Analysis and Research on the Fault Phenomenon of Car Sunroof

Guangming Li

1, 2

, Congrui Zuo

3, a, *

, Yi Ma

1, 2

and Qike Huang

1, 2

1

Department of Mechanical and Energy Engineering, Shaoyang University, Shaoyang 422000, China

2

Key Laboratory of Hunan Province for Efficient Power System and Intelligent Manufacturing, Shaoyang University,

Shaoyang 422000, China

3

Institute of Thermal And Energy Metrology, Hunan Institute of Metrology And Test ,Changsha 410000,China

Keywords: Car sunroof, Bad fault, Improved design, Structural optimization, Process optimization.

Abstract: Car skylight in view of the after-sales returns, customer site failure problem analysis, found abnormal closed,

out of sync, sound and sealing strip fracture phenomenon, put forward by means of structural optimization

and process optimization improvement scheme, according to the design parameters of automobile skylight

components, through the corresponding module of 3 d software to complete the mechanical group of 3 d

model before and after improvement. The rationality of the improved mechanical group was verified

through experiments, and the fracture of seal strip was emphatically analyzed to verify the rationality of the

improved scheme

1 INTRODUCTION

According to the data, the earliest sunroof appeared

in the early 1930s. In 1937, Nash automobile

company added the configuration of sunroof glass to

some of its models, which is considered to be the

earliest sunroof model in the automobile industry

(Lu qiang, 2011). After that, there was a boom, and

then there were sunroofs. With the development of

economy, people's living standard is gradually

improving. Cars have entered every family and can

be seen everywhere in daily life. As a convenient

device for ventilation when driving, car sunroof has

gradually become the standard configuration of cars

produced by automobile manufacturers, mainly

installed in commercial SUV, car and other models.

As one of the important configurations of

automobiles, sunroof occupies a large proportion in

today's automobile market, so it has higher

requirements on the structural functions of sunroof

(Chen jian, 2017). The sunroof is installed on the

roof of the car, which can effectively circulate the

air inside the car and increase the access of fresh air.

At the same time, the car window also has the

function of beautifying decoration, broadening the

view and increasing the fun of driving. In addition,

with the rapid development of automobile

electronization and intelligentization, automobile

sunroof has been developed from simple

mechanization to high-tech products integrating

electronics, optics, material science, photovoltaic

energy and other technologies (Zhang zhimin, et.al,

2013).

Table 1 is the sunroof fault arrangement

collected by xiangtan geely automobile after-sales

service department. The fault complaint rate of the

skylight is also increasing day by day. The skylight

problem needs to be urgently repaired and solved.

We need to collect the parts of the skylight that have

problems in the after-sales market to find out the

problems through material analysis, improve product

Table 1. Fault arrangement of certain type of skylight.

Failure mode

Skylight

sound

Sealing strip

extrusion

Skylight

leaking

Seal strip

broken

motor no work

intermittently

other

number

20

15

10

5

2

1

percentage

37.74%

28.30%

18.87%

9.43%

3.77%

1.89%

combined

37.74%

66.04%

84.91%

94.34%

98.11%

100.00%

64

Li, G., Zuo, C., Ma, Y. and Huang, Q.

Analysis and Research on the Fault Phenomenon of Car Sunroof.

DOI: 10.5220/0008868000640069

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 64-69

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

quality and production process, and improve the

reputation of the enterprise among consumers.

2 FAULT STUDY OF SKYLIGHT

According to the evidence and object analysis of the

old parts returned from after-sales service and

produced by the customer on site, it is found that in

the same state, the proportion of defects of the

skylight is: 90% of the deformation of the soft shaft

and 10% of the fracture of the seal strip. Therefore,

the following failure mechanism to do the key

solution.

2.1 Failure Point 1 Study

According to the material analysis, it can be

determined that the reason is the friction between the

soft shaft and the bottom of the front beam caused

by deformation and pressure. As a result, the soft

shaft can't be fully integrated with the gear when it

turns to the gear, and the car sunroof can't be closed

normally after a long period of rotation, which is not

synchronous and abnormal sound. Analyze the

reasons for the failure: failure to comply with the

inspection standards, problems in the production

process of workers, unreasonable structure of

product design.

With digital multimeter and electronic tension

meter to the structure of physical test, on the soft

shaft collected old and without the use of soft shaft

bending resistance numerical tests before and after

comparison, table 2, it can be seen without bending

soft shaft new pieces after bending resistance than

soft shaft after bending to an old piece of resistance

value, so that the soft shaft deformation resistance is

too large, need to review the complete product

structure.

