Mechanical Properties and Morphology Biocomposites of

Polycaprolactone (PCL)/Modified using Trisodium

Trimetaphosphate

Marpongahtun

1*

, Cut Fatimah Zuhra

1

, Sovia Lenny

1

, Darwin Yunus Nasution

1

, Aulya M.

1

,

Suci A. Amaturrahim

1

, Mahmud

2

, Fitria Puspa Dewi

1

and Irmayani

1

1

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara, Jl. Bioteknologi

No. 1 Kampus USU Padang Bulan, Medan 20155, Indonesia

2

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Negeri Medan,

Sumatera Utara, Indonesia

fitriapuspadewi24@gmail.com, yirma1743@gmail.com

Keywords: Biocomposite, Breadfruit Strach Modified, Polycaprolactone, Mechanical Properties.

Abstract: The determination of the mechanical properties and morphology of polycaprolactone (PCL) / breadfruit

polytocyte biocomposites tied up with trisodium trimetaposphate was performed. The breadfruit starch is

tied with trisodium trimetaposphate to produce pospat starch. The highest degree of substitution was

obtained in variation of trisodium weight of trimetafosfat 3%, that is 0,0633. PCL / Starch Biocomposite

was prepared by mixing method between PCL in chloroform solvent with modified 3% sodium starch then

printed at 75˚C since 10 minutes. Mechanical properties, functional group, and morphological of

PCL/Modified breadfruit starch biocomposite was analyzed. The result of evaluation showed an optimal

tensile test value of 90%: 10% with tensile strenght of 7,4287 MPa and Modulus Young’s of 27,852 MPa.

The functional group analysis of phosphate starch showed asymmetric P-O-C group at wave number

1018,41 cm

-1

. Analysis with FT-IR from PCL/Modified Breadfruit Starch Biocomposite showed of physical

interaction occurred between PCL and modified breadfruit starch. Morphological analysis using SEM

showed smooth and homogeneous surface of biocomposite.

1 INTRODUCTION

Biocomposite is a type of composite that one of the

constituents, namely the padding or matrix derived

from natural materials (Xanthos, 2005). The matrix

used in this study is the polymer matrix.

Polymer matrixs that derived from nature were

start being selected by the community in the

manufacture of biocomposites because they were

considered more environmentally friendly. This

study uses matrix padding in the form of breadfruit

starch derived from breadfruit. Breadfruit is high in

carbohydrates and a valuable source of starch.

Breadfruit produced 18.5 grams/ 100 grams of starch

with 98.86% purity, 27.68% of amylose and 72.32%

of amylopectin (Rincon and Padilla, 2004).

Biocomposite in this study was made by mixing

breadfruit starch with polycaprolactone (PCL) with

the aim for improving the mechanical properties of

biocomposite. PCL is generally used as one of the

basic ingredients for making biomaterials. PCL has

good mechanical properties, that biocompatible with

many types of polymers. The use of PCL for tissue

regeneration is very limited due to its hydrophobic

nature which affect cell regeneration and

degradation rate. A simple way to increase its

hydrophilicity, by mixing PCL with natural

polymers (Wang et al., 2009).

Starch modification and processing techniques

have developed rapidly, natural starch can be

modified so it has better properties. Because the

starch industry wants a stable thickness of starch at

both high and low temperatures, good endurance to

mechanical treatment, and thickening power that

resistant to acidic and high temperature. (Koswara,

2009).

(Wang et al., 2005) conducted a study of thermal

and thermomechanical behavior of polycaprolactone

Marpongahtun, ., Fatimah Zuhra, C., Lenny, S., Yunus Nasution, D., M., A., Amaturrahim, S., Mahmud, ., Puspa Dewi, F. and Irmayani, .

Mechanical Properties and Morphology Biocomposites of Polycaprolactone (PCL)/Modified using Trisodium Trimetaphosphate.

DOI: 10.5220/0008925802870292

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 287-292

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

287

and starch/ polycaprolactone compound for

biomedical applications, corn starch was used where

a compound of corn starch with 30/70% weight of

PCL (SPCL), and used a commercial PCL. After

conducting thermal analysis, the melting peak

temperature and melting enthalpy for PCL is higher

than SPCL which is equal to 58.40

0

C and 59.80

0

C

at SPCL crystallization rate is much higher than

PCL which is equal to 47.60

0

C, this indicates that

starch acts as an agent for PCL .

