A Solution to Increase Natuna D Alpha’s Resource Utilization by

Cryogenic Distillation: Conceptual Design & Sensitivity Study

Wijoyo Niti Daton, Ezra Revolin, Siptian Nugrahawan, Prasandi Abdul Aziz, Tutuka Ariadji, Steven

Chandra and J. A. Nainggolan

Petroleum Engineering Program, Institut Teknologi Bandung, Jalan Ganesha No 10 Bandung, Indonesia

Keywords:

Cryogenic Distillation, CO

2

Separation, CO

2

Transportation.

Abstract:

Natural gas extracted from its respective reservoir needs to be processed to meet the specifications of sales

gas. CO

2

is one of the components that needs to be separated from natural gas. The CO

2

concentration of

natural gas varies from a content of less than 20 mole % to more than 80 mole%. There is a problem when

the content of CO

2

is very high so it is necessary to modify the CO

2

level reduction by modifying the equip-

ment or changing the operating conditions to meet the desired CO

2

purity. In this study, field conditions and

characteristics reviewed is East Natuna Gas Field which has a gas composition of 71% CO

2

and 29% methane

with modified pressure based on the capability and capacity of available equipment. From the conditions and

characteristics of the field, the CO

2

method of separation from natural gas using cryogenic distillation was

chosen.This research presents analysis and sensitivity of technical parameters that influence the method of

CO

2

separation from natural gas using cryogenic distillation. The sensitivity is done by changing parameters

of pressure and very high feed gas flow rate into the column. In addition, the calculation of the diameter and

height of the distillation column using the calculation of the formula and the results of the simulation using

commercial process flow software. This study applies a CO

2

separation process with cryogenic distillation

and the desired product specification of CH

4

is 99%. The design of the equipment was simulated using two

distillation columns with operating pressure at the first distillation column of 45 bar and the temperature of

19.19 oF, and for the second distillation column the operating pressure was reduced to 35 bar. The results are

for the 8000 MMSCFD flow rate case obtained the first number of columns as many as 16 with the size of

7.4 meters diameter and 17.66 meters high, while the number of second column of 4 with the size of 8 meters

diameter and 22.38 meters high. The results presented are still less suitable with the conditions in the East

Natuna Gas Field because offshore constrains so need to be studied further for design and other methods in

application in the field.

1 INTRODUCTION

Natural gas is one of most the important energy

sources in the world. Today humans use natural gas

to meet energy needs, where the use of gas is esti-

mated to increase by 1.5% each year (IEA, 2017).

Global gas demand for natural gas increased from

3635 bcm in 2016 to more than 5300 bcm in 2040

(IEA, 2017) Indonesia is one of the archipelagic coun-

tries that has large gas reserves spread across sev-

eral regions, one of which is the East Natuna Block.

Natuna Timur block is one of the gas fields that has an

abundant source of gas reserves, which makes Natuna

the largest undeveloped gas reserve in Southeast Asia

(Fenter et al., 1996). However, the abundant potential

of gas reserves also has a very high CO

2

gas content

so that CO

2

separation technology is needed so that

the gas produced can be utilized properly. Impuri-

ties such as CO

2

, H2S, and other acid gases need to

be removed from natural gas because in the presence

of water, this content can make pipes and other tools

corroded(Rufford et al., 2012).

At present, various methods of acquisition and

technology have been implemented to increase nat-

ural gas production. The existing technology is ad-

justed to the field conditions and characteristics. One

challenge that is often faced is the presence of acid

gas contained in it. Sources of acid gas are natural

gas resources that contain most of CO

2

and/ or H2S

(Burgers et al., 2011). The separation process can be

designed to overcome differences in molecular prop-

erties or thermodynamic properties and the .

342

Daton, W., Revolin, E., Nugrahawan, S., Aziz, P., Ariadji, T., Chandra, S. and Nainggolan, J.

A Solution to Increase Natuna D Alpha’s Resource Utilization by Cryogenic Distillation: Conceptual Design Sensitivity Study.

DOI: 10.5220/0009427203420348

In Proceedings of the Second International Conference on Science, Engineering and Technology (ICoSET 2019), pages 342-348

ISBN: 978-989-758-463-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

displacement of components in the mixture (Ruf-

ford et al., 2012). Therefore several methods of sepa-

ration of acid gas have been developed, or commonly

called sweetening gas processes for H2S separation,

such as absorption, adsorption, membrane and cryo-

genic methods, each of which is used for different

properties and conditions of fluid and field. In this

study, the selection of CO

2

separation method with

reference characteristics from the East Natuna Gas

Field was carried out and a process simulation was

carried out to obtain the results of the high CO

2

con-

tent separation by observing the effect of pressure and

the feed rate from CO

2

gas was very high.

Natuna Gas Field is located in Indonesian waters

precisely in the Natuna Sea. This field is 140 miles

northeast of the Natuna Islands and 218 miles north-

west of the island of Borneo. The water depth of this

field is around 475 feet. The amount of gas volume

in the reservoir is estimated at 222 TSCF with the

composition of the gas contained among others 71%

CO

2

, 28% methane and heavy diffraction hydrocar-

bons, 0.5% H2S, and 0.5% N2 (Fenter et al., 1996).

The Natuna Gas Location Map is shown in Figure 1.

Figure 1: Location of Natuna Field (Fenter et al, 1996).

Natuna gas reservoir is interpreted in the form of

carbonate domes which are isolated and contained in

the Miocene Reef Formation (Fenter et al., 1996). If

the formation is a carbonate formation, calcite disso-

lution will form CO

2

. The high CO

2

content in the

Natuna gas reservoir is estimated to be the result of

the calcite dissolution process (Suarsana et al., 2010).

This reservoir has a pressure of 5717 psig and a tem-

perature of 340 F which is measured by measuring

the well at the central depth. The estimated gas yield

from this field is 75% with recoverable hydrocarbon

gas of 46 TSCF (Fenter et al., 1996).

Natuna Field Reservoir contains more CO

2

than

hydrocarbons. CO

2

dominates the aging of the reser-

voir phase and controls the production method. Be-

cause this reservoir fluid contains more hydrocar-

bon components, this reservoir is considered a non-

hydrocarbon reservoir (Suarsana et al., 2010).

2 OVERVIEW OF NATURAL

GAS-CO

2

SEPARATION

PROCESS

During the requirement of separating CO

2

from nat-

ural gas, not all available methods can be applied in

every field. Considerations of methods available on

separating high levels of CO

2

is important so that the

selection of the right method will give good results.

In addition, differences also depend on the thermody-

namic and transport properties (interphase), in which

case the properties considered include vapor pressure,

boiling point, solubility, adsorption capacity, and dif-

fusivity (Rufford et al., 2012). Based on the nature

of the components to be separated, the main opera-

tion in the gas separation and purification mechanism

follows the mechanism: (1) phase formation by heat

transfer and / or shaft work into or from the mixture,

(2) absorption on liquid sorbents or solids, