Thermal Properties of Chitosan-roselle Films

Irwana Nainggolan

1,2*

, Tulus Ikhsan Nasution

3,2

and Khairel Rafezi Ahmad

4

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan 20155,

Sumatera Utara, Indonesia

2

Pusat Unggulan Green Chitosan dan Material Maju, Universitas Sumatera Utara, Medan 20155, Sumatera Utara,

Indonesia

3

Department of Physic, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Medan 20155,

Sumatera Utara, Indonesia

4

School of Materials Engineering, Universiti Malaysia Perlis, Jejawi 02600, Arau, Perlis, Malaysia

Keywords: Chitosan-roselle, Thermal Properties, Casting Method, Cure Temperature.

Abstract: The chitosan-roselle films were fabricated by casting method. The roselle ratio and cure temperature of films

were varied to study the thermal properties of the chitosan-roselle films. Thermal properties of chitosan-

roselle films showed higher heat resistance when blend roselle ratio and cure temperature were increased. The

temperature at maximum degradation rate of chitosan-roselle films was determined by DTG. The chitosan-

roselle films were degrade faster when the roselle ratio increased at ambient temperature. The cure

temperature was varied to 50, 60 and 70

o

C, the most optimum cure temperature was 60

0

C which showed the

lowest weight loss and exhibited the highest heat resistance compared to the other cure temperature. SEM

results showed the surface structure of different ratio of chitosan-roselle films which were cure at 50, 60 and

70

o

C. The surface structure become smoother when the ratio of chitosan-roselle was increased. FTIR result

showed that the intensity percentage of functional group exist in pure chitosan films were improved by adding

roselle to become chitosan-roselle films. The results showed the most optimum cure temperature was 60

o

C

which showed high intensity percentage compared to the other cure temperature.

1 INTRODUCTION

The potential of biopolymers, especially the polymers

obtained from renewable resources has long been

recognized. In the last decade there has been

increasing interest in developing thermoplastic

biopolymers, especially those are derived from

renewable sources. However, these biopolymers are

mostly used in food industry but very less to replace

synthetic materials. Packaging based on conventional

synthetic materials has brought the threat to ecology.

These concerns lead to a need for more effective

safety regulations and better system to maintain the

quality of the food (Portes, 2009). The biopolymers

that are used as coating in food packaging have the

advantages to be available from biocompatible,

biodegradable and better quality of fresh foods as

well as of environmentally friendly packaging.

Biomass is a naturally abundant source and has long

been recognized as sustainable biopolymers, and in

the recent years, growing environmental awareness

has led to studies of biopolymer as alternative

packaging films to be used as edible coatings in food

packaging (Tharanathan, 2003). This approach will

be very interesting from an academic point of view

and large-scale usage in the food industry.

Biopolymers such as polysaccharides, proteins, lipids

and combination of those components are potential to

be made as films. Biopolymer films are known as

edible films. Edible films have been particularly

considered in food preservation because of their

capability in improving global food quality

(Tharanathan, 2003 and Norashikin, 2010).

Nowadays, the materials most used for packaging

are petrochemical based polymers because of their

availability in large quantities with low cost and many

functional features, such as good tensile strength and

tear strength, good barrier properties and heat

stability of oxygen. However, these materials are non-

biodegradable which lead to very serious ecological

and environment pollution problem. As a solution,

there is a need to shift to eco-friendly biodegradable

materials, especially from renewable agriculture by

266

Nainggolan, I., Ikhsan Nasution, T. and Rafezi Ahmad, K.

Thermal Properties of Chitosan-roselle Films.

DOI: 10.5220/0008921402660273

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 266-273

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

products such as chitosan, food processing industry

wastes and low- cost natural resources such as starch

(Alves, 2006).

In this context, chitin is representing as a second

most abundant biopolymer after cellulose (Ou, 2005).

Chitosan is a linear amino polysaccharide obtained

from the deacetylation of chitin (Portes, 2009) (a

process of remove the acetyl function group at chitin),

the major structural component of the exoskeleton of

invertebrates and the cell walls of some plant like

fungi. In addition, in view of the most biopolymers

are either biodegradable or compostable, it can also

be argued that chitosan could be fit with the ‘cradle-

to-cradle’ concept, which means that on disposal, it

could become ‘food’ for the future generation of

materials (Ou, 2005).

Chitosan has biodegradability and

biocompatibility properties, and compared with

chitin, it shows better solubility in common solvents.

This is why chitosan is commonly used in several

applications instead of chitin. Chitin and chitosan

have applications from cosmetic to pharmaceutical

industries and its total annual production estimated at

least 1000 tons per year. Due to this variety of

applications, there is a necessary to fully understand

their molecular nature to increase their uses (Leceta,

2013). Chitosan has been studied as natural

antibacterial, bio-based active films and excellent

compatibility with other substances by the presence

of the high density of amino groups and hydroxyl

groups in chitosan polymer structure (Betzabe, 2009

and Ngah, 2011).

Chitosan film can be easily prepared, but it is

difficult to handle due to the curving during drying

phase, if no assisting means and weight are used to

keep it straight (Kammoun, 2013 and Annala, 2007).

In general, the properties of chitosan solutions depend

on several parameters including ionic strength,

concentration, temperature, acid concentration and

type of acid. Acetic acid was used in this study since

chitosan is soluble in acetic acid (ZhenXing, 2007;

Esam, 2010 and Jayakumar, 2007). In this study,

roselle was used as admixture to produce chitosan-

roselle films. Roselle has unique properties such as

ionic liquid forming because it contains of high

minerals concentration especially ferrum and

minerals enable the blend films are thermally stable.

Blends of chitosan and roselle were produced by

using acetic acid as a solvent media. Different

temperatures which are 50, 60 and 70

o

C were applied

to cure chitosan-roselle films.

Throughout the years, some researches have done

some improvement on the performance of

biodegradable film in the food packaging area. From

all the points above, an attempt was done to

investigate the effect of different chitosan

concentration in a composite biodegradable film

(Cissé, 2013 and Kumirska, 2010). Chitosan is a

linear β-1,4-D-glucosamine is a biocompatible,

nontoxic compound mainly obtained by deacetylation

of chitin, a natural structural component present for

instance in crustaceans. This biopolymer presents

interesting properties by excellent film forming

capacity and gas and aroma barrier properties at dry

conditions, which makes it a suitable material for

designing food packaging structure. However,

biodegradable films are often have limited

temperature resistance (Kammoun, 2013). A simple

blend process of the chitosan solution with roselle

extract was used to produce the chitosan-roselle

which may able to be used to improve the thermal

properties of chitosan films.

2 MATERIALS AND METHOD

Chitosan powder (medium grade, 99.9% purity)

synthesized from crab shell was purchased from Sigma

Aldrich Ltd, medium molecular weight). 2% of acetic

acid with 99.9% purity (Merck) and methanol (GMBH)

were used as solvents in this research. Roselle was

extracted by using a mixture of acetic acid, methanol

and deionized water with ratio 1:4:5 and it was used as

a biomaterial to be blended with chitosan. Chitosan

solution gel was prepared by dissolving weighted

chitosan powder into 50 ml of acetic acid 2%. The

chitosan powder was weighted 1.75 g and pours into

100 ml of acetic acid 2% and then stirred by using a

magnetic stirrer with 300 rpm for 12 hours at room

temperature to fully dissolve the chitosan powder into

the acetic acid. Acetic acid 2% was the most suitable

solvent to dissolve chitosan. This is due to chitosan

which is soluble in weak acid. Chitosan-roselle solution

was prepared by mixing roselle extract with the chitosan

solution. First, to prepare roselle extract, the seed of

roselle flower was removed to obtain roselle calyxes.

