Energy Productivity Ratio (EPR) in Producing Aren Sugar from Nira

Aren Tree: Traditional Processing

Bode Haryanto, Hendrik Khosman, Asmiah Hasibuan, Fenny Wijaya, Putri Herfayati

and Tubagus Rayyan F. Sinuhaji

Chemical Engineering Department Faculty Engineering, Universitas Sumatera Utara, Medan 20155, Indonesia

putriherfa@gmail.com, eaglefansrayyan@gmail.com

Keywords: Energy, Productivity, Palm-Sugar.

Abstract: A study on energy productivity ratio (EPR) in producing aren sugar (palm sugar) from nira solution of aren

trees is the result of this paper. This study was based on the energy ratio of the input energy in comparison to

the output energy in processing nira solution become palm sugar. Calculations were based on the data obtained

through literature survey of nira processing into palm sugar traditionally in many parts of village areas in

Indonesia. The major output energy was based on the palm sugar product compared to the input energy based

on all nira price, used energy, and depreciation of instruments used. The EPR result as palm sugar product is

> 3.0 for the utilization of nira solution from aren trees. The EPR result is positive information on the potential

to develop the product in factory scale. It is an indication that the palm sugar product from aren trees is an

energetically reasonable business enterprise based on EPR. The nira of aren tree has potential as raw material

in producing the sugar.

1 INTRODUCTION

Aren tree or sugar palm plant (Arrenga pinnata

Merr.) is a very potential plantation crop in terms of

overcoming food shortages and easily adapting to

various agro-climate, starting from lowland to 1,400

m above sea level. The main products of aren as the

result of nira tapping are palm sugar, beverage,

vinegar and alcohol. In addition, sugar palm plants

can be produced intofood products such as: kolang-

kaling from the ripe female fruit and sugar palm flour

for food ingredient in the form of cakes, breads, and

biscuits that come from processing the stem part of

the plant (Effendi, 2010).

Coconut nira is a part of coconut plant that is

widely developed as coconut sugar (Pratama et al.,

2015). Palm sugar is the product of the concentration

of palm sugar with heat (cooking) until the water

content is very low (<6%) so that the product hardens

when it is cold. Making palm sugar is almost the same

as making palm syrup. The sap is heated until thick.

After that, the thick liquid sugar is poured into the

mold and left until it is cold. Making palm sugar is

also easy and can be done using simple equipment.

The sugar produced from processing is very helpful

in increasing people’s income. So far, the palm sugar

industry is still a sideline, especially by rural

communities (Radam and Rezekiah, 2015).

The demand of aren palm sugar granules is

growing rapidly due to its ease in use, handle,

package, storage and it contains more complete

nutrition than cane sugar. One of the important

nutients of palm sugar granules is the various

minerals. The EDX analysis shows that the mineral

content of aren palm sugar consist of potassium (2%),

sodium (0.05%), magnesium (0.04%), calcium

(0.01%), iron (0.11%), copper (0.75%), zinc

(0,.46%), manganese (0.08%) and chromium

(0.11%). Because of these advantages, palm sugar

granules become popular and demanded by

developed countries (Iskandar et al., 2014).

356

Haryanto, B., Khosman, H., Hasibuan, A., Wijaya, F., Herfayati, P. and F. Sinuhaji, T.

Energy Productivity Ratio (EPR) in Producing Aren Sugar from Nira Aren Tree: Traditional Processing.

DOI: 10.5220/0009204203560359

In Proceedings of the 2nd Economics and Business International Conference (EBIC 2019) - Economics and Business in Industrial Revolution 4.0, pages 356-359

