Modification and Characterization Natural Cycle Rubber

(Resipren-35) with Oleat Acid using Dicumyl Peroxide and

Divinilbenzena as Compatibility

Barita Aritonang

1,4

, Tamrin

2*

, Basuki Wirjosentono

2

and Eddiyanto

3

1

Postgraduate Chemistry Study Program, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara,

Jl. Bioteknologi No. 1 Kampus USU, Medan, Indonesia

2

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara Jl. Bioteknologi

No.1 Kampus USU Padang Bulan, Medan, 20155

3

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Negeri Medan,

Medan, Indonesia

4

Faculty of Science, Technology and Information, University of Sari Mutiara Indonesia

Keywords: Cyclic Natural Rubber, Oleic Acid, Dicumil Peroxide, Divinyl Benzene, Grafting Copolymer.

Abstract: Modification of cyclic natural rubber with oleic acid using initiator diumil peroxide and divinilbenzene as a

compositer through the melting phase in the internal mixer using the copolymer grafting method at 160 oC

for 8 minutes at 80 rpm was carried out with the aim of increasing its compatibility as a paint binder. Varia-

tions in the concentration of oleic acid were used 3, 6 and 9 phr while the initiator concentrations of dicumil

peroxide 0.5 phr and divinilbenzena 1.0 phr. Determination of the degree of grafting was carried out by titra-

tion method and FT-IR spectra analysis to determine the presence of oleic acid grafting in the cyclic natural

rubber chain. The results showed that the process of transplanting oleic acid into the chain of cyclic natural

rubber molecules with the presence of initiators dicumyl peroxide and divinylbenzene was successfully car-

ried out marked the emergence of new absorption peaks at wave number 1705.07 cm-1 which is a typical

uptake of oleic acid indicating the presence of bond vibrations C=O carbonyl group asymmetry derived from

oleic acid. The maximum percentage grafting degree is 0.2630% at 9 phr oleic acid monomer concentration.

The degree of grafting increases with increasing concentration of oleic acid.The transition temperature of

cyclic natural rubber glass before being grafted with oleic acid is 102.86 0C but after the transplanting process

using the initiator diumil peroxide and divinylbenzene the glass transition temperature (Tg) decreases to 83.98

0C this proves that the process of transplanting oleic acid into the cyclic natural rubber molecule chain has

been successfully carried out with the formation of the new CNR-g-AO product.

1 INTRODUCTION

Natural rubber is a renewable polymer containing car-

bon atoms (C) and hydrogen atoms (H) obtained from

Hevea brasiliensis trees which have good tensile

strength and tear resistance, and have a fairly good

stickiness so that they can be widely used as adhe-

sives in the coating / coating industry (Khan et al.,

2011; Hirata et al., 2014).

However, as unsaturated polymers, natural rubber

has the limitation that it will experience gradual deg-

radation at high temperatures when exposed to oxy-

gen, ozone or ultraviolet, and its solubility in hydro-

carbon solvents thus affecting the quality of natural

rubber itself (Grassie et al., 1988; Wypych, 2015).

One of the efforts made to overcome the weakness

of natural rubber is chemical modification through

cyclization reaction using Lewis acid catalyst. The

aim of the chemical modification of natural rubber is

to improve the properties of natural rubber so that

new products are produced that are more useful, eco-

nomical and have superior properties, so that they can

be applied in various types of rubber products

(Tanaka et al., 2004; Saelao et al., 2005).

Cyclic natural rubber (CNR) is a chemical modifi-

cation of natural rubber through cyclization reaction

using Lewis acid catalyst, has considerable potential to

be applied as an adhesive, printing ink and paint indus-

try because it has abrasion resistance properties (fric-

tion), resistant to corrosion and has good adhesion to

Aritonang, B., Tamrin, ., Wirjosentono, B. and Eddiyanto, .

Modification and Characterization Natural Cycle Rubber (Resipren-35) with Oleat Acid using Dicumyl Peroxide and Divinilbenzena as Compatibility.

DOI: 10.5220/0008859701450151

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 145-151

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

145

metals, wood, rubber, leather, textiles and paper (Sire-

gar et al., 2014; Eddiyanto et al., 2015; Aritonang et al.,

2018; Ritonga et al ., 2018; Barita Aritonang et al.,

2019).

