Global Warming, Energy Conservation, Competence based Training

and Competency Certification of Energy Auditor

Sunyoto

1

, Robinson Situmorang

2

, Etin Sulihati

2

1

PhD Student of Technology Education Department, Universitas Negeri Jakarta Indonesia, Jl. Rawamangun Muka Pulo

Gadung, Jakarta Timur, Daerah Khusus Ibu Kota Jakarta 13220, Indonesia.

2

Technology Education Department, Universitas Negeri Jakarta, Jl. Rawamangun Muka Pulo Gadung, Jakarta Timur,

Daerah Khusus Ibu Kota Jakarta 13220, Indonesia

Keywords: Global warming, energy conservation, energy management, energy auditor certification

Abstract: Global warming is a form of imbalance of the ecosystem on Earth due to the onset of the process of increasing

the average temperature of the atmosphere, oceans, and landmasses on Earth. Increasing the average

temperature of the Earth's surface that occurs is due to increasing emissions of greenhouse gases, such as;

carbon dioxide (CO2), methane (CH4), dinitro oxide (NO2), hydrofluorocarbons (HFCS), perfluorocarbon

(PFCS), and sulfur hexafluoride (SF6) in the atmosphere. These emissions are primarily generated from the

combustion of fossil fuels (oil and coal) as well as due to the deforestation and the burning of forests. Sector

energy users is the sector that most of its contribution to greenhouse gas emissions. The use of renewable

energy and conservation mitigation is to reduce greenhouse gas emissions. Energy conservation is one of the

efforts the planned, systematic, and integrated in order to preserve domestic energy resources as well as

increase the efficiency of its utilization. Energy savings can lead to reduced costs, as well as increasing the

value of the environment, state security, personal security, as well as comfort. Efficiency of energy is

implemented through the energy audit. Cement industry as energy users more than 6000 TOE (ton oil

equivalent) appropriate to Government Regulation Permen ESDM No. 14/2012 about applying compulsory

energy management system by appointing managers, carry out energy audits energy at regular intervals,

implement the recommendations of the audit results, and reporting the implementation of the energy

conservation of energy every year. This audit should be done by a certified auditor. Energy Auditors for

certification in the cement industry is a competency-based training refers to the standard National Indonesia

Work Competence (SKKNI) and is certified by independent agencies, institutions of professional certification

(LSP) under the National Board certification of Professions (BNSP)

1 INTRODUCTION

Global warming is a form of imbalance of the

ecosystem on Earth due to the onset of the process of

increasing the average temperature of the atmosphere,

oceans, and landmasses on Earth. Increasing the

average temperature of the Earth's surface that occurs

is due to increasing emissions of greenhouse gases,

such as; carbon dioxide, methane,

hydrofluorocarbons, dinitro oxide, perfluorocarbon,

and sulfur hexafluoride in the atmosphere. These

emissions are primarily generated from the

combustion of fossil fuels (oil and coal) as well as due

to the deforestation and the burning of forests.

The gas that is categorized as greenhouse gases

(GRK) are gases that effect directly or indirectly

against the greenhouse effect that is causing climate

change. In the UN Convention on climate change

(United Nations Framework Convention on Climate

Change-UNFCCC), there are six types of which are

classed as GRK namely carbon dioxide (CO2),

methane (CH4) gas, dinitrogen oxide (N2O), sulfur

hexafluoride (SF6), perfluorocarbon (PFCS) and

hydrofluorocarbons (HFCS). In addition there are

several gases which are also included in GRK i.e.

Sunyoto, ., Situmorang, R. and Sulihati, E.

Global Warming, Energy Conservation, Competence based Training and Competency Certification of Energy Auditor.

DOI: 10.5220/0009034706270635

In Proceedings of the International Conference on Education, Language and Society (ICELS 2019), pages 627-635

ISBN: 978-989-758-405-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

627

carbonmonoxy (CO), nitrogen oxides (NOX),

chlorofluorocarbons (CFCS), and organic gases in

nonvolatile metal.

