substitution Degree

The substitution degrees of succinic galactomannan

determined by titration method are presented in

Table 2.

Table 2: The substitution degree of succinic

galactomannan in various reaction time

Reaction time

(min)

Substitution degree

value

3

0.404

5

0.460

7

0.503

9

1.527

11

1.090

As can be seen from Table 2, the substitution degree

was increased in the increasing of reaction time in

the microwave with the highest of substitution

degree values occurred at 9 minutes is 1.527.

However, the substitution degree value was

decreased at 11 minutes showed of 1.09. This is

probably due to the temperature that was too high in

the microwave at reaction time of 11 minutes which

caused the degradation of the galactomannan

Synthesis Succinic Galactomannan from Galactomannan Arenga pinnata Merr. and Succinic Anhydride using Microwave Method

71

indicated by the product was blackish brown. Based

on that observations, the longer the reaction time in

the microwave, the temperature increases and thus if

the temperature increases, the value of the

substitution degree is higher. Prashanth et al. (2006)

also showed that increasing in temperature could

increase in the substitution degree value.

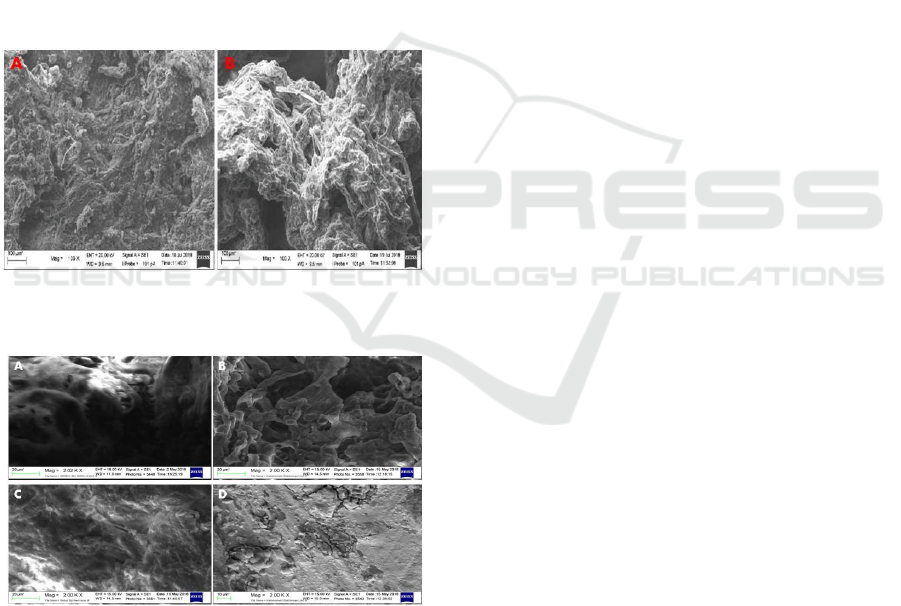

3.5 SEM Analysis

The SEM images of succinic galactomannan

produced from 9 minutes reaction time is presented

in Figure 3. As can be seen in Figure 3,

galactomannan and succinic galactomannan showed

changes in surface morphology. The galactomannan

showed a smooth surface shape that is irregular and

fused to one another, whereas succinic

galactomannan showed that the surface is a bit rough

and bumpy indicates an esterification reaction on

galactomannan has been occurred.

Figure 3: The SEM images of (A) galactomannan and (B)

succinic galactomannan

Figure 4: The SEM images polysaccharide of (A) hard

APE, (B) soft APE and carboxymethyl

polysaccharide from (C) hard APE, (D) soft

APE

4 CONCLUSIONS

The yield of galactomannan extracted from APE

using ethanol solvent was 12.6205 grams. Succinic

galactomannan has been synthesized through a

reaction between galactomannan and succinic acid

anhydride with NaHCO

3

as a catalyst under

microwave irradiation for several reaction times.

The FT-IR spectra confirm the formation of

galactomannan ester by appearance a spectrum at a

wavelength of 1735 cm

-1

indicating the vibration of

C=O of the ester compound. The highest degree of

substitution obtained was 1.527 which occurred

from reaction time of 9 minutes. The SEM images

showed the changes in the morphology of

galactomannan which were smooth and fused to one

another and rough and bumpy on succinic

galactomannan.

REFERENCES

Buriti, F. C. A., Dos Santos, K. M. O., Sombra, V. G.,

Maciel, J. S., Teixeira Sá, D. M. A., Salles, H. O.,

Oliveira, G., De Paula, R. C. M., Feitosa, J. P. A.,

Monteiro Moreira, A. C. O., Moreira, R. A. & Egito,

A. S. 2014. Characterisation of partially hydrolysed

galactomannan from Caesalpinia pulcherrima seeds as

a potential dietary fibre. Food Hydrocolloids, 35, 512-

521.

Dey, P. M. 1978. Biochemistry of Plant Galactomannans.

Advances in Carbohydrate Chemistry and

Biochemistry.

Dong, C. & Tian, B. 1999. Studies on preparation and

emulsifying properties of guar galactomannan ester of

palmitic acid. Journal of Applied Polymer Science, 72,

639-645.

Gong, H., Liu, M., Chen, J., Han, F., Gao, C. & Zhang, B.

2012. Synthesis and characterization of carboxymethyl

guar gum and rheological properties of its solutions.

Carbohydrate Polymers, 88, 1015-1022.

Kooiman, P. 1971. Structures of the galactomannans from

seeds of Annona muricata, Arenga saccharifera, Cocos

nucifera, Convolvulus tricolor, and Sophora japonica.

Carbohydrate Research, 20, 329-337.

Mathur, N. 2011. Industrial galactomannan

polysaccharides, CRC Press.

Mohd Fuad, M. a. H., Hasan, M. F. & Ani, F. N. 2019.

Microwave torrefaction for viable fuel production: A

review on theory, affecting factors, potential and

challenges. Fuel, 253, 512-526.

Prashanth, M. R. S., Parvathy, K. S., Susheelamma, N. S.,

Harish Prashanth, K. V., Tharanathan, R. N., Cha, A.

& Anilkumar, G. 2006. Galactomannan esters—A

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

72

simple, cost-effective method of preparation and

characterization. Food Hydrocolloids, 20, 1198-1205.

Sarkar, S. & Singhal, R. S. 2011. Esterification of guar

gum hydrolysate and gum Arabic with n-octenyl

succinic anhydride and oleic acid and its evaluation as

wall material in microencapsulation. Carbohydrate

Polymers, 86, 1723-1731.

Singh, V., Srivastava, A. & Tiwari, A. 2009. Structural

elucidation, modification and characterization of seed

gum from Cassia javahikai seeds: A non-traditional

source of industrial gums. International Journal of

Biological Macromolecules, 45, 293-297.

Tarigan, J. B. 2014. Karakterisasi Edible Film Yang

Bersifat Antioksidan Dan Antimikroba Dari

Galaktomanan Biji Aren (Arenga pinnata) Yang

Diinkorporasi Dengan Minyak Atsiri Daun Kemangi

(Ocimum basilicum L.). Doktor Disertasi, Universitas

Sumatera Utara.

Synthesis Succinic Galactomannan from Galactomannan Arenga pinnata Merr. and Succinic Anhydride using Microwave Method

73