Emulsion Treatment using Local Demulsifier from Palm Oil

Emre Fathan and Tomi Erfando

Departement of Petroleum Engineering, Universitas Islam Riau, Pekanbaru, Indonesia

Keywords:

Emulsion, Local Demulsifier, Palm Oil, Bottle Test

Abstract:

Conventional demulsifier (chemical) are still used until now in many of oil industries which the formulas are

both expensive and harmful for the environment.In this research, the new formula of local demulsifier will be

tested with palm oil, lemon, glycerin, and KOH as the materials. Those materials are more friendly for the

environment and contain hexane group and octadecenoic acid that are composition in plant that can break the

emulsion. Crude oil (20.8

◦

API) is taken from wellhead of the X Field in Riau, Indonesia. Emulsion sample

will be treated with formula local demulsifier and tasted in water bath for 3 hours vulnerable with 30 minutes

of observation. Bottle test method will be used with the following of 40

◦

C, 60

◦

C, and 80

◦

C as temperature

test.The test revealed that the formula demulsifier + lemon (DKL) given the best result than conventional

demulsifier within 120 – 180 minutes at 80

◦

C that separated 39 ml of water with 5 ml of concentration.P-value

of temperature is the only less than the significance value (α=0.05) means that the linear regression model meet

the criteria of linearity and the changes that occur are significant.

1 INTRODUCTION

The participation of water in the production process of

oil is common in upstream oil and gas activities. The

water is formation water that has a chemical content

that will cause problems in the series of equipment

both under and above the surface. The occurrence

of one of them is the forming of an emulsion.

These problems result in high pumping costs, pipe

corrosion, and special handling of certain equipment

(Abdel-Raouf, ). An emulsion is a mixture of two

immiscible fluids, one of which is shaped droplets

on the other and chemically bound or stabilized

by emulsifying agents (Soffian and Niven, 1993).

Demulsifier injection is often used to overcome

emulsion problems. The process of breaking down

oil-water emulsions into an oil phase and the water

phase is called the demulsification (Kokal, 2005).

However, its use is still using commercial

(chemical) materials which are relatively expensive

(Emuchay, Onyekonwu, Ogolo, & Ubani, 2013)

and cause damage to the environment. In several

studies, demulsifier tests with local materials have

been carried out, for example testing with coconut

oil (Emuchay et al., 2013),lime(Erfando et al., 2018),

and curcas oil (Sulaiman et al., 2015). Where in

all the three studies shows the potential of local

demulsifiers.The potential in the oil and gas sector

should be developed to increase local and national

revenues(Erfando and Herawati, 2017).

In this study, new of local demulsifier are

formulated to minimize the negative impact of

commercial demulsifier both in reduce the high

cost and minimize the negative impact of using

chemical on the environment. The new local

demulsifier formula will be formulated using palm

oil, gliserin, lemons and KOH compounds. Palm oil

contain hexane group and octadecenoic acid. Those

compositions are two main plant components that can

break the emulsion (Yaakob and Sulaimon, 2017).

For the result, those local and commercial

demulsifiers will be comparing within take abest

result of temperature, concentration of separation,

and the time of separation.This study was conducted

to know which formula will give the best result in

separated the water and to know the contribution of

the parameter toward the test through analysis of

regression.

The emulsion is defined as a colloidal system

in which small grains from one of the phase

presses in other phases where they are usually not

mutually mixed. An emulsion can be found in the

production process and equipment. The type that

we often encounter in the field is water emulsion

in oil (w/o). The stability of the emulsion itself

cannot be separated from crude oil asphaltenes

Erfando, T. and Fathan, E.

Emulsion Treatment using Local Demulsifier from Palm Oil.

DOI: 10.5220/0009360102990303

In Proceedings of the Second International Conference on Science, Engineering and Technology (ICoSET 2019), pages 299-303

ISBN: 978-989-758-463-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

299

and resins (Abdel-Raouf, 2012). Emulsion in the

production field can be classified into three types,

Water-Emulsion in Oil (W/O);Oil Emulsion in Water

(O/W); and Complex Emulsion (Multiple/Complex).

Emulsion is an unstable system, according to (Wylde

et al., 2009), classifying the length of time an

emulsion system is separated based on its stability:

• Loose emulsion: is separated in minutes;

• Medium emulsion: separate in 10 minutes or

more;

• The emulsion sight will be stable for hours or even

days and in some cases, will not be able to be

overcome.

Some of the causes of the stability of the

emulsion are explained in the study (Kokal, 2005).