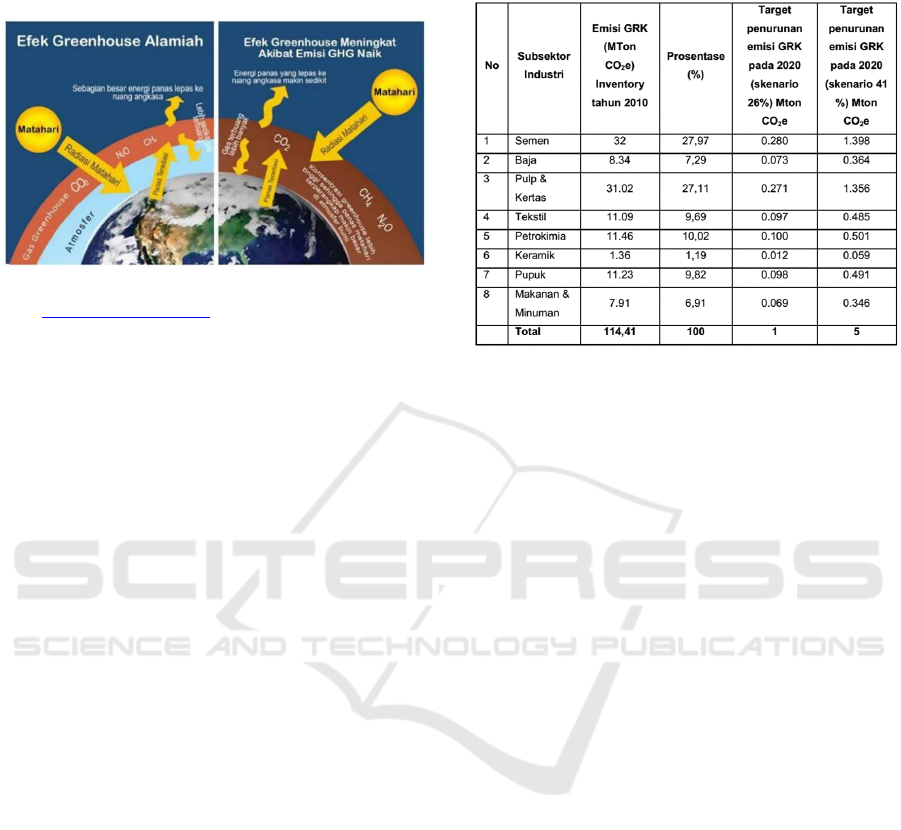

Figure 1: mechanism of effek greenhouse gases (modified

from http://i.livescience.com)

Greenhouse gases are expressed most contribute

to the symptoms of global warming are CO2, CH4,

N2O, NOX, CO, PFC and SF6. However, for

Indonesia two gas called the last emissions are still

very small, so it is not taken into account. Of the six

greenhouse gases, carbon dioxide (CO2) is the largest

contributing towards global warming followed by

methane gas (CH4). More than 75% of the

composition of the atmosphere is CO2 in GRK so if

CO2 contribution from various activities can be

reduced significantly then there are chances that the

impact of global warming on climate change will be

reduced. Total emissions in Indonesia GRK from all

sectors in the year 2000 amounted to 1,377,982 Gg

CO2e and industrial sector contributed amounted to

3.12%. To reduce the negative effects of the

phenomenon of climate change, need to be calculated

the amount of emissions from industrial activity

greenhouse gases. Therefore, compiled technical

guide to assist stakeholders in the calculation of the

emission of greenhouse gases.

All sectors of the industry contributes to the

emission of GRK, but the biggest contributor is the

cement industry, steel industry, pulp paper, textile

industries &, petrochemical industry, fertilizer

industry, ceramic industry, food and beverage

industry. Based on the presidential Regulation No. 61

year 2011 National action plan of Decreasing

Greenhouse Gas emissions (RAN-GRK) target a

decrease in emissions from industrial sectors was of

0.001 Gton CO2e scenario (26%) and of 0.00510

Gton CO2e scenario (41%) in the year 2020. The

results of the inventory of GRK conducted in 2010

shows that emissions GRK in 8 (eight) subsector of

the industry heartily energy is as described in table 1.

