Analysis of K&C of Torsion Beam Suspension based on a Vehicle

Model

Liguang Wu

1, a

, Guang Li

1, b

and Lixin Jing

1, c

1

China CATARC(Tianjin) Automotive Engineering Research Institute Co.,Ltd, Tianjin, P.R. China

Keywords: The opening angle, Beam position, Bush installation angle, Toe angle, Height of the roll center.

Abstract: In this paper, through the flexible body of torsion beam established by HyperMesh is introduced into

ADAMS/CAR software for simulation of suspension K&C characteristics. The influences of three factors,

such as the opening angle of the beam, beam position and bush installation angle, on the K&C performance

of the suspension are obtained. The analysis shows that the opening angle and position of the beam have a

great influence on the K&C characteristics of the suspension, especially the change of toe angle and height

of the roll center, and provides a reference for the design of the torsion beam at early stages and a direction

for the suspension K&C characteristics optimization in late period.

1 INTRODUCTION

The vehicle suspension is an important component

of the vehicle in affecting the ride comfort and

handling stability (Shang Guan, etc, 2009),

especially when the vehicle passes uneven road, the

impact of suspension on the performance of the

vehicle is obvious. The torsion beam suspension is

semi-independent suspension between rigid axle

suspension and independent suspension, because the

torsion beam is elastic, both sides of the wheel have

a certain independence. Due to the small space and

low manufacturing cost, the torsion beam suspension

is widely used in various economical cars and SUV.

In severe conditions, the beam has a more stable

effect on the body roll and steering roll, equivalent

to a stabilizer bar (Liao and Su, 2015). Therefore,

taking into account the role of load transfer, a

reasonable beam opening angle and position are

required.

In this paper, based on a model, through the

flexible body of torsion beam established by

HyperMesh is introduced into ADAMS/CAR

software for simulation. The influences of three

factors, such as the opening angle of the beam, beam

position and bush installation angle, on the K&C

performance of the suspension are obtained.