Then the calyxes were washed with tab water to remove

unwanted particle and cut into small pieces to be

mashed. Then, it was blended into paste follow by

extract squeezing into a breaker. A mixture of acetic

acid, methanol and deionized water were prepared with

ratio 1:4:5. The 50 ml blended roselle juice was added

into 50 ml mixture of methanol, acetic acid and

deionized water. Then, the mixture was stirred by using

a magnetic stirrer with 300 rpm for 30 minutes at room

temperature. The well mixed mixture was then filtered

by using 125 mm size of filter paper. After the chitosan-

roselle solution was prepared, it was poured into a mold

Thermal Properties of Chitosan-roselle Films

267

and left it to dry in an oven with different curing

temperature which were 50, 60 and 70

o

C. The film

thickness was measured with a 0-25 mm micrometer

with an accuracy of ± 0.01 mm in four random locations

for each film. After the solution completely dry into

film, several characterizations using Differential

Scanning Calorimeter (DSC), Thermogravimetry

Analyzer (TGA), Scanning Electron Microscope (SEM)

and Fourier Transform Infrared Spectrocopy (FTIR)

were performed.

The difference in heat flow of the composite was

measured as a function temperature by using

Differential Scanning Calorimetry (DSC) which

recorded by a NETZSCH DSC 204 F1 (Germany)

instrument with standard ASTM D34218 DSC. The

onset temperature and degree of crystallinity data was

obtained from the DSC thermograms. In this study,

DSC was used to determine the possible transition of the

chitosan-roselle composite film. The thermogram was

run by placing the samples (3-10 mg) in an aluminium

pan and a heating scan was conducted from range of 30

to 480

o

C at a heat rate 10

o

C/min. Purge gas flow was

adjusted to 50 ml/min using nitrogen gas. The mass or

changes in mass of the sample as a function of

temperature or time both was measured by using

Thermogravimetric Analysis (TGA). TGA analysis was

conducted according to ASTM D258 standards. The

specimens of 10 mg were put in the platinum pan. TGA

measures the amount and rate of change in the weight of

material as a function of temperature or time in a

controlled atmosphere. This technique can characterize

materials that exhibit weight loss or gain due to

decomposition, oxidation, or dehydration (Dev Raj,

2013). TGA was used to determine the estimated

lifetime and weight change in the samples.

Purge gas flow need to be adjusted to 50 ml/min

using nitrogen gas. The heating rate was set at 30 to

900

o

C at 10

o

C/min. In this study, the surface

morphology of chitosan-roselle films were examined by

using a Jeol JSM- 6460LA scanning electron

microscopy (SEM) at an accelerating voltage of 5 kV.

FT-IR spectra measurements were conducted by a

Perkin Elmer RX1 FT-IR spectrometer.

3 RESULTS AND DISCUSSION

3.1 Making of Charcoal

All films were easily peeled from the film-casting

mold. Thin film formation was easy due to the low

surface tension on the casting surface. Peeled films

were then conditioned at testing temperature to obtain

soft, flexible, and easy to handle films. Chitosan-

roselle films were cured at temperature 50, 60 and

70

o

C.

Figure 1: The FTIR spectra of chitosan-roselle films which

are cured at 60

o

C.