Table 1. The contribution of Emissions from the industrial

sector GRK

Source: Study of the development of policies and Strategies

of energy conservation, BAPPENAS 2010

Global warming is a form of imbalance of the

ecosystem on Earth due to the onset of the process of

increasing the average temperature of the atmosphere,

oceans, and landmasses on Earth. Increasing the

average temperature of the Earth's surface that occurs

is due to increasing emissions of greenhouse gases,

such as; carbon dioxide (CO2), methane (CH4),

dinitro oxide (NO2), hydrofluorocarbons (HFCS),

perfluorocarbon (PFCS), and sulfur hexafluoride

(SF6) in the atmosphere. These emissions are

primarily generated from the combustion of fossil

fuels (oil and coal) as well as due to the deforestation

and the burning of forests

2 RESEARCH METHODS

This research aims to develop Technical Guidance

Instructional model of energy Audit to get a

Certification of competence of the profession in the

cement industry is expected to increase the

effectiveness of learning. Instructional model that

will be developed in this research is the ability to

solve problems in the workplace especially in the

aspect of knowledge in the implementation of the

activities of the energy audit. Research and

development (R&D) is a research method that is used

to produce a particular product, and test the

effectiveness of these products. As expressed by Gall,

Gall & Borg in his book “An Introduction

Educational Research 4th Edition, (2003)”. that

research and development in education is an industry-

based model of development where research findings

ICELS 2019 - International Conference on Education, Language, and Society

628

used to design new products and procedures, which

are then systematically tested in field, evaluated, and

enhanced to meet certain criteria, namely

effectiveness and quality. According to Borg and

Gall., "educational research and development

approaches is used to develop and validate

educational product", or it can mean that the research

is the development of education is a process used to

develop and validate product education. The result of

the research of the development of not only the

development of an existing products but also to find

the answers to the knowledge or practical problems.

Based on the above definition, it is understood that

development research is a move to develop a new

product or refining existing products and

effectiveness test, as well as the longitudinal nature of

the gradual or can multi-years.

Furthermore, the Borg and Gall. Describes four

main characteristics in research and development,

namely: 1) Wadi research findings pertinent to the

product to be develop, which means, doing the initial

research study or to find research findings related to

the product will be developed. 2) Developing the

product base on these findings, that is to say,

developing products based on the findings of such

research. 3.) Field testing it in the setting where it will

eventually be used to mean, he did field test in the

setting or actual situation where the products were

later used, 4.) Revising it to correct the deficiencies

found in the field-testing stage, that is to say, did the

revision to correct the weaknesses found in the stages

of field test. Of the four main characteristics of the

R&D, giving an overview of the key features that

R&D is the initial research steps related to the

products that will be developed. Based on the results

of research education and training products are

designed and developed to test and then

repaired/revised.

In the early research, researchers tried to find out

whether there is any energy conservation is concerned

with competency-based training (CBT) in the cement

industry for the energy auditor must be developed.

Technical Guidance Training on energy Auditor in

the cement industry is necessary in order to certify the

energy auditor competencies to meet the mandate of

Government Regulation and applicable legislation

3 THEORETICAL STUDIES

The notion of global warming is the process of

increasing the average temperature of the Earth, be it

on a layer of the atmosphere, land, and sea. Global

warming is closely associated with the air pollution

around the world. The increasing amount of carbon

dioxide, the greenhouse effect, gas resulting from

combustion of fossil fuels, and other human activities,

is the main source of the onset of global warming for

years. Based on the results of research experts

mentioned that the Earth's temperature has increased

drastically during the last century, that is, achieving

0.6 ° c. It might look small, but the impact of global

warming is so great for life on Earth.

(https://www.maxmanroe.com/vid/umum/

pengertian-pemanasan-global.html).

Furthermore, https://helpsavenature.com/what-

causes-global-warming says: “Global warming is

basically a change in the climatic conditions of the

Earth, brought about by a considerable rise in the

near-surface temperature of the planet…..Global

warming, and the resulting climate change, can be

caused by natural as well as man-made factors

(anthropogenic factors, to be precise). The natural

factors causing this are sudden warming of the planet

include the greenhouse effect, solar activity, volcanic

emissions, orbital forcing (slow tilting of the Earth's

axis), etc. The anthropogenic causes, on the other

hand, include various human activities - right from

breathing (respiration), to the use of vehicles and

various industrial processes, which add to the

greenhouse effect and cause the Earth to become

warm.”

In order to better understand what is global

warming, then we can refer to the opinion of some

experts, as follows: 1. According to The United States

Environmental Protection Agency (USEPA) United

States Environmental Protection Agency, the notion

of global warming is the increase in the average

temperature at the Earth's surface, either elapsed or is

going on at the moment. The greenhouse effect is the

cause of global warming that is causing most of the

necessary changes in climate. 2. New According to

the New Mexico solar energy Association, United

States the notion of global warming is the increase in

the temperature or the temperature average in the

Earth's surface as the impact of the greenhouse effect.

The greenhouse effect is a heat trapped events on

earth because it is hindered by such emissions carbon

dioxide gas (smoke motor vehicles, factories or

industries, forest fires) in the atmosphere. 3.

According to Natural Resources Defence Council

(NRDC), global warming is the process of increasing

air temperature due to heat trapped in the atmosphere

by carbon dioxide gas which could threaten the

climate changes and it may cause a disaster on the

surface of the Earth. The NRDC said the global

warming is the biggest humanitarian and

environmental crisis that is happening at the moment.

