Optimization of Polymer Networks using Variations in Moleculer

Weight of Polyetilen Glycol in the Manufacture of Semi – IPN

Hidrogels from Coconut Water Cellulose Bacteria

Tamrin* and Emma Zaidar

Department of Chemistry, Faculty of Mathematics and Natural Sciences, Universitas Sumatera Utara

Keywords: Hydrogel IPN, Coconut Water, Bacterial Cellulose.

Abstract: Research heve been done to find out the effect of variation moleculer weight polietylen glikoln 1000; 3000

and 6000 on manufacture semi interpenetrating polymer networks hidrogel from bacterial selulose with

sytem fermentation using accetobacterial-xylinum in based coconut water. IPN hidrogel by polietilenglikol

6000 has more croslinks compared using peg 3000 and peg 1000. Analysis thermal hidrogel IPN using peg

6000 is 457,14

0

C, compared PEG 3000 is 252, 80

0

C and PEG 1000 is 249,30

0

C. semi-IPN hydrogel

formed was characterized by, crosslink percentage, chemistry structural analysis using Fourier Transform

Infrared (FT-IR) spectroscopy, water absorption test and thermal resistance using Differential Thermal

Analysis (DTA). From the analysis, they showed Semi Interpenetrating Polymer Network Hydrogel with

using PEG 6000 the highest crosslink percentage (64,3%) for PEG 3000 is 42.5 % and PEG 1000 is 15. 7

%. Characterization results of FTIR indicate the occurrence of crosslinking between Polyacrylic acid and

MBA. This shown in existence of 1403 cm

-1

and 1560 cm

-1

(COO

-

) and 3413 cm

-1

(NH amine). Thermal

analysis using Differential Thermal Analysis (DTA) shows thermal optimum thermal stability at the

addition of Polietilengiikol 6000 to semi-IPN hydrogel which was completely degraded at 680

o

C, reaction

that occurs during the decomposition process is endothermic and exothermic reaction.

1 INTRODUCTION

Hydrogel is a hydrophilic polymer with a network

structure that has crosslinking. Hydrogels have the

ability to absorb a certain amount of water without

the dissolution process and have hydrodynamic

properties of cells in many ways (Lee, 2009).

Making hydrogels can be done by several

methods, namely graft polymerization methods,

crosslinking physics, chemical crosslinking, and

crosslinking radiation (d). One way to improve the

mechanical properties of the hydrogel is to make

modifications through the formation of the

Interpenetration Polymer Network (IPN) (Rimmer,

2011).

Making semi-JPI hydrogels for biomedical

applications can be mixed with natural ingredients.

Another natural material that may be developed as

an alternative to biomedicine is Centella asiatica

plant. Gotu Kola is believed to cure various types of

diseases because it has bioactive components that

are useful for the body. The chemical content of

gotu kola including Triterpenoid: asiaticosida,

madekasosida, cyanic acid, indosentoat acid,

bayogenin; Flavonoids: kaemferol, kuesertin;

Saponins: sentelasapogenol A, B and D; and Tanin

(BPOM RI, 2010). Bioactive components contained

in gotu kola have a function for health, one of which

is antibacterial. Bioactive components of gotu kola

which have antibacterial properties are flavonoids,

tannins and saponins (Zhao et al., 2009). The

mechanism of flavonoids inhibits bacterial growth

by denaturing bacterial cell proteins, causing all

bacterial cell metabolism to stop, tannins can inhibit

bacteria by changing the permeability of the

cytoplasmic membrane. Saponins can form complex

compounds with cell membranes through hydrogen

bonds so that they can destroy the permeability of

bacterial cell walls.

Zhao et al, (2009) stated that Pegagan ethanol

extract had higher antimicrobial activity than

petroleum ether and water extract. The results

showed that Gotu kola ethanol extract had a

minimum inhibitory content (MIC) of 125 µg / ml in

Propionibacterium vulgaris, Staphylococcus aureus,

Tamrin, . and Zaidar, E.