FT-IR spectrum was used to identify the chemical

structure of chitosan-roselle films by scanning the

chitosan-roselle films using FT-IR. The results of FT-

IR spectra which were cured at 60

o

C are reported in

Figure 1. The O–H stretching mode of chitosan was

observed in the region of 3200– 3650 cm

-1

where in

these spectra pure chitosan falls at 3618 cm

-1

. This

peak due to overlapping of extension of C-H and O-

H in chitosan. The peak at 2395 cm

–1

is due to

extension of C–H group. The peaks at 2362 and 2339

cm

-1

are due to C-N bond. Since the absorption peaks

ranges is available until 3650 cm

-1

, so the peaks over

3650 cm

-1

were assumed as impurities. The peak at

2060 to 1886 cm

-1

indicating the existence of Fe-S

bond. The presence of the ferrodoxin in the structure

can improve the thermal properties of the film. The

peaks at 1623 cm

–1

were the C=O stretching (amide

I) and NH bending (amide II). The peak near 1780

cm

–1

suggested the presence of a carbonyl group in

the chitosan and roselle films. The absorption peaks

at 1016 and 1019 cm

-1

were probably due to the C–

O–H bending mode. Clear differences can be detected

in the infrared spectra of chitosan and roselle, both in

the different absorbance values and shapes of the

bands and in their location. A decrease in the intensity

of the O–H absorption band at 3323 cm

-1

was

observed, indicating that the hydroxyl group contents

in roselle. The lower xylan content in roselle was

proved by a weak carbonyl band at 1699 cm

-1

. The

enhanced carbonyl absorption peak at 1779 cm

-1

(C=O ester), C–H absorption at 1381 cm

-1

(C–CH3),

and C–O stretching band at 1242 cm

-1

confirmed the

formation of ester bonds. Also, it was proved by an

increase in the intensity of OH in plane bending

vibration at 1366 cm

-1

band specific to the component

cellulose and hemicelluloses. A small band at 16243

cm

-1

were assigned to the absorbed water and ß-

glucosidic linkages between the sugar units,

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

268

respectively. Weak absorptions between 1500 and

1400 cm

-1

arose from the aromatic ring vibrations and

ring breathing with C–O stretching in lignin.

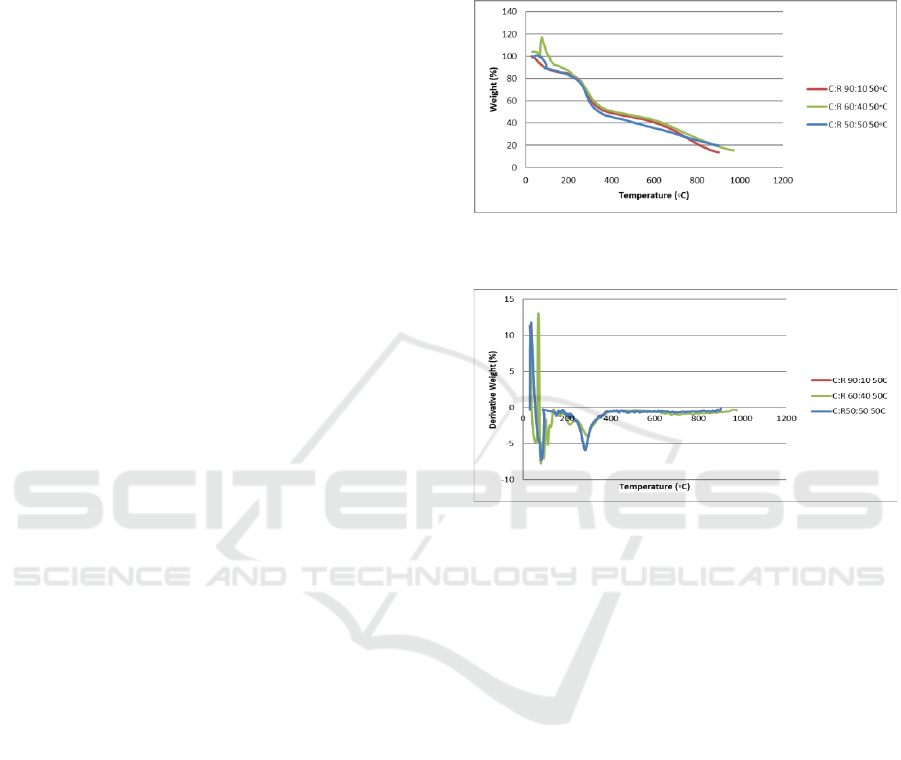

Figure 2 shows curve of weight loss (%) as a

function of temperature for chitosan-roselle films

which are cured at 50 0C with heating rate of 10

o

C

/min in the temperature range from room temperature

to 980

o

C. All ratio of chitosan-roselle films almost

have similarity in the shape of the curves, but

magnitudes of weight loss is varied. The initial weight

loss for all the samples starts near 100

o

C, the loss of

weight is about 10%, as a result of removing the

adsorbed water on the composite and loss of bound

water and acetic acid from the composites. The

weight increase in the range of 33 to 70

o

C is because

of the reaction between chitosan and roselle at ratio

60:40. It was, however, much smaller than the weight

loss in the range of 70 to 120

o

C and then the weight

increases almost disappeared. The weight loss in the

second starts in range 82.13-86.05

o

C and continues

up to 280

o

C of melting temperature, Tm. There was

about 40% weight loss was due to the decomposition

of blend. The third weight loss was observed in the

range 66.35- 67.69

o

C which probably due to the

structural decomposition of the blend caused by the

loss of water. There was about 70% weight loss and

it may be referred to a complex process including the

dehydration of the saccharide rings and

depolymerization. As would be expected, the higher

the gas temperature, the faster the heating rate and the

more rapid and weight loss is increase. The TGA

curves for the chitosan-roselle films with ratio 90:10

and 60:40 illustrated similar patterns of weight loss,

however, chitosan-roselle films with ratio 50:50

exhibited a greater weight loss than the other samples

at temperature around 290

o

C. It was observed that the

weight loss of chitosan-roselle films with ratio 60:40

was the highest at first until Tm. It is probably due to

the easy of chitosan-roselle to react with each other.