However, cyclic natural rubber has a very weak

adhesion to the polar surface. This is because cyclic

natural rubber is a nonpolar polymer which is very

vulnerable to oxidation degradation reactions by

ozone, oxygen or utraviolet (uv) compounds and has

a double bond in the polymer chain and its surface

energy is very weak, causing interface interactions

and the adhesion is weak when mixed with polar pol-

ymers. To overcome this problem, it is necessary to

do chemical modifications to the structure of cyclic

natural rubber using the method of grafting (copoly-

mer grafting). An effective method for modifying cy-

clic natural rubber is the copolymer grafting tech-

nique, so that cyclic natural rubber can be functional-

ized according to the desired properties without af-

fecting the basic structure of cyclic natural rubber.

Oleic acid is a polar unsaturated fatty acid that can

be used as a monomer to increase CNR compatibility,

reactivity and adhesive strength because the double

bonds in AO provide an opportunity to be able to

modify the CASH structure through a copolymer

grafting process and the same acid composition can

react with hydroxyl groups. This has been proven by

Zhou et al. (2002), that through oleic acid monomer

polymerization (AO) grafting process successfully

grafted the main acrylonitrile-butadiene-styrene

(ABS) chain using benzoyl peroxide (BPO) initiator

in 1.2 solution -dichloroethane. The result is that AO

can increase the flexibility, elasticity and stability of

polymers against heat and ultraviolet radiation.

Preliminary research that has modified cyclic natu-

ral rubber using the copolymer grafting method, Sire-

gar Said et al (2014) modified cyclic natural rubber us-

ing monomer maleic anhydride in the presence of ben-

zoyl peroxide through melting techniques in mixer in-

ternal mixers using the copolymer grafting method.

The results of the study obtained AM-g-CNR products.

The higher the concentration of maleic anhydride, the

more maleic anhydride groups are grafted on the CNR

polymer chain. Transplant products have physical

properties that do not experience significant changes

except the glass transition temperature, where there is

an increase. Nasution et al. (2015) modified cyclic nat-

ural rubber using monomer methyl methacrylate with

the presence of the initiator diumil peroxide.

The results of the study obtained CNR-g-MMA

products, which are characterized by the appearance

of wave number absorption peaks in the area of 1731

cm

-1

(absorption of carbonyl groups) typical for car-

bonyl (C = O) from metal methacrylate.

2 MATERIALS AND METHODS

The materials used consisted of Acetone, ethanol

(C

2

H

5

OH), commercial cyclic natural rubber (CNR)

production of PTPN-3, dicumyl peroxide (DKP),

oleic acid (OA), divinil benzene (DVB), hydrochloric

acid (HCl), xylene. Glassware, Mettler Toledo Ana-

lytical Balance, Memmert Oven, Thermo haake pol-

ydrive mixer Shimadzu FT-IR Spectrophotometer,

Shimadzu Differential Scanning Calorimetry (DSC).

Grafting of oleic acid in cyclic natural rubber with

heat initiation, without dicumil peroxide As many as

33 grams of cyclic natural rubber are put into the

chamber slowly and left for about 4 minutes until all

of them melt perfectly. Then add 6 phr oleic acid into

the chamber so that it mixes and undergoes a copoly-

merization reaction. After 8 minutes, the process is

stopped by pressing the STOP button. Furthermore,

in rapid heat conditions the copolymerization product

is removed from the chamber. After the cold is made

in the form of pellets / granules.

2.1 Grafting Oleic Acid in Cyclic

Natural Rubber using Dicumyl

Peroxide

Cyclic natural rubber is weighed as much as 33 grams

(100 phr), after which the Thermo mixer internal

mixer temperature is set haake polydrive at 160

o

C,

then slowly cyclic natural rubber is inserted into the

internal chamber mixer and allowed to last for ap-

proximately 4 minutes until cyclic natural rubber

melts perfectly, then added with oleic acid as much as

6 phr, followed by the addition of initiator dicumyl

peroxide as much as 0.5 phr until mixed homogene-

ously. The mixing process is carried out for 8 minutes

to experience the grafting reaction. After 8 minutes,

the process is stopped. In hot conditions quickly the

reaction product is removed from the chamber. The

products produced are then chilled and made in the

form of granules / pellets. Variations in the concen-

tration of oleic acid used 3, 6 and 9 phr.

