Analysis and Research on Defrosting Ventilation Pipe Deformation of

Automobile

Guangming Li

1, 2

, Congrui Zuo

3, a, *

, Yi Ma

1, 2

and Qike Huang

1, 2

1

Department of Mechanical and Energy Engineering, Shaoyang University, Shaoyang 422000,China

2

Key Laboratory of Hunan Province for Efficient Power System and Intelligent Manufacturing, Shaoyang

University,Shaoyang 422000,China

3

Institute Of Thermal And Energy Metrology, Hunan Institute Of Metrology And Test ,Changsha 410000,China

Keywords: Car, defrosting ventilation pipe, Deformation, The finite element.

Abstract: According to the market feedback, automobile defrosting ventilation pipe does not fit in the top 10 of

xiangtan geely automobile market quality problems. According to the detection of vehicles in this condition,

the reason for the deformation of automobile defrosting ventilation pipe position is that the gap between

instrument cover and ventilation pipe is less than 4mm. Ventilation tube ends around not level off, the

present state of collapse, and the intensity of this state collapse is due to the lack of overall deformation, for

deformation reasons of automobile ventilation pipe outlet increase 11 on the back of the improved design

scheme of reinforcement, using the method of three-dimensional modeling, design parameters, according to

auto defrost ventilation tube through the Pro/E 3 d software to complete the ventilation pipe before and after

the improvement model, using ANSYS Workbench software of finite element analysis was carried out on

the ventilation pipe before and after improvement, the maximum deformation analysis ventilation pipe

outlet, After the improvement, the deformation amount decreased from 10.643mm to 10.283mm, and the

maximum stress value of the ventilation pipe decreased from 85.783MPa to 55.781MPa, less than the

ultimate strength of 70MPa, verifying the rationality of the improved design, Solve the quality problem for

the enterprise, have very good reference value.

1 INTRODUCTION

According to the feedback from the market, the

defrosting ventilation pipe on the instrument table is

deformed, which affects the product quality and

brand image of the vehicle. Therefore, the

elimination of defrosting defrosting ventilation pipe

on the instrument has become an improvement

object. According to statistics: in January 2018, the

problem of unconformity of automobile defrosting

ventilation pipe was ranked among the top 10 in the

market, so the project was immediately started to

solve the problem of automobile. In the old parts

collection list, 200 vehicles of a certain model found

deformation of defrosting outlet position on the

instrument, as shown in figure 1:

Defrosting system (Tang Zhiliang, 2014) is an

important function to ensure the safe driving of

drivers in low temperature environment. Common

failure modes of automobile defrosting system

include no air supply, uneven air output,

deformation of ventilation pipes and pipelines, and

poor sealing of pipelines. Poor defrosting

performance reduces user experience and affects

driving vision, and serious defrosting will lead to

safety accidents. Therefore, as an important

functional part of an automobile, its quality needs to

be strictly controlled in the design stage and

manufacturing process.

In the stage of automobile design, the body

accessories will be rigorously verified. However, in

the manufacturing process, there are often

unqualified parts provided by suppliers, or improper

matching problems that cannot be found in the

actual assembly process. In this paper, we study the

defrosting export position ventilation tube

deformation is one of the common problems, in

order to solve the fault, eliminate defrost is not

completely safe hidden trouble, should be according

to the failure situation, analysis question reason,

make the corresponding improvement measures,

improve the quality of automobile products and

54

Li, G., Zuo, C., Ma, Y. and Huang, Q.

Analysis and Research on Defrosting Ventilation Pipe Deformation of Automobile.

DOI: 10.5220/0008867800540058

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 54-58

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

brand image, effectively improve the safety of

driving, to better protect the safety of members.

Figure 1. Defrosting ventilation pipe on instrument is

deformed.

2 CAUSE ANALYSIS OF

DEFROSTING VENTILATION

PIPE POSITION

DEFORMATION

2.1 Automobile Defrosting Ventilation

Pipe Deformation Phenomenon

Automobile defrosting ventilation pipe deformation

phenomenon: defrosting ventilation pipe on the

instrument cover deformation occurred in the

matching position and the collapse deformation of

the left and right ends of the ventilation pipe.