Optimization of Polymer Networks using Variations in Moleculer Weight of Polyetilen Glycol in the Manufacture of Semi – IPN Hidrogels from Coconut Water Cellulose Bacteria.

DOI: 10.5220/0009003203290334

In Proceedings of the 1st International Conference on Chemical Science and Technology Innovation (ICOCSTI 2019), pages 329-334

ISBN: 978-989-758-415-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

329

Escherichia coli, Aspergillus niger and Candida

albicans. Whereas in Bacillus subtilis and

Aspergillus flavus is 62.5 µg / ml. (Heibesh et al.,

2013) found antimicrobial activity of asiatic acid

which is a saponin derivative in gotu kola against

several gram positive and gram negative bacteria.

Gotu kola is also used as a toothache medicine in the

general public, but until now there has been no

research or clinical data that supports it.

Heibesh (2013), has made a semi-JPI hydrogel

by mixing isopropyl acrylamide and cellulose. From

the results of Heibest's research, it was obtained

semi-JPI because cellulose was used in the form of a

linear carbon chain which was optimum at the

addition of cellulose by 20%.

Bajpai (2014), has made a semi-JPI hydrogel

from microcrystalline cellulose and acrylic acid with

N crosslinking, N'-Methylene Bisacrylamide.

Microcrystalline cellulose produced from cellulose

bacteria was dissolved in PEG (1000, 3000, and

6000) / NaOH solvents which were then

polymerized.

This study aims to make semi-JPI hydrogels

using various types of polyethylene glycol and

analyze how the crosslink degree and absorption

power obtained in PEG / NaOH solvent systems

with acrylic acid using N, N'-Methylene

Bisacrylamide crosslinking and the effect of adding

bacterial cellulose which functions as a biopolymer

which can improve the nature of hydrogel

absorption.

2 EXPERIMENTALS

Bacterial cellulose is made from coconut water with

the help of Acetobacter-xylinum bacteria. put into a

beaker glass containing 100 mL solvent system

Polyethylene Glycol 1000 (6% wt / vol) and NaOH

(8% wt / vol). The dispersion that occurred in the

refrigerator at -5

o

C for 24 hours. The frozen solid

obtained was left at room temperature with stirring

for 2 hours. The clear solution produced is then

filtered with ordinary filter paper which will be used

to make hydrogels. The same method is carried out

using 3000 polyethylene glycol and polyethylene

glycol 6000.

2.1 Hydrogel Preparation

A total of 5 mL of bacterial cellulose (BC) 1000

solution was put into a glass beaker then added

10.75 mmol of Acrylate Acid monomer, 200 µmol

of initiator of Potassium Per Sulfate, then added

little by little 260 µmol N crosslinking, N'-

Methylene bisacrylamide. Then stir for 15 minutes

at 60

o

C. After the polymerization is complete, the

results of the spring JPI hydrogel are poured into a

test tube, then heated into the oven at 60

o

C for 2

hours. After that, the results of the hydrogel were

released and flowed with distilled water and then

stored in a desiccator for 3 days.

