Research on Fault Diagnosis of Hydraulic Oil Leakage in the ABS

System of Automobile

Yue Liang

1, a, *

, Zhixiao Wang

1, b

, Zhichun Wang

1, c

1

Hunan Defense Industry Polytechnic, Xiangtan, Hunan, China

Keywords: Oil leakage, ABS failure, dynamic signal, car safety.

Abstract: At present, the self-test of ABS system cannot detect faults in mechanical parts, such as solenoid

valve clamping and hydraulic oil leakage. In an indoor environment, a dynamic monitoring

system is built that uses sound signals, vibration signals and pressure signals to detect mechanical

parts of the ABS system. The hydraulic oil leakage failure will cause the oil pressure to decrease,

fail to meet the working conditions of the hydraulic system, and reduce the working efficiency.

In severe cases, the hydraulic system may even fail, which may cause the ABS system to

malfunction and cause a traffic accident. The mechanical fault diagnosis of the automotive ABS

system is an important way to ensure the safe operation of the vehicle and the good performance

of the ABS system.

1 INTRODUCTION

At present, the self-test of the ABS system can only

detect electrical faults such as open circuit and short

circuit, while typical faults of the mechanical part,

such as hydraulic oil leakage faults, are not within

the scope of its self-test. Independently build a

dynamic monitoring system built in an indoor

environment, using sound signals, vibration signals

and pressure signals to detect mechanical parts of

the ABS system. The mechanical fault diagnosis is

an important way to ensure the safe operation of the

vehicle and the good performance of the ABS

system.

In addition to the in-depth research conducted by

manufacturers of ABS systems, scholars currently

studying in universities and research institutes in

China have studied the fault diagnosis technology of

ABS systems, they have proposed many simulation

analysis of the faults diagnostic methods, these

studies have laid the foundation for further in-depth

research, which greatly stimulated the research

interest in the field of ABS system fault research and

urged efforts to solve the faults. (Struss P, 1997) The

ABS system and its failures have been studied very

early in the world, such as Peter Struss of the

Technical University of Munich, and Martin

Sachenbacher of BOSCH, who use the automation

and intelligent inference techniques to troubleshoot

the ABS system. A team of Professor Harald Straky

from Darmstadt University of Technology built a

real-time observation system for hydraulic brakes

based on the residual method, they used hydraulic

control models to detect hydraulic system air mixing

and brake fluid leakage.

2 THE FAULT OF HYDRAULIC

OIL LEAKAGE

During the operation of the hydraulic system, due to

the high pressure value in the hydraulic pipe or the

gap between the installation components of the

hydraulic system. (Sachenbacher M, Struss P, Carl,

et al, 2000) When the pressure reaches a certain

value, a small amount of hydraulic oil leakage will

occur in the gap between the systems or components.

This leakage will result in a reduction in oil pressure

in the hydraulic system and will not meet the

operating conditions of the hydraulic system. It will

also reduce the working efficiency of the hydraulic

system. When a hydraulic oil leak occurs in the

hydraulic system of the ABS system, the pressure in

the hydraulic cylinder and the amount of leakage in

the cylinder

Q

determine the value of a leak. The

pressure

P

is a linear relationship with the brake

50

Liang, Y., Wang, Z. and Wang, Z.

Research on Fault Diagnosis of Hydraulic Oil Leakage in the ABS System of Automobile.

DOI: 10.5220/0008865400500053

In Proceedings of 5th Inter national Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 50-53

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

torque

T

.

R

is the leakage coefficient,

t

K

is the

factor of the brake pedal brake, and obtains a

leakage equation (1):

btb

bi

lia

a

PKT

RPQ

QQP

V

(1)

