Design and Simulation of Vehicle Cab Noise Reduction based on

Symplectic Geometry Method

Ziyu Zheng

1, a

1

Shenzhen Senior High School, China

Keywords: Symplectic Geometry; Automobile Cab; Acoustics; Noise Reduction.

Abstract: The noise caused by the vibration of the car body will reduce the comfort of the car. In order to reduce the

indoor noise, through the experimental modal analysis of the cab, the change of natural frequency and basic

mode of vibration is obtained. It is found that when the frequency is 120.44 Hz, the cab noise has the

greatest impact. Through symplectic geometric analysis and panel acoustic contribution analysis, it is found

that the cab panel has the greatest influence on the sound pressure near the ear of the roof driver. In order to

solve the above problems, the noise reduction method of the cab roof using stiffened panels and the sound

radiation theory is used to simulate the noise reduction effect of the improved cab. It is found that the sound

pressure of the improved cab is significantly reduced, the low-frequency noise is effectively suppressed, and

the comfort of the car is improved.

1 INTRODUCTION

With the increasing demand for car ride comfort,

more and more attention has been paid to the impact

of body panel vibration on the human body. The

research on the vibration level of cab panel has

penetrated into the whole vehicle development

process, so it is important to analyze and control cab

vibration and noise. From 1966 GLADWELL et al.

(G ML Gladwell, G Zimmermann, 1966) for the first

time, the finite element technology has been applied

to the field of acoustics. Today, the finite element

technology has been more and more applied to the

prediction and analysis of low-frequency structural

vibration and noise. In recent years, scholars at

home and abroad have made a lot of efforts in

perfecting and applying the finite element boundary

element technology in vehicle vibration and noise.

So far, the basic research method of reducing

vibration and noise of automobile cab is to use three-

dimensional software to model and then use finite

element software to calculate theoretical modal and

compare with experimental modal. Finally, it is

imported into the acoustic software for acoustic

analysis. This method is more complex, and the

software interface is a difficult problem. In this

paper, the natural frequencies and modes of cab

vibration are obtained directly through modal test

analysis. Based on the thin plate theory, the

symplectic geometry method of Hamilton system is

used to calculate the natural frequencies of cab

vibration accurately. Compared with the frequencies

obtained from the test analysis, the more influential

panels are analyzed, and the acoustic analysis is

carried out directly in the acoustic software, and the

noise reduction measures are put forward, so as to

improve the cab structure design.

2 MODAL TEST ANALYSIS OF

AUTOMOBILE CAB

The modal test is an effective method for identifying

the dynamic characteristics of engineering structures

by experimental methods (Shilei, 2012). Its main

task is to measure the input and output signals of the

system at the same time and to process them

digitally, so as to estimate the frequency response

function or impulse response function of the system

under test, so as to provide an accurate and reliable

basis for modal analysis. The single-point excitation

analysis method is mainly used in the cab modal test

of this automobile. The single-point excitation

modal vibration testing system is mainly composed

of three parts: excitation part (including signal

generator, power amplifier and exciter), sensing part

102

Zheng, Z.

Design and Simulation of Vehicle Cab Noise Reduction based on Symplectic Geometry Method.

DOI: 10.5220/0008870401020107

In Proceedings of 5th International Conference on Vehicle, Mechanical and Electrical Engineering (ICVMEE 2019), pages 102-107

ISBN: 978-989-758-412-1

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

(including sensor and adjustable amplifier and

related connections) and analysis part (including

analysis system and peripheral equipment such as

plotter and printer) (Fu Zhifang, 1990). The block

diagram of the test system is shown in Figure 1.

Fig 1. Block diagram of test system.

When the modal test is carried out, the exciting

force is generated by the exciting equipment, which

causes cab vibration. Then the force signal and the

response signal measured by the acceleration sensor

mounted on the cab are amplified and transmitted to

the structural dynamic analyzer for FFT analysis,

and the frequency response function is obtained. The

average frequency response function is obtained by

fitting the whole frequency response function, and

then the modal parameters are identified, from

which the experimental modal parameters are

obtained. The first ten vibration modes and mode

characteristics of the cab are calculated by the

software, as shown in Table 1.

