Research and Discussion on Flexible Automatic Production Line

Upgrade System

Guokun Xie

1, a

, Sen Hao

1

, Yaya Wang

1

, Kai Zheng

1

, Yajuan Jia

1

1

School of Electrical Engineering, Xi 'an Transportation Engineering College, Xi 'an 710300, China

Keywords: Flexibility, PLC, programming, debugging, mechatronics.

Abstract: Modular flexible automatic production line training system consists of six units. They are respectively:

loading detection unit, handling unit, processing and testing unit, installation unit, installation handling unit

and classification unit. The control system can be controlled by Siemens, Mitsubishi or Omron PLC, which

are all have good flexibility, namely each station has a set of independent control of PLC control system.

After the completion of the training in the basic unit module, and the adjacent of two station, three stops can

be... up to six stations are connected together to learn the control, programming, assembly and debugging

techniques of complex systems. The practical training system contains a variety of control technologies such

as pneumatic, motor drive and control, PLC, sensor and so on, which is suitable for engineering practice,

course design and training of engineering and technical personnel at the beginning of the post. It is an ideal

equipment for training mechatronics talents.

1 RESEARCH AND

DEVELOPMENT STATUS AT

HOME AND ABROAD

1.1 Research Status of Flexible

Manufacturing System Abroad

FMS is still developing rapidly in Japan, the United

States and Germany. As early as the middle of last

century, MIT developed CNC milling machine,

which is not only the first flexible automation

equipment in the world [1]. More importantly, it

ushered in an era of flexible production, from which

small batches and multiple varieties would not be a

production problem. In the early 1960s, in the

American Melrose company, CNC automatic

production line came into being, which also created

a precedent in related fields [2]. In the late 1960s,

two American companies developed and designed

related automatic production lines, and from then on,

flexible manufacturing system in its true sense began

to come into people's vision [3].

1.2 Domestic Research Status of

Flexible Manufacturing System

At home, flexible manufacturing is much later than

abroad for many years. Under this huge gap of

nearly 20 years, we can only import relevant systems

from abroad at a high price. Until the end of the last

century, with the strong support of the state, China

was able to develop relevant flexible systems

independently [4]. Through the practice, although

our country starts late, but the development speed is

not slow; many related systems emerge at the

historic moment in our country. More delightedly,

the gap between China's flexible manufacturing

level and that of foreign countries is narrowing [5].

However, this development is doomed to be short-

lived, because there is no future for this kind of

imitation related system, and the number of relevant

scientific research institutions in China is too small,

most products do not have independent intellectual

property rights, so it seems that domestic flexible

system development is a long way to go.

378

Xie, G., Hao, S., Wang, Y., Zheng, K. and Jia, Y.

Research and Discussion on Flexible Automatic Production Line Upgrade System.

DOI: 10.5220/0008855903780381

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 378-381

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

1.3 Domestic and International Status

of Teaching Flexible

Manufacturing System

The flexible teaching system in our country lags

behind many foreign countries. Universities such as

those in Japan, Singapore, the UK and Germany are

far ahead of us in the relevant allocation [6]. In

universities in these countries, flexible systems

range from simple to complex, allowing students to

experience operating platforms themselves. In the

process, students can also research, debug and

program on these advanced flexible systems. In

China, many of the country's top universities also

provide students with teaching systems, but most of

them are imported from Britain or Germany, and

needed a lot of money. Although some universities

are trying to develop relevant systems independently,

most of them still lack relevant teaching systems and

cannot provide relevant practical links.