(1) The defrosting ventilation pipe on the

instrument is deformed in the matching position: 1)

there is a large gap between the upper cover and the

ventilation pipe at the defrosting ventilation pipe on

the instrument; 2) defrosting ventilation pipe on the

meter is deformed.

(2) Collapse and deformation of the left and right

ends of the ventilation pipe

Phenomenon: there is a large gap between the

overlap position of the ventilation pipe and the upper

cover of the instrument, the maximum gap has

reached 10mm, and the left and right ends of the

ventilation pipe are obviously collapsed and

deformed.

2.2 The Cause of Defrosting

Ventilation Pipe Deformation of

Automobile

(1) In order to find out the deformation reasons of

automobile defrosting ventilation pipe, the following

results are obtained through on-site disassembly

analysis:

1) Vehicle status and temperature related, the

noon gap is greater than the morning gap;

2) Cutting instrument table cover, instrument

table cover and ventilation pipe without interference;

3) Separate instrument table high temperature

test, qualified products, not deformation.

(2) According to the fault phenomenon of the

vehicle, the 4M method is used to analyze the cause

of ventilation pipe deformation.

4M method (Wangjiansong, 2018), also known

as 4M inspection method, is also known as "man-

machine-material-method" analysis method, which

is one of the tools to judge the causes of problems

and formulate solutions. The gap between the

instrument cover and the ventilation pipe is less than

4mm. The left and right ends of the ventilation pipe

are not flat, showing collapse state. And this

collapse state is caused by insufficient strength,

according to this main line, measures can be

formulated.

2.3 Automobile Defrosting Ventilation

Pipe Improvement Scheme

In order to meet the strength requirements of the

ventilation pipe, two measures are generally adopted:

(1) increase the basic thickness of the ventilation

pipe; (2) increase the number and layout of the

stiffeners.

Analysis and Research on Defrosting Ventilation Pipe Deformation of Automobile

55

According to the information of the ventilation

pipe, the ventilation pipe can improve its strength by

increasing its thickness. However, considering the

cost, if the basic thickness of the ventilation pipe is

increased to improve the strength, the material cost

will increase.

Although the contribution effect of reinforcing

rib to the improvement of structural strength is not

great, the strength of ventilation pipe is enhanced

without increasing the wall thickness of ventilation

pipe, so as to save material consumption, reduce

weight and reduce cost. It can overcome the collapse

of ventilation pipe caused by the uneven stress

caused by the difference of wall thickness.

PP material (Songke, 2015) is a kind of material

in injection molding. In order to ensure the strength

of the ventilation pipe without causing the wall of

the ventilation pipe to thicken, reinforcing ribs are

set on the back of the ventilation pipe, which can not

only avoid the deformation of the ventilation pipe,

but also improve the flow of the ventilation pipe

under certain circumstances. In order to increase the

strength of the ventilation pipe, it is preferred to

increase the number of stiffeners rather than the wall

thickness.

Therefore, this paper uses reinforcing bars to add

11 reinforcing bars on the back of the air outlet of

the automobile ventilation duct.

3 STRUCTURE ANALYSIS AND

IMPROVEMENT DESIGN

MODELING OF AUTOMOBILE

DEFROSTING VENTILATION

PIPE

3.1 Ventilation Pipe Parametric

Modeling Process

(1) Ventilation duct grille

In order to ensure that the air velocity at the

outlet of the grille meets the requirements, the grille

blade width of the ventilation duct is generally 1.5-

3mm. The spacing between grid blades is generally

10-25mm, and the thickness of grid blades is no

more than 2mm, so the width of blades is 3mm, the

spacing between blades is 20mm, and the thickness

of blades is 2mm.

(2) Selection of contour size of ventilation pipe

Minimum size of ventilation tube inlet width:

25mm; Then the width is 75mm. Generally speaking,

the length size of the air inlet of the ventilation pipe

is 350-400mm. Take it as 400mm, and the width of

the air outlet of the ventilation pipe is 15-25mm.

Then the width is 25mm; the air outlet length of the

ventilation pipe is equal to the grille length of 550-

850mm, which is 600mm.