2.2 Failure Point 2 Study

The analysis of the failure parts can determine that

the reasons are the insufficient strength of the

broken seal strip and the short length of the seal strip

design. The reasons for the failure are analyzed: the

upper and lower mold temperature and vulcanization

standard do not meet, the length of the sealing strip

is not consistent.

During the test, the maximum tensile stress of

the sealing strip to be tested depends on the

production standard of the enterprise. The higher the

tensile stress that the interface strength can

withstand, the better the quality produced. Moreover,

the test temperature and vulcanization time data of

upper and lower mold used in the production and

test of seal strip are also obtained from the

production site.

Table 2. Fault arrangement of certain type of skylight.

number

current

Resistance after bending

Survey of

current

Unbent post-bending

resistance

1

5.7A

160N

4.0A

71N

2

5.5A

155N

3.8A

65N

3

5.94A

150N

3.9A

83N

4

6.45A

200N

4.2A

78N

5

5.62A

163N

4.1A

68N

Table 3. Interface tensile strength tracking record (before improvement).

Process conditions

Measurement

value of 1

Measurement value

of 2

Measurement value

of 3

Measurement value

of 4

upper module 245 degrees/

lower module 270 degrees

Curing time

Constant value

24S

95

98

98

101

28S

116

115

118

114

32S

108

111

109

113

36S

Wrinkled surface, unqualified appearance

Analysis and Research on the Fault Phenomenon of Car Sunroof

65

Table 4. Interface tensile strength tracking record (after improvement).

Process

conditions

Measurement value of

1

Measurement value of

2

Measurement

value of 3

Measurement value of

4

upper module

230 degrees/

lower module

260 degrees

Curing time

Adjust the upper and lower die temperature for measurement

28S

97

96

98

100

32S

128

125

127

130

36S

114

115

110

116

40S

Wrinkled surface, unqualified appearance

After the condition test, the interface tensile

strength was compared before and after

improvement, and the production process was

optimized and improved. Before improvement, when

the temperature of the upper and lower molds is

fixed, the curing time reaches 28 seconds, and the

tensile strength of the sealing strip interface is the

largest, as shown in table 3. After improvement,

lower the upper and lower mold temperature by 10

degrees, and it will be found that when the curing

temperature reaches 32 seconds, the tensile strength

of seal strip interface reaches the best state, as

shown in table 4.

Then, the length of sealing strip of the skylights

of two models is compared. The measured length

standard of sealing strip of the skylights of taizhou

hongyun automobile is shown in table 5. The length

standard of seal strip measured for a certain brand is

shown in table 6. It is also necessary to reverify the

sealing strip length.

Table 5. Taizhou hongyun brand seal strip length standard.

location

PU glass length

(measured)

Standard length of

sealing strip

Difference lower

tolerance

upper

2488mm

2460±4mm

-20mm

rabbet

2465mm

2460±4mm

5mm

bottom

2482mm

2460±4mm

-12mm

Table 6. Standard length of seal strip of a certain brand.

location

PU glass

length

(measured)

Standard length of sealing strip

(before) (after)

Tolerance

under

difference

(before)

Tolerance

under

difference

value (after)

upper

2456mm

2430±4mm

2440±4mm

-30mm

-22mm

rabbet

2430mm

-4mm

4mm

bottom

2448mm

-22mm

-13mm

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

66

3 FAILURE POINT

IMPROVEMENT PLAN AND

VERIFICATION

3.1 Failure Point 1 Improvement

Results and Validation

Because the analysis of failure parts confirmed that

there was a problem with their structure, the

improvement result diagram of failure point 1 was

designed, and then the overall structure optimization

of the product was verified.