ISBN: 978-989-758-498-5

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

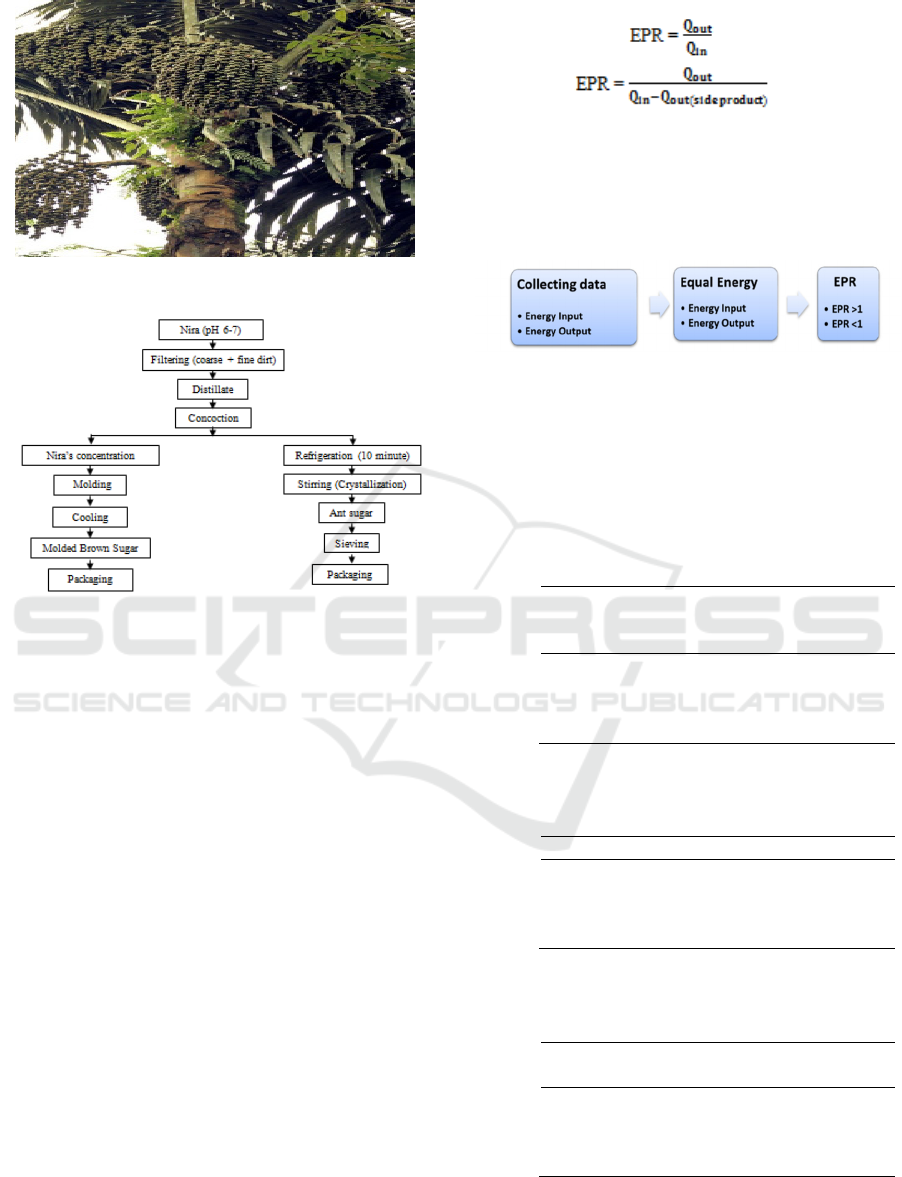

Figure 1. Aren Tree (Kartika et al., 2013)

Figure 2. The scheme of making traditional palm sugar and

ant sugar (Soetedjo and Suharto, 2009).

2 METHODOLOGY

In conducting this study, the required data has been

collected, searching for the equal energy of dregs aren

and aren sugar in calculating the value of energy

productivity ratio (EPR) based on ton/year. The EPR

of a product can be defined as the ratio of primary

product energy plus its by-product energy compared

to the total energy of raw materials, electricity and

other energy used and the processing tool

depreciation. The calculation is based on the

production capacity per year (Haryanto, 2000;

Haryanto et al., 2018a). Ratio energy from

ingredients biofuel can be applied as ratio of non-

renewable Energy that be used on the value of energy

production from fuel and some utility product side.If

energy output : energy input is 1 > 1 then the

production of the renewable fuel or a product could

be continued, but if the ratio energy 1 < 1 then

production of the product resulted in net loss, and

declared as not defined source of renewable energy or

the product (Batchelor et al., 1995).To calculate EPR,

the equations that be used are (Haryanto et al.,

2018b).

(1)

(2)

Study related to EPR was reported based on price

of 1 liter diesel is Rp. 8,000.- (Pertamina cost) with

equal energy is 42.96 MJ/kg (Pertamina, 2018; Felten

et al., 2013). In his study the EPR energy base on 1

kg firewood equal to 14.4 MJ/kg (Francescato et al.,

2008).