(Sujito, Munawaroh and Purwandari, 2013)

conducted a study of the mechanical properties and

ability of biodegradation of poly lactic acid

biocomposite with amplifier of thin bamboo sheets

and sengon wood, biodegradation test of

biocomposite was carried out using the land fill

method where the materials was buried in the soil

for 4 weeks and watered with ± 150 cc / day.

Observation of the test material was carried out

every week by calculating the percentage changes in

relative mass and physical changes from the material

using a microscope. The results showed a decrease

in the quality of biocomposite synthesized materials

due to burial.

(Zuhra and Marpongahtun, 2016) conducted a

study of breadfruit starch modification by

crosslinking method using trisodium

trimetaphosphate with various weight of sodium

trimethaphosphate 1%, 2%, 3% and 30, 60, and 90

minutes of reaction times. Results from the research

using IR spectroscopy phosphate starch was formed

asymmetric P-O-C vibrations at wave numbers

1050-995 cm

-1

and 1643 cm

-1

. The effect of

increasing Trisodium trimetaphosphate

concentration increases the value of substitution

degree and decreases the swelling power value. The

highest degree of substitution was 0.003 gram at 3%

concentration and 60 minutes of reaction time.

Starch can be divided into 2 types, native starch

which has not been modified and modified starch.

Modifications made to improve the properties of

native starch, including producing higher brightness

starch, lower viscosity and gel formed, starch

granules break more easily and higher gelatinization

time and temperature (Koswara, 2009).

Cross-linking is a method that can be used to

modify starch by replacing -OH groups with groups

of added crosslinking agents such as esters, ethers or

phosphates (Siswanto, Manurung and Budiyati,

2012). The advantage of using the crosslinking

method is to produce starch with little swelling

power. This will strengthen starch granules so that it

is not easily broken during heating and make the

starch more resistant to acidic and heat media. In

addition, it strengthens hydrogen bonds in granules

with chemical bonds that act as bridges between

starch molecules. As a result, when starch is heated

in water, the granules will expand that make the

hydrogen bonds weaken (Koswara, 2009).

In this study, a combination of polycaprolactone

and modified starch was mixed homogeneously

through perfect stirring. That is produce a thin

membrane formed by pouring and evaporating the

solvent at room temperature. Characterization

carried out is the mechanical strength test, functional

group analysis and surface morphology analysis.

2 MATERIALS AND METHODS

2.1 Equipment

Tools used in this research are analytical scale,

measuring cup, hotplate, stirrer, glass funnel, beaker

glass, oven thermometer, desiccator, aquadest bottle,

measuring flask, aluminum foil, hot press, magnetic

stirrer, pH meter, spectrophotometer FT-IR, tensile

testing equipment, Scanning Electron Microscopy

(SEM), and whatman filter paper No.1.

2.2 Materials

Materials used in this study include: breadfruit,

trisodium trimetafosfat (TMP), vanadate-molybdate

reagent, Na

2

CO

3

, KH

2

PO

4

, 0.5 N NaOH, 0.5 N HCl,

polycaprolactone (PCL), chloroform, aquadest and

water.used in this study include: breadfruit,

trisodium trimetafosfat (TMP), vanadate-molybdate

reagent, Na

2

CO

3

, KH

2

PO

4

, 0.5 N NaOH, 0.5 N HCl,

polycaprolactone (PCL), chloroform, aquadest and

water.

2.3 Methods

2.3.1 Isolation Starch from Breadfruit

Breadfruit that has yellowed peeled and removed the

stalks of fruit, then washed from dirt and sap. Then

cut into small pieces and mashed with blender.