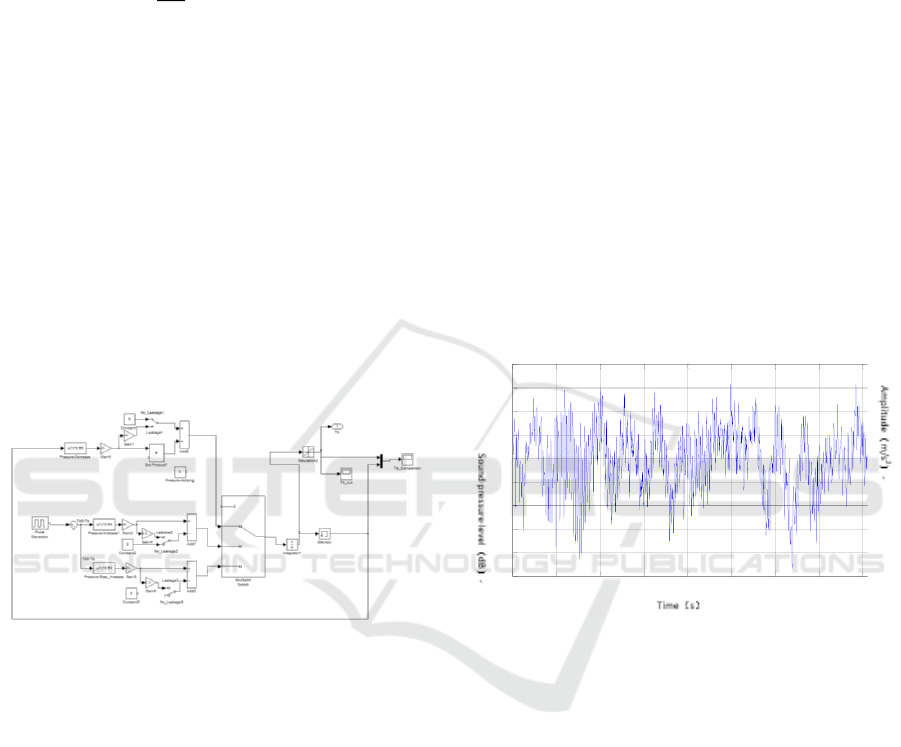

3 A SIMULATION MODEL

According to the control and logic of BOSCH, the

threshold value of the addition and deceleration

speed, with reference to the slip rate threshold, a

single wheel model is established. This is a fault

simulation model for establishing (Yue Liang, 2018)

ABS system oil leakage in Matlab/Simulink. As

shown in Figure 1 below:

Figure 1. Simulation of oil leakage fault of ABS system.

4 HARDWARE COMPONENTS

OF THE DYNAMIC

MONITORING SYSTEM

Independently build an indoor hardware experiment

platform, through the seamless integration of

software and hardware through dSPACE. The sound

sensor is equivalent to a microphone, placed as close

as possible to the solenoid valve, receives sound

waves, and will display a vibration image of the

sound generated by some ABS solenoid valves.

Between the sound sensor and the computer, a sound

amplifier is connected to make the acquired data

more accurate. On the experimental platform, the

leak port was selected as the screw mounting hole on

the hydraulic cylinder of the ABS system. The main

reason for selecting this hole as the hydraulic oil

leakage port is that the hole is located above the

hydraulic pipe, and there is no oil leakage in the

hydraulic pipe when the brake pedal is not depressed.

This position is convenient for sampling when

simulating the leakage of hydraulic oil, and it can

also reduce the error.

5 DYNAMIC SIGNAL

MONITORING OF

MECHANICAL FAULTS

5.1 Sound Signal

Since the collected sound signal data is large and

continuous, the feature value parameter is extracted

from the sound information, and the health state of

the ABS system can be confirmed by comparing the

reference template corresponding to the sound.

Figure 2. Sound signal under oil leakage.

When collecting the sound signal, start the ABS

system of the test bench and press the brake pedal

until the bottom. According to the pressure of the

pressure, the amount of hydraulic oil sprayed is not

the same, generally in the range of 1ml - 8ml.

(Shi Z, Gu F, Ball A, 2010) For example, when

the oil leakage in a test is 3.8ml, the maximum value

of the sound data collected by the test bench is

86.5977, the minimum value is 82.6429, and the

covariance value is 62.4611. Comparing the data of

the same condition ABS system under normal state,

the maximum value of sound is 84.0733, the

minimum value is 83.7740, and the covariance value

is 41.5371. Make a type match and get the difference

value. According to the graph and data, it can be

concluded that the ABS system works louder in the

event of oil leakage.