Figure 3. Research steps : collecting data, equal energy

quantity and EPR calculation (Haryanto et al., 2019)

3 RESULTS AND DISCUSSIONS

1. Material requirements and utilities

Table 1. The information of material

requirements and utilities in producing aren sugar

No

Material

Requirements

and Utili

t

ies

Total

1

N

ira Aren 500 liters/da

y

2Wate

r

800 liters/da

y

3 Electricity 70 kW/day

4 Firewood

1 m

3

/da

y

2. Material Prices

Table 2. The information of material prices in

producing aren sugar

N

o Material Prices Total

1 Nira Aren

Rp.

2,000/lite

r

2 Firewood

Rp.

30,900/m

3

3. Equipment Prices

Table 3. The information of equipment prices in

producing aren sugar

No

N

ame of

Equipmen

t

Tool Prices

1 Evaporato

r

Rp. 20,000,000

2Cr

y

stallize

r

Rp. 15,000,000

3

Packing

Machine

Rp. 4,500,000

The usage period of the three tools is estimated to

be around 5 years.

Energy Productivity Ratio (EPR) in Producing Aren Sugar from Nira Aren Tree: Traditional Processing

357

The total depreciation value of the three above

tools is calculated and obtained at Rp. 33.450.000,-

4. Input Energy

Table 4. The information of input energy in

producing aren sugar

No Input Resources

Priceor

Ener

gy

Use

d

1

Price of Nira

Aren 150,000

liters

Rp. 300,000,000

2 Electricit

y

/Yea

r

21,000 kWh

3 Firewoo

d

300 m

3

4

Depreciation of

Equipmen

t

Rp. 33,450,000

Energy base = 1 kg firewood = 14.4 MJ/kg

1 m

3

firewood = 650 kg = Rp. 30,900.-

1 kg firewood = Rp. 30,900/650 kg = Rp.47.5/kg

Energyfrom nira aren 150,000 liters/year:

Energy

Rp. 300,000,000.

Rp. 47.5 /kg

14.4 MJ/kg

Energy 90,947,368,4 MJ

Electrical energy used per year:

21,000 kWh 3,6

MJ

kWh

75,600 MJ

Energy from firewoods:\

300 m

650 kg/m

Rp.47,5/kg

Rp. 9,262,500.

Energi

Rp. 33,450,000.

Rp. 47.5/kg

14,4 MJ/kg

Energy from depreciation:

Energy

Rp. 33,450,000.

Rp. 47.5/kg

14.4 Mj/kg

Tabel 5. The information of input resources from

input energy in producing aren sugar

N

o Input Resources Energy Used

(MJ/Years)

1 Price of Nira

Aren 150,000

liters

90,947,368.4

2 Electricit

y

/Yea

r

75,600

3 Firewoo

d

2,808,000

4 Depreciation of

Equipmen

t

10,140,631.58

Total 103,971,600

5. Output energy

The selling price of sugar products produced:

In a day, number of packages can be

produced is:

112 packs (500 grams packaging), with

a selling price per pack of Rp. 16,000.-

56 packs (1 kilogram packaging), with a

selling price per pack of Rp. 30,000.-

In a year, number of packages can be

produced is:

112 packs × 300 = 33,600 packs

56 packs × 300 = 16,800 packs

Selling price:

33,600 packs × 16,000 = Rp. 537,600,000.-

16,800 packs × 30,000 = Rp. 504,000,000.-

Total selling price = Rp. 1,041,600,000.-

Table 6. The information of output resources from

output energy in producing sugar aren

N

o Output

Resources

Energy Used

1Aren

Sugar

(Crystal

Shape)

Rp.

1,041,600,000

Energy produced by palm sugar

𝐸𝑛𝑒𝑟𝑔𝑦

𝑅𝑝. 1,041,600,000.

𝑅𝑝. 47.5/𝑘𝑔

14.4 𝑀𝐽/𝑘𝑔

Energy 315,769,263 MJ

Tabel 7. The information of output

energy in produced palm sugar

N

o Output

Resources

Energy

(MJ/

y

ear)

1Aren Su

g

a

r

315,769,263

Total 315,769,263

6. Calculation of EPR

From the calculation above, the total input

and output energy values have been

obtained. Then the EPR calculations can be

done using the formula:

EPR

Output product

Input by product

In the process of making palm sugar, by

product = 0, thus:

EBIC 2019 - Economics and Business International Conference 2019

358

EPR

Output product

input

315,769,263

103,971,600

3.037

From the calculation result,the EPR value

obtained is 3.037.

Which means that EPR>1. This means that

the energy produced by output is greater than

the energy needed for input, which indicates

that factory production is profitable for the

company.