Such as agitation, the grain size, surfactant, effect

of pH, the composition of brine water, viscosity,

and temperature. For demulsification of emulsion,

injecting the demulsifire is one of the option for

separate the emulsion to dissolve dispersed phase

from the dispersing phase. The molecule of a

demulsifier will mobilize to the interface of oil-water

and separated both natural surfactant (asphaltenes

and resins) (Zhou et al., 2014). Over the years

there has been an over dependence on the use of

foreign/commercial demulsifiers this has been found

not to be quite effective in most cases due to

incompatibility with the nature of some kinds of

crude (Emuchay et al., 2013). For some cases it

will led to the challenge for the advanced studies to

locallyformulated demulsifier in result for improved

cost efficiency and effectiveness.

2 MATERIAL & METHOD

2.1 Material

The material we used for laboratory study of emulsion

and demulsification are a water bath (Memmert

WNB 14), heater and stirrer (Wisd.), digital scale

(Amastech), bottle for test (duran), several breakers

(Pyrex Iwaki TE-32), several graduated cylinder

(Pyrex), density bottle, and stopwatch. For producing

local demulsifier we used a commercial palm

oil, potassium hydroxide (KOH), aquades, glycerin

(C

3

H

8

O

3

), and citrus limon.

2.2 Method

Generally we used saponification, bottle test method,

and statistical test. In order to produce the liquid soap

as a base of local demulsifier, we used saponification

with following step based on (Naomi et al., 2013;

Sukeksi et al., 2017; Zulkifli and Estiasih, 2014).

Bottle test used to observing the result and converting

the data into graphic. As for statistical method will

be using statistic application that allows providing

which parameter (time of separation, temperature, or

injecting volume) most contribute for the test.

2.2.1 Production of Local Demulsifier

Local demulsifier (DKS) will be formulated with

saponification method, with the following step;a) 50

ml of palm oil commercial was added to a breaker

and heated with 80

◦

C for 30 minutes. b) 12.5 g of

KOH add into breaker along with 25 ml aquades and

then heated until homogenous; c) Add KOH + Aq into

palm oil and stir it with heater and stirrer in 80

◦

C, 800

rpm, for 3 hours and 20 minutes; d) For the last add

50 ml of aquades and stir for 5 minutes, then wait

the formula for 24 hours until the formula become

liquid. Both formulas are the local demulsifier for this

research.

2.2.2 Demulsification with Bottle Test Method

The following formulas that will be tasted are: a)

Local demulsifier (DKS); b) Local demulsifier +

lemon (DKL); c) Commercial demulsifier (DK);and

d) Base case (without adding demulsifier). Those

formulas will be injected to a bottle of sample

emulsion (1 ml, 3 ml, and 5 ml). Each volume are

tested in several temperature (40

◦

C, 60

◦

C, and 80

◦

C)

for 3 hours.

Emulsion separation was recorded at various time

intervals (Hirasaki et al., 2010).The process was

monitored for every 30 minutes in 3 hours. The step

based on (Erfando et al., 2019; Hirasaki et al., 2010)