0 0.5 1 1.5 2 2.5 3 3.5 4 4.5

82.5

83

83.5

84

84.5

85

85.5

86

86.5

87

时间(秒)

声压级(

dB

)

Research on Fault Diagnosis of Hydraulic Oil Leakage in the ABS System of Automobile

51

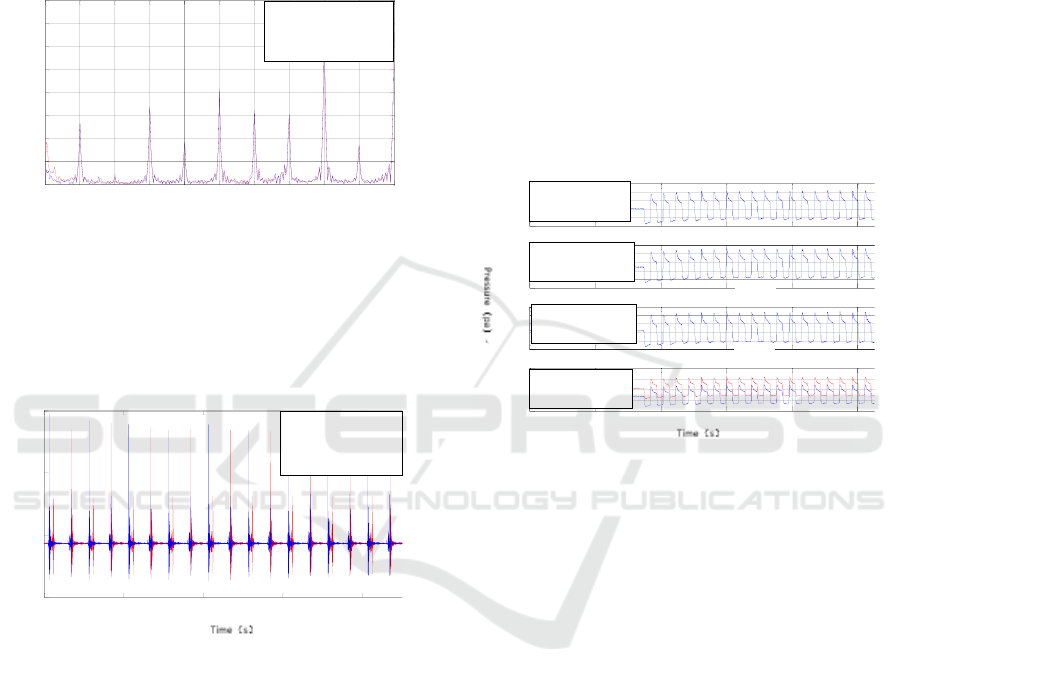

5.2 Vibration Signal

A frequency domain vibration signal diagram of the

dynamic detection of the ABS system, with

frequency as an independent variable, established a

relationship between the amplitude, phase and

frequency of a vibration signal. The abscissa is Hertz

and the ordinate is the magnitude.

Figure 3. Vibration signal of the oil leakage fault

(frequency domain).

The time-domain vibration signal diagram of the

dynamic detection of the ABS system is time

independent variable, which describes the

characteristics and relationship of these vibration

signals over time in the oil leakage state.

Figure 4. Vibration signal of oil leakage fault (time

domain).

It can be seen from the frequency domain image

that the fundamental frequency of the vibration

signal is lower than the normal state in the fault state,

and the vibration is weakened; It can be seen from

the time domain image that in the oil leakage fault

state, the vibration amplitude is significantly lower

than the normal state, and the vibration is weak. This

is because when the oil leakage occurs, the pipeline

pressure is reduced and the vibration is naturally

weakened. Connect to the dynamic signal collector

via a pressure transmitter to collect the pressure of

each hydraulic line. The experimental results show

that when the hydraulic oil leaks, the hydraulic

pipeline pressure drops, which in turn affects the

working effect of the ABS system.

5.3 Pressure Signal

Figure 5 shows the pressure change curve of each

channel collected when the pipeline of the left rear

wheel leaks oil. It can be clearly seen that the oil

pressure causes the pipeline pressure to drop. Due to

the three-channel structure of the ABS system, that

is, the left rear wheel and the right rear wheel are the

same channel, comparing the pressure changes of

the two channels, It can be seen that the left rear

wheel pressure (blue line) where the oil leakage

occurred is significantly lower than the right rear

wheel pressure (red line) without oil leakage.