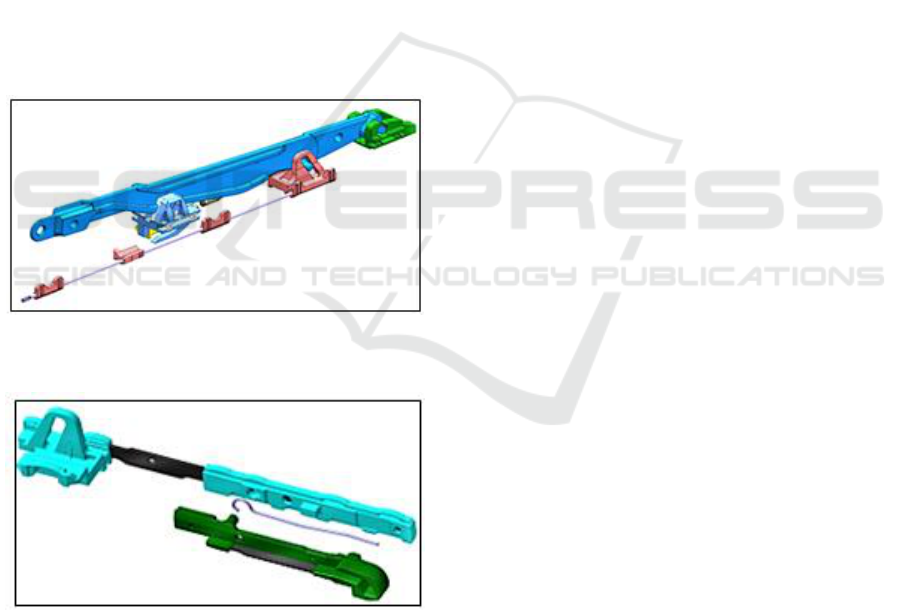

Respectively to draw the original car sunroof rail

slider old machinery group structure diagram 1 and

the improved new mechanical structure diagram 2,

the new machinery group is in the entire history of

the old mechanical group structure directly change

the structure, pressure spring effect is to make the

locking block into the locking hole, locking function

limit block, a new structure to solve the motor

sliding and locking groove sound problem.

Figure 1. Old mechanical group structure diagram: guide

block.

Figure 2. New mechanical structure diagram: guide block

+ lock block + compression spring assembly.

After asking the workers, most parts of the old

mechanical group used no. 45 steel, so other parts of

the new mechanical group still used no. 45 steel,

because no. 45 steel after proper heat treatment, has

high toughness, plasticity and wear resistance and

other comprehensive mechanical properties, suitable

for the mechanical group in a long time movement;

The pressure spring of the new mechanical group,

after searching for relevant information, can use the

piano steel wire, the material itself has very high

strength limit and elastic limit, can be widely used in

small spring material, its quality and performance

can meet the requirements.

Verification: before the durability test, the

operation resistance of the old mechanical group in

motion is tested and recorded. After a period of use,

its movement resistance value is tested. After that,

the movement resistance values generated during the

operation before and after the endurance of the new

mechanical group after the improvement were

recorded, and the data before and after the endurance

test of the mechanical group were compared and

confirmed, as shown in the following table 7.

Conclusion: after testing, it is concluded that the

trajectory of the new mechanical group is

controllable and the motion resistance is small, so as

to achieve a smoother movement and reduce the

amount of deformation caused by the movement. No

abnormal state (valid) was found in the mechanical

group whose new result state was verified before

and after the durability of its products.

3.2 Failure Point 2 Improvement

Results and Verification

Because the experimental state of various pieces

under various conditions was analyzed, the

improvement result of failure point 2 was obtained,

and then the condition change verification and

sealing strip length management were further

verified.

In the sealing strip processing, mold temperature

control machine to change the mold temperature

after curing. The main functions of changing mold

temperature are: to improve the molding efficiency

of products, reduce the production of defective

products, improve the appearance of products, and

restrain the defects of products; when the product is

vulcanized, vulcanizing agent and accelerator are

added. Under certain temperature and pressure

conditions, the linear macromolecules in the rubber

are transformed into three-dimensional mesh

structure to realize the crosslinking vulcanization of

the rubber. After vulcanization of the rubber, change

the original strength of low, small elasticity, cold

and hard heat viscosity, easy to age and other defects,

improve wear resistance, resistance to swelling, heat

resistance and other aspects, expanded its scope of

application.

Analysis and Research on the Fault Phenomenon of Car Sunroof

67

Table 7. Comparison of operating resistance.

experiment

number

Old structures last

old structure

durable

new structures last

new structure

durable

1

108N

163N

69N

73N

2

94N

173N

68N

72N

3

103N

176N

79N

84N

4

92N

165N

61N

65N

5

88N

181N

66N

71N

The main factors affecting vulcanization degree

and physical and mechanical properties of rubber are

the amount of vulcanizing agent and accelerator,

vulcanizing temperature and vulcanizing time,

which have the following relationship:

(1) The larger the amount of vulcanizing agent

and accelerator, the faster the vulcanization rate, the

higher the degree of vulcanization can be achieved.