(3) Radius of rounded corners of the ventilation

pipe

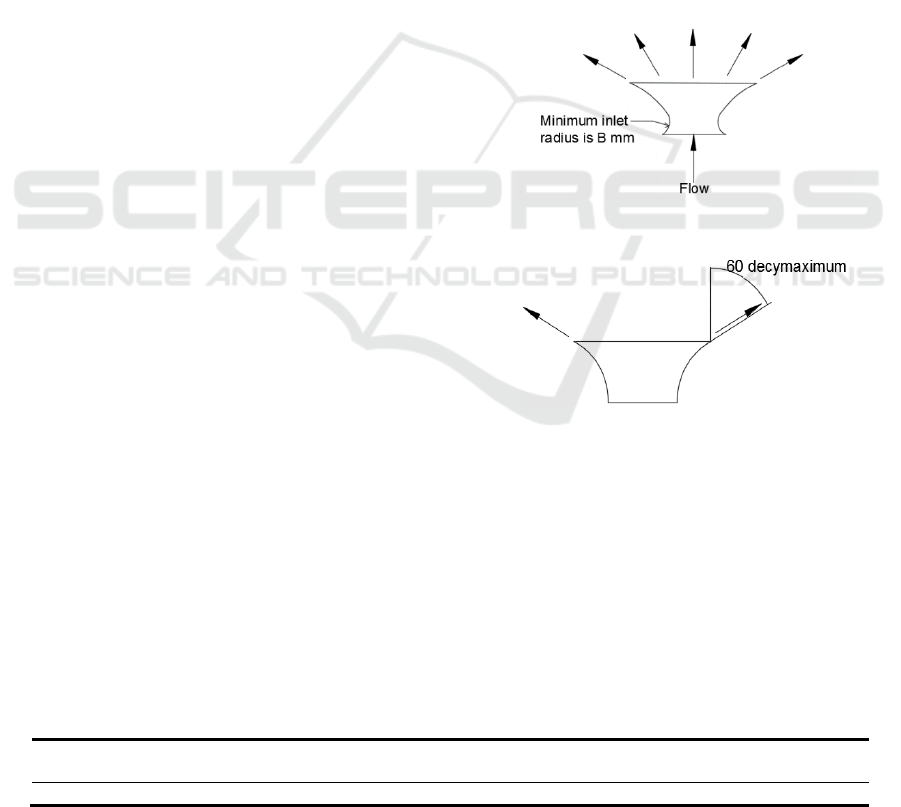

The minimum fillet radius of the ventilation pipe

is 8mm, as shown in figure 2.

(4) Angle on both sides of ventilation pipe

The Angle on both sides of the ventilation pipe

should not exceed 60°, in order to reduce airflow

loss, as shown in figure 3.

Figure 2. Minimum rounded radius of ventilation pipe.

Figure 3. Angle of both sides of ventilation pipe.

(5) Left and right ventilation pipes

The left and right ventilation ducts are located at

the lower end of the outlet of the main ventilation

ducts. The diameter of the left and right ventilation

ducts is 27mm.

(6) Chamfering of ventilation pipe

When designing chamfering, the wall thickness

of the parts shall be uniform and uniform, and the

chamfering design shall be 3.2mm. The main size

data of ventilation pipe are shown in table 1.

Table 1. Main size data of ventilation pipe (unit: mm).

Outlet

width

Outlet length

Inlet width

Inlet length

Ventilation height

Ventilation pipe

thickness

25

600

75

400

80

2

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

56

3d software Pro/E was used to establish the

model before and after improvement of the

ventilation pipe, as shown in FIG.4 and FIG. 5.

Figure 4. Before improvement of ventilation model.

Figure 5. Improved ventilation model.

4 COMPARATIVE ANALYSIS OF

FINITE ELEMENT

STRUCTURE BEFORE AND

AFTER VENTILATION PIPE

IMPROVEMENT

The material properties of the ventilation pipe finite

element model are shown in table 2.