2 DYNAMIC ANALYSIS OF

TORSION BEAM SUSPENSION

2.1 Torsion Beam Suspension Model

Torsion beam suspension includes two coil springs

and an integral V-section beam which welds a

variable cross-section tubular arm to form an overall

framework. The front of the trailing arm is

articulated with the body by bushings and the rear is

connected with the hub and shock absorber (Chen

and Ma, 2006). When the car passes through

different roads, torsion beam suspension transmits

force to the body through bending and torsional

deformation. The torsion beam suspension topology

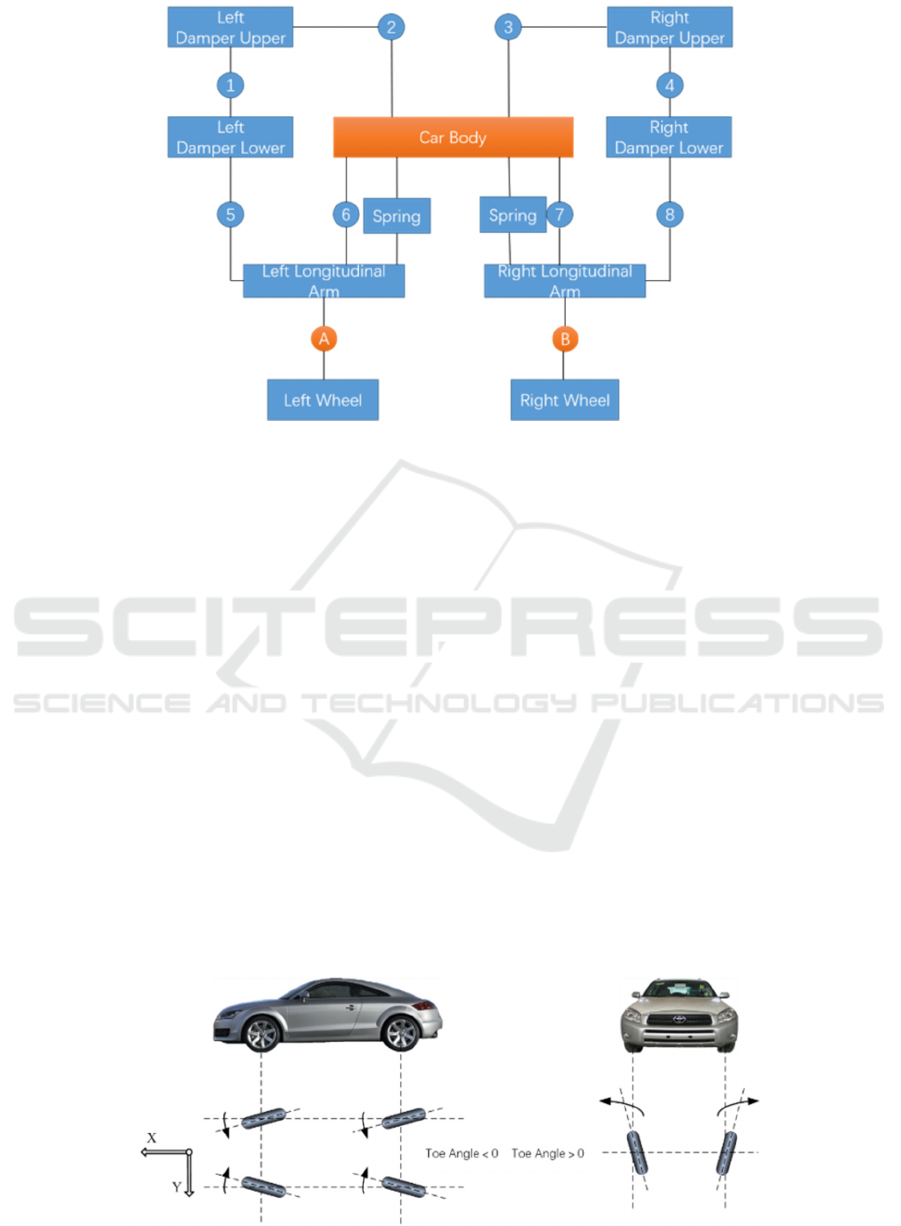

is shown in Figure 1.

When the vehicle is driving, the wheels drive the

beam to swing up and down relative to the body

with the rubber bushes which are an asymmetric

rubber wedge structure with low radial stiffness and

large axial stiffness at the front of the trailing arm as

the fulcrum; The V-shaped section beams produce

torsional deformation when the deformation of the

suspension on both sides of the beam is not the

same, so it should have greater flexibility and act as

a stabilizer bar.

78

Wu, L., Li, G. and Jing, L.

Analysis of KC of Torsion Beam Suspension based on a Vehicle Model.

DOI: 10.5220/0008868900780084

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 78-84

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Fig 1. Torsion beam suspension topology.

2.2 Analysis of K&C Characteristics of

Torsion Beam Suspension

The kinematics of the suspension system is mainly

divided into two aspects: kinematics and elastic

kinematics (Kinematics & Compliance), Kinematics

related to comfort describes changes in wheel

alignment parameters and vertical stiffness

characteristics of the suspension during spring

deformation or wheel turning; Elastic kinematics

related to handing stability describes the changes of

wheel alignment parameters and suspension

stiffness(Sun, 2012). Operating conditions of

suspension K&C feature include Parallel wheel

jump, rolling conditions, lateral force conditions,

aligning torque conditions, longitudinal force

conditions, steering conditions. And related

parameters include toe angle change, roll stiffness

change, suspension roll center height, etc.

The toe angle is the angle between the

longitudinal center plane of the car and the line of

intersection between the center plane of the wheel

and the ground. If the front of the wheel is inclined

toward the longitudinal center plane of the car, it is a

toe angle greater than zero, conversely, less than

zero, as shown in picture 2. The toe angle is equal to

the side slip angle of the tire when viewed in the

direction of travel of the car(Chen, 1997), as shown

in picture 3, so the car has a good straight-line

driving performance and no side-slipping due to the

symmetrical arrangement of the wheels diagonally

to the longitudinal center plane. In order to reduce

the wear and rolling resistance of the tire and ensure

the straight running performance of the vehicle,

there should not be a large change in the toe angle

when wheels jump. For the rear suspension which

has a greater effect on the steady state rotation of the

vehicle compared with the front suspension. The toe

angle increases when the wheel is jumping, and the

toe-angle decreases when the wheel is lowered, what

ensures the rear axle produces understeer when the

car turns.

Fig 2. Toe angle.

