Porous Concrete using White Cement as Binding Agent

Arusmalem Ginting

1

, Prasetya Adi

1

and Yosep Prasetyo

1

1

Department of Civil Engineering, Janabadra University, Yogyakarta, Indonesia

Keywords: Porous Concrete, White Cement, Compressive Strength, Porosity, Unit Weight.

Abstract: Porous concrete is made by mixing Portland cement, coarse aggregate, with or without fine aggregate,

additives, and water. Concrete that uses white or colored cement creates a highly contrasting visual and

enhances traffic safety. A study was carried out on porous concrete using white cement as a binding agent.

There are 6 types of gravel/cement ratio by mass used, namely 4, 4.5, 5, 5.5, 6, and 6.5. There are 2 types of

water/cement ratios used, namely 0.27 and 0.30. SicaCim concrete additives are used as chemical admixtures.

The total test specimens were 36 pieces, and 3 pieces for each variation. The results show that increasing

gravel / white cement ratio decreases compressive strength and increases porosity. Compressive strength of

wcr 0.27 is smaller than wcr 0.30. Porosity of porous concrete in general with a wcr of 0.27 is greater than a

wcr of 0.30. The effect of water cement ratio (wcr) and aggregate / white cement ratio is not too significant

on the unit weight of porous concrete.

1 INTRODUCTION

Building construction and pavement in urban areas

causes increase the impermeable areas so that surface

runoff cannot infiltrate into the ground and cause

flooding. The existing drainage system only floods

downstream so that the urban drainage system leads

to search for new technologies aimed at increasing

infiltration and reducing surface runoff.

Pervious concrete is concrete with a slump near

zero, uniform gradation, which is made by mixing

Portland cement, coarse aggregate, with or without

fine aggregate, additives, and water. Pervious

concrete has interconnected pores and water can pass

through it easily. Pervious concrete has porosity

between 15 to 35%, and compressive strength

between 2.8 to 28 MPa. Drainage levels vary

depending on aggregate size and density of the

mixture. Pervious concrete serves to reduce surface

runoff, improve surface runoff quality, refill

groundwater, and reduce the effects of urban heat

islands (ACI Committee 522, 2010).

Other names for pervious concrete are porous

concrete. Porous concrete can be used for parking

lots, driveways, sidewalks, and greenhouse floors

(NRMCA, 2004).

No-fines concrete pavement has several positive

aspects such as increased slip resistance and high

permeability but do not have the high strength

required for high traffic areas. No-fines concrete have

been shown to have properties suitable for use in low

volume traffic areas (Harber, 2005).

The strength of no-fines concrete is lower than

normal concrete, but it is sufficient for structural use.

Because of the high continuous void ratio, this

concrete has a high permeability (Abadjieva and

Sephiri, 1988).

Water cement ratio for pervious concrete between

0.27 to 0.30 including proper chemical admixtures.

The relation between water-cement ratio and

compressive strength is clearly seen in conventional

concrete, whereas in pervious concrete is not clear

because the total pore is more than the total paste

(Tennis et al., 2004).

Generally in pervious concrete, the mass ratio

between aggregate and cement is 4 to 4.5 (Tennis et

al., 2004), The greater the maximum aggregate size in

porous concrete, decreases the compressive strength

and increases porosity (Ginting, 2019).

For floors and walkways, decorative concrete can

be used completely or only for surfaces. Decorative

concrete floors made with white cement can be

specified as a substitute for top-grade coatings

because they are durable and attractive. For

transportation projects, concrete that uses white or

colored cement creates a highly contrasting visual and

enhances traffic safety (PCA, 2014).

16

Ginting, A., Adi, P. and Prasetyo, Y.

Porous Concrete using White Cement as Binding Agent.

DOI: 10.5220/0009200900160020

In Proceedings of the 2nd International Conference on Applied Science, Engineering and Social Sciences (ICASESS 2019), pages 16-20

ISBN: 978-989-758-452-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

White Portland cement is white hydraulic cement

and is produced by grinding white Portland cement

slag which is mainly calcium silicate and milled

together with additives in the form of one or more

crystalline forms of calcium sulfate compounds

(BSN, 2004).