From the test data measured in Table 1, it can be

seen that the frequency of the cab roof vibration is

relatively frequent, and the left and right panels and

the rear panels also have local vibration. Therefore,

it is preliminarily determined that roof vibration is

the main cause of the noise. From the modal

analysis, it can be seen that the roof vibration is the

largest when the modal frequency is the seventh

order of 120.44Hz. The mode shapes of the cab are

shown in Fig. 2, which show the obvious vertical

vibration of the cab roof, accompanied by the overall

rotation of the cab around the Z axis. If we want to

improve the interior noise of the cab, the most

effective way is to reduce the vibration response of

the roof.

3 SYMPLECTIC GEOMETRY

METHOD FOR ANALYZING

ROOF NATURAL FREQUENCY

The model of the cab is shown in Figure 3. The cab

is considered to consist of 10 thin-walled panels of

different sizes. Cab roof vibration is the largest, so it

is taken as the research object. Because the cab is

fixed on the surrounding panel by welding and

screw connection, the panel is set as a rectangular

thin plate, the boundary condition of the four sides is

adopted, and the structure is set as full restraint.

Table 1. The first ten modes and modal characteristics of

cab structure measured.

Modal

order

Natural

Frequency(Hz)

Modal mode

characteristics

1 21.186

Slight vibration of

roof

2 29.325

Local Vibration of

Rear Wall Plate

3 37.508

Roof Vibration,

Transverse Local

Vibration of Left Wall

4 66.085

Local Vibration of

Rear and Right

Wallboard

5 75.341

Roof Vibration, Right

Wall Transverse

Local Vibration

6 113.534

Roof Vibration, Local

Vibration of Left and

Right Wallboard

7 120.44

Vertical vibration of

roof

8 167.055

Vertical vibration of

roof and torsional

vibration of back wall

9 183.892

Vibration of rear

panel and left and

right panel

10 195.45

Left and right lateral

vibration

Design and Simulation of Vehicle Cab Noise Reduction based on Symplectic Geometry Method

103

Fig 2. The seventh mode shapes of the cab.

Figure 3. Cab structure.

The basic equation of free vibration for the cab

roof is established:

0(1)

Where W is the mode function of the roof; D is

the flexural strength; is the mass of the unit area of

the roof; is the natural frequency of the roof.

The relationship between roof bending moment

and torsion is as follows:

0

0

0

(2)

Where,

,

and

are the bending moment

of the roof,

and

are the torsion of the roof,

and

and

are the shear force and total shear

force. After analysis and transformation, the

relationship among the parameters can be expressed

by Hamilton equation (Zhong Yang, Li Rui, Tian

Bin, 2011), which can be written in the form of

matrix:

(3)

Where, F=

01

/

0

, G=

01

01/

,

Q=

0

02(1)

/

, Z is

the state vector of a thin plate.

The symplectic geometry method is used to

analyse the vibration mode function. The formula

(3) is solved by the method of separating variables.

The solutions of the vibration mode function in the

X and Y directions are as follows:

cos

sin

cosh

sinh

cos

sin

cosh

2

sinh

2

(4)

Where,

,

,

,

,

,

,

and

are

undetermined constants.

The boundary conditions in the X and Y

directions of the clamped thin plates are as follows:

∣

∣

0

∣

∣

0

(5)

The partial derivative substitution formula (5) of

equation (4) is obtained, and the equation about

coefficient is obtained. The determinant of

coefficient matrix is zero. The eigenvalue

transcendental equation about X and Y axisymmetry

is obtained as follows:

R

tan

R

R

tanh

R

0

tan

2R

tanh

2R

0

(6)

The values of R and can be obtained from

equation (6). From R= ω

/

, the frequency of

rectangular thin plate with four edges fixed can be

further obtained.