Global Warming, Energy Conservation, Competence based Training and Competency Certification of Energy Auditor

629

4. According to the National Wildlife Federation,

global warming is the increase in temperatures on

Earth resulting in the occurrence of various natural

disasters, such as storms, droughts, floods, and others.

Global warming also resulted in changes to the

landscape of life on Earth and killing many species.

Global warming is happening because of human

lifestyles, consumption patterns, and existing

technologies in various developed countries. Some

developed countries are the biggest contributor to

global warming is for example the United States,

China, Russia, the United Kingdom, and other

countries.

In the schematic, using a mind map Dr. Jane

Genovese (https://www.learningfunda-mentals.com/)

as shown in the picture below shows the impact of

global warming:

Figure 2: the impact of global warming source: Dr. Jane

Genovese "Global Warming Mindmap",

https://www.learningfundamentals.com/

Refer to understanding global warming above, the

following are some of the efforts to minimize: 1.

Reduce the use of motor vehicles. Motor vehicles

have become the current human needs as a means of

transportation. However, we often forget that the

fumes of motor vehicles accounted for CO2 that

results in global warming to prevent global warming,

we can reduce the use of private vehicles and use

mass transit. So, air pollution will be reduced and can

help tackle global warming. 2. Maintaining the

sustainability of nature. Excessive exploitation of the

natural results more detrimental than beneficial for

the long term. Felling and burning of forests to open

land was supposed to be controlled or stopped.

Replant trees in burned or trees that have been cut

down is a real step can be done to tackle global

warming. 3. Controlling electricity use. Excessive use

of electricity can also cause global warming. This

impressed very trivial but their impact is enormous.

Lights and electrical equipment can be issued.

Imagine how much heat is being issued when all

humans on earth use electricity in excess. In addition

to help cope with global warming, by controlling the

power consumption then we will be more energy

efficient and cost effective. 4. Control of the waste.

Waste can be pulled out harmful gases into the air.

These harmful gases in addition to cause a foul smell,

can also cause a greenhouse effect which causes solar

heat trapped in the Earth's surface. By controlling

waste, household waste is good as well as industrial

waste, then this can help address global warming. 5.

Energy conservation is defined as the systematic,

well-planned effort, and integrated in order to

preserve domestic energy resources as well as

increase the efficiency of its utilization. Energy-

saving or energy conservation is the act of reducing

the amount of energy use. Energy savings can be

achieved by efficient energy use where similar

benefits are obtained by using less energy, or by

reducing consumption and activities that use energy.

Energy savings can lead to reduced costs, as well as

increasing the value of the environment, State

security, personal security, as well as comfort.

Efficiency of energy is implemented through the

energy audit.

Mindmap of Dr. Jane Genovese

(https://www.learningfundamentals.com/) as shown

in the picture below shows one of the ways in

reducing the impact of global warming is through an

energy audit in order to achieved efficiency energy

use:

Figure 3: Efforts to combat the effects of global warming

source: Dr. Jane Genovese "Global Warming Mindmap",

https://www.learningfundamentals.com/

Two of Dr. Jane Genovese mind maps can be

made a thorough overview of the impacts of global

warming, and solving global warming as seen in the

picture below (Figure 4) shows one of the ways in

ICELS 2019 - International Conference on Education, Language, and Society

630

reducing the impact of global warming is through

energy saving. In the cement industry, energy saving

can be done through diversification of energy and

conservation of energy. Both, good diversification of

energy and conservation of energy can be done

through energy management. One of the important

parts in the management of energy is an energy audit.

This energy audit was carried out in order to make use

of its energy efficiency can be achieved.

Cement industry as energy users more than 6000

TOE (ton oil equivalent) appropriate to Government

Regulation PerMen ESDM No. 14/2012 about

applying compulsory energy management energy

management system by appointing managers, carry

out energy audits energy at regular intervals,

implement the recommendations of the audit results,

and reporting the implementation of the energy

conservation of energy every year. This audit should

be done by a certified auditor. Energy Auditors for

certification in the cement industry is a competency-

based training refers to the standard National

Indonesia Work Competence (SKKNI) and is

certified by independent agencies, institutions of

professional certification (LSP) under the National

Board Certification of Professions (BNSP)