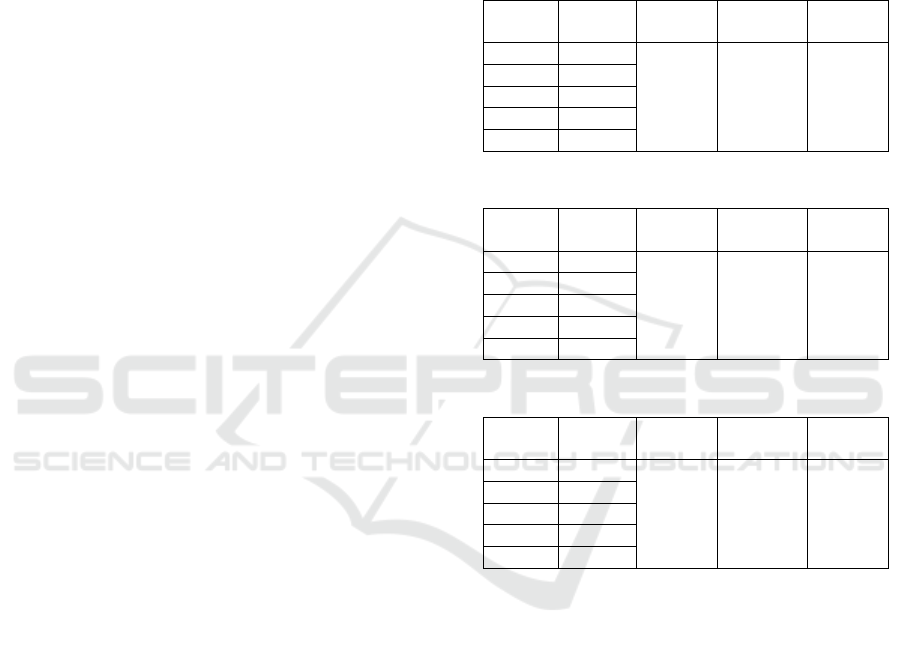

Table 1: Comparison of Additions of BC 1000.

Sample

BC

(g)

Aac

(mmol)

MBA

(umol)

KPS

(umol)

A

0.2

10.75

260

200

B

0.4

C

0.6

D

0.8

E

1.0

Table 2: Comparison of Additions of BC 3000.

Sample

BC

(g)

Aac

(mmol)

MBA

(umol)

KPS

(umol)

A

0.2

10.75

260

200

B

0.4

C

0.6

D

0.8

E

1.0

Table 3: Comparison of Additions of BC 6000.

Sample

BC

(g)

Aac

(mmol)

MBA

(umol)

KPS

(umol)

A

0.2

10.75

260

200

B

0.4

C

0.6

D

0.8

E

1.0

2.2 Test of Water Absorption

Testing of water absorption was carried out by

determining the percent swelling ratio by measuring

the initial weight (mo) of the sample which was then

immersed in distilled water for 24 hours. The

samples that have been soaked are then filtered

using filter paper and measured again heavily (me).

The amount of water absorbed in the hydrogel can

be calculated using the following equation:

E = (me-mo) / mox 100% (1)

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

330

2.3 Percentage Test of Crosslinks

The percentage of crosslinking was carried out by

determining the crosslink percent percent where the

dry weight of the resulting hydrogel was weighed.

Then the hydrogel is soaked with a solvent

(chloroform) for 24 hours. After immersion, the

hydrogel is heated at a temperature of 60

o

C to dry

for 3 hours. The dry weight of the hydrogel after

immersion is determined by weighing using an

analytical balance. The degree of crosslinking can be

determined by the following equation:

% DC = Wg / (Wo) x 100 (2)

Where Wg is the weight of the dry hydrogel after

immersion and Wo is the weight of the dry hydrogel

before immersion.

2.4 FTIR Analysis

The specimens are clamped at the place where the

sample is then placed on the tool in the direction of

infrared light. The results will be recorded on a

paper scale of the wave number curve to the beam

intensity in the form of a spectrum graph.

2.5 TGA Analysis

Weighed ± 10 mg of sample, then put into aluminum

cell then pressed. The pressed cell is placed in a

position adjacent to the reference cell. After the

instrument is in equilibrium, the analysis device is

operated with a temperature of 40ºC to 600ºC with a

speed of heating increase of 10ºC / minute and the

gas used is nitrogen. The results obtained are in the

form of graphs of% of mass lost to temperature.