Furthermore, filtered the mashed breadfruit using

gauze and left until precipitate. Washed the

precipitate repeatedly with water until the top layer

is clean. The obtained starch is dried in the oven at

45 °C for 24 hours. Ground and sifted the crude

starch. Then, analyzed breadfruit starch using FT-IR.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

288

2.3.2 Phosphate Starch Manufacture

Dissolved 30 grams of breadfruit starch with 45 mL

aquadest until a suspension was formed and then

added 1% trisodium trimetaphosphate while stirring

to pH 10 by dripping 1 M NaOH. Then heated the

compound at 45 °C while stirring for 60 minutes.

Furthermore, neutralized the obtained starch

porridge to pH 6.5 with 1 M HCl then washed

thoroughly using distilled water. Phosphate starch

then dried at 40° for 24 hours. Ground and sifted the

coarse phosphate starch. Used the same procedure

for trisodium trimetaphosphate 2 and 3% weight.

Furthermore, the obtained phosphate starch was

characterized by FT-IR and calculated the degree of

substitution (DS).

2.3.3 Determination of Degree of

Substitution for Crosslink Starch

(Phosphate Starch)

Determination of phosphate substitution degrees was

carried out according to (Deetae et al., 2008) as 1.5

grams of sodium carbonate were dissolved in 5 mL

aquadest. Then added 2.5 grams of starch phosphate

to the sodium carbonate solution and put into the

kiln at 550 °C for 6 hours to be ignited. Dissolved

the sample that has been ignited with 2 mL of 25%

HCl and stirred until it dissolves. Then added

aquadest until it reach 50 mL volume of solution.

Piped 10 mL from the solution and added vanadate-

molybdate reagent, then left at room temperature for

± 45 minutes. After that, observed the samples using

a UV-Visible spectrophotometer at a 435nm

wavelength should be aligned to the center with

linespace exactly at 13-point. The text must be set to

11-point.

2.3.4 Manufacture of Modified Starch

Biocomposite with PCL

Dissolved 9 grams of PCL with chloroform at 60 °C.

Then added with 1 gram of starch phosphate while

being distirer until homogeneous for 30 minutes,

then cooled and dried. Next, put it into the mold and

pressed with a Hot Press tool at 75 °C for 10

minutes. Use the same procedure on the manufacture

of biocomposite according to predetermined

variations. Then carried out biocomposite

characterization of tensile test analysis, FT-IR and

SEM.should appear aligned to the center including

organisation, address and e-mail.

3 RESULT AND DISCUSSION

3.1 Phosphate Starch Manufacture

Phosphate starch is starch obtained from cross-

linking reaction between starch and trisodium

trimetaphosphate in the presence of sodium

hydroxide which acts as a catalyst.

The reaction between starch and sodium

hydroxide starts with the attack of Na atom from

sodium hydroxide on C2 starch atom. Sodium

hydroxide will break the C2-C3 bond which has a

secondary alcohol group to form the phosphate

starch. And the secondary -OH group on C2 starch

atom attacks H atoms of C3 starch atoms to produce

water. Then the C2-C3 bond is cut off and the

electron is displaced to produce phosphate starch.