Figure 4: Mind map of the effects of global warming (global

warming cause-impact) and attempt to solve it (the global

solving energy) modification of Dr. Jane Genovese "Global

Warming Mindmap",

https://www.learningfundamentals.com/

4 RESULT AND DISCUSSION

Activity in producing a product in the cement

industry cannot be detached from the enormity of the

use of electrical energy and heat energy. The increase

in the price of energy is derived from fossil that

continue to occur will have a direct impact on the

soaring cost of production, especially the production

of cement requires high energy costs, which typically

reach 30-40% of the cost of production, excluding the

cost of the investment. Often found some cases that

the intensity of use of electrical energy and heat

energy is high, then it can add to the amount of

emissions from the production process. This of course

being the spotlight with increasingly tight and high

pressure for industry to increasingly care about

environmental sustainability. In order to this, Algore

in his book ““Our choice, a Plan to Solve the Climate

Crisis” (2009) environmental sustainability. former

45

th

Vice President of the United States mentions:

“Global population is still growing, but expected to

plateau at slightly more than nine billion people

halfway through the 21st century. However, even as

human population stabilizes, greenhouse gas

emission rates are increasing. Annual carbon

emissions have quadrupled since 1950, and their rate

of growth sharply increased between 2000 and 2008.

Many scientists say that CO2 concentrations must be

stabilized at 350 parts per million in the atmosphere,

which would require a real reduction from the present

concentration”, reaffirms how serious a problem

global warming if not handled properly

With the issue of energy costs and the impact on

global warming due to industrial exhaust gas

produced, then it is important to implement energy

management system. With the implementation of the

energy management system, the energy efficiency

efforts can be optimal to fruition. In applying this

system must be supported by all elements of the

Organization, from each of these elements should be

concerned and contributing as well as in achieving the

success of an energy management.

Energy management is an integrated program that

is planned and carried out systematically to utilize

energy resources and energy effectively and

efficiently by conducting planning, record keeping,

monitoring and continuous evaluation without

reducing the quality of the production/service.

Pencakup energy management planning and

operation of unit consumption and production related

to energy. Energy management objectives, namely

the conservation of resources, climate protection, and

cost savings. Next to running an energy management

the needed preliminary data from all the instruments

involved in the use of energy. To get the data then

required the existence of an energy Audit.

Energy management is an integrated program that

is planned and carried out systematically to utilize

energy resources and energy effectively and

efficiently by conducting planning, record keeping,

monitoring and continuous evaluation without

Global Warming, Energy Conservation, Competence based Training and Competency Certification of Energy Auditor

631

reducing the quality of the production/service. Energy

management encompasses the planning and operation

of unit consumption and production related to energy.

Energy management objectives, namely the

conservation of resources, climate protection, and

cost savings. Next to running an energy management

the needed preliminary data from all the instruments

involved in the use of energy. To get the data then

required the existence of an energy audit.

In addition, the Government Regulation through

PerMen ESDM No. 14/2012 about energy

management that set the industry with energy use

more than 6000 TOE (ton oil equivalent) is required

to apply energy management systems and industrial

energy use is less than 6000 TOE (ton oil equivalent)

in order to implement energy management systems or

energy savings. The setting of limits on numbers

6,000 (six thousand) was done based on the

consideration that the user with the consumption of

energy is greater than or equal to 6,000 (six thousand)

tons of oil equivalent per year is not too much, but the

total energy consumption reached about 60% of the

national energy usage.

Energy conservation measures undertaken with

energy management, namely with: a) appoints

Manager of energy; b) devised a program of energy

conservation; c) implementing energy audits at

regular intervals; d) implement the recommendations

of the energy audit results; and e) report on the

implementation of the energy conservation each year

to the Minister, Governors, or Bupati/Walikota in

accordance with its respective

An energy audit is a process evaluation of the

users of energy and energy saving opportunities

identification as well as recommendations for

increased efficiency in a company. While the

meaning of the word Audit itself in broader sense

meaningful evaluation of an organization, system,

process, or product. The audit was carried out by a

competent, objective, and impartial, which is called

an auditor. The goal is to verify that the subject of the

audit have been resolved or walking in accordance

with standards, regulations, and practices that have

been approved and received.

Energy-saving or energy conservation is the Act

of reducing the amount of energy use. Energy savings

can be achieved by efficient energy use where similar

benefits are obtained by using less energy, or by

reducing consumption and activities that use energy.

Energy savings can lead to reduced costs, as well as

increasing the value of the environment, State

security, personal security, as well as comfor

Based on the source of the Head of the Center for

the Assessment of Green Industry and the

Environment of the Ministry of Industry.