White cement can be used to make

concrete because the compressive strength of

concrete produced is high enough (Temiz et al.,

2013). Fresh concrete slump using white cement is

greater than Portland cement type I. Initial setting

time and final setting time using white cement is

smaller than Portland cement type I . Compressive

strength using white cement is greater than Portland

cement type I at ages 1 and 28 days (Hamad, 1995).

Based on the description above, a study was

carried out on porous concrete using white cement as

a binding agent.

2 METHODOLOGY

The main material is white cement and gravel from

the river Progo, Yogyakarta, Indonesia. Gravel has a

maximum size of 40 mm. There are 6 types of weight

ratio of gravel/white cement, namely 4, 4.5, 5, 5.5, 6,

and 6.5. Water cement ratios (wcr) of 0.27 and 0.30

were used. The dosage of SicaCim Concrete

Additives as admixtures is 7.5 ml per kilogram of

white cement. The total cylinder specimens are 36

and 3 cylinders for each variation as shown in Table

1.

Some types of tests carried out include testing:

gravel, compressive strength, porosity, and unit

weight. The results of the gravel test are presented in

Table 2 and Figure 1.

The equipment used is: concrete mixer, concrete

compression machine, and falling head test apparatus.

Concrete cylinder mold diameter of 150 mm and

height of 300 mm. Concrete mixture is placed in 3

layers, each layer is consolidated with tamping rod 25

times, after consolidation is complete the surface of

the concrete is leveled, then the specimen mold is

sealed with plastic. Specimens removed from the

mold after 24 hours, then soaked in a soaking tub

filled with water of 25 ° C (BSN, 1990).

Concrete compressive strength testing refers to

(ASTM C 39, 2009). The testing procedure is as

follows:

1. Compression tests are carried out after the test

specimens have been removed from depository.

2. The moisture of the test specimen must remain

stable until the test is carried out.

3. Placing the specimen.

4. Apply the load continuously and without shock.

5. The load is applied increasing until it reaches the

maximum load and is stopped after the load has

decreased and the crack pattern is clearly visible.

6. The compressive strength of concrete is obtained

by dividing the maximum load by the average

cross-sectional area.

Table 1: Concrete cylinder specimens.

Gravel/White

Cement

Ratio

wcr

Numb.

Cylinder

Specimen

4.0

0.27 3

0.30 3

4.5

0.27 3

0.30 3

5.0

0.27 3

0.30 3

5.5

0.27 3

0.30 3

6.0

0.27 3

0.30 3

6.5

0.27 3

0.30 3

36

Table 2: Gravel test results.

Types of tests Unit Results

Water content % 1.48

Density (SSD) - 2.47

Absorption % 3.38

Unit weight gr/cm

3

1.71

Fineness modulus - 7.25

Abrasion % 43.70

Figure 1: Gradation of gravel.