After passed the Tm, the weight loss of other ratio

was higher than it. The chitosan-roselle films of ratio

90:10 and 50:50 were more resistance to heat before

reach Tm and rapidly degrade after reach Tm. At this

cure temperature, chitosan-roselle film with ratio

90:10 showed great thermal resistance properties than

other ratios. The peaks of chitosan-roselle blend films

were very weak around temperature 600

o

C may be

due to the desorption of the adsorbed water on the

sample when it was kept overnight. It can be seen

that the DTGA curves and the maximum peaks

temperature shifted as the heating rate increases. An

increase of the heating rate tended to delay thermal

decomposition process towards higher temperatures,

most probably due to heating rate implies that the

material reaches that temperature in a shorter time.

According to the results, the yield of chitosan-roselle

films at about 20% and the behavior of TGA curves

were almost similar in the composites films (Figure

2-Figure 7).

Figure 2: TGA curves for thermal decomposition of

chitosan-roselle films at 50

o

C.

Figure 3: DTGA curves for thermal decomposition of

chitosan-roselle films at 50

o

C.

Figure 3 shows curve of weight loss (%) as a

function of temperature for chitosan-roselle films

which cured at 60

o

C with heating rate of 10

o

C/min in

the temperature range from room temperature to

980

o

C. From the Figure 2-7, all ratio of chitosan-

roselle films almost have similarity in the shape of the

curves, but magnitudes of weight loss were varied.

The initial weight loss for all samples at

approximately 100

o

C is around 10%. This may due to

the evaporation of water and due to the loss of water

content and acetic acid from the composite. The

weight loss in the second range started around 180

o

C

and continued up to 253

o

C melting temperature, Tm.

refer to combustion of cellulose from roselle. The

weight loss third stage observed in the range 255

o

C

corresponds to structural decomposition of the blend

which there was about 66% weight loss of the original

sample. It was observed that the weight loss of

chitosan-roselle films with ratio 60:40 was highest

than others ratio. Combination of chitosan-roselle

improved the thermal properties of chitosan film at

cure temperature 60

o

C. This ratio was more resistance

to heat before reach Tm and rapidly degraded after

reach Tm. At this cure temperature, chitosan-roselle

Thermal Properties of Chitosan-roselle Films

269

with ratio 60:40 showed great thermal resistance

properties than other ratios. According to the results,

the char yield of chitosan-roselle films at about 14%

and the behavior of TGA curves were almost similar

in the composites films (Figure 2-Figure 7). The

results showed that, the char yield of chitosan:roselle

at all ratio were less which were between 15% and

17% respectively. Therefore, the addition of roselle

can improve the thermal stability of chitosan-roselle

films. It was found that the char yield of chitosan-

roselle film was enhanced as addition of roselle in

chitosan-roselle composite. These results means high

thermal stability of chitosan-roselle films.

Figure 4: TGA curves for thermal decomposition of

chitosan-roselle films at 60

o

C.

Figure 5: DTGA curves for thermal decomposition of

chitosan-roselle films at 60

o

C.

Figure 6 shows curve of weight loss (%) as a

function of temperature for chitosan-roselle films

which cured at 70

o

C with heating rate of 10

o

C/min in

the temperature range room temperature to 980

o

C.

From the Figure 7, the initial weight loss for all

samples at approximately 100

o

C was around 10%.

This may due to the evaporation of water and due to

the loss of water content and acetic acid from the

composite. The weight loss in the second range

started around 202.5

o

C which was referred to

combustion of cellulose from roselle. The weight loss

third stage found in range 255-463.1

o

C corresponds

to a complex process including the dehydration of the

saccharide rings and depolymerization. The TGA

curves showed that chitosan-roselle composite films

slowly decline above 350

o

C with a maximum rate of

decomposition occurring at about 300-340

o

C.

