Cocoa Pod (Teobroma cacao L.) Utilization as Material for CMC

Yeni Afriani, Zanira Urfa Harahap, Era Fazira Matondang and Cut Fatimah Zuhra*

Department of Chemistry, Faculty of Mathematics and Natural Science, Universitas Sumatera Utara, Medan, Indonesia

Keywords: CMC, Alkalization, Carboxymethylation, Cacao Pod.

Abstract: Cacao pod contain 31.25% cellulose. It can be used for CMC (carboxymethyl cellulose) with four phases

involving alkalization, carboxymethylation, neutralization and drainage were used to making of CMC. The

first proses using NaOH. Media such as methanol, propanol, sodium monochloroacetate, and water. The

neutralization process, acetic acid was added. And for the last step it was heating in the oven. The result

showed that contents of CMC of NaCl 87-91%, viscosity 5.5 cP, pH 8, and DS value is 0.872. On the other

hand, acetic acid did not give significant effect for colors of CMC.

1 INTRODUCTION

Indonesia is the third largest producer of cacao

(Theobroma cacao L.) in the world. The large number

of processing cocoa fruit in Indonesia are mostly only

used the seeds and pulp to be produced while the

cocoa pod husks were being a waste unused. S hile it,

in the pod husks containing crude fiber composed of

cellulose (31.25%), hemicellulose (48.64%) and

lignin (20.11%) (Ashadi, 1988).

Cellulose is a polysaccharide which if hydrolysed

will produce glucose monomers and some cellobiose.

Cellulose can swell if reacted with alkali metal, salts

in strong base solutions and amine compounds. The

amine compound that is commonly used to develop

cellulose bonds is NaOH (Irawadi, 1990). Cellulose

is also insoluble in water and is very easy to absorb

water. It’s really support to make the pod husks as raw

material for the manufacture of carboxymethyl

cellulose or carboxymethyl cellulose (CMC).

CMC is derivative from cellulose used in industry

food for get good texture. There are several the most

important CMC function that is as thickener,

stabilizer, gelling agent, as emulsifier, and in some

could levelling spread antibiotics. CMC has group

carboxyl, then viscosity CMC solution is affected by

the pH of the solution (Winarno, 1995). CMC is

capable tie water so water molecules are trapped in

gel structure formed by CMC. CMC is an ingredients

stabilizer that has power strong tie and play a role for

improve viscosity and texture product food, like jelly,

salad and produkes (Belitz and Grosch, 1987).

Rahman et al. (2016) conducted a study on the use

of cellulose to CMC produced from rice straw cellulose

resulting in optimum purity conditions of CMC, which

were added to 4 grams of NaMCA (sodium

monochloroacetic) and 5 grams of cellulose. The

amount of sodium monochloroacetate used will affect

it substitution of anhydrous unit glucose in cellulose.

Increasing the amount of alkali used will result in an

increase in the amount of monocloroacetate. This

carboxymethylation process is actually an

etherification process. At this stage is the process of

attaching the carboxylic group to the cellulose

structure. This is very important to control when

making CMC (Personal, 1985).

2 MATERIALS AND METHODS

2.1 Materials

The materials used in this study include: Cocoa pod,

NaOH 30%, NaOH 2%, H

2

O

2

10%, methanol,

propanol, acetate acid 90%, aquadest, Fehling A,

Fehling B, Na-MCA, K

2

CrO

4

, AgNO

3

, Nitric acid.

2.2 Preparation PVA 10%

Waste of cocoa fruit peel is broken and cleaned with

water. Then dried in the sun. Mashed using a blender.

Sifted using 80 mesh sieves. Furthermore, the water

content is determined by weighing 2 grams of cocoa

pod powder into a weighing bottle, put in the oven for

Afriani, Y., Harahap, Z., Matondang, E. and Zuhra, C.

Cocoa Pod (Teobroma cacao L.) Utilization as Material for CMC.

DOI: 10.5220/0008857201210123

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 121-123

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

121

4 hours at 105°C and then put into the desiccator and

weighed until the weight remains.

2.3 Isolation of Cellulose

Cocoa pod husk was weighed as much as 250 grams

then mixed with NaOH 2% and then heated at 80°C

for 4 hours while stirring. Then is filtered, the

sediment will be washed with aquadest until pH 7 and

then bleached with H2O2 10% as much as 250 ml

after that it was heated at 60°C for 15 minutes then

left for 1 night. Ovened cellulose for 1 night at 75°C

then characterized by FT-IR and tested qualitatively.

Cellulose is prepared in the form of pulp. Porridge is

examined in a thin film placed between flat salt

plates. The test is done by clamping the mixed film

on the sample site. Then the film is placed on the plate

in the direction of infrared light. The result will be

recorded periodic paper in the form of a 4000-200 cm

-

1

wave number curve flow to intensity.