2.2 Purification Process of Cyclic

Grafted Natural Rubber Products

Oleic Acid

Oleic acid which has been grafted on cyclic natural

rubber (CNR-g-OA) is weighed as much as 1 gram

and refluxed with 100 ml of xylene with a series of

reflux devices namely heating, boiling pumpkin and

liebig condenser at 110

o

C until dissolved, 100 ml

added after dissolving ethanol to form deposits. The

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

146

precipitate formed is filtered with Whatman filter pa-

per No.42 which is connected with a vacuum pump

and washed with ethanol repeatedly with the aim of

dissolving the remaining acidic reactions. The precip-

itate formed was dried in an oven at a temperature of

120

o

C for 24 hours, then determined percent degree

of grafting. Determination of the degree of grafting is

done using the following formula:

(%) DG =

𝑁 (𝑒𝑞/𝐿) [(𝑉𝑜−𝑉) 𝑚𝑙] 𝐵𝑀𝐴𝑂 𝑔/𝑒𝑞

𝐵𝑆 𝑥 1000 𝑚𝑔/1𝑔

x 100 (1)

Where,

N = KOH concentration (0.05 N)

V = ml of KOH titration used on CNR-g-AO

samples modified

V0 = ml of KOH titration used on he CNR sample

blank is not modified

BM oleic acid = 282.47 g / mol

BS = sample weight

1000 = Conversion factor of carboxylic groups

from oleic acid molecules

3 RESULTS AND DISCUSSIONS

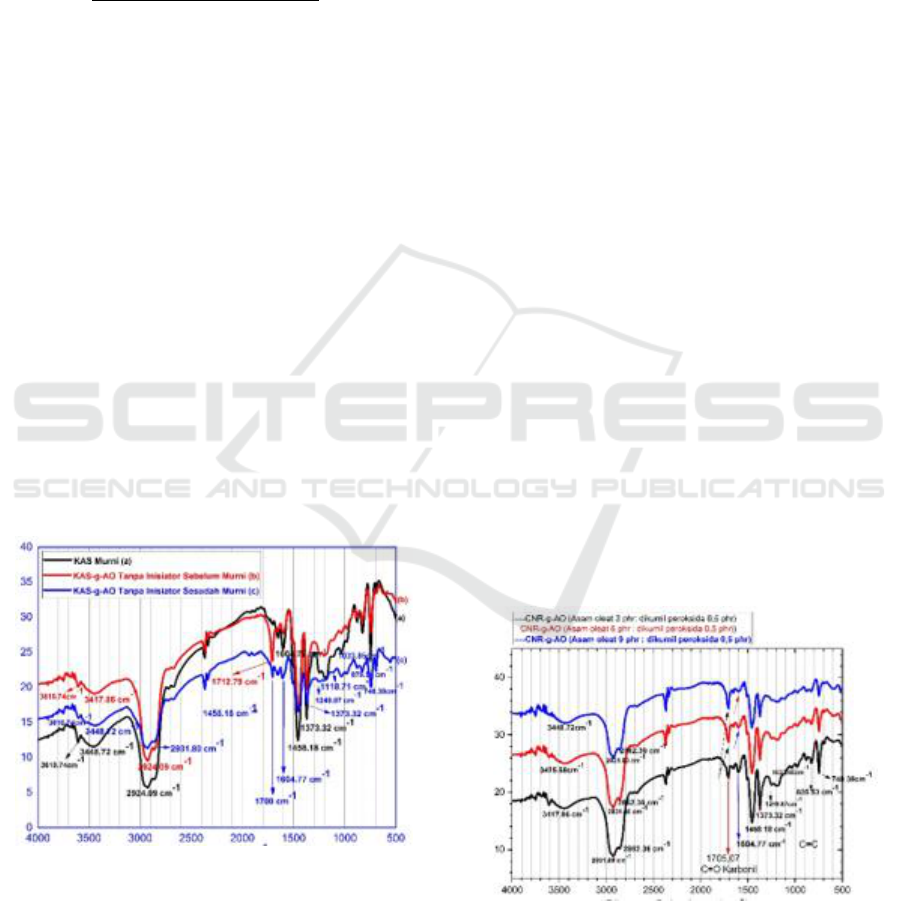

Analysis of CNR-g-AO FT-IR without dicumyl Per-

oxide Initiator To determine the success or failure of

the oleic acid grafting process into the cyclic natural

rubber molecule chain with and without the presence

of the initiator dicumyl peroxide after being purified,

it can be seen from the analysis of the spectroscopic

Fourier Transformed-Infra Red shown in Figure 1.