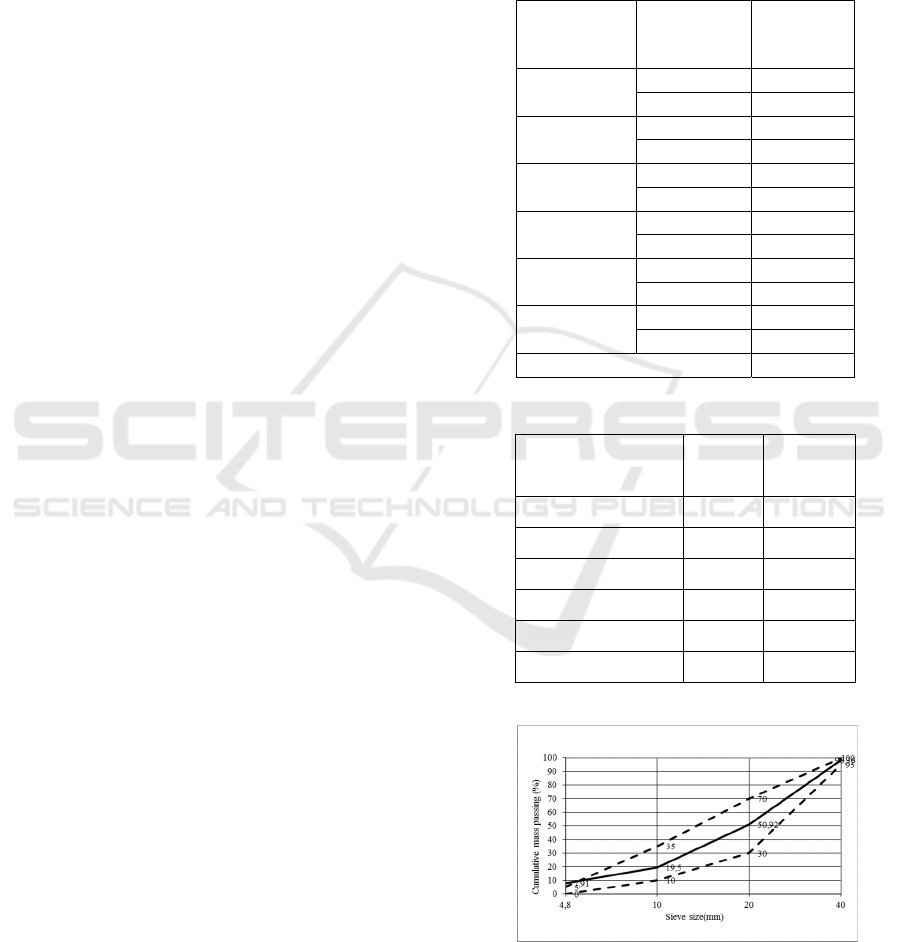

The porosity testing can be seen in Figure 2.

Porous Concrete using White Cement as Binding Agent

17

Figure 2: Porosity testing.

Testing porosity of concrete with falling head

method steps as follows:

1. At the bottom of the porosity test apparatus is

placed the concrete cylinder.

2. A pipe with a length of 1m is connected to the

bottom of the porosity test apparatus, so that

concrete cylinder is inside the pipe.

3. The drain pipe is closed, fill the water as high as a

concrete cylinder.

4. Water is added to the pipe up to 1 m, then open

the drain pipe.

5. Measured time for water to fall to 0.5 m.

6. The flow rate is obtained by dividing the volume

of water that reduces with time.