2.4 Antimicrobial Activity

About 10 gram cocoa pot husk put into 3 neck flask

placed on waterbath then added 400mL propanol p.a,

50 ml methanol, 50 mL aquadest and stirred for 10

minutes. Then added 30% NaOH solution (22 grams

of NaOH) drop by drop and the alkalization process

continues for 1hour at 24°C. After completed

followed carboxymethylation process by adding as

much as 20 grams of sodium monochloroacetate for

3.5 hours at a temperature of 55°C.

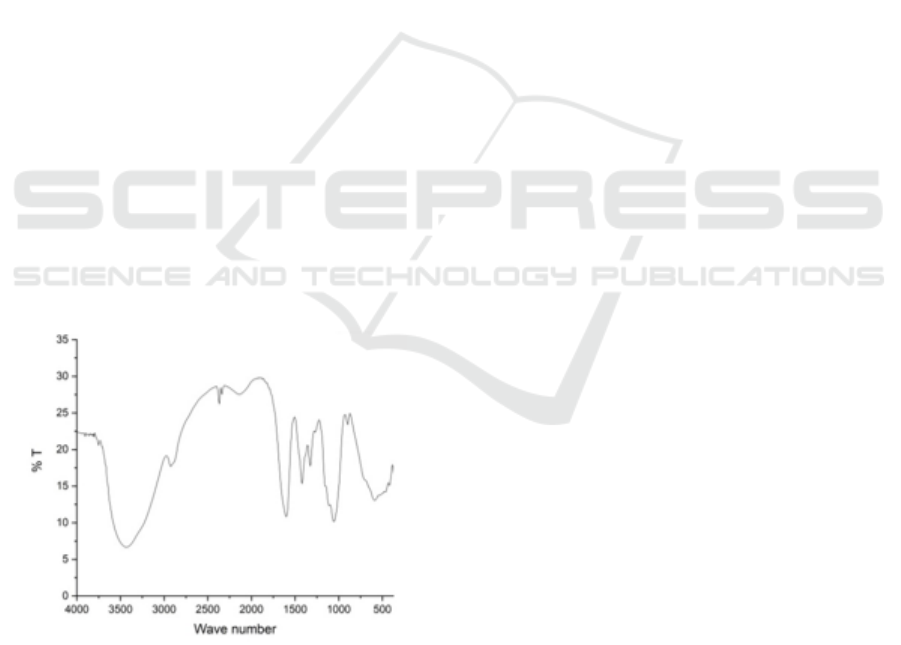

Figure 1: FTIR spectra of CMC.

After the carboxymethylation process is complete,

the stirrer is turned off then the mixture is transferred

to the beaker glass and the pH is measured. Next, 90%

acetic acid was added until the pH was neutral and

decanted. The residue obtained was added with 200

mL of methanol and stirred and then filtered using a

vacuum pump. Finally wrapped in aluminum foil

dried in the oven for 4 hours at 60°C. The dried CMC

is then mashed with a blender and stored in a closed

place. The CMC obtained will be analyzed by FT-IR.

CMC is prepared in the form of pulp. Porridge is

examined in a thin film placed between flat salt

plates. The test is done by clamping the mixed film

on the sample site. Then the film is placed on the plate

in the direction of infrared light. The result will be

recorded periodic paper in the form of a 4000-200 cm

-

1

wave number curve flow to intensity.

3 RESULTS AND DISCUSSION

3.1 Characterization of Cellulose

The FT-IR spectrophotometric test results also

showed positive results by comparing wave number

of bagasse cellulose and commercial cellulose. Figure

1 is the result of FT-IR spectroscopic test which

shown spectrum with vibration peak in area of

3448.72 cm

-1

for –OH group, supported by

emergence of vibrational peaks at wave number

2900.94 cm

-1

which shows C–H stretching groups,

1064, 71 cm

-1

which shows the ether group, and the

glycoside bond in α-cellulose structure is found at

wave number 1635.64 cm

-1

(Epriadi, 2017).

Results infrared spectra from cellulose to show

absorption on number wave 3332,66 cm

-1

which is is

a OH area on number wave 1321,54 cm

-1

to show

area peak for CH groups, and on number wave

1040,31 cm

-1

which is is a C-O-C group.