Figure 6: TGA curves for thermal decomposition of

chitosan-roselle films at 70

o

C.

Figure 7: DTGA curves for thermal decomposition of

chitosan-roselle films at 70

o

C.

Table 1: The thermal decomposition of chitosan-roselle

films.

Differential scanning calorimeter (DSC)

measurements were performed to estimate the

thermal transition of chitosan-roselle films by ratio

90:10 and 60:40 of chitosan-roselle at different

testing temperature. All the samples were heated from

room temperature to 480°C and rate of 10

o

C/min.

The DSC glass transitions are shown in Figure 8-10.

Figure 8 shows thermal transition of the chitosan-

Sample

Temperature

Decomposition (ºC)

Weight loss (%)

2

nd

stage at

3

rd

stage

2

nd

stage at

3

rd

stage

C:R 90:10 50

◦

C

132.4

193.8

17.87

35.65

C:R 60:40 50

◦

C

203

259

16.85

35.97

C:R 90:10 60

◦

C

180

233.1

32.55

34.55

C:R 60:40 60

◦

C

197

274

17.63

32.96

C:R 90:10 70

◦

C

202.5

-

27.06

-

C:R 60:40 70

◦

C

191

255

15.62

33.27

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

270

roselle films in cure temperature 50

o

C. Figure 8 does

not show any peak for glass transition temperature. It

shows crystallization and melting point chitosan-

roselle films as stated in the Table 1. Chitosan-roselle

films showed an endothermic peak at around 94.48 to

98.33°C associated with the dehydration (loss of

water associated with the hydrophilic groups of the

polymer) in film matrix. The exothermic peak which

appears in the temperature ranges about 279.45 and

281.89°C corresponds to the decomposition of the

polymer. Based on the previous research, the thermal

degradation of chitosan begins at about 250°C. The

exothermic can be explained through the

crystallization of chitosan. The melting point of

chitosan-roselle films were 212.85 and 209.96 °C

respectively following the ratio. These peak

temperatures tend to shift to lower temperatures with

increased roselle concentration. In crystalline

molecules of original chitosan was packed in a way

that their interactions are strongest. When the

chitosan was blended, it stretches the crystal lattice,

molecules are not in the optimal positions and their

interactions are weaker, thus less energy is required

to break them. At cure temperature 50

o

C, chitosan-

roselle films with ratio 60:40 showed the highest

melting temperature while 90:10 showed the lowest

melting temperature.

Figure 8: The DSC glass transitions of chitosan-roselle

films at 50◦C.

Thermal transition of the chitosan: roselle films

were affected by different ratio of chitosan and roselle

in cure temperatures 60◦C as shown in Figure 9. The

sample were heated from room temperature to 480

o

C

at a rate of 10

o

C/min. Chitosan-roselle films exhibited

a broad endothermic peak at 91.59

o

C and 85.82

o

C

respectively following the ratio because of the

dehydration (loss of water associated with the

hydrophilic groups of the polymer) in the films. The

exothermic peak which appeared in the temperature

ranges at 287.91 and 302.34°C corresponds to the

decomposition of the polymer. Based on the previous

research, the thermal degradation of chitosan begins

at about 250°C. The exothermic can be explained

through the crystallization of chitosan. The melting

point of chitosan-roselle films were 214.77 and

216.69°C respectively following the ratio. In

crystalline molecules of original chitosan was packed

in a way that their interactions are strongest. When

the chitosan is blended, it stretches the crystal lattice,

molecules are not in the optimal positions and their

interactions are weaker, thus less energy is required

to break them. At cure temperature 60

o

C, chitosan-

roselle films with ratio 60:40 showed the highest

melting temperature while 90:10 showed the lowest

melting temperature. When compare the result of cure

temperature of 60

o

C with other two cure temperature,

it showed the highest melting temperature. In other

meaning, 60

o

C is the most optimum temperature to

produce high melting temperature (heat resistance

films).