Opportunities and Challenges of Energy

Conservation in the Cement Industry Sector are

Opportunities for Energy Conservation in the

Industrial Sector; The industrial potential that has to

do energy efficiency is quite high with the potential

for considerable savings because 1) Generally

companies need assistance for implementing energy

conservation, 2) The industry already knows the

government is promoting the development of green

industry, 3) Availability of energy efficiency and

business actors the existence of free energy audits

from the government, 4) Increased banking

knowledge and attention to the implementation of

energy efficiency businesses.

Challenges of Energy Conservation in the

Industrial Sector: 1) Not yet optimal implementation

of energy management, 2) Not enough number of

competent industrial human resources to carry out

systematic energy management, 3) Lack of

willingness; industry knowledge and capabilities

change business as usual, 4) lack of knowledge and

ability of service providers in carrying out energy

efficiency business from technical and financial

aspects, 4) lack of incentive mechanisms that directly

benefit energy efficiency actors, 5) lack of

understanding of the relationship between energy

efficiency efforts with reduced emissions in terms of

easy access to banking

While the barriers to the implementation of

energy conservation in the Industrial Sector are as

follows: 1) In general, the industry still does not care

about energy conservation, they are still reluctant to

conduct energy audits, unless the audit is free.

Besides the audited industry, if you have to replace

equipment, they are still reluctant to do it, because

they have to spend high investment costs. 2) The

industry is still not cultured to report its energy use to

the government and generally still considers all data

to be confidential; 3) Large industries, especially

those with export orientation, have competent experts

so that they are often unsure of the ability of local

auditors. 4) Integrity of local auditors is often not

proven by their competence, especially in the ability

to manage confidentiality data. 5) Inability of

industrial HR to distinguish confidential data / not

confidential, so it is considered all the secrets, 6) The

energy management capability in the industry is very

low, the number of new energy managers is around

25% -30% of what is needed; 7) Lack of industry

appreciation for implementing energy management.

Only 40% of companies in the cement sector carry out

energy conservation; 8) Plan-Do-Check-Action in

Industry according to the Energy Management

ICELS 2019 - International Conference on Education, Language, and Society

632

System Standard ISO 50001: 2011 has not been

running optimally; 9) The main orientation of the

industry is still productivity and quality; 10) The price

of technology is still expensive, there has been no

significant government assistance; 11) The

implementation of a monitoring system in the

framework of energy audits has not been optimal.