3.2 FT-IR Spectrum Analysis of

Breadfruit Starch and Modified

Starch

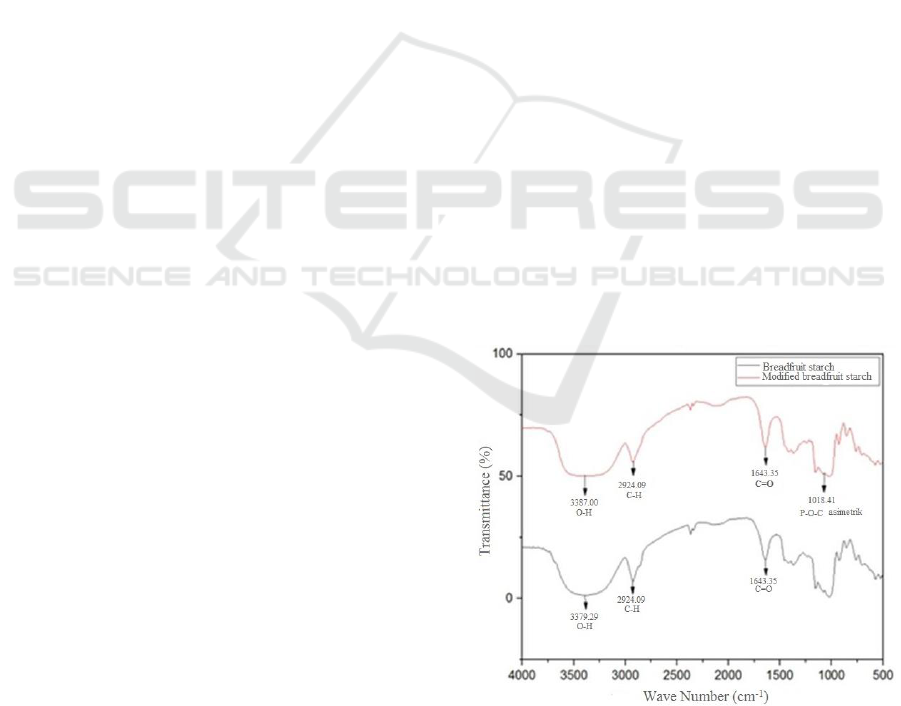

Function group analysis using FT-IR for starch and

modified starch from the breadfruit isolation can be

seen from FT-IR spectroscopic data. The FT-IR

spectrum of breadfruit starch (Figure 1) shows the

group contained in starch, where the wave number

3379.29 cm

-1

shows the –OH group; 2924.09 cm

-1

shows the –CH group; 1643.35 cm

-1

shows the C =

O group. The results of FT-IR spectrum analysis

showed that starch isolation was successfully carried

out can be seen in Figure 1.

Figure 1: FT-IR Spectrum Breadfruit Starch and Modified

Breadfruit Starch.

The FT-IR spectrum phosphate starch supports

the emergence of a vibration peak in the wave

Mechanical Properties and Morphology Biocomposites of Polycaprolactone (PCL)/Modified using Trisodium Trimetaphosphate

289

number 1149 cm

-1

– 1018,41 cm

-1

indicating the

presence of a P=O aliphatic group that supported by

band absorption which indicate the presence of

asymmetric P-O-C groups in the wave number

1080,14 cm

-1

. The vibration peak at the wave

number 1643 cm

-1

shows the hydrogen

intramolecular bond and the break-off of the

hydrogen bond so that the -OH group is converted

into phosphate ester (Li and Yeh, 2001). This

absorption comes from an added crosslinking agent,

namely trisodium trimetaphosphate which replaces

the -OH group in starch molecules. This shows the

addition of new groups to the modified starch.

3.3 Determination of Phosphate

Percentage and Degree of

Substitution (DS)

Determination degree of substitution was carried out

using UV-visible spectrophotometry. The results of

determining the degree of substitution can be seen in

Table 1.

Table 1: Results of determination degree of substitution of

variations in the trisodium trimetaphosphate weight.

Treatment

Phosphate

Percentage

Degree of

Substitution (DS)

0,3 g TMP

0,9592

0,0520

0,6 g TMP

1,1585

0,0633

0,9 g TMP

1,2426

0,0681

Results of the substitution degrees obtained

ranged from 0,0520 – 0,0681. The highest value of

0,0681 was obtained from phosphate starch with a

variation weight of 0,9 gram trisodium

trimetaphosphate with 60 minutes reaction time. The

more crosslinking agents were added and the longer

the reaction time, the more phosphate groups can

substitute the -OH group. This is because the longer

the contact time between trisodium trimetaphosphate

and starch, the weakens the hydrogen bonds found in

starch molecules.