Figure 1: Spectrum of CNR-g-AO FT-IR without DKP

Initiator.

Seen in Figure 1 (b) the FT-IR spectrum of CNR-

g-AO before being purified new functional groups ap-

pear with sharp absorption peaks and high intensity

wave numbers 1712.79 cm

-1

, after purification there

is a shift in peak absorption of wave numbers and

changes in intensity shown in Figure 1 (c) FT-IR

spectrum CNR-g-AO, obtained a weak absorption

peak with low intensity wave number 1700 cm

-1

shows the existence of strain vibration C = O carbonyl

group derived from oleic acid. This is in accordance

with the results of previous studies which explained

that absorption peaks with spectral regions 1760-

1665 cm

-1

showed the presence of a group C = O car-

bonyl derived from oleic acid (Liu Mingzhu et al.,

2003; Zhou et al., 2002; Boonyod et al., 2017; Wirjo-

sentono et al., 2018; Barita Aritonang et al., 2019).

The emergence of new functional groups in CNR-

g-AO samples after being grafted in the mixer inter-

nal mixer through heat initiation without using an in-

itiator before and after being purified at the peak wave

number 1700 cm

-1

and 1712.79 cm

-1

indicates the

presence of carbonyl groups (C = O) which is a typi-

cal absorption derived from oleic acid (AO), has

proven that the process of transplanting oleic acid in

cyclic natural rubber in the mixer internal mixer has

been successfully carried out.

3.1 Analysis of CNR-g-AO FT-IR with

Dicumyl Peroxide Initiator

The FT-IR analysis test was carried out on CN-g-AO

samples without initiator in bulk peroxide by compar-

ing CNR-g- [AO / DKP] samples with the presence

of initiators in wax peroxide after being purified by

looking at the absorption peaks in the CNR spectrum

and CNR spectrum- g- [AO / DKP] especially in the

area of wave number which is an indication of the ex-

istence of C = O and C-O bonds from oleic acid. The

FT-IR CNR-g- [AO / DKP] spectrum with the di-

cumyl peroxide initiator is shown in Figure 2.

Figure 2: CNR-g-AO FT-IR Spectrum Using DKP Initiator.

Figure 2 analysis of CNR-g-AO FT-IR spectra

shows that there has been a chemical interaction be-

tween CNR, AO and DKP, this can be proven from

Modification and Characterization Natural Cycle Rubber (Resipren-35) with Oleat Acid using Dicumyl Peroxide and Divinilbenzena as

Compatibility

147

the results of the copolymer grafting of oleic acid into

cyclic natural rubber with a new absorption peak at

wave number 1705,07 cm

-1

which is a typical uptake

of AO indicates a vibration of the C = O carbonyl

group asymmetry which originates from oleic acid,

and is also supported by the presence of CO bonds at

wave number 1257.59 cm

-1

. At 3448.72 cm

-1

wave

number obtained the peak of the widening and strong

absorption band with high intensity shows the pres-

ence of a hydroxyl group O-H vibration vibration

originating from CNR. The typical strong and sharp

absorption peak with high intensity derived from

CNR appears at wave number 2931.80 cm

-1

which is

a stretching vibration of C-H methyl group, at wave

number 2862.36 cm

-1

is stretching vibration of CH

3

methylene group. At the peak of wave number

1458.18 cm

-1

shows the vibration of CH

2

methylene

group strain and at the peak of wave number absorp-

tion band 1373.32 cm

-1

shows the presence of methyl-

CH

3

group amplified by vibrations of swing group -

CH

2

methylene at peak wave number 719 cm

-1

. At the

peak of absorption wave number 1257.59 cm

-1

with a

spectrum area of 1080-1300 cm

-1

indicates the pres-

ence of vibrations of C-O bonds. Based on the FT-IR

spectrum analysis data described above it can be con-

cluded that the copolymerization process of grafting

AO into the CNR molecular chain has been success-

fully carried out.