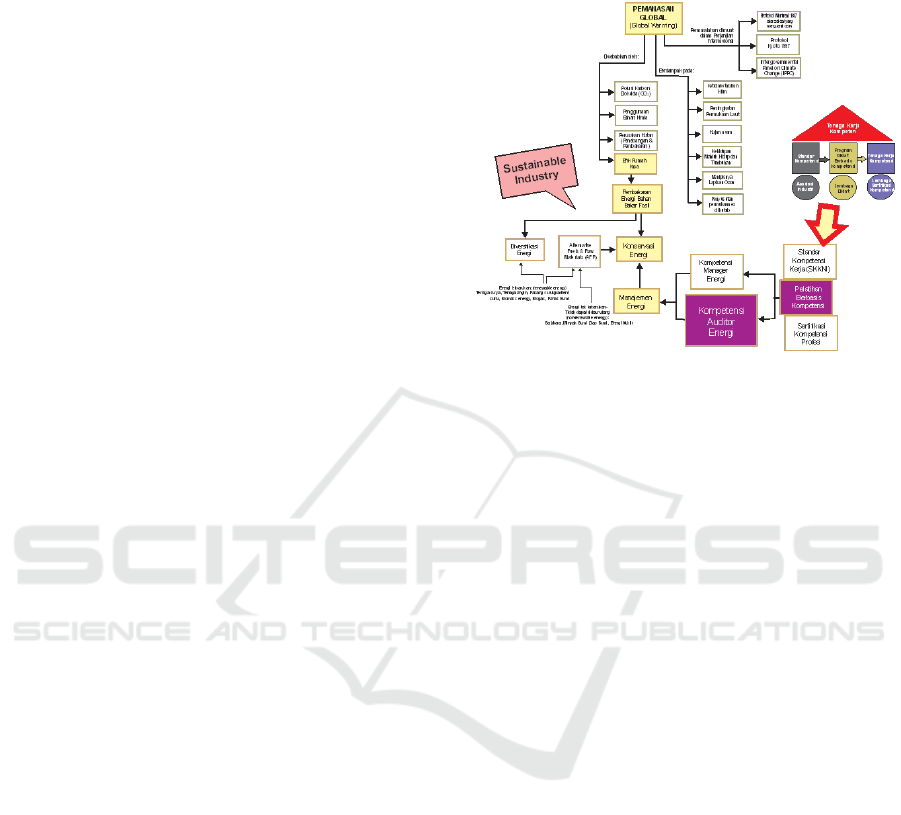

The scheme of global warming and energy

conservation in the industry and its relation to the 3

(three) pillars of professional competency

certification in the chart below (figure 3) refer to mind

map Dr. Jane Genovese "Global Warming Mind

map", shows how the effects of global warming occur

and how the cement industry tries to overcome them

with energy conservation efforts where an energy

audit is needed. For energy audits, auditors are

required to be certified. This Energy Auditor

Certification is related to 3 pillars of HR

development, SKKNI / KKNI, Competency-Based

Training, and Competency Certification from the

Government cq the Ministry of Manpower and

Transmigration of the Republic of Indonesia.

The scheme of global warming and energy

conservation in the industry shows that global

warming is characterized by, among other things, the

depletion of the ozone layer, and the greenhouse

effect. Global warming has triggered a number of

adverse consequences for both the environment and

every aspect of human life. Some of them are as

follows: 1. Melting of the ice sheet at the North and

South Poles. 2. Increased intensity of extreme

weather phenomena. 3. Extinction of various types of

fauna. 4. Animal habitat changes due to changes in

temperature, humidity and primary productivity

factors 5. Increased sea level, tide and erratic rainy

season causes increased frequency and intensity of

flooding. 6. The height of high mountains decreases

due to melting ice at its peak. 7. Changes in air

pressure, temperature, wind speed and direction cause

changes in ocean currents. This can have an effect on

fish migration, so that it has an impact on capture

fisheries. 8. Changing habitat 9. Threatening damage

to coral reefs in the coral triangle area in six countries,

namely Indonesia, Malaysia, Salomon Islands, Papua

New Guinea, Timor Leste, and the Philippines.

Minimizing the Impact of Global Warming,

among others by 1) environmental conservation, 2)

using energy sourced from alternative energy to

reduce energy use of fossil fuels (petroleum and coal),

recycling and energy efficiency.

The scheme of global warming and energy

conservation in the industry shows that Energy Audit

including the certification of professional

competence is an important part of the

implementation of Indonesia's energy conservation,

especially in the cement industry, where energy use is

more than 6000 TOE (ton oil equivalent).

Figure 5. The concept of energy conservation in industry

and three pillars of competence Certification

The cement industry as an energy user is more

than 6000 TOE (ton oil equivalent) according to the

Minister of Energy and Mineral Resources, NO.

14/2012 concerning energy management must

implement an energy management system by

appointing energy managers, carrying out periodic

energy audits, implementing recommendations from

energy audits, and reporting on the implementation of

energy conservation every year. This audit must be

carried out by a certified auditor.

For the certification of energy auditors in the

cement industry, it is needed competency-based

training that refers to the Indonesian National Work

Competency Standards (SKKNI) with a curriculum

that emphasizes what should be done by energy

auditors in the world of work after following the

technical guidance of the Energy Auditor (outcome)

and as representation is a shift from an emphasis on

entering the process into technical guidance (input).

Referring to the triangle of human resource

development with various competencies (Fig. 6), the

implementation of Competency Based Training

(PBK) for Technical Guidance for Energy Auditors in

Industry must meet the PBK component, namely:

Indonesian National Work Competency Standards

(SKKNI) and Indonesian National Work

Qualifications (KKNI)

Global Warming, Energy Conservation, Competence based Training and Competency Certification of Energy Auditor

633

Figure 6. Integration of Human Resource Development

Triangle competency-based

5 CONCLUSIONS

Global warming is a form of ecosystem imbalance on

earth due to the process of increasing the average

temperature of the atmosphere, sea, and land on earth.

The increase in the average temperature of the earth's

surface that occurs is due to increased greenhouse gas

emissions, such as; carbon dioxide, methane, dinitro

oxide, hydrofluorocarbons, perfluorocarbons, and

sulfur hexafluoride in the atmosphere. These

emissions are mainly generated from the process of

burning fossil fuels (petroleum and coal) as well as

due to deforestation and burning of forests. The

energy user sector is the sector with the largest

contribution to greenhouse gas emissions.

The use of renewable energy and conservation is

mitigation to reduce greenhouse gas emissions.

Energy conservation is one of the systematic, planned

and integrated efforts to conserve domestic energy

resources and improve the efficiency of their use.