The sound pressure on the roof surface can be

expressed by Helmholtz integral equation (Yang

Xiaowei, et al, 2009):

p

R

(7)

Among them, p is the sound pressure of the

structure surface, is the normal velocity of the

structure surface, r=

|

|

is the distance between

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

104

two points on the structure surface, and S is the

surface of the vibration structure.

The elastic modulus of the cab panel is 206 GPa,

Poisson's ratio is 0.3, the strength limit is 450 MPa,

the thickness of the thin panel is 7850 kg/m3, the

thickness is 5 mm, the length and width of the roof

are 2510 mm and 1263 mm, respectively. By

substituting the parameters of cab panel (6), the

natural frequency of the roof can be calculated to be

121.42Hz, which is basically consistent with the

model test value. Thus, it can be judged that the

analytical solution of the symplectic geometry

method is correct and applicable.

4 CAB ACOUSTIC

CHARACTERISTIC

CALCULATION

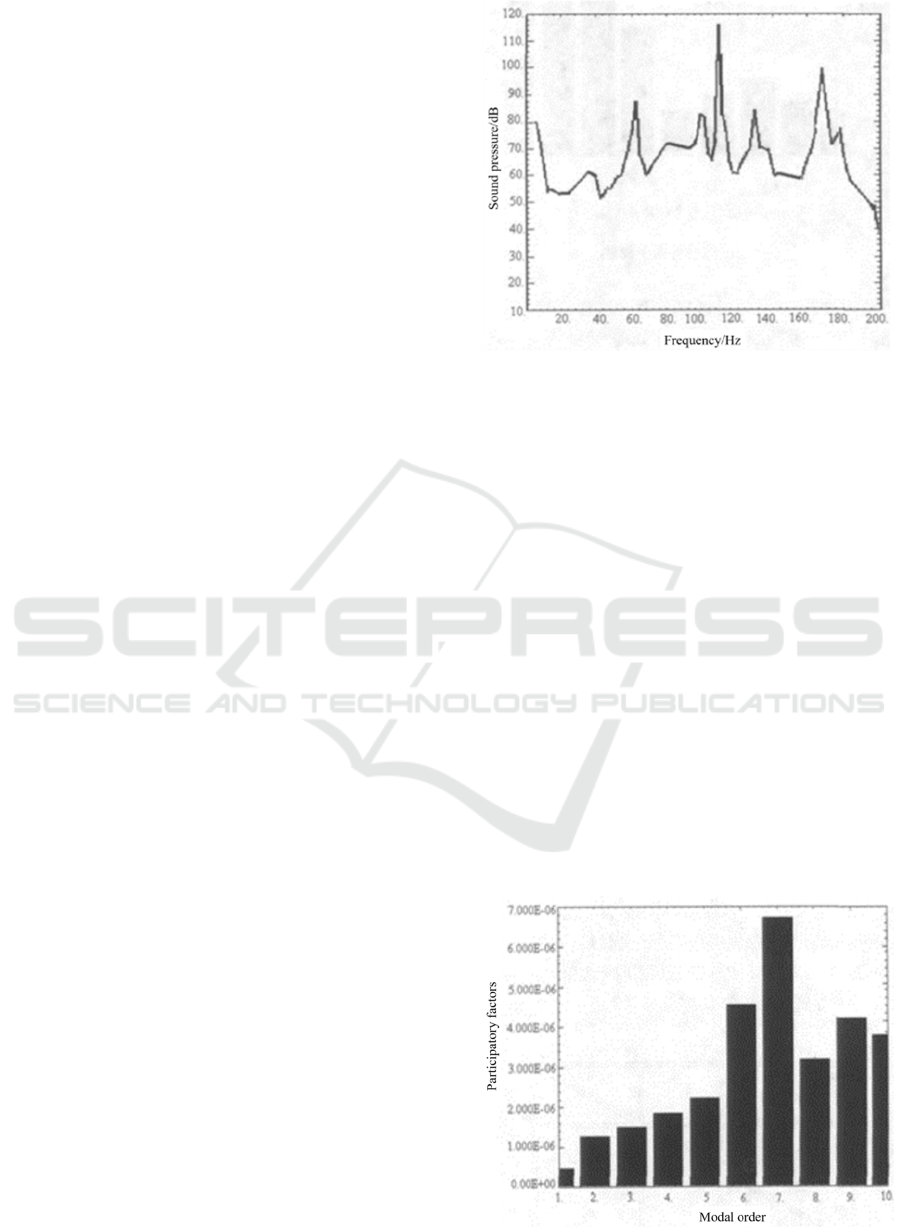

The acoustic characteristics of the cab are analyzed

in the acoustic software, and the sound pressure

level curve near the driver's ear is obtained, as

shown in Figure 4. It can be seen from the curve that

the peak sound pressure appears at frequencies of 18

Hz, 40 Hz, 64 Hz, 70 Hz, 114 Hz, 120 Hz, 129 Hz,

170 Hz, 180 Hz and 195 Hz. The results are

basically consistent with the frequencies of cab

modal test analysis. Further modal participation

factor analysis is carried out for the cab (Li

Zenggang, 2005). The so-called modal participation

factor refers to the degree to which each order of

modal participates in the dynamic response of the

structure when the modal superposition method is

used to calculate the dynamic response. From the

analysis of the partially modal participation factor

curve shown in Fig. 5, it can be seen. At frequencies

of 47 Hz, 120 Hz and 195Hz, the effects of the last

five frequencies on the sound pressure near the

driver's ear are greater than those of the first five

frequencies. The modal participation factor

corresponding to the seventh order is always at the

maximum, and its corresponding frequency is 120

Hz, which coincides with the natural frequency

value of the roof vibration analyzed above.

Therefore, it can be accurately judged that roof