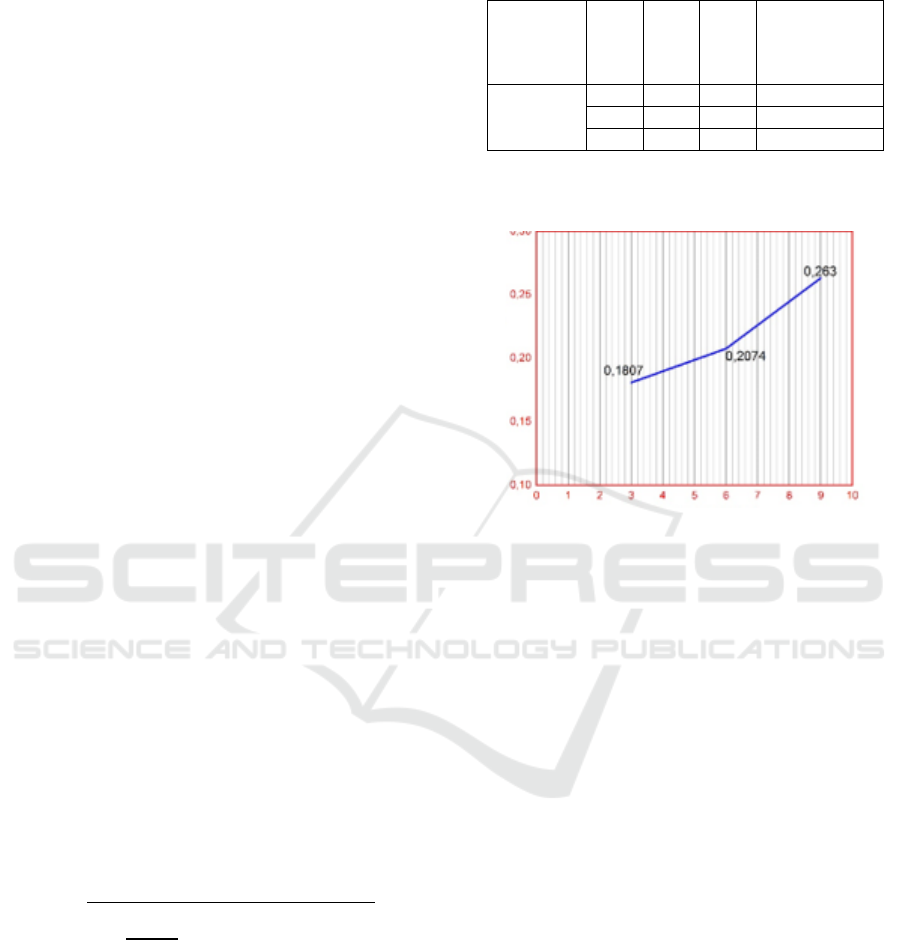

3.2 Determination of Grafting of

CNR-g-AO Products

The purpose of refining CNR-g-AO products is to

find out how much oleic acid is grafted on a cyclic

natural rubber polymer chain. Determination of the

degree of grafting of CNR-g-AO products after puri-

fication was determined by the acid-base titration

method. Based on the results of the research that has

been done, the percentage of grafting for CNR-g-AO

products before being purified can be seen in table 1.

(%) DG =

0,05 (𝑒𝑞/𝐿)

[(

0,42 𝑚𝑙−0,29 𝑚𝑙

)]

282,47𝑔/𝑒𝑞

1,0162 𝑥 1000 𝑚𝑔/1𝑔

=

1,8361

1016,2

= 0.1807

Table 1: Effect of Oleic Acid Concentration on Grafting

Degrees.

CNR

phr

AO phr

DKP

phr

Grafting degree

(%)

CNR-g-OA

100

3

0,50

0,1807

100

6

0,50

0,2074

100

9

0,50

0,2630

The effect of monomer concentration on percent

degree of grafting is shown in Figure 3.

Figure 3: Graph of the Effect of Oleic Acid Concentration

on Degrees of Grafting.

Figure 3 clearly shows that percent degree of

grafting, in this case the amount of oleic acid that is

grafted (attached / grafted) to CNR increases with in-

creasing concentration of oleic acid monomers. Per-

centage of minimum grafting degree was obtained at

0.1807% at 3 phr oleic acid monomer concentration,

at 6 phr oleic acid monomer concentration obtained

percent degree of grafting at 0.2074%, for percent

grafting maximum degree obtained at 0.2630% at

acid monomer concentration oleat 9 phr, this shows

that percent degree of grafting is increasing gradually

with increasing concentration of oleic acid monomers

used, even though the increase is not too significant.