Table 2. Ventilation pipe material properties.

elasticity

modulus

(N/mm2)

poisson

ratio

density

(kg/m

3

)

load

(N)

ultimate

strength

(MPa)

1300

0.39

910

1500

70

Reinforcing bars were added to the ventilation

pipe. Finite element analysis was carried out before

and after the ventilation pipe was improved by

ANSYS Workbench, and the deformation amount

and stress cloud diagram were obtained as shown in

figure 6, 7, 8 and 9 respectively.

Figure 6. Deformation of ventilation pipe before

improvement.

Figure 7. Deformation of ventilation pipe after

improvement.

By observing the deformation amount of

ventilation pipe in FIG. 6 and 7, it can be seen that

the maximum deformation amount of ventilation

pipe before improvement in FIG. 6 is 10.643mm.

The ventilation pipe was reinforced, and the

improved deformation was reduced from 10.643mm

to 10.283mm.

Figure 8. Before improvement of ventilation pipe stress.

Figure 9. Improved ventilation pipe stress.

By observing FIG. 8 and 9 strain diagram of

ventilation pipe, it can be seen that the maximum

stress value of the ventilation pipe before

improvement in FIG. 6 is 85.783mpa, which is

greater than the ultimate strength of 70MPa, and

fails to meet the requirements of ventilation pipe

strength. The maximum stress value of the

ventilation pipe after the reinforcement was added

was 55.781MPa, less than 70MPa, which met the

strength requirements of the ventilation pipe.

In summary, the deformation and stress values of

the ventilation pipe before and after improvement

are shown in table 3. It can be known from the table

that the maximum stress value of the ventilation pipe

before improvement is 85.783MPa, greater than the

ultimate strength of 70MPa, and the maximum stress

value of the ventilation pipe after improvement is

55.781MPa, less than the ultimate strength of

70MPa, meeting the strength requirements. The

Analysis and Research on Defrosting Ventilation Pipe Deformation of Automobile

57

Table 3. Ventilation pipe material properties.

Load(N)

Deformation (mm)

Stress value(MPa)

before improvement

improved

before improvement

improved

1500

10.643

10.283

85.783

55.781

1500

9.4603

9.1404

76.252

49.584

1500

8.2777

7.9978

66.721

43.387

1500

7.0952

6.8553

57.191

37.189

1500

5.9127

5.7127

47.660

30.992

1500

4.7301

4.5702

38.129

24.795

1500

3.5476

3.4276

28.598

18.598

1500

2.3651

2.2851

19.067

12.400

1500

1.1825

1.1425

9.5356

6.2029

comparison of ventilation before and after

improvement shows that it is feasible to add

reinforcing bars to the ventilation pipe.

5 SUMMARY

This paper is mainly based on the automobile

defrosting ventilation pipe does not fit seriously

affect the automobile brand and driving safety, find

out the defrosting ventilation pipe position

deformation reason, according to the deformation

reason to put forward the improvement plan of

adding reinforcement on the back of the ventilation

pipe. By using Pro/E software on car ventilation tube

before and after improvement, 3 d modeling, using

ANSYS Workbench software model for finite

element analysis before and after improvement of

ventilation tubes, through the comparison and

analysis to verify the ventilation pipe add

reinforcement on the back of the rationality of the

improved scheme, the auto defrost ventilation pipe

has certain reference significance, optimal design to

improve design quality, reduce design cost and

shorten the development cycle, has good practical

significance.

ACKNOWLEDGMENTS

Fund projects: outstanding youth project of

education department of hunan province (16B235),

general scientific research project of education

department of hunan province (17C1444 and

16C1432), and CX2016SY015 of postgraduate

scientific research innovation project of shaoyang

university.

About the author: li guangming (1983-), male, born

in shaoyang, hunan province, master degree, mainly

engaged in vehicle engineering teaching and

research of automobile testing technology.

REFERENCES

Tang Zhiliang. Research on defusing performance of

automobile windshield frost fog [D]. Hunan

University, 2014.

Wangjiansong. Research on the Measurement and

Estimation of Gravity Vertical Line Deviation [D].

Southeast University, 2018.

Songke. Study on fatigue damage properties of PP

materials [D]. Kunming University of Technology,

2015.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

58