3 RESULTS AND DISCUSSION

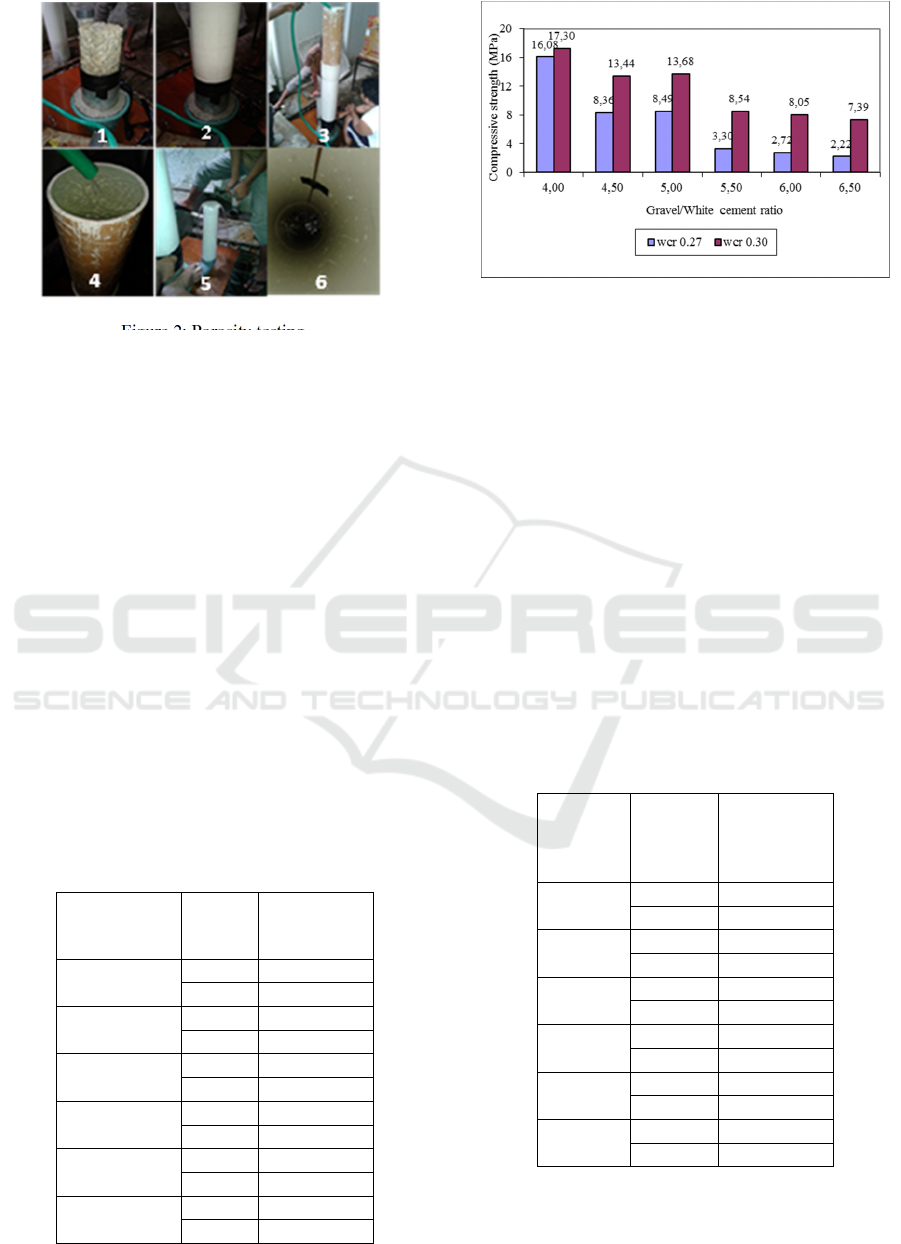

Compressive strength is shown in Table 3 and Figure

3.

Table 3: Compressive strength.

Ratio of

gravel / white

cement

wcr

Compressive

Strength

(MPa)

4.0

0.27

16.08

0.30

17.30

4.5

0.27

8.36

0.30

13.44

5.0

0.27

8.49

0.30

13.68

5.5

0.27

3.30

0.30

8.54

6.0

0.27

2.72

0.30

8.05

6.5

0.27

2.22

0.30

7.39

Figure 3: Compressive strength.

Table 3 and Figure 3 show that at the same water

cement ratio (wcr), compressive strength decreases

with increasing gravel/white cement ratio. This is

because the amount of white cement decreases with

increasing gravel/white cement ratio. The highest

compressive strength will occur at the maximum

amount of cement as long as the cement used has not

reached the optimum limit.

In all white gravel/cement ratios, compressive

strength of porous concrete with wcr 0.27 is smaller

than wcr 0.30, theoretically the highest compressive

strength will be obtained at the lowest wcr. At water

cement ratio (wcr) 0.27 compressive strength is

smaller than 0.30 due to the amount of water that is

too few so that the hydration process does not work

perfectly.

Porosity is shown in Table 4 and Figure 4.

Table 4: Porosity.

Ratio of

gravel /

white

cement

wcr

Flow rate

(lt/sec/m

2

)

4.0

0.27

25.25

0.30

18.23

4.5

0.27

44.27

0.30

18.03

5.0

0.27

43.55

0.30

38.27

5.5

0.27

74.82

0.30

44.26

6.0

0.27

71.57

0.30

52.82

6.5

0.27

69.87

0.30

78.01

ICASESS 2019 - International Conference on Applied Science, Engineering and Social Science

18

Figure 4: Porosity.