3 RESULTS AND DISCUSSIONS

Making semi-JPI hydrogels was obtained through

free radical polymerization of acrylic acid

monomers (AA) in the presence of MBA

crosslinkers and dissolved cellulose polymers. The

polymer network formed consists of crosslinked

covalent poly (acrylic acid) chains that are

physically entangled with cellulose and parts of PEG

macromolecules. The illustration of making a semi-

JPI hydrogel is shown in Figure 3.1. The

crosslinking used in this study is N, N'-Metilen

Bisakrilamida (MBA) which reacts with carboxyl

functional groups in the polymer chain so that a

polymer network is formed as shown in Figure 1 and

2.

Figure 1: Manufacture of Semi-IPN Hydrogel.

Figure 2: Polylactic acrylic crosslinking process.

Figure 3 showed the final form of the semi-IPN

Hydrogel.

Figure 3: Semi-IPN hydrogel with the addition of KMS as

much as (a) 0.2 g (b) 0.4 g (c) 0.6 g (d) 0.8 g (e) 1.0 g for

polyetilen glycol 6000.

Optimization of Polymer Networks using Variations in Moleculer Weight of Polyetilen Glycol in the Manufacture of Semi – IPN Hidrogels

from Coconut Water Cellulose Bacteria

331

The percent value of cellulose hydrogel swelling

ratio can be seen in Table 4

Table 4: Percentage of Semi-IPN Hydrogel Swelling Ratio

Data.

Weight

KMS

(g)

Initial

Weight

(g)

Final

Weight

(g)

Swelling

(%)

0.2

0.83

4.00

382

0.4

0.83

5.40

551

0.6

0.98

6.51

564

0.8

0.83

6.50

683

1.0

0.71

5.05

611

Based on Table 4, it is seen that the percent value

of the swelling ratio increases with increasing KMS

weight. This is because the amount of weight of

KMS in the polymerization mixture affects the

percent value of the swelling ratio in the hydrogel.

The more the number of KMS, the -OH group

group also increases, causing high hydrophilicity.

Therefore, the water in the hydrogel increases.

However, at the addition of 1.0 grams of KMS, the

percent swelling ratio decreases again, this is due to

the optimum physical interaction which causes the

diffusion of water in the hydrogel to decrease,

according to Bajpai's research (2014) that cellulose

hydrogels can absorb water due to the presence of -

OH group of cellulose.

Data determination of the degree of crosslinking

can be seen in Table 5.

Table 5: Data on the degree of crosslinking of Semi-JPI

Hydrogels.

Weight

KMS

(g)

Initial

Weight

(g)

Final

Weight

(g)

Crosslink

(%)

0.2

0.55

0.18

32.70

0.4

0.71

0.25

35.21

0.6

0.54

0.20

37.03

0.8

1.37

0.58

42.30

1.0

1.57

0.61

38.80

Based on Table 5, it can be seen that the percent

degree of crosslinking increases with the increase in

the number of KMS used. This is because the more

number of KMS used, the hydrogel will be more

dense but still elastic. Cross ties play an important

role in determining elasticity. The expected network

is the formation of chains as long as possible and

cross-bound only in a few places. On the addition of

KMS 1.0 gram percent crosslinking degree has

decreased. This is due to physical interactions or the

formation of hydrogen bonds between hydrogen

groups from KMS with hydrogen bonds from acrylic

acid, these bonds are like hydrogen bridges or

vanderwalls thus increasing the limited elasticity

properties. In this case the physical bond that occurs

has been optimum and so there is a decrease in

mechanical properties (addition of 1.0 gram KMS)

as shown in table 5. This decrease is due to the

occurrence of equilibrium so that the addition of

KMS can reduce mechanical properties due to

irregular polymer chain chains.