Figure 9: The DSC glass transitions of chitosan-roselle

films at 60◦C.

Thermal transition of the chitosan-roselle films

were affected by different ratio of chitosan and roselle

in cure temperatures 70

o

C as shown in Figure 10. The

sample were heated from room temperature to 480

o

C

at a rate of 10

o

C/min. Chitosan-roselle films exhibited

a broad endothermic peak at 84.85 and 88.7

o

C

respectively following the ratio because of the

dehydration (loss of water associated with the

hydrophilic groups of the polymer) in the films. The

exothermic peak which appeared in the temperature

ranges at 303.31 and 307.99

o

C corresponded to the

decomposition of the polymer. Based on the previous

research, the thermal degradation of chitosan begins

at about 250°C. The exothermic can be explained

through the crystallization of chitosan. The melting

point of chitosan-roselle films were 215.73 and

208.03°C respectively following the ratio. In

crystalline molecules of original chitosan was packed

in a way that their interactions are strongest. When

the chitosan was blended, it was stretched the crystal

lattice, molecules are not in the optimal positions and

their interactions are weaker, thus less energy is

required to break them. At cure temperature 70

o

C,

chitosan-roselle films with ratio 60:40 showed the

Thermal Properties of Chitosan-roselle Films

271

highest melting temperature while 90:10 showed the

lowest melting temperature. When compare the result

of cure temperature of 70◦C with other two cure

temperature, it showed the lowest melting

temperature.

Figure 10: The DSC glass transitions of chitosan-roselle

films at 70◦C.

Table 2: The melting temperature of chitosan-roselle films.

Sample name

Crystallization

temperature

(

o

C)

Melting

temperature

(

o

C)

C:R 90:10 50

o

C

94.48

212.85

C:R 60:40 50

o

C

98.33

209.96

C:R 90:10 60

o

C

91.59

216.77

C:R 60:40 60

o

C

85.82

214.69

C:R 90:10 70

o

C

84.85

215.73

C:R 60:40 70

o

C

88.70

208.03

Scanning Electron Microscopy (SEM) was used to

study the surface morphology of the chitosan-roselle

films. There are 4 magnification used which are x100,

x250, x500 and x2000. The morphology of chitosan-

roselle films which cured at 60◦C are reported in

Figure 11. SEM images for chitosan-roselle films

with ratio 100:0 and 90:10 showed the largest rough

surface. The surface of chitosan films was smooth and

not homogenous due to the present of phase

separation. Roselle did not disperse well within the

chitosan matrix in the blend films. Chitosan-roselle

films with the ratio of 80:20, 70:30 and 60:40 had

smoother surface than chitosan-roselle films with

ratio 100:0 and 90:10. From the micrograph under

magnification, the surface of chitosan-roselle films

became smoother as the ratio of chitosan-roselle films

decreased. This may be due to chitosan-roselle films

particles have failed to crystallize.

Figure 11: SEM images of chitosan-roselle films which

cured at 60◦C.

4 CONCLUSIONS

FTIR result showed that the intensity percentage of

functional group exist in pure chitosan films were

improved by adding roselle to become chitosan-

roselle films. Besides, it showed the most optimum

cure temperature was 60

o

C which showed high

intensity percentage compared to other cure

temperature (50 and 70

o

C). From the thermal testing

(TGA, DTG, and DSC), the melting temperature of

chitosan-roselle films showed higher melting

temperature when increase the roselle ratio in the

blend films at cure temperature 50, 60 and 70

o

C.

This means that chitosan-roselle films showed

higher heat resistance when ratio of roselle

increased. The temperature at maximum

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

272

degradation rate of chitosan-roselle films determined

by DTG were lower when increased the roselle ratio

in the blend films at cure temperature of 50, 60 and

70

o

C. Thus, the chitosan-roselle films were degrade

faster when increased the roselle ratio in blend film

at ambient temperature. From the cure temperature

50, 60 and 70

o

C, the most optimum cure temperature

was 60

o

C which showed the lowest weight loss and

exhibited the highest heat resistance compared to

other cure temperature. SEM results showed the

surface structure of different ratio of chitosan-roselle

films which were cure at 60◦C. The higher ratio of

chitosan-roselle, the surface structure become

smoother. As conclusion, chitosan-roselle films have

higher heat resistance, degraded faster and have

smoother surface at most optimum cure temperature

(60

o

C). The smoother surface of chitosan-roselle

films made the higher thermal resistance of these

blend films.