(2) If the curing temperature is increased by 10°C,

the curing time will be reduced by nearly half.

(3) Curing time is an important part of curing

process. If the time is too short, the degree of

vulcanization is insufficient. Too long, vulcanization

degree is too high.

They cannot reach the desired effect, only the

appropriate curing time, can make the rubber reach a

certain degree of vulcanization, to ensure the best

Comprehensive performance.

Vulcanization time and tensile modulus has

certain proportional relationship, in certain cases,

curing agent, curing temperature within the scope of

a particular seal of the longer the curing time,

appropriate to reduce the mould temperature, the

higher the tensile modulus, improve the sealing strip

tension value contrast before and after the following

table 8, high low temperature alternating test

chamber to test sealing strip under the environment

of high temperature contrast variation before and

after sealing strip, such as table 9.

Validation: carry out the validation of condition

change, strengthen the validation of seal strip length

management, the value of condition change should

meet the relevant standards of production process,

and the tension value obtained before and after the

test of seal strip length management verification

should also meet the standard requirements of

production process.

(1) After the mold temperature and curing time

are changed, the tensile value of the seal strip is

verified to confirm that the tensile value of the seal

strip has an obvious effect.

Table 8. Improve the tension value of sealing strip before and after comparison.

differentiate

improve the former

After the improvement

Upper and lower mould

temperature

Upper die: 245±10°C

Lower die: 270±10°C

Upper die: 230±10°C

Lower die: 260±10°C

Curing time

28s±2s

32s

Tension value

110N-118N

128N-133N

Table 9. Comparison of changes before and after sealing strip in high temperature environment.

differentiate

Before the high temperature

After the high temperature

improve the former

109N

102N

After the improvement

133N

126N

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

68

(2) After strengthening the management of the

length of sealing strip, put the parts into high and

low temperature boxes, and then compare the

changes before and after, the improved sealing strip

is more reasonable.

Conclusion: it can be concluded that the process

improvement has significant effect (the scheme is

effective) through the verification of the process

improvement products.

After optimization and improvement of structure

and process, the number of aftersales defects of car

sunroof has been reduced a lot, and the expected

target has been reached. And by analyzing the

market expected, if after the improved structure and

the optimization of process: improved after skylight

according to logoff benchmark vehicle after-sale bad

quantity have dropped significantly, the number of

from dozens to several machines, reduce the failure

rate of more than ninety percent, by this scheme to

improve, each year can substantially reduce losses

due to bad failure, decreased failure rate is reduced

greatly.

4 SUMMARY

This chapter is mainly bad fault analysis, physical

analysis of the soft shaft, motor, front beam and seal

strip, etc., get the main reasons for the fault, and

then according to its problems for research and

improvement. Compared with the new and old

mechanical group after the improvement of fault

point 1, the structure is optimized to eliminate

abnormal noise and unsynchronization. Failure point

2 is to strengthen the process, lower the upper and

lower mold temperature and lengthen the curing

time in the seal strip, so that the production of the

seal strip in the strength and adapt to high and low

temperature environment performance has been

strengthened. Finally, after verification, the

improvement scheme is reasonable and has certain

reference significance in the optimization design of

car sunroof, which has good practical engineering

significance for improving design quality, reducing

design cost and shortening development cycle.

ACKNOWLEDGMENTS

Fund projects: outstanding youth project of

education department of hunan province (16B235),

general scientific research project of education

department of hunan province (17C1444 and

16C1432), and CX2016SY015 of postgraduate

scientific research innovation project of shaoyang

university

About the author: li guangming (1983-), male, born

in shaoyang, hunan province, master degree, mainly

engaged in vehicle engineering teaching and

research of automobile testing technology.

REFERENCES

Chen jian. Fracture failure analysis of mechanical group of

panoramic sunroof [J]. Automotive practical

technology, 2017 (14):15-17.

Gao Yang. Automotive lightweight technology scheme

and application examples [J]. Journal of automotive

engineering, 2008, 8(01):1-9.

Lu qiang. Common faults and maintenance methods of the

skylight of jianghuai car [J]. Automotive maintenance,

2011 (08): 7-10.

Wang zhutang. Development of automobile industry and

aluminum [J]. Light alloy processing technology, 2011,

39 (01):7-15.

Zhang zhimin, tao yongqin. Design of smart car sunroof

based on embedded system [J]. Electronic test, 2013

(09): 111-113.

Analysis and Research on the Fault Phenomenon of Car Sunroof

69