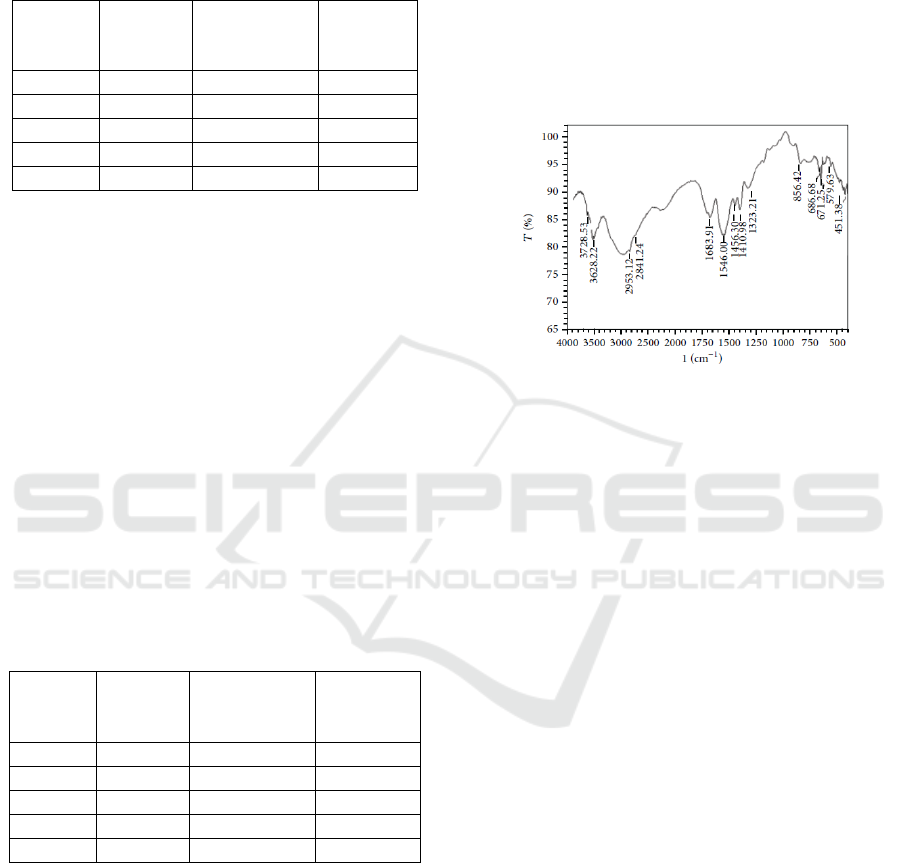

Figure 4: Commercial and Semi-IPN Hydrogel KMS

Spectrum.

In the FTIR spectrum of commercial

carboxymethyl cellulose it was seen that the

absorption area of 1635 cm

-1

and 1427 cm

-1

showed

the presence of COO-carboxyl strain vibrations and

CH2 bonds originating from the ester group. This

shows the characteristic of carboxymethyl cellulose

compounds containing carboxyl groups as a

substitution between monochloro acetate and

cellulose compounds. So based on the results of the

FTIR analysis it can be concluded that true

commercial carboxymethyl cellulose is a

carboxymethyl cellulose compound.

In the FTIR spectrum of Semi-JPI Cellulose

Hydrogel it was seen that the absorption area at

wave number 1403 cm

-1

and 1560 cm

-1

showed

stretching by Karaaslan simetry and asymmetry of

carboxylic anions (2001). In the absorption area with

wave numbers 1636 cm

-1

and 2110 cm

-1

, the

presence of C = C and CH2 groups originating from

crosslinking. OH wave number 3600 cm

-1

to 2400

cm

-1

is OH group carboxylic acid, and OH group

absorption alcohol about 3400 cm

-1

(Sadeghi and

Yarahmadi, 2011). So that the absorption of the OH

group carboxylic acid covers uptake of OH KMS

groups and OH groups from PEG 1000 and NH

amide groups from the MBA.