2 RESEARCH CONTENT, KEY

TECHNOLOGIES AND

RESEARCH OBJECTIVE

2.1 Research Content

Modular flexible automatic production line training

system is one of the most typical mechatronics and

automation products. It is for vocational colleges,

technical schools, education training institutions and

developed, such as it is suitable for automation and

machinery manufacturing, mechanical and electrical

integration, electrical engineering and automation,

automation engineering, control engineering,

measurement and control technology, computer

control, automatic control, mechanical and electrical

engineering, mechanical design and theory and other

related professional teaching and training. It not only

specially designed for teaching, but also

strengthened various control technology and

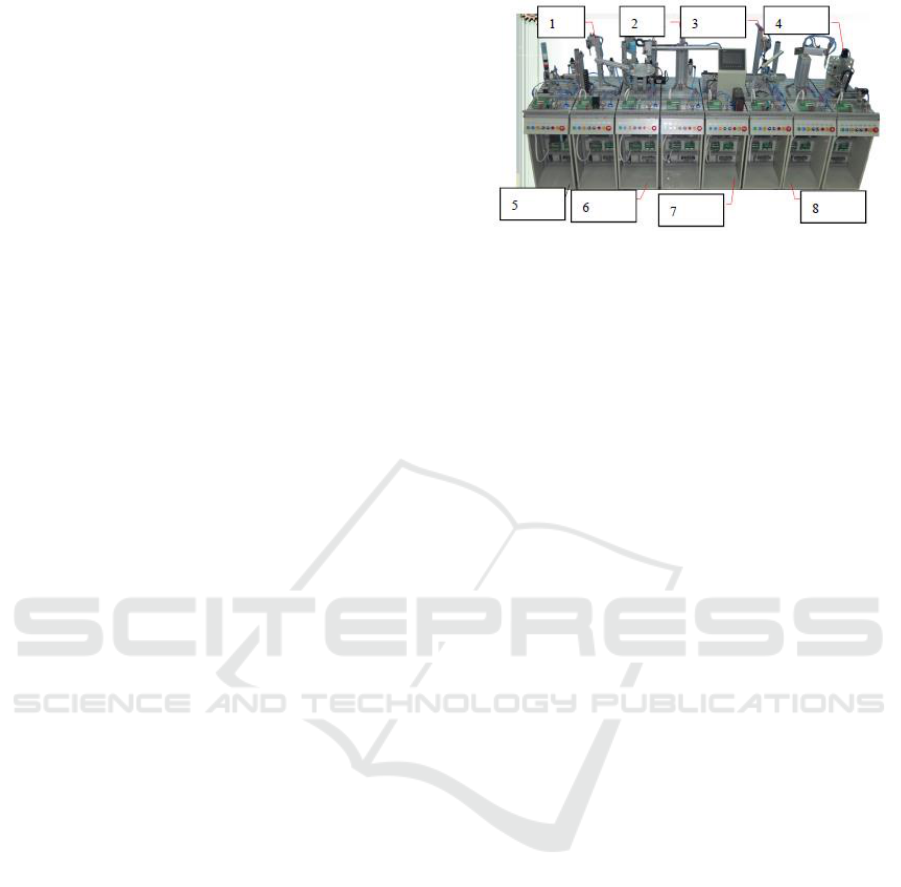

engineering practice ability. The original system is

shown in figure 1.

1-detecting unit; 2-handling unit; 3-Extract installation

unit; 4-Ster; eo storage unit; 5-feeding unit; 6-processing

unit; 7-Sorting and conveying unit; 8-Operator unit

Fig 1. Schematic diagram of the original automatic

production line.

2.2 Key Technologies

(1) The system organically integrates mechanical,

pneumatic, electrical control, motor transmission,

sensing and testing, PLC and industrial network

control technology, with modular structure and easy

combination. Can complete all kinds of individual

skills training and comprehensive project training,

can also carry out mechanical parts installation and

debugging, pneumatic system installation and

debugging, electrical control circuit installation and

PLC programming, mechanical and electrical

equipment installation and debugging, automatic

control system installation and debugging, industrial

network control system installation and debugging

in one. It can meet the needs of practical teaching

and engineering training.

(2) Regardless of mechanical structure or control,

the system adopts unified standard interface, with

high compatibility and expansibility. With the rapid

development of industrial field technology, this

system can keep pace with the upgrading and

expansion of field technology and fully meet the

needs of practical training and teaching

(3)This system can exercise learners' innovative

thinking and practical ability. Learners can use this

system to carry out engineering training in

mechanical assembly, electrical design, wiring, PLC

programming and debugging, field bus construction

and maintenance, etc.

(4) Siemens PLC adopts Siemens PROFIBUS-

DP network communication, which enables the real-

time exchange of control information and state data

between various stations. It is equipped with 10.4-

inch, 256-color industrial color touch screen to

realize industrial control.

Research and Discussion on Flexible Automatic Production Line Upgrade System

379

2.3 Research Objectives

In order to satisfy the practical teaching of the

teaching class, this paper upgrades the existing set of

automatic production line in the laboratory of school

of electrical engineering, and the schematic diagram

of the upgraded automatic production line is shown

in figure 2. The original automatic production line

can only be demonstrated for students to watch, after

technical upgrading, students can modify the

program to complete the change of action. To meet

the needs of different teaching practices, students

participate in the teaching interaction through the

automatic production line teaching system platform,

gradually grasp, eventually integrate what they have

learned, and improve their comprehensive ability.

Fig 2. Schematic diagram of the upgraded automated

production line.