Even though the percentage of grafting obtained is

very small, but can change the surface of non-polar

CNR to be polar hydrophilic, this proves that oleic

acid has been successfully grafted into the molecular

chain of CNR. This data is supported based on the re-

sults of research conducted by Kang and Liaw (1999)

reporting that even though the percent of grafting ob-

tained is very small, it has been able to change the

nonpolar surface of the polymer to be polar.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

148

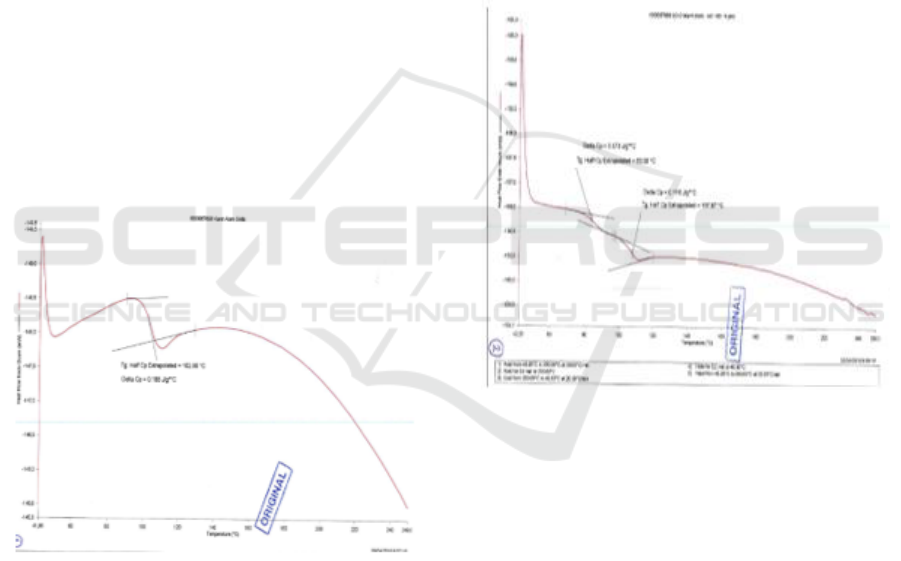

3.3 Analysis of Thermal Properties of

Pure CNR before and after

Grafting with Oleic Acid using

Differential Scanning Calorimetry

(DSC)

Differential Scanning Calorimeter (DSC) analysis is

one of the tools of the Thermal Analyzer that is used

to study phase transitions, such as melting tempera-

ture (Tm), glass transition temperature (Tg), or exo-

thermic decomposition, and to analyze the stability of

oxidation and heat capacity of a material. Glass tran-

sition temperature (Tg) is the temperature when the

polymer changes from the glass state to rubber.

Where when the outside temperature approaches the

glass transition temperature, a polymer undergoes a

change from a rigid hard state to a soft rubber. Melt-

ing temperature (Tm) is the temperature at which sol-

ids turn into liquids at a pressure of one atmosphere,

in other words, the melting temperature is the temper-

ature when the solid and liquid phases are equally in

equilibrium. Based on the results of the research that

has been done while the glass transition temperature

(Tg) of pure CNR before copolymerized grafts (co-

polymer grafting) can be seen in Figure 4.

Figure 4: DSC Pure Cyclic Natural Rubber Thermogram.

Based on Figure 4 the results of the DSC thermo-

gram of pure CASH samples before copolymer graft-

ing had a temperature of glass transition temperature

(Tg) 102.86 0C and enthalpy change (ΔH) of 0.188 J

/ g 0C. The higher the glass transition temperature

(Tg) shows the polymer is increasingly brittle.

3.4 Analysis of Thermal Properties of

Grafted Differential Scanning

Calorimetry CNR with Dicumyl

Peroxide Initiator

The product formed from the oleic acid grafting reac-

tion into the CNR molecular chain using the dicumil

peroxide initiator (DKP) in the mixer internal mixer

is CNR-g-AO. The CNR-g-AO product formed was

then characterized by Differential Scanning Calorim-

etry (DSC) to determine the glass transition tempera-

ture (Tg) and melting temperature (Tm). The results

of the analysis of thermal properties in the form of

DSC thermograms of CNR-g-AO products that have

been grafted using dicumil peroxide initiator (DKP)

after purification can be seen in Figure 5.