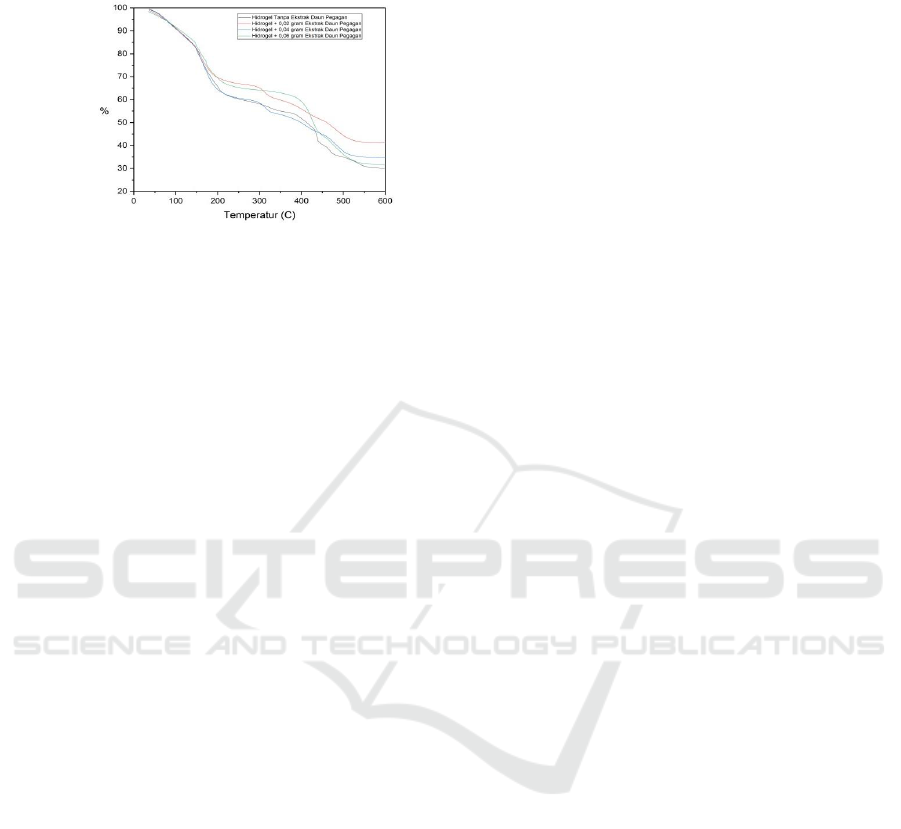

DTA is used to study thermal properties and

phase changes due to enthalpy changes of a material.

DTA analysis has been performed on the optimum

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

332

semi-JPI Hydrogel sample which can be seen in

Figure 5.

Figure 5: DTA results from optimum Semi-IPN

Hydrogels.

In Figure 5 shows the thermogram of DTA for

semi-JPI hydrogels with the addition of 0.8 grams

of KMS. DTA analysis is carried out at a

temperature of 20-650

o

C. The endothermic reaction

occurs at 120

o

C, the first exothermic point occurs at

380

o

C, and the second exothermic point occurs at

650

o

C which shows that the hydrogel has

completely degraded. Hydrogel with the addition of

0.8 gram KMS has the highest thermal stability

(optimum) this is directly proportional to the

crosslinking degree of the hydrogel, where the

higher the percent degree of crosslinking the

hydrogel has a high thermal resistance as well.

According to Bajpai (2014), hydrogels at

temperatures below 350

o

C of water molecules

bound to the polar group are released, and

decarboxylation of COO groups associated with

Poly (Sodium Acrylate) occurs. When the

temperature is above 350-433

o

C, the number of

PEG is low. At temperatures of 415-510

o

C, the loss

of CO and CO

2

groups with a small amount of each

other overlap. In the end, slowly and gradually at

temperatures above 510

o

C carbonization or

degradation of the process into ash.