Analysis of KC of Torsion Beam Suspension based on a Vehicle Model

79

Fig 3. Toe angle in the direction of driving.

The roll center of the suspension belongs to a

point in the cross section of the car at the axle. At

this point, when the lateral force is applied to the

vehicle body, the angular displacement of the sprung

mass does not occur. Because the roll center is the

instantaneous center of rotation of the cross section

of the car at the axle. It is also called "the instant

heart"(Ma, etc, 1999). When the vehicle turns, the

load of the vehicle shifts laterally. Under the effect

of centrifugal force, the carriage roll around the roll

center, so that the body roll moment changes. The

roll moment is the sprung mass centrifugal force

multiplied by the roll center to the force vertical

distance. For the torsion beam suspension, the

torsion beam suspension is twisted when the vehicle

is running on a curve, increasing the lateral stiffness

of the suspension, reducing the body roll angle.

Plays a role in improving the stability and stability

of vehicles. The torsion force of the torsion beam is

shown in Figure 4, and the roll center is shown in

Figure 5.

Fig 4. Torsion beam force when rolling.

Fig 5. Roll center height of torsion beam Suspension.

The beam torsional moment T of torsion beam is

generated by two pairs of couples:

2

0

θ

(1)

In the formula:

a —The longitudinal distance from the torsion

beam to the body mounting point;

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

80

b —The longitudinal distance from the torsion

beam to the rear wheel center;

c —The rear wheel track;

d —The lateral distance from the torsion beam to

the body mounting point;

θ —The relative twist angle of the two ends of

the beam

The greater the height of the roll center, the

shorter the distance from the center of roll to the

center of mass, the smaller the roll arm and roll

moment, so that the vehicles achieve a smaller body

roll angle and lateral transfer load, what contributes

to the vehicle's transient steering performance.

However, if the roll center is too high, the wheelbase

changes too much when the body roll occurs, which

intensifies tire wear, and straight-line driving

performance of the car reduced. If the roll center is

reduced, the wheelbase changes greatly, and a

camber angle less than zero is formed, what increase

the ability to withstand lateral forces, but will reduce

the jump limit of the suspension. In short, the height

of the roll center of the suspension needs to have a

reasonable range. Generally, the height range of the

front independent suspension center is 0~120mm,

and the rear independent suspension range is

80~150mm. Rear torsion beam suspension has a

higher roll center height of 100-150mm.

Roll center height H:

H

∗

(2)

In the formula:

— the change of wheel track, — round

trip,

—track distance.

3 THE K&C SIMULATION

ANALYSIS OF TORSION BEAM

SUSPENSION

Based on a small car with a rear torsion beam

suspension, the comparison of the K&C

characteristics of the suspension is performed by

selecting different opening beam angles, beam

positions, and the bush installation angle. The main

design parameters of the rear suspension of this

sample car are shown in Table 1.

In this paper, the three-dimensional models of

different torsion beams established by CATIA

software are imported into the HyperMesh finite

element processing software, are divide grid with

attributes, and are import into ADAMS/CAR

software. Finally, a rigid-flexible coupled multi-

body dynamics model of the rear torsion beam

suspension was established and simulated of K&C.

The simulation results are compared with the test

results to verify the accuracy of the model.

Table 1. Design Parameters.

system parameter value

Vehicle

Total mass (Kg) 1058

Wheelbase (mm) 2320

Track distance

(mm)

1450

Rear torsion

beam

suspension

Toe angle (°)

-

0.476

Camber (°) -1

Spring stiffness

(N/mm)

30.7

Beam thickness

(mm)

29

In the original model, the opening direction of

rear torsion beam is downward, Then performing a

suspension K&C comparison analysis by rotating 90

degrees, 180 degrees clockwise, turning 90 degrees

counterclockwise from the beam original state;

performing a suspension K&C comparison analysis

by 50mm in longitudinal direction and 50mm in

backward direction from the beam original position;

performing a suspension K&C comparison analysis

by rotating 45 degrees, 90 degrees, 135 degrees of

longitudinal arm bush from original installation

angle.