Figure 5: CNR-g-AO DSC Thermogram Using Dicumyl

Peroxide Initiator.

Based on Figure 5 the results of research that have

been carried out from the DSC thermogram curve ob-

tained two glass transition temperatures (Tg) which

were observed at temperatures of 83.98

0

C and 107.67

0

C. Based on the results of the DSC thermogram

curve analysis in Figure 5, there has been a decrease

in glass transition temperature (Tg) in cyclic natural

rubber before being grafted with oleic acid. The tran-

sition temperature of cyclic natural rubber glass be-

fore being grafted with oleic acid is 102.86

0

C but af-

ter the transplanting process using the initiator diumil

peroxide and divinylbenzene the glass transition tem-

perature (Tg) decreases to 83.98

0

C this proves that

the process of transplanting oleic acid into the cyclic

natural rubber molecule chain has been successfully

carried out with the formation of the new CNR-g-AO

product. According to Yang et al, (2003) the main

Modification and Characterization Natural Cycle Rubber (Resipren-35) with Oleat Acid using Dicumyl Peroxide and Divinilbenzena as

Compatibility

149

trigger for transplantation reactions (copolymeriza-

tion grafting) is when the initiator decomposes into

free radicals and there are one or more unpaired elec-

trons. The oleic acid (AO) grafting process (AO) into

the cyclic natural rubber molecule chain can occur

when AO monomers attach and form covalently

branching to the main chain of cyclic natural rubber

molecules when the polymer becomes radical by the

presence of an initiator. In the early stages of initiator

dicumyl peroxide (DKP) will form free radicals that

will attack the CNR polymer chain, so that cyclic nat-

ural rubber free radicals will be formed, then the cy-

clic natural rubber free radicals that form will initiate

the process of transplanting oleic acid into the natural

rubber molecule chain cyclical.

4 CONCLUSIONS

Based on the results of the research that has been

done, a conclusion can be drawn as follows:

a) Modification of cyclic natural rubber with oleic

acid using dicumyl peroxide and divinylbenzene

in an internal mixer with a temperature of 160 oC

and a rotor speed of 80 rpm using the graft copol-

ymer method has been successfully carried out.

This can be proven from the results of FT-IR spec-

tra analysis of emerging new absorption peaks at

wave number 1705.07 cm-1 which is a typical ab-

sorption of oleic acid indicating the presence of vi-

brations of the C=O bond of asymmetric carbonyl

groups originating from oleic acid.

b) The amount of oleic acid grafted on cyclic natu-

ral rubber increases with increasing concentra-

tion of oleic acid monomers in the presence of

dicumyl peroxide initiators and the addition of

divinylbenzene comonomers. The maximum

percent degree of grafting is 0.2630 % at the con-

centration of oleic acid monomers 9 phr.

c) The transition temperature of cyclic natural rubber

glass before grafted with oleic acid was 102.86

o

C

but after the graft process was carried out using the

initiator dicumyl peroxide and divinylbenzena the

glass transition temperature decreased to 83.98

o

C

this proves that the graft process of oleic acid into

the chain of cyclic natural rubber molecules has

been successfully carried out with the formation of

a new product CNR-g-AO

REFERENCES

Aritonang, B., Tamrin, T., Wirjosentono, B., & Eddiyanto,

E. (2018). Functionalization of cyclic natural rubber

(CNR) with oleic acid and divinylbenzene as compati-

bilizer in variation of dicumylperoxide. In AIP Confer-

ence Proceedings (Vol. 2049). https://doi.org/

10.1063/1.5082465

Aritonang, B., Tamrin, T., Wirjosentono, B., & Eddiyanto, E.

(2019). Grafting of Oleic Acid on Cyclic Natural Rubber

Resiprene-35 Using Dicumyl Peroxide Initiator and

Divinylbenzene Compatibilizers for Paint Binder in Pol-

yamide Thermoplastics. Oriental Journal of Chemistry,

35 (1), 173–179. https://doi.org/10.13005/ojc/350119

Boonyod, S., & Vudjung, C. (2017). Effect of Oleic Acid

on Properties of Natural Rubber Filled Bacterial Cellu-

lose. In Key Engineering Materials (Vol. 744, pp. 295-

299). Trans Tech Publ.