4 CONCLUSIONS

1. The optimum mixture concentration in making

semi-JPI hydrogels between KMS and Acrylate

Acid in the presence of crosslinking N, N-

Methylene Bisacrylamide and initiator of

Potassium Per Sulphate is in comparison of

KMS: KPS: MBA (0.8: 0.05: 0.041 b / b) where

as much as 0.8 gram KMS is dissolved into the

PEG 1000 / NaOH solvent system which is then

added to 0.05 grams of KPS initiator and 0.041

grams of the MBA crosslinker.

2. Effect of variation molecular polyetylen glycoln

weight 1000; 3000 and 6000 on manufacture

semi interpenetrating polymer networks

hydrogel from bacterial cellulose with

fermentation systems using accetobacterial-

xylinum in based coconut water. IPN hydrogel

by polyethylene glycol 6000 has more croslinks

compared to peg 3000 and peg 1000. Analysis

of IPN thermal hydrogel using peg 6000 is

457.14

o

C, compared to PEG 3000 is 252, 80

o

C

and PEG 1000 is 249.30

o

C. Semi-IPN hydrogel

formed was characterized by, crosslink

percentage, chemistry structural analysis using

Fourier Transform Infrared (FT-IR)

spectroscopy, water absorption test and thermal

resistance using Differential Thermal Analysis

(DTA). From the analysis, they showed the

highest Semi Interpenetrating Polymer Network

Hydrogel with polyethylene glycol 6000

crosslink percentage (64.3%) for crosslink

polyethylene glycol 3000 is 42.5% and

polyethylene glycol 1000 is 15. 7%.

Characterization results of FTIR indicate the

occurrence of crosslinking between Polyacrylic

acid and MBA. This is shown in existence of

1403 cm-1 and 1560 cm

-1

(COO-) and 3413 cm

-

1

(NH amine). Thermal analysis using

Differential Thermal Analysis (DTA) shows

that it was completely degraded at 680

o

C, the

reaction that occurs during the decomposition of

the process is endothermic and exothermic

reaction.

REFERENCES

Lee, J. 2009. Current Situation and Aplication Of Medical

Polymeric Materials.

http://polymerization.asia/articles.

Rimmer, S. 2011. Biochemistry, Manufacture and Medical

Applications. Biomedical Hydrogels. UK: Woodhead

Publishing

Zhao, S., Cao, M., Li, H., Xu, W. 2009. Synthesis and

Characterization Of Thermo-Sensitive Semi-IPN

Hydrogels Based On Poly (erhylene glycol) – co –

poly (Ɛ-caprolactore) macromer, N-

isopropylacrulamide, and Sodium Alginate.

Carbohydrate Research 345 (2010): 425-431

Heibesh, A., S, Farag., S, Sharaf., Th, I. Shaheen. 2013.

Thermal Responsive Hydrogels Based On Semi

Interpenetrating Network Of Poly (NIPAm) and

Cellulose Naniwhiskers. Carbohydrate Polymers. 102

(2014) 159-166

Bajpai, S. K. 2014. New Semi-IPN Hydrogels Based on

Cellulose for Biomedical Application. Journal Of

Polymer. India: Hindawi Publishing Coorporation

Optimization of Polymer Networks using Variations in Moleculer Weight of Polyetilen Glycol in the Manufacture of Semi – IPN Hidrogels

from Coconut Water Cellulose Bacteria

333

Karaaslan MA, Tshabalala MA and Buschle-Diller G,

2010. Wood Hemicellulose / Chitosan – Based – Semi

– Interpenetrating Network Hydrogels: Mechanical,

Swelling, and Controlled Drug Release Properties.

BioResource 5 (2): 1036-1054Kirk Othmer. 2001.

Encyclopedia Of Chemical Technology.John Willey &

Sons.

Sadeghi M dan Yarahmadi M, 2011. Synthesis and

characterization of superabsorbent hydrogel based on

chitosan-g-poly (acrylic acid-co-acrylonitrile). African

Journal of Biotechnology, 12265-12275.

ICOCSTI 2019 - International Conference on Chemical Science and Technology Innovation

334