3 TECHNICAL SCHEME,

INNOVATION POINT AND

ADVANCEMENT

3.1 Technical Solution

Figure 3 shows the logistics transfer process of the

work piece from one station to another in the system:

The loading detection unit will arrange the large

work pieces in order before lifting and sending them

out; The transfer station moves the large work pieces

from the loading detection unit to the processing

station; Processing station will be large pieces of

processing after the station; the installation and

handling station moves large pieces of work from

the transmission station to the installation station and

puts them down. Then the installation station will be

the corresponding small work piece into the large

work piece. After that, the installation and handling

station will send the installed work piece to the

sorting station, which will send the work piece to the

corresponding stock bin.

Fig 3. Working process diagram.

(1) Use the instructions learned to complete the

programming of each station.

(2) This training is divided into six units. By

getting familiar with the composition of control parts

and execution parts, some common basic

instructions are used to complete routine control in

production practice.

(3) By getting familiar with the first station, you

can obtain relevant contents of electrical

components installation, mechanical disassembly,

mechanical design, wiring technology, PLC

programming, etc., to prepare for the integration and

debugging of the whole six stations.

(4) Cultivate students' interest in learning, apply

what they have learned to practice, and cultivate the

ability to analyze and solve problems.

(5) Enable students to develop a sense of

cooperation and unity in learning.

(6) Strengthen safety education, so that students

develop good safe operation habits.

3.2 Innovative Point

Through the practical training and skill training of

the intelligent control system of teaching-type

automatic production line, students have a clear

understanding of the technical process and standard

requirements of industrial production, and greatly

improve their sense of professional identity and

recognition. In addition, after practical training,

students have a deeper understanding of basic

engineering knowledge; significantly improve their

operational ability, teamwork awareness and

engineering management ability. Through the

practice of training, greatly stimulate students'

innovative thinking and innovative ability, for the

improvement of the quality of students to play a

positive and effective role.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

380

3.3 Advancement

The intelligent control system of flexible automatic

production line for teaching is designed, which fused

automation professional motion control field of the

core technology. Each workstation can be an

independent system, and is a mechatronic integrated

system, at the same time, the system also has a

strong flexibility, convenient for different work tasks

configuration, meet the needs of different teaching

practice. Through the automated production line

teaching system platform, students participate in the

teaching interaction, from the shallow to the deep,

from the point to the surface, gradually master, and

eventually integrate the learned knowledge, improve

their comprehensive ability. To ensure the quality of

automatic skilled personnel training.

4 APPLICATION PROSPECT

ANALYSIS

Flexible automatic production line is a production

line composed of several adjustable machine tools

and automatic transport devices. It is a production

system with complex technology and high

automation. It uses computers for management and

combines various production modes, which can help

enterprises reduce production costs, improve product

quality, shorten product replacement time, and

finally reflect the improvement of enterprise

competitiveness. Based on hardware and supported

by software, the flexible automatic production line

can achieve the required control by changing the

program, so it is flexible and easy to adjust. To

realize the flexibility and high efficiency of

manufacturing process is the main way to adapt to

multi-variety, small and medium batch production.

In the process of production line operation, the

material transfer system of flexible automatic

production line has the ability to bypass the fault

machine by itself, with stable production capacity,

strong strain capacity, simple structure and flexible

assembly. It can be combined freely according to the

size of the production workshop, increase or

decrease equipment appropriately according to the

actual needs, and arrange the system reasonably, so

as to solve the problems such as limited enterprise

space, no place for new product production line, and

too long product replacement time.

REFERENCES

Chen Peng, Liu Fei, Ning Junfeng. Integrated model and

application of multi-objective monitoring for

automatic machining production line [J]. Computer

Integrated Manufacturing System, 2017, (03):473-481.

Keith Barrow. Automatic Train Control takes to the main

line [J]. International Railway Journal, 2018, (01):16-

17.

Shukai Li, Lixing Yang, Ziyou Gao. Optimal switched

control design for automatic train regulation of metro

lines with time-varying passengers arrival flow [J].

Transportation Research Part C, 2018, (01):425-440.

Song Yanke, Zhao Yugang, Zhao Run. Structural design

and control system research of five-axis micro-cnc

milling machine [J]. Machine Tools and Hydraulic,

2017, (23):66-69.

Yang Bin, Wang Zhenyu. Intelligent manufacturing talent

cultivation based on flexible manufacturing system

engineering training teaching [J]. Laboratory Research

and Exploration, 2017, (01):192-195+200.

Zhang Guijun, Chen An, Wang wen, et al. Development

of modular flexible manufacturing integrated training

and teaching management system [J]. Laboratory

Technology and Management, 2017, (12):161-163.

Research and Discussion on Flexible Automatic Production Line Upgrade System

381