Eddiyanto, Ardina, Y. W., & Siregar, M. S. (2015). Modi-

fication of the Process of Making Cyclic Natural Rub-

ber through Chain Scission and Cyclization. AGRIUM:

Journal of Agricultural Sciences, 18 (1).

Grassie, N., & Scott, G. (1988). Polymer degradation and

stabilization. CUP Archive.

Hirata, Y., Kondo, H., & Ozawa, Y. (2014). Chemistry,

Manufacture and Applications of Natural Rubber.

Woodhead / Elsevier, Amsterdam, 325–352.

Kang, E. T., Neoh, K. G., Shi, J. L., Tan, K. L., & Liaw, D.

J. (1999). Surface modification of polymers for adhe-

sion enhancement. Polymers for Advanced Technolo-

gies, 10 (1-2), 20-29.

Khan, I., & Poh, B. T. (2011). Natural rubber-based pres-

sure-sensitive adhesives: a review. Journal of Polymers

and the Environment, 19 (3), 793.

Liu, M., Liu, Z., Ding, S., Li, S., & Zhang, L. (2003). Graft

copolymerization of oleic acid onto low-density poly-

ethylene in the molten state. Journal of Applied Poly-

mer Science, 90 (12), 3299–3304.

Nasution, A. S., Said, E., & Siregar, M. S. (2015). Methyl

Methylacating in Natural Cycle Rubber with Dicumyl

Peroxide Initiator: Monomer Concentration Effects.

Agrium: Journal of Agricultural Sciences, 19 (1).

Ritonga, A. H., Aritonang, B., & Zai, L. I. P. (2018). Mod-

ification of Natural Cycle Rubber Oleat Acid Coololy-

mer Using Benzoil Peroxide Initiator and Materials

Filling Trimethyl Ammonium Bromida Bentonits.

Journal of Chemistry of Mulawarman, 16 (1), 45–51.

Saelao, J., & Phinyocheep, P. (2005). Influence of styrene

on grafting efficiency of maleic anhydride onto natural

rubber. Journal of Applied Polymer Science, 95 (1), 28–

38.

Siregar, M. S., Thamrin, B. W. S., & Eddiyanto, J. A.

(2014). Grafting of Maleic Anhydride on Natural Cy-

clized Reactive Processing: the Effect of Maleic Anhy-

dride Concentrations. Chem. Mater. Res., 6 (11), 15–

20.

Siregar, M. S., Thamrin, Basuki, Eddiyanto, & Mendez, J.

A. (2014). Grafting of Maleic Anhydride to Natural Cy-

clized Rubber: The Effect of Maleic Anhydride Con-

centrations. Chemistry and Material Research, 6 (11),

15–21.

Tanaka, Y., Ichikawa, N., Sakaki, T., Hioki, Y., & Hayashi,

M. (2004, September 28). Modified natural rubber.

Google Patents.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

150

Wirjosentono, B., Siregar, A. H., Nasution, T. I., Da-

limunthe, K. Z., & Nasution, D. A. (2018). Compatibil-

itation of cyclic natural rubber (Resiprene-35) with pol-

ypropylene in the presence of oleic acid and benzoyl

peroxide. In the Journal of Physics: Conference Series

(Vol. 1116, p. 42043). IOP Publishing.

Wypych, G. (2015). Handbook of UV degradation and sta-

bilization. Elsevier.

Yang, L., Zhang, F., Endo, T., & Hirotsu, T. (2003). Micro-

structure of maleic anhydride grafted polyethylene by

high-resolution solution-state NMR and FTIR spectros-

copy. Macromolecules, 36 (13), 4709–4718.

Zhou, Z. F., Huang, H., & Liu, N. C. (2002). Kinetic and

terpolymer mechanism of crotonic acid onto acryloni-

trile-butadiene-styrene. Journal of Applied Polymer Sci-

ence, 85 (4), 726–733. https://doi.org/10.1002/app.10621

Modification and Characterization Natural Cycle Rubber (Resipren-35) with Oleat Acid using Dicumyl Peroxide and Divinilbenzena as

Compatibility

151