3.1 The Opening Direction of Beam

In this section, the torsion beam suspensions with

different opening directions are simulated about

K&C characteristic analysis. And analyzing the

large difference curve in K&C simulation results,

Torsion beam suspension structure is shown in

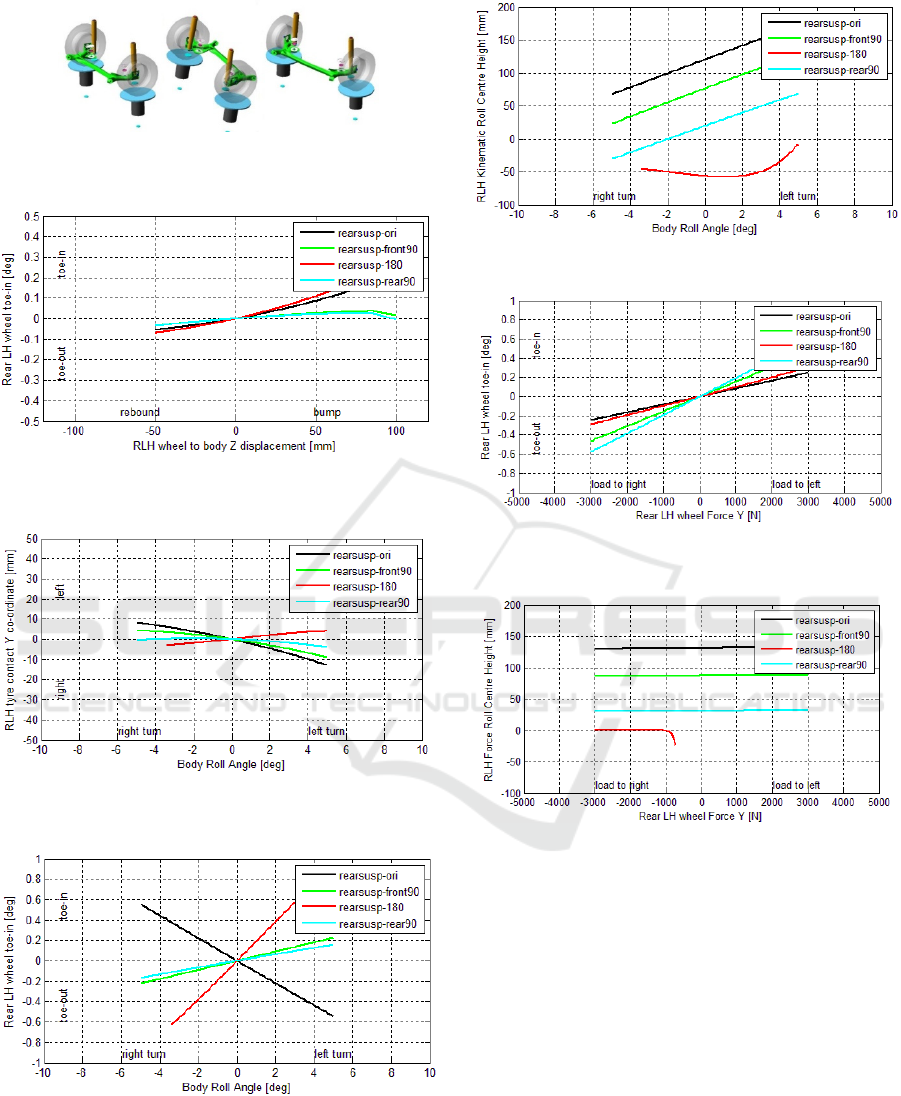

Figure 6. The resulting curves are shown in Figure

7-12.

Analysis of KC of Torsion Beam Suspension based on a Vehicle Model

81

Fig 6. Torsion beam suspension with different opening

direction beams.

Fig 7. Variation of toe angle in parallel wheel jumping

conditions.

Fig 8. Lateral displacement of the tire's grounding point in

rolling conditions.

Fig 9. Variation of toe angle in rolling conditions.

Fig 10. Rolling center height in roll condition.

Fig 11. Variation of toe angle in reverse lateral force

conditions.

Fig 12. The height of the roll center in the same lateral

force conditions.