3 RESULT

Table 1 is the properties data for sample oil. The

data was calculate to determine the type of oil. The

type of oil sample is heavy oil with SG = 0.929 and

20.8

◦

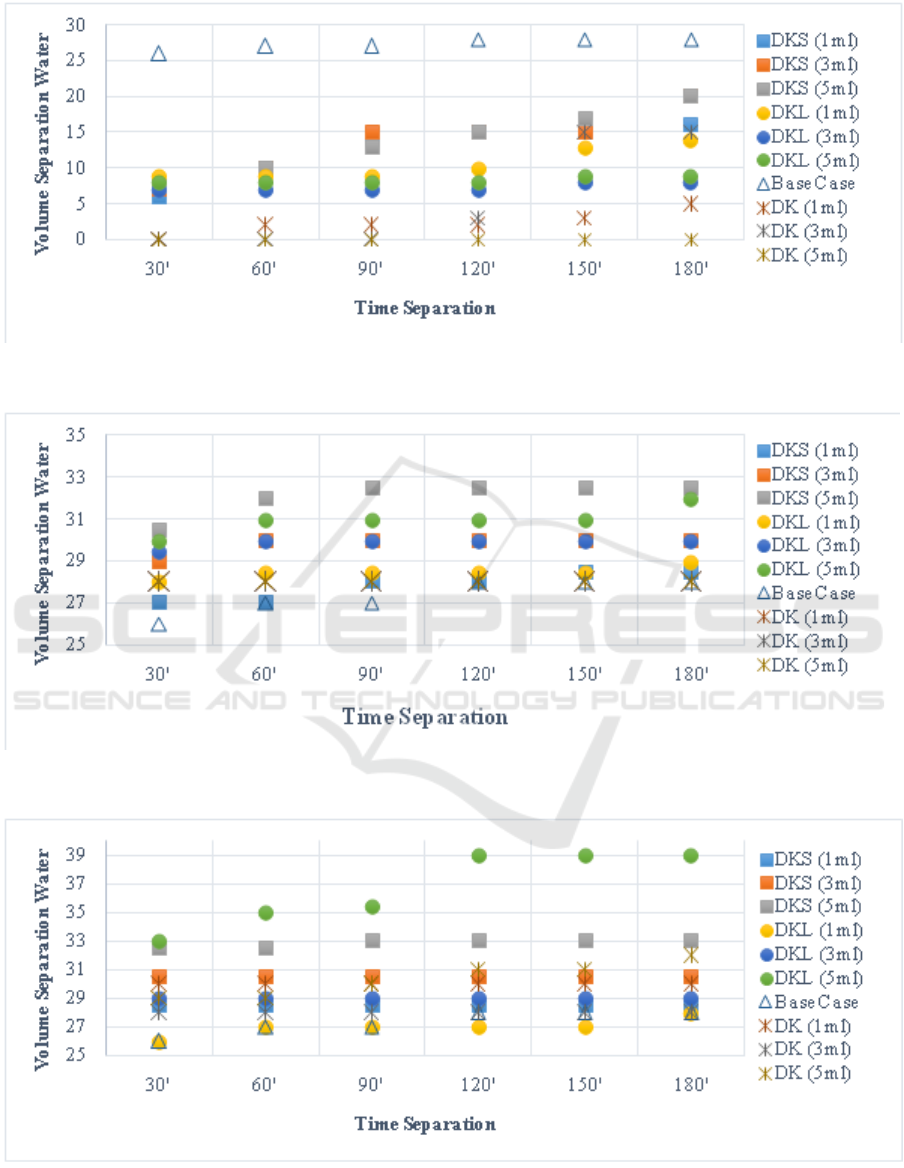

API. Figure 1-3 are the result of the test with

bottle test method in water bath.From those figures

we found out the best, highest, and also the bad

separation within the formulas.

Based on data, base case formula has the highest

separation in figures 1 (40

◦

C). Meanwhile not the

case in temperature of 60

◦

C and 80

◦

C. Formula

DKShas the highest separation value on figure 2 when

adding 5 ml concentration. Figures 2 shown that

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

300

commercial formula (DK) has stable separation at

temperature of 60

◦

C. Meanwhile bad at temperature

of 40

◦

C (figure 1).

Table 1: Properties of Crude Oil

No Properties Value Unit

1 Oil Mass 23.2 gr

2 Oil

Density

0.93 gr/ml

3 Specific

Gravity

0.93 -

4

◦

API 20.8 -

In figure3, formula DKL (5 ml,80

◦

C) given the

stable and highest separation from 120 to 180 minutes

with temperature of 80

◦

C.The result from the bottle

test method shown in figure 3, that the value of local

+ lemon demulsifier (DKL) separation is 39 ml.

Based on the data above, the best result

shown in figure 3 as DKS and it takes 120 –

180 minute for water separated from emulsion

sample.(Hayuningwang et al., 2015) said, moreover

the salinity and temperature here also affects the

amount of separation of water, but the higher the value

of salinity the process of separating oil from water

takes longer.

Based on data, the additional of 5 ml is the best

concentration for injecting the formulas into sample,

while temperature of 80

◦

C is the ideal temperature

in this research.(Augustina and Sylvester, 2015)said,

the temperature or heat broke up some of the weak

emulsion thereby causing coalescence and dropping

of water out of the emulsion which settle in the bottom

of bottle. When the temperature is rise there is also an

increase of demulsification efficiency. The research

of (Erfando et al., 2019) also make an explanation

that the temperature is one of the parameters that can

affect the condition of emulsion significantly.

3.1 Analysis of Regression and

Correlation

Table 2: Regression Analysis Data

No Parameter P-Value R-Sq

R-Sq

(adj)

1 Temperature 0 62.2 62.1

2 Injected Volume 0.362 0.4 0.1

3 Time 0.1 0.9 0.6

Comparison of the linear regression models

determines the effect of variables X on Y (Subekti,

2015). If the contribution is positive then the

value of variable X agrees to the value of variable

Y.Theanalysis of regression and correlation from this

research are from statistical software, to get the

information of regression and correlation from the

parameters (time, injected volume, and temperature)

versus separation.

From table 2, at the output obtained p-valueof

temperature is the onlyless than the significance value

(α=0.05) means that the linear regression model meet

the criteria of linearity and the changes that occur are

significant(Draper and Smith, 1998).

R-Sq (ad j) of temperature is 62.1%, the value is

interpreted as a percentage of contribution in the test.

Both parameter injected volume and time have each

0.1% and 0.6%. From those data temperature has the

highest contribute.