vibration is the main source of cab noise.

Fig 4. The curve of sound pressure level near the driver's

ear.

5 CAB SIMULATION ANALYSIS

AND IMPROVEMENT

According to the above analysis, the cab structure is

improved and designed. Because the vibration of

roof is the main cause of the noise, the structural

improvement of roof is mainly carried out in the

redesign, mainly through the following two ways:

first, the surface of cab panel is damped to reduce

the indoor noise; second, the structure improvement

of cab panel is carried out. To improve its stiffness

and reduce the interior noise. Because the vehicle

belongs to the engineering field, the strength of the

cab is required to be high (Chen Shuming, et al,

2012). Considering the economic point of view and

practical aspects, this paper adopts the method of

improving the stiffness of the cab roof to reduce

vibration and noise.

(a) Modal Participation Factor Curve at 47Hz

Design and Simulation of Vehicle Cab Noise Reduction based on Symplectic Geometry Method

105

(b) Modal Participation Factor Curve at 120Hz

(c) Modal Participation Factor Curve at 195Hz

Fig 5. Modal Participation Factor Curve.

There are two ways to improve the stiffness of

the cab panel. The first is to increase the thickness of

the wallboard; the second is to reinforce the

wallboard (Wang Xianyi, et al, 2008). Thickening of

cab roof will increase the dead weight of cab, and

the material is not fully utilized. Reinforcement of

roof under certain conditions can increase the dead

weight of cab roofless and improve the performance.

In this paper, two kinds of reinforcement methods

are compared. One is the four corner reinforcement

of the roof, as shown in Figure 6, and the other is the

reinforcement through the center of the roof, as

shown in Figure 7.

Fig 6. Cross-sectional diagrams of four corner stiffeners

on the roof.

Fig 7. Cross-sectional diagrams of stiffened roof through

the center of roof.

Acoustic analysis is carried out for the two kinds

of reinforcement arrangement. The sound pressure

level curve is shown in Fig. 8. The calculation

results of sound pressure near the driver's ear are

shown in Table 2.

Figure 8. Sound pressure curves using stiffened panels for

noise reduction.

Table 2. Comparison of driver's ear sound pressure before

and after reinforcement.