In the case of parallel wheel jumping and rolling

conditions, the variation of toe angle is significantly

different. In the parallel wheel-jumping condition,

the rate of change of the toe angle between the

forward and backward directions of the opening of

the beam is significantly reduced. Which is not

conducive to the understeer; in the rolling

conditions, the direction of the toe angle changes in

the opposite direction to the original change, which

leads to oversteering of the vehicle and is not

conducive to the vehicle's lane changing

performance; the lateral displacement of the tire's

grounding point is significantly different, When the

opening direction of the beam is upward, the lateral

displacement of the tire ground point is a positive

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

82

rate of change, which aggravates the tire wear. In the

rolling conditions and the reverse lateral force

conditions, the height of the suspension roll center is

reduced, especially, when the opening direction of

the beam is upward, the height of the roll center is

zero, even less than zero, which is not conducive to

the steady-state steering performance of the car.

3.2 Beam Position

The torsion beam suspension is a semi-independent

suspension, namely a composite suspension. The

more forward the beam is, the closer the suspension

performance is to the independent suspension.

Conversely, the closer the beam is to the wheel

center, the closer the suspension performance is to

the rigid axle suspension. Because of the structural

constraints, this section will move the beam position

50mm forward and 50mm backward, and compare

them with the initial position. The resulting figure is

as follows:

Fig 13. Reverse lateral force toe angle change.

Fig 14. Same lateral force roll center height.

In the same lateral force conditions, the toe angle

and the roll center height change significantly. The

results can provide reference for model optimization.

3.3 Bushing Installation Direction

When the vehicle is turning, if lateral load transfer is

not considered, that is, the lateral forces acting on

the left and right tires are the same, the force acting

on the tire's grounding point can be decomposed into

the lateral force acting on the connecting body's

bushing which helps to increase the understeer and

the moment acting on the torsion beam's beam. Due

to the large bushing used for the bushing at the body

joint, the rigidity in the X and Y directions is

different. This section investigates the effect of the

bushing on the K&C characteristics by turning the

bushings at different angles.

Fig 15. Variation of toe angle in the same lateral force

conditions.

Fig 16. Variation of lateral stiffness in the same lateral

force conditions.

Fig 17. Variation of longitudinal stiffness in the same

longitudinal force conditions.

Analysis of KC of Torsion Beam Suspension based on a Vehicle Model

83

The angle of rotation of the bushing at the

connection between the longitudinal beam and the

body has little effect on the characteristics of the

suspension K and has an effect on the characteristics

of the suspension C. From the above figure, we can

see that the installation direction of the bushing has a

greater influence on the toe angle change and

stiffness change in rolling conditions. The change of

the toe angle of the lateral force condition should be

consistent with the direction of the lateral force, and

the change gradient is positive, which is conducive

to the under steering of the vehicle. The stiffness

changes in longitudinal conditions affect the pitch

attitude of the vehicle and affect the smooth

performance of the vehicle.

4 CONCLUSIONS

1. The opening direction of the beam of torsion

beam suspension has significant influence on the

K&C characteristics of the suspension. By adjusting

the opening direction, optimizing variation of toe

angle and height change of roll center, the vehicle

performance can be improved.

2. The beam position of the torsion beam

suspension has a great influence on the roll center

height, which can provides a reference for the design

of the early suspension.

3. In this paper, by changing the beam position

and opening direction, we study their effects on the

K&C characteristics of the suspension. But the

strength and life of the torsion beam are not

analyzed. In the later period, the finite element

analysis of the torsion beam can be added, and the

influence of the beam on the performance of the

vehicle can be studied.

REFERENCES

Chen, J.R, Ma, T.F. (2006) Automotive Structure (Part 2),

P249-230, Beijing, China Communications Press.

Chen, S.M. (1997) Automobile Dynamics (Second

Edition), Beijing, China Communications Press.

Liao, X.H, Su, H.L. (2015) “Optimization Analysis and

Dynamic Characteristics of Torsion Beams”. Machine

Design and Manufacturing, Vol.4, P74-80

Ma, J.J, Xu, G.X, Tong, Y. (1999) “Calculation and

Analysis of the Roll Center for a Double Wishbone

Suspension”, Journal of Hefei University of

Technology, Vol.4, P132-136

Shang Guan, W.B, Tian, Z.L, Wang, X.L. (2009)

“Rubber-metal Rubber in Automotive Suspension

Systems”, Modern Components, Vol.6, P86-88

Sun, H.Y. (2012) Research on K&C Performance Index

Analysis of Suspension Based on Vehicle Handling

Stability. Master, Jilin University.

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

84