ACKNOWLEDGEMENTS

This work was supported by Faculty of Mathematic

and Natural Sciences, Universitas Sumatera Utara

and School of Materials Engineering, Universiti

Malaysia Perlis.

REFERENCES

Alves, V., Costa, N., Hilliou, L., Larotonda, F., Gonçalves,

M., Sereno, A., & Coelhoso, I., 2006. Design of

biodegradable composite films for food packaging.

Desalination, 199(1-3), 331-333.

Betzabe Gonza Lez-Campos, Evgen Prokhorov, Gabriel

Luna-Bárcenas, Abril Fonseca-García, & Isaac

C.Sanchez., 2009. Dielectric relaxations of chitosan:

The effect of water on the α-relaxation and the glass

transition temperature. Journal of Polymer Science Part

B Polymer Physic, 47(22), 2259-2271.

Cissé M., Kouakou A.C., Montet D., Loiseau G., Ducamp-

Collin M.N., 2013. Food Hydrocolloids, 30 (2), 576-

580.

Dev Raj. and J. Yamini, 2013. Preparation and

Characterization of Pharmaceutical Grade Chitosan and

Hydrated Chitosan Gums for Topical Preparations.

Chem. Phys Journal. 1(9), 858-860.

Esam A. El-hefian and Abdul H. Yahaya., 2010.

Rheological study of chitosan and its blends: An

overview of chitosan, International Journal of

Carbohydrate Chemistry 4(02), 210-220

Portes, E., Gardrat, C., Alain, C., & Véronique, C., 2009.

Environmentally friendly films based on chitosan and

tetrahydrocurcuminoid derivatives exhibiting

antibacterial and antioxidative properties. Carbohydrate

polymers. 76(4), 578-584.

Jayakumar, N. Nwe, S. Tokura, H. Tamura, 2007. Sulfated

chitin and chitosan as novel biomaterials. International

Journal of Biological Macromolecules, 40(3), 175-181

Kammoun , M., Haddar , M., Kallel , T. K., Dammak, M.,

& Sayari, A., 2013. Biological properties and

biodegradation studies of chitosan biofilms plasticized

with PEG and glycerol. International Journal of

Biological Macromolecules.

Kumirska, Jolanta., Czerwicka, M., KaczyÅski, Z.,

Bychowska, A., Brzozowski, K., Thoming, J., &

Stepnowski, P., 2010. Application of Spectroscopic

Methods for Structural Analysis of Chitin and Chitosan.

Marine Drugs. 8(5), 1567-636.

Leceta, I., Guerrero, P., Ibarburu, I., Dueñas, M.T., de la

Caba, K., 2013. Characterization and antimicrobial

analysis of chitosan-based films. Journal of Food

Engineering, 116,(2013), 889–899.

Ngah, W.S.W., Fatinathan, S. and Yosop, N.A., 2011.

Isotherm and kinetic studies on the adsorption of humic

acid onto chitosan-H2SO4 beads. Desalination. 272,

293–300.

Norashikin, M. I., 2010. Fabrication and Characterization

of Sawdust. World Academy of Science, Engineering

and Technology, 716-719.

Ou, Y. Wang, S. Tang, C. Huang, and M. G. Jackson, 2005.

"Role of ferulic acid in preparing edible films from soy

protein isolate," Journal Food Eng, vol. 70, pp. 205-

210.

Tharanathan, R. N., 2003. Biodegradable films and

composite coatings: past, present and future. Trends in

Food Science and Technology, 14, 71-78.

Tuija Annala, 2007. Chitosan Film Preparation, Instruction

for laboratory experiments, Rev 0.

ZhenXing Tang, and JunQinQin, 2007. Use of chitosan gel

for the purification of protein, Engineering AND

Technology, College of Chemical Engineering and

Materials Science, Zheijiang University of Technology,

Hangzhou, Zhejiang, China.

Thermal Properties of Chitosan-roselle Films

273