Modal order 1 2 3 4 5

No

reinforcement

/dB

53.2 54.1 58.9 72.3 61.8

Corner

stiffening /dB

51.3 52.7 55.5 68.6 58.0

Central

reinforcement

/dB

49.8 51.4 53.2 60.2 53.9

Modal order 6 7 8 9 10

No

reinforcement

/dB

75.3 118.7 55.6 59.2 48.9

Corner

stiffening /dB

70.4 114.8 52.7 55.1 48.2

ICVMEE 2019 - 5th International Conference on Vehicle, Mechanical and Electrical Engineering

106

Central

reinforcement

/dB

73.1 108.4 51.9 50.4 49.1

The black line and the gray line in Figure 8 show

the sound pressure curves of the cab roof reinforced

by four corner stiffeners and through the center

stiffeners, respectively. It can be seen from the curve

that the sound pressure of cab roof decreases after

stiffening, and the noise reduction effect of stiffeners

applied through the center of the roof is better than

that of four corner stiffeners. For the measurement

of sound pressure, 387 nodes near the center of the

cab roof are selected as the test points. The peak

value of the sound pressure curve is basically

consistent with the fixed frequency value measured

in front. The maximum value appears at 120 Hz,

which is consistent with the maximum vibration of

the roof analyzed in front when the natural

frequency is 120.44 Hz. The sound pressure value

decreases from 118.7 dB to 114.8 dB by applying

ribs at the edge corners, while the sound pressure

value decreases to 108.4 dB by applying ribs

through the center of the roof, and the decrease of

sound pressure in the latter arrangement is greater

than that in the former arrangement at other peak

points. This is because the sound pressure is

gradually divergent from the central part of the roof.

Therefore, the cab roof is eventually laid out through

the center of the roof with reinforcement bars. By

improving the cab roof design, the cab's internal

noise has been significantly reduced, which not only

improves the comfort of passengers but also

improves the driver's response ability, so that the car

can be better applied.

6 CONCLUSIONS

In this paper, the cab of an engineering vehicle is

taken as the research object, and the natural

frequency and mode of cab vibration are

preliminarily determined by means of the

experimental modal analysis method. It is concluded

that the vibration of the cab roof is the main cause of

indoor noise. The symplectic geometry method of

Hamilton system is used to analyze the natural

frequency of cab noise, which is consistent with the

experimental data. It provides a theoretical basis for

the future study of vehicle interior vibration. In the

application process, the frequency value can be

resolved by directly substituting the relevant data of

the research object into the formula, without

modeling and calculation, which saves time and

improves work efficiency. The acoustic

characteristics of the cab are analyzed, and the

method of panel contribution is used to further prove

that the roof vibration contributes the most to the

indoor noise. The sound pressure near the driver's

ear is calculated, and the seventh mode has the

greatest influence. Two methods are put forward to

improve the cab structure. The noise level near the

driver's ear is obviously reduced by stiffening

through the center of the roof, which effectively

reduces the noise in the cab as a whole.

REFERENCES

G ML Gladwell, G Zimmermann. On energy and

complementary energy formulations of acoustic and

structural vibration problems [J].Journal of Sound and

Vibration, 1966, (3): 233-241.

Shilei. Application of modal test analysis to solving

vehicle vibration problems [J].Automotive Science

and Technology, 2012, (5): 22-26.

Fu Zhifang. Vibration modal analysis and parameter

identification [M]. Beijing: Machinery Industry Press,

1990.

Zhong Yang, Li Rui, Tian Bin. Hamiltonian analytical

solution for free vibration of rectangular thin plates

with fixed edges [J]. Journal of Applied Mechanics,

2011, 28 (4): 323-327.

Yang Xiaowei, et al. [J].Journal of Mechanical

Engineering, 2009, 45 (8): 221-227.

Li Zenggang.SYSNOESE Rev5.6 [M]. Beijing: National

Defense Industry Press, 2005.

Chen Shuming, et al. [J].Computer simulation, 2012 (4):

287-291.

Wang Xianyi, et al. [J].Journal of Vibration Engineering,

2008, (2): 13-17.

Design and Simulation of Vehicle Cab Noise Reduction based on Symplectic Geometry Method

107