Energy saving or energy conservation is an action to

reduce the amount of energy use. Energy savings can

be achieved by using energy efficiently where the

same benefits are obtained by using less energy, or by

reducing consumption and activities that use energy.

Energy savings can lead to reduced costs, as well

as increased environmental value, state security,

personal security, and comfort. This energy

efficiency is carried out through an energy audit. The

cement industry as an energy user is more than 6000

TOE (ton oil equivalent) according to the Minister of

Energy and Mineral Resources, No. 14/2012

concerning energy management must implement an

energy management system by appointing energy

managers, carrying out periodic energy audits,

implementing recommendations from energy audits,

and reporting on the implementation of energy

conservation every year.

This audit must be carried out by a certified

auditor. For the energy auditor certification in the

cement industry, it is needed competency-based

training that refers to the Indonesian National Work

Competency Standards (SKKNI) and is certified by

an independent institution, Professional Certification

Institution (LSP) under the National Professional

Certification Agency (BNSP)

REFERENCES

Al Gore, “Our choice, a Plan to Solve the Climate Crisis”

Published by ButtlerTanner & Dennis, Frome, London,

2009, hal.227

Aryanie Amellina, Enhancing Indonesia's Efforts in

Climate and Energy Policy, Indonesia Joint Crediting

Mechanism Secretariat, Climate Change Expert Group

(CCXG) Global Forum at OECD, ParisBreakout

Group B: Enhancing pre-2020 mitigation action in the

energy sector, 18 March 2015

Asosiasi Semen Indonesia, “Industri Semen di Indonesia,

Prospek dan Potensi industri Semen Indonesia 2010-

2015” hal. 7

Church, J. A. and N.J. White (2006), A 20th century

acceleration in global sea level rise, Geophysical

Research Letters, 33, L01602,

doi:10.1029/2005GL024826

Dr. Jane Genovese “Global Warming Mindmap”,

https://www.learningfundamentals.com/ Presentasi

Kepala Pusat Pengkajian Industri Hijau dan

Lingkungan Hidup Kementrian Perindustrian di

[31Workshop Bidang Teknik Asosiasi Semen

Indonesia, 22 Oktober 2012

International Finance Corporation, Improving Thermal

And Electric Energy Efficiency At Cement Plants:

International Best Practice, 2017. 2121 Pennsylvania

Avenue, N.W. Washington, D.C. 20433

IPCC Fifth Assessment Report, Summary for Policymakers

B.D. Santer et.al., “A search for human influences on

the thermal structure of the atmosphere,” Nature vol

382, 4 July 1996, 39-46

Gabriele C. Hegerl, “Detecting Greenhouse-Gas-Induced

Climate Change with an Optimal Fingerprint Method,”

Journal of Climate, v. 9, October 1996, 2281-2306

Ramaswamy V.et.al., “Anthropogenic and Natural

Influences in the Evolution of Lower Stratospheric

Cooling,” Science 311 (24 February 2006), 1138-1141

Santer B.D. et.al., “Contributions of Anthropogenic and

Natural Forcing to Recent Tropopause Height

Changes,” Science vol. 301 (25 July 2003), 479-483.

National Research Council (NRC), 2006. Surface

Temperature Reconstructions For the Last 2,000 Years.

National Academy Press, Washington, D.C.

ICELS 2019 - International Conference on Education, Language, and Society

634

The International Energy Agency (IEA), Energy Effisiensi

2017, Laporan Khusus: Effisiensi Energi di Indonesia,

2017

United Nations Industrial Development Organization,

Promoting industrial energy efficiency through system,

Indonesia Independent mid-term review, Vienna, 2016

http://earthobservatory.nasa.gov/Features/GlobalWarming/

page3.php (uploaded 17 Juli 2018)

https://www.ipcc.ch/pdf/assessment-

report/ar5/syr/AR5_SYR_FINAL_SPM.pdf (uploaded

27 Agustus 2018)

https://www.ncdc.noaa.gov/indicators/ (uploaded 11 Juli

2018)

http://www.cru.uea.ac.uk/cru/data/temperature (uploaded

20 Juli 2018)

http://data.giss.nasa.gov/gistemp (uploaded 11 Agustus

2018)

https://id.wikipedia.org/wiki/Pemanasan_global (uploaded

17 Juli 2018)

https://www.maxmanroe.com/vid/umum/pengertian-

pemanasan-global.html (uploaded 17 Agustus 2018)

Global Warming, Energy Conservation, Competence based Training and Competency Certification of Energy Auditor

635