Figure 5. Pressure curve of each channel when the left rear

wheel hydraulic line leaks oil.

6 SUMMARY

The real-time monitoring system of the dynamic

signal explores the health status of the ABS system

through the characterization of these sound signals,

vibration signals and pressure signals, and studies

the oil leakage faults that cannot be detected in the

self-checking function. The experimental results

prove that these dynamic signals can indeed reflect

the working state of the ABS system. In the oil

leakage fault state, the dynamic signal changes

reflect the changes in the health status of the ABS

system. The purpose of this study is to find a way to

directly detect the internal mechanical failure of the

ABS system by enclosing the external layer magnets,

that is, to reflect the working state by the

characteristics of the dynamic signals. However, due

to the limited faults that can be simulated, the core

technology of the ABS system is unknown, and it

can only be modeled according to its working

0 10 20 30 40 50 60 70 80 90 100

0

0.002

0.004

0.006

0.008

0.01

0.012

0.014

0.016

频率(Hz)

幅值

液压油泄漏

正常状态

0 0.3 0.6 0.9 1.2 1.5

-50

0

50

100

时间(s)

幅值

(m/s

2

)

液压油泄漏

正常状态

0 5 10 15 20 25 30 35

0

2000

4000

6000

8000

10000

时间/s

压力

/Pa

0 5 10 15 20 25 30 35

0

2000

4000

6000

8000

10000

时间/s

压力

/Pa

0 5 10 15 20 25 30 35

0

2000

4000

6000

8000

10000

时间/s

压力

/Pa

0 5 10 15 20 25 30 35

0

2000

4000

6000

8000

时间/s

压力

/Pa

Left front wheel

Right front wheel

Left rear wheel

Left rear wheel

Oil leakage failure

Normal status

Oil leakage failure

Normal status

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

52

principle. However, the accuracy of the model can only be as realistic as possible based on the data, and

the parameters are constantly adjusted according to

the actual vehicle condition. At present, the accuracy

is still lacking, and the simulation model needs to be

continuously optimized. It can be adjusted according

to the ABS system data of different models,

considering multiple external factors, improving the

accuracy of the simulation model and the accuracy

of the simulation results. There are many aspects of

the mechanical failure of the ABS system, but due to

the current inspection requirements, the overall

disassembly inspection cannot be performed.

Therefore, many internal structural mechanical

faults are difficult to detect, and it is difficult to

simulate the internal structure of the ABS system. In

the indoor environment, more faults are explored

and simulated, the characteristics of the dynamic

signals are analyzed, and more fault databases are

established. This will be the future development

direction of the health monitoring of the ABS

system.

ACKNOWLEDGEMENTS

Fund Project: Hunan Defense Industry Polytechnic,

General Issues, Research on Dynamic Signal

Detection System of Auto ABS System Braking

Platform (Project number: 2017YJYBKT08).

REFERENCES

Struss P. Fundamentals of model-based diagnosis of

dynamic systems[C]. In 15th International Joint

Conference on Artificial Intelligence. 1997:480-485.

Sachenbacher M, Struss P, Carl, et al. A prototype for

model-based on-board diagnosis of automotive

systems. [J]. Ai Communications, 2000, 13(2):83-98.

Shi Z, Gu F, Ball A. Prediction of Anti-lock Braking

System Condition with Vehicle Stationary Using

Model-based Approach, International Journal of

Automotive Technology, 2010, 11 (3):363-373.

Yue Liang. The New Autonomous Incentive Hardware

Platform Indoor of Automotive ABS System [A].

Institute of Management Science and Industrial

Engineering. Proceedings of 2018 3rd International

Conference on Materials Science, Machinery and

Energy Engineering(MSMEE 2018)[C].Institute of

Management Science and Industrial Engineering:

(Computer Science and Electronic Technology

International Society), 2018: 4.

Research on Fault Diagnosis of Hydraulic Oil Leakage in the ABS System of Automobile

53