Table 4 and Figure 4 show that at the same water

cement ratio (wcr), in general an increase in the ratio

of gravel/white cement results in an increase in

porosity of porous concrete. This happens because the

greater the ratio of gravel/white cement results in less

amount of cement. A small amount of cement will

produce a small amount of paste, so that the cavity

covered by the paste is not too large so that the

porosity is still high.

In all gravel/white cement ratios, porosity of

porous concrete in general with a wcr of 0.27 is

greater than a wcr of 0.30. This happens because

porous concrete with wcr 0.27 is thicker than wcr

0.30. A mixture that is too liquid causes the cement

paste to flow to the bottom resulting in sedimentation

and a decrease in porosity.

Unit weight is shown in Table 5 and Figure 5.

Table 5: Unit weight.

Ratio of

gravel /

white

cement

wcr

Unit weight

(kg/m

3

)

4.0

0.27

2037

0.30

2018

4.5

0.27

1808

0.30

1746

5.0

0.27

1800

0.30

1997

5.5

0.27

1685

0.30

1870

6.0

0.27

1715

0.30

1713

6.5

0.27

1679

0.30

1773

Figure 5: Unit weight.

Table 5 and Figure 5 show that the unit weight

varies between 1679 to 2037 kg/m

3

. Porous concrete

has a lower unit weight and some are higher than

lightweight concrete in general, which is around 1800

kg / m

3

. The effect of water cement ratio (wcr) and

aggregate/white cement ratio is not too significant on

the unit weight of porous concrete.

4 CONCLUSION

From the study porous concrete using white cement

as binding agent be obtained that compressive

strength decreases with increasing gravel / white

cement ratio. At water cement ratio (wcr) 0.27

compressive strength is smaller than 0.30. Increase in

the ratio of gravel / white cement results in an increase

in porosity. In general, porosity with a wcr of 0.27 is

greater than a wcr of 0.30. The effect of water cement

ratio (wcr) and aggregate / white cement ratio to unit

weight is not too significant.

REFERENCES

Abadjieva, T., Sephiri, P., 1988. Investigations on Some

Properties of no-Fines Concrete, Private Bag 0061,

Department of Civil Engineering, University of

Botswan. Gaborone, Botswana.

ACI Committee 522, 2010. Report on Pervious Concrete

(ACI 522R-10). Farmington Hills, MI.

ASTM C 39, 2009. Standard Test Method for Compressive

Strength of Cylindrical Concrete Specimens, ASTM

International, West Conshohocken, PA, USA.

BSN, 1990. Metode pengujian kuat tekan beton, SNI 03-

1974-1990, National Standardization Agency of

Indonesia.

Porous Concrete using White Cement as Binding Agent

19

BSN, 2004. Semen Portland putih (White Portland cement),

SNI 15-0129-2004, National Standardization Agency

of Indonesia.

Ginting, A., 2019. Comparison of compressive strength and

porosity of porous concrete using the coarse

aggregates graded uniform with continuous gradient.

In: Journal of Physics: Conf. Series 1175. IOP

Publishing.

Hamad, B.S., 1995. Comparative studies of Type I and

White Portland cements. J. Adv. Cem. Based Mater.

Sci. Elsevier 2, 127–168.

Harber, P.J., 2005. Applicability of No-Fines Concrete as a

Road Pavement, Dissertation Bachelor of Engineering

(Civil). University of Southern Queensland.

NRMCA, 2004. “What, Why, and How? Pervious

Concrete,” Concrete in Practice series, CIP 38. Silver

Spring, Maryland.

PCA, 2014. WHAT IS WHITE CEMENT ? Portland Cement

Association, Old Orchard Road, Skokie, Illinois.

Temiz, H., Kose, M.M., Genc, H.M., 2013. Mechanical

Behavior of White Concrete. TEM J. 2, 73–79.

Tennis, P.D., Leming, M.L., Akers, D.J., 2004. Pervious

Concrete Pavements. Portland Cement Association,

Skokie, Illinois.

ICASESS 2019 - International Conference on Applied Science, Engineering and Social Science

20