4 CONCLUSION

Based on laboratory test, formula DKL given the

high result than conventional demulsifier within 120

– 180 minutes at 80

◦

C that separated 39 ml of water

with 5 ml of injected volume. The effectiveness of

emulsion breakdown using local material is better

based on base case reference and it’s comparison with

a conventional demulsifier result.The temperature has

the biggest contributes among all the parameters seen

from the regression analysis data.

ACKNOWLEDGMENTS

The author gratefully acknowledge financial

support from Universitas Islam Riau and Petroleum

Engineering’s laboratory for the facilities.

Emulsion Treatment using Local Demulsifier from Palm Oil

301

Figure 1: Bottle test in temperature of 40

◦

C.

Figure 2: Bottle test in temperature of 60

◦

C.

Figure 3: Bottle test in temperature of 80

◦

C.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

302

REFERENCES

Abdel-Raouf, M. E. S. (2012). Factors affecting the stability

of crude oil emulsions.

Augustina, O. and Sylvester, O. (2015). Emulsion

Treatment in the Oil Industry: A Case Study of Oredo

Field Crude Oil Emulsion. SPE Nigeria Annual

International Conference and Exhibition.

Draper, N. R. and Smith, H. (1998). Applied regression

analysis (Vol. 326).

Emuchay, D., Onyekonwu, M. O., Ogolo, N. A., and

Ubani, C. (2013). Breaking of emulsions using

locally formulated demusifiers. SPE Nigeria Annual

International Conference and Exhibition.

Erfando, T., Cahyani, S. R., and Rita, N. (2019). The

utilization of citrus hystrix and citrus limon as an

organic demulsifier formulation. IOP Conference

Series: Materials Science and Engineering,

509(1):12145.

Erfando, T. and Herawati, I. (2017). Analysis of petroleum

downstream industry potential in riau province.

Journal of Geoscience, Engineering, Environment,

and Technology, 2(2).

Erfando, T., Rita, N., and Cahyani, S. R. (2018).

Identifikasi Potensi Jeruk Purut Sebagai Demulsifier

Untuk Memisahkan Air Dari Emulsi Minyak di

Lapangan Minyak Riau. Jurnal Kimia Mulawarman,

15(2).

Hayuningwang, D., Fadli, A., and Akbar, F. (2015).

Pengaruh Salinitas KCl & NaCl terhadap Kestabilan

Emulsi Minyak Mentah–air di Lapangan Bekasap. PT.

Chevron Pacific Indonesia. Jurnal Online Mahasiswa

Fakultas Teknik Universitas Riau, 2(1).

Hirasaki, G. J., Miller, C. A., Raney, O. G., Poindexter,

M. K., Nguyen, D. T., and Hera, J. (2010). Separation

of produced emulsions from surfactant enhanced oil

recovery processes. Energy & Fuels, 25(2).

Kokal, S. L. (2005). Crude oil emulsions: A state-of-the-art

review. SPE Production & Facilities.

Naomi, P., Gaol, A. M. L., and Toha, M. Y. (2013).

Pembuatan sabun lunak dari minyak goreng bekas

ditinjau dari kinetika reaksi kimia. Jurnal Teknik

Kimia, 19(2).

Soffian, R. M. and Niven, T. L. (1993). Emulsion Treatment

Program. SPE Asia Pacific Oil and Gas Conference.

Subekti, P. (2015). Perbandingan Perhitungan Matematis

Dan SPSS Analisis Regresi Linear Studi Kasus

(Pengaruh IQ Mahasiswa Terhadap IPK). 1–21.

Sukeksi, L., Sidabutar, A. J., and Sitorus, C. (2017).

Pembuatan Sabun dengan Menggunakan Kulit Buah

Kapuk (Ceiba Petandra) sebagai Sumber Alkali.

Jurnal Teknik Kimia USU, 6(3).

Sulaiman, A. D. I., Abdulsalam, S., and Francis, A. O.

(2015). Formulation of Demulsifiers from Locally

Sourced Raw Materials for Treatment of a Typical

Nigerian Crude Oil Emulsion. (January 2015).

Wylde, J. J., Coscio, S. E., and Barbu, V. (2009). A case

history of heavy-oil separation in northern alberta:

A singular challenge of demulsifier optimization and

application. SPE Production & Operations.

Yaakob, A. B. and Sulaimon, A. A. (2017). Performance

assessment of plant extracts as green demulsifiers.

Journal of the Japan Petroleum Institute, 60(4).

Zhou, H., Dismuke, K. I., Lett, N. L., and Penny,

G. S. (2014). Development of More Environmentally

Friendly Demulsifiers. (February), 15–17.

Zulkifli, M. and Estiasih, T. (2014). Sabun Dari Distilat

Asam Lemak Minyak Sawit: Kajian Pustaka [In Press

Oktober 2014]. Jurnal Pangan Dan Agroindustri,

2(4).

Emulsion Treatment using Local Demulsifier from Palm Oil

303