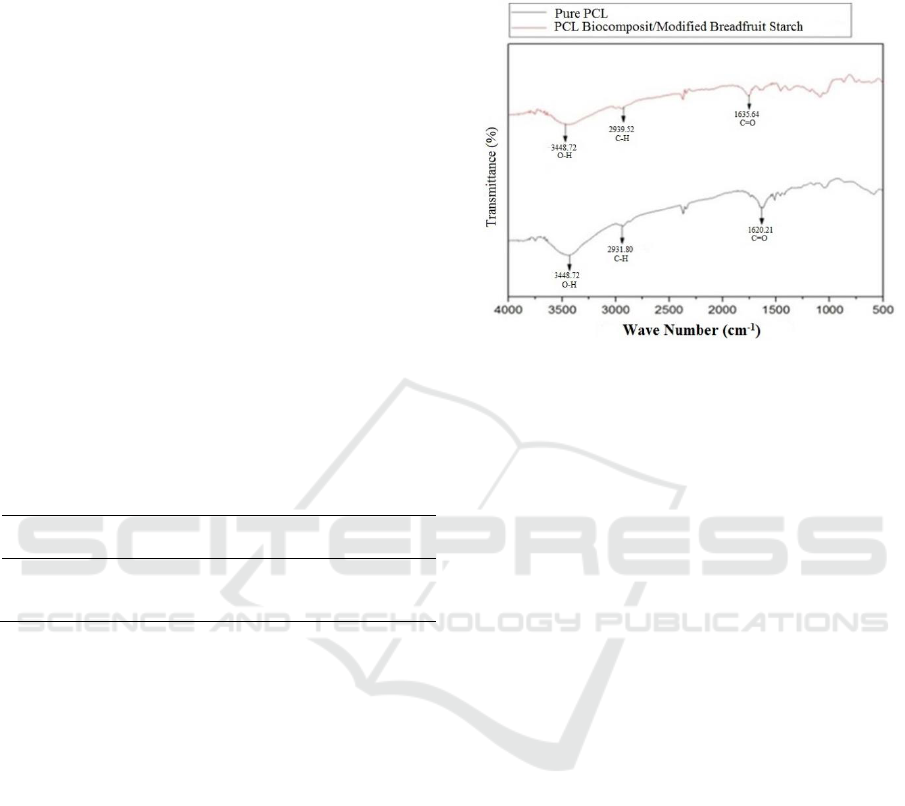

3.4 FT-IR Spectrum Analysis of PCL

Biocomposite/Modified Breadfruit

Starch

FT-IR spectroscopy was used to determine the

characteristics of composite membranes functional

groups. The FT-IR spectrum of polycaprolactone

(PCL) and PCL biocomposite/modified breadfruit

starch can be seen in Figure 2.

The FT-IR spectrum of polycapolactone shows the

-OH, -CH, C=O group at wave numbers respectively

3448,72 cm

-1

, 2931,80 cm

-1

, 1620,21 cm

-1

.

Figure 2: FT-IR Spectrum of Pure PCL and Biocomposite

PCL/ Modified Breadfruit Starch.

The FT-IR spectrum of biocomposite PCL/

breadfruit starch showed –OH, C–H, and C=O

groups at wave numbers of 3448,72 cm

-1

, 2939,52

cm

-1

, and 1635,64 cm

-1

, respectively.

Based on FT-IR analysis, it can be seen that the

functional groups formed are a combination of

specific functional groups found in their constituent

components. The functional group reappeared on the

spectrum compound between polycaprolactone and

breadfruit starch where the intensity was almost

same and new functional group was not found. This

proves that the compound of PCL/ breadfruit starch

produced is a physical mixing process.