4 CONCLUSION

The value of energy productivity ratio (EPR) in this

study result is based on input to input and input to

output the EPR was 3.037. Base on the value of the

EPRs show that processing Palm Sugar from Nira in

this traditional processing is feasible to be operated

and developed into a factory because it gives profit to

the company.

REFERENCES

Batchelor, Sheila; E. Elaine J. and Kerr C. Walker Booth.

1995. Energy Analysis of Rape Methyl Rester (RME)

Production from Winter Oilseed Rape. Industrial Crops

and Products an International Journal. UK: Elsevier.

Effendi, Dedi Soleh. 2010. Prospek Pengembangan

Tanaman Aren (Arenga pinnata Merr) Mendukung

Kebutuhan Bioetanol di Indonesia. Perspektif. 9(1) :

36-46. ISSN 1412-8004.

Felten D. Froba N. Fries J and Emmerling C. 2013. Energy

Balances and Greenhouse Gas-Mitigation Potential of

Bioenergy Cropping Systems (Miscanthus, Rapeseed

and Maize) Based on Farming Condition in Western

Germany. Renewable Energy and International

Journal. Germany: 55, 160-167, Elsevier.

Francescato, Valter; Eliseo Antonini and Luca Zuccoli

Bergomi. 2008. Wood Fuels Handbook. Publisher:

AIEL - Italian Agriforestry Energy Association.

Haryanto, B. 2000. Studi Neraca Energi Pembuatan

Biodiesel dari Minyak Sawit. Thesis. Bandung: ITB,

Indonesia.

Haryanto, B.; R. Br. Bukit; E.M. Situmeang; E.P Christina

and F. Pandiangan. 2018a. Study on Energy

Productivity Rasio (EPR) at Palm Kernel Oil

Processing Factory: Case Study PT-X at Sumatera

Utara Plantation. IOP Conference Series, Material

Science and Engineering. 309(1), 012043.

Haryanto, B.; EB. B. Tarigan; R. Br. Bukit; JI Tarigan; P.

Ginting. 2018b. Utilization of The Sand from Mount

Sinabung Eruption as Material for Planting Media.

Proceeding Series, Advanced in Economics, Bussines

and Management Research.

Haryanto, B., H Harahap, R Tambun, R Hasibuan, P

Suherman, D Haryanto, J Wijaya. 2019. Study on

Energy Productivity Ratio (EPR) on Pre-Factory

Design of Glucose Syrup at Riau Indonesia. IOP

Conference Series: Materials Science and Engineering.

505(1), 012073.

Iskandar, Ade; Indah Yuliasih; Machfud and Bambang

Haryanto. 2014. Effect of Temperature and Time on

Dry Granulation Process of Arenga Palm Sugar.

IMPACT : International Journal of Research in

Engineering and Technlogy (IMPACT: IJRET). Vol 2,

Issue 9, page: 33-44. ISSN(E) : 2321-8843; ISSN(P):

2347-4955.

Kartika, Devina; Aristarchus P K dan Margana. 2013.

Perancangan Fotografi Pembuatan Gula Aren.

Surabaya: Universitas Kristen Petra.

Pertamina. 2018. Harga Bahan Bakar Minyak. Access on

June 23 2019

Pratama, Ferry; Wahono Hadi Susanto and Indria

Purwantiningrum. 2015. Pembuatan Gula Kelapa Dari

Nira Terfermentasi Alami (Kajian Pengaruh

Konsentrasi Anti Inversi Dan Natrium Metabisulfit) –

Making Coconut Sugar From Natural Fermented Sap.

Jurnal Pangan dan Agroindusti. 3(4) : 1272-1282.

Radam, Rosidah R. and Arfa Agustina Rezekiah. 2015.

Pengolahan Gula Aren (Arrenga pinanata Merr) di

Desa Banua Hanyar Kabupaten Hulu Sungai Tengah -

Processing of Palm Sugar (Arrenga pinnata Merr) in

The Banua Hanyar Village Sungai Selatan Regency.

3(3) : 267-276. ISSN 2337-7771.

Soetedjo, Jenny Novianti M. and Ign. Suharto. 2009.

Perancangan dan Uji Coba Alat Evaporator Nira Aren.

Laporan Penelitian LPPM. Bandung: Universitas

Katolik Parahyangan, Indonesia.

Energy Productivity Ratio (EPR) in Producing Aren Sugar from Nira Aren Tree: Traditional Processing

359