3.2 Characterization of CMC

The CMC samples were analyzed by FTIR, which can

be depicted in the two spectra in Fig. 1. The x-axis

represents the wavelength (cm

-1

) and y-axis whos the

light transmittance through the sample. The FTIR

spectrum of the sample shows that the carboxyl,

methyl and hydroxyl functional groups are found at

wavelength of 1617.60, 1454.44 and 1195.72 cm

-1

(for CMC-55-10), 1613.57, 1426.01 and 1214.54 cm

-

1

(for CMC-28-10), respectively. However, for

sample CMC-82-10 only carboxyl and methyl

functional groups are shown in the peak at 1654.16

and 1458.13 cm

-1

. Consequently, for all CMC

samples synthesized the IR spectra indicates the

typical absorptions of the cellulose backbone as wel

as the presence of the carboxymethyl ether group at

1654.16, 1617.60 and 1613.57 cm

-1

consecutively for

each sample. The additional peak at wavelength of

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

122

2357.27 cm

-1

at sample CMC-55-10 might be due to

the existence of the contamination from impurities or

combination band with water. Subsequently the bands

around 1458.15 – 1420.05 cm

-1

are assigned to CH2

scissoring. It is obvious that those in the broad

absorption band of approximately above 3500 cm

-1

is

due to the stretching frequency of the hydroxyl group

(-OH) (Saputra, 2014). Based on Table 1, the

viscosity of CMC is 5.5 cP. The purity of CMC based

on NaCl contents is 94,15%. The substitution degree

during carboxymethylation was 0.872.

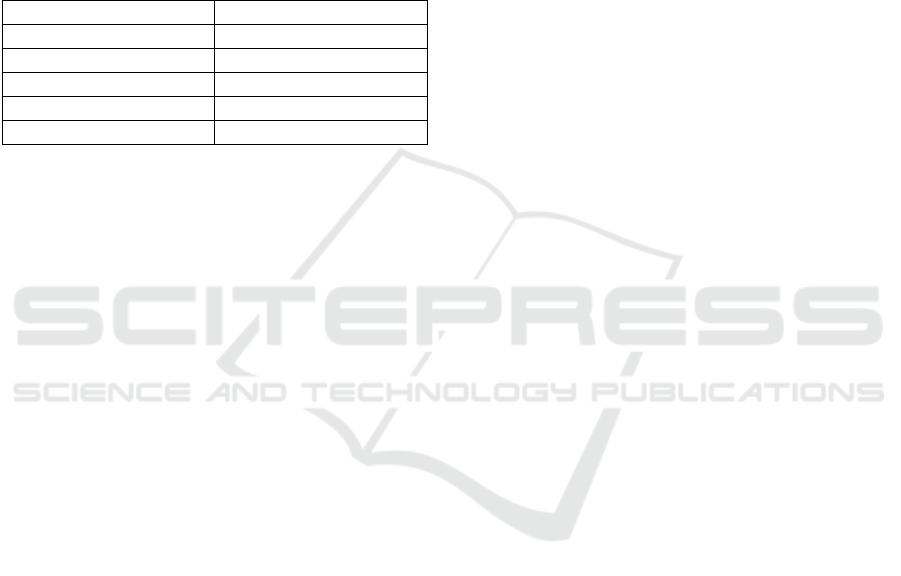

Table 1: Result of viscosity test.

CMC (g)

Viscosity (cP)

0.01

5.5

0.02

5.3

0.03

5.6

0.04

5.5

0.05

5.6

4 CONCLUSIONS

Based on the results of the research it can be

concluded that CMC from cacao pod husk can be

used. But CMC were obtained to show less result s

well from facet viscosity. Expected next researcher

more pay attention composition in making CMC.

ACKNOWLEDGEMENTS

The authors would like to send gratitude to Risekti

dikti for the financial support towards this research in

the PKM-PE Project 2019 and also for Universitas

Sumatera Utara which facilitated this research.

REFERENCES

Adinugraha M. P, Marseno, D. W., Haryadi., 2005.

Synthesis and Characterizationof Sodium

Carboxymethyl Cellulose from Cavendish Banana

PseudoStem (Musa cavendishii LAMBERT).

Carbohydrate Polymers, 62: 164-169.

Figueira A, Janick J., 1993. New products from Theobroma

cacao: Seed pulp andpod gum.New York: New crops.

475- 478

Hong, K. M., 2013.Preparation and Characterization of

Carboxymethyl Cellulose from Sugarcane Bagasse.

Malaysia: Universiti Tunku Abdul Rahman. 1:21-84.

Mandal, A, Chakrabarty D. 2011.Isolation of Nanocellulose

from Sugarcane

Bagasse (SCB) and Its Characterization Carbohydrate

Polymers. 86(1): 1292 –1299.

McKee T, McKee J. R., 2003 .Biochemistry: The

Molecular Basis of Life.New York:McGrawHill

Companies, Inc. 3: 219-220.

Ott, Spurlin., 1995. Cellulose and Cellulose Derevative,

Vol 5 Part 2. New York: Inter Science Publisher Inc.

Preparation, Proximate Composition and Culinary

Properties, Journal of food research 18: 1283-1287.

Susanto, F. X., 1994. Tanaman Kakao: Budidaya dan

Pengolahan Hasil. Yogyakarta: Penerbit Kanisius. 43-

54

Cocoa Pod (Teobroma cacao L.) Utilization as Material for CMC

123