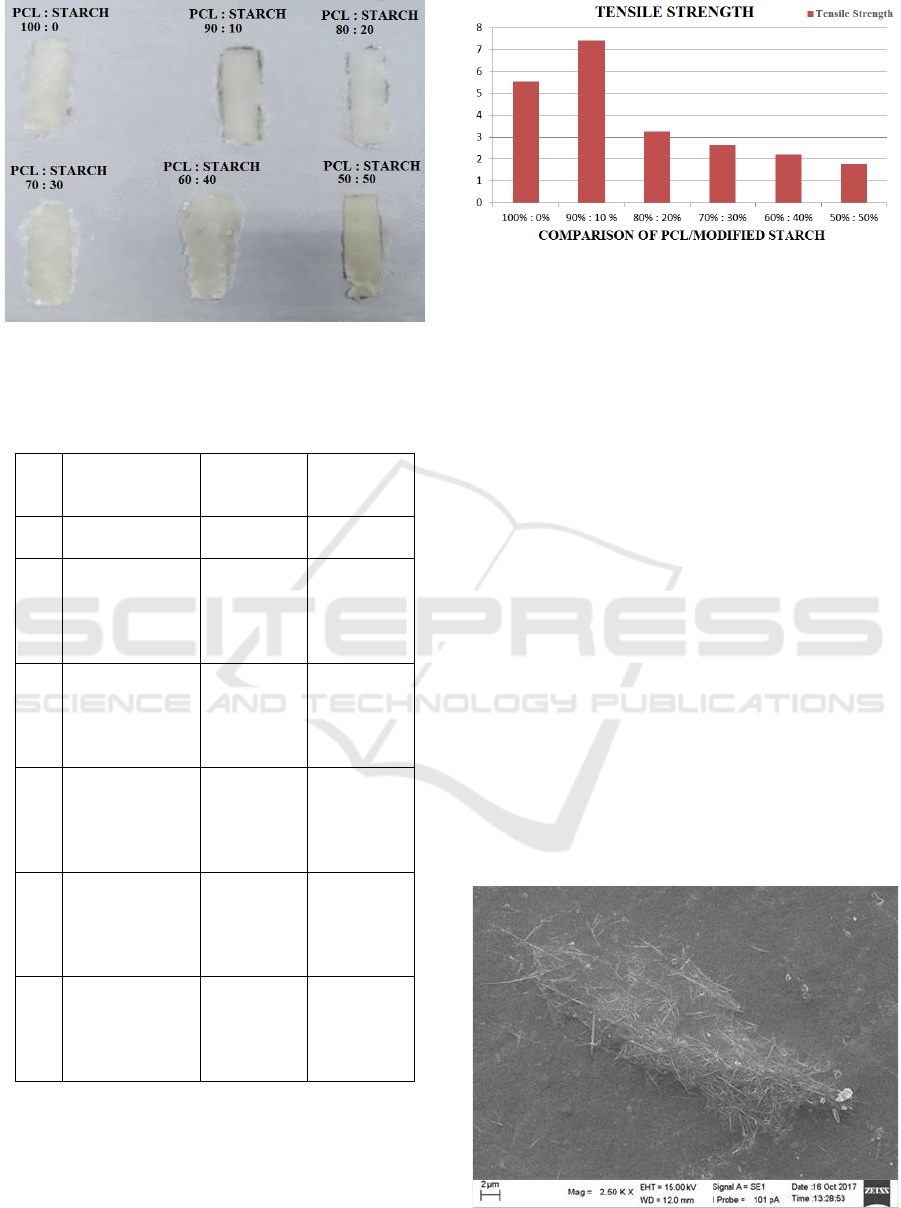

3.5 Mechanical Properties Analysis of

Biocomposite PCL/Modified

Breadfruit Starch

Tensile strength is the ability of a material to hold a

load without breaking the material. Mechanical

properties are carried out to determine the tensile

strength and biocomposite elasticity produced.

Composites with good mechanical properties can

be obtained if the padding material is well dispersed

in the matrix. Fillers and matrixs must be

compatible, that is, they are suitable when mixing. In

this study, the fillers used were starch and the matrix

was polycaprolactone. The results of the mixture

between PCL / breadfruit starch and the results of

tensile strength analysis can be seen in Figures 3 and

Figure 4 and in Table 2.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

290

Figure 3: PCL Biocomposite/ Modified Breadfruit Starch.

Table 2: Result of Tensile Strength and Modulus Young’s

from Pure PCL Pure and Biocomposite PCL / Modified

Breadfruit Starch.

NO

Material Type

Tensile

Strenght

(MPa)

Modulus

Young

(MPa)

1

Pure PCL

(100% : 0%)

5.5473

4.9771

2

Biocomposite

PCL/Modified

Breadfruit

Starch

(90% : 10%)

7.4287

27.852

3

Biocomposite

PCL/Modified

Breadfruit

Starch

(80% : 20%)

3.2615

58.126

4

Biocomposite

PCL/Modified

Breadfruit

Starch

(70% : 30%)

2.6466

13.309

5

Biocomposite

PCL/Modified

Breadfruit

Starch

(60% : 40%)

2.2155

4.732

6

Biocomposite

PCL/Modified

Breadfruit

Starch

(50% : 50%)

1.7954

42.968

The comparison of the tensile strength result and

Modulus Young's can be concluded that

biocomposite with a ratio of 90%: 10% has the most

optimum value, with 7.4287 Mpa of tensile strength

and 27.852 Mpa of Modulus Young’s.

Figure 4: Tensile Strength Graph of Pure PCL and

Biocomposite PCL / Modified Breadfruit Starch.

The mixing process is more stable and the

mixture of starch added is less so that it increases the

value of the tensile strength produced. The value of

the tensile strength mixture is decreases with

increasing starch. This is consistent with (Sabo et

al., 2013) which states that the more starch mixtures

werw added, the lower the tensile strength value,

because starch molecules will interact with the

polymer chain structure which causes the polymer

chain to be difficult to move because of the

intermolecular forces between starch molecules.

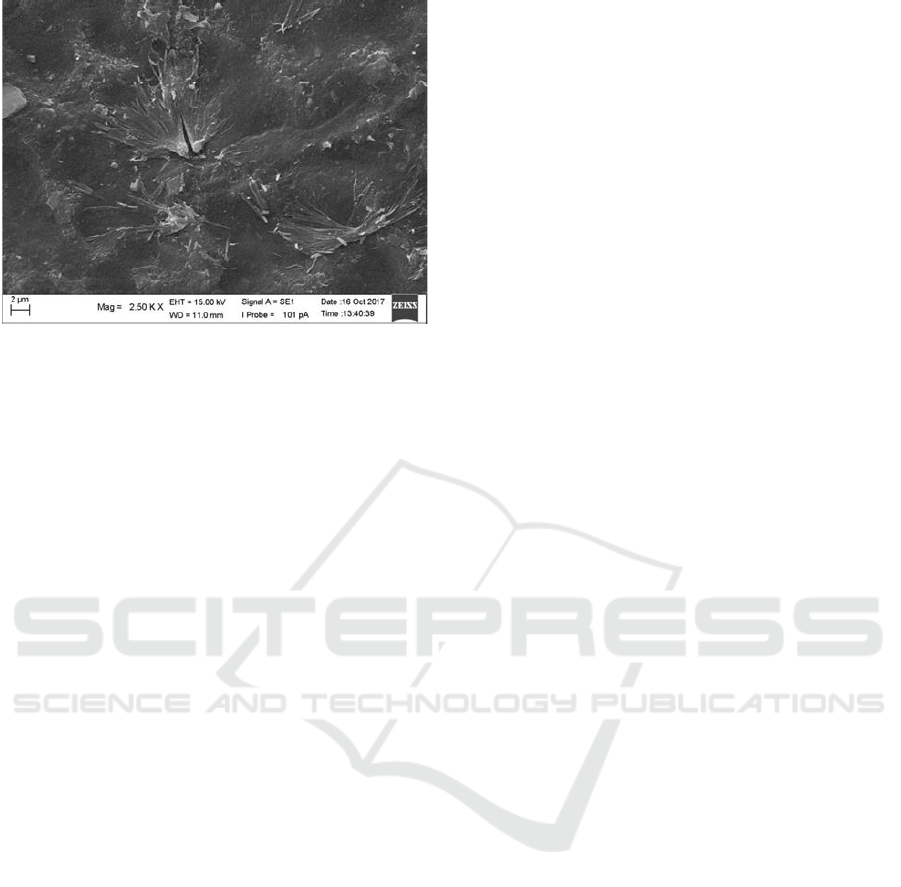

3.6 Morphological Analysis with SEM

Surface morphology analysis with SEM was carried

out to provide information about the shape and

change of surface from pure PCL and modified

biocomposite PCL /breadfruit starch. Figures 5 and

6 are SEM results of pure PCL and modified PCL /

modified breadfruit starch with a ratio of 90%: 10%

that obtained from the most optimum tensile test

analysis result. Morphological analysis was carried

out using a ZEISS device with a magnification of

2500 times with a power of 15,0 kV.

Figure 5: SEM Analysis of Pure PCL.

Mechanical Properties and Morphology Biocomposites of Polycaprolactone (PCL)/Modified using Trisodium Trimetaphosphate

291

Figure 6: Biocomposite PCL/Modified Breadfruit Starch

(90%: 10%).

From the SEM results, it can be seen that PCL has

more evenly surface, because PCL is not filled with

padding so that it produces a more evenly and smooth

surface (Panindia, 2015) .Meanwhile, biocomposite

PCL/breadfruit starch shows that starch can be

distributed evenly on the PCL surface with the

presence of physical interactions that produce a more

evenly and smoothly surface. PCL and starch have the

ability to mix with each other because both have good

properties and characteristics so that they have

compatibility when mixing to produce a smooth and

more evenly surface morphology.

4 CONCLUSIONS

The results from the research conducted can be

concluded that phosphate starch in the variation of

the weight of trisodium trimetaphosphate 3% is the

most optimum condition with the highest value of

Substitution Degrees which is 0,0681. Mechanical

biocomposite analysis of PCL/Starch Breadfruit with

90%: 10% showed an optimum conditions with

tensile strength values of 7,4287 MPa and 27.852

Mpa of Modulus Young's. FT-IR analysis on

optimum biocomposite showed the occurrence of

physical interactions between starch molecules and

PCL. Morphological analysis shows the formation of

a homogeneous surface and evenly distributed on the

surface of the biocomposite.

ACKNOWLEDGEMENTS

Author would like to thank to Rector of University of

Sumatera Utara for the funding from the project of

PD-TALENTA 2018 Number: 122/UN/5.2.3.1/PPM/

KP-TALENTA USU/2017

REFERENCES

Deetae, P. et al. (2008) ‘Preparation, pasting properties

and freeze-thaw stability of dual modified crosslink-

phosphorylated rice starch’, Carbohydrate Polymers.

doi: 10.1016/j.carbpol.2007.12.004.

Koswara, S. (2009) Starch Modifications Technology.

Li, J. Y. and Yeh, A. I. (2001) ‘Relationships between

thermal, rheological characteristics and swelling

power for various starches’, Journal of Food

Engineering. doi: 10.1016/S0260-8774(00)00236-3.

Panindia, N. (2015) Preparation of

Polycaprolacton/nanocrystal cellulose of sweet

corncobs (Zea mays saccarata) nanocomposites.

University of Sumatera Utara.

Rincon, A. and Padilla, F. (2004) ‘Physicochemical

properties of Venezuelan breadfruit (Artocarpus altilis)

starch’, Arch Latinoam Nutr., 54(4), pp. 449–56.

Sabo, R. et al. (2013) ‘Effect of environmental conditions

on the mechanical properties and fungal degradation

of polycaprolactone/ microcrystalline cellulose/wood

flour composites’, BioResources. doi:

10.15376/biores.8.3.3322-3335.

Siswanto, S., Manurung, T. and Budiyati, S. (2012)

‘Modification Of Flour From Umbi Gadung Using

Ginger Raw Extract As Functional Food Ingredients’,

Journal of Chemistry Technology and Industry, 1(1),

pp. 109–117.

Sujito, Munawaroh, H. and Purwandari, E. (2013)

‘Mechanical Properties and Biodegradation Capability

of Poly Lactic Acid Composites with Strengthening of

Bamboo and Sengon Thin Sheets’, Kimia Dasar,

14(2), pp. 67–72.

Wang, T. et al. (2009) ‘Bone marrow stem cells

implantation with α-cyclodextrin/MPEG-PCL-MPEG

hydrogel improves cardiac function after myocardial

infarction’, Acta Biomaterialia. doi:

10.1016/j.actbio.2009.04.040.

Wang, Y. et al. (2005) ‘Thermal and thermomechanical

behaviour of polycaprolactone and

starch/polycaprolactone blends for biomedical

applications’, Macromolecular Materials and

Engineering. doi: 10.1002/mame.200500003.

Xanthos, M. (2005) Modification of Polymer Mechanical

and Rheological Properties with Functional Fillers.

Zuhra, C. and Marpongahtun (2016) ‘Physical-Mechanical

Properties And Microstructure Of Breadfruit Starch

Edible Films With Various Plasticizer’, Eksakta, 13,

pp. 56–62. doi: https://doi.org/10.20885/eksakta.

vol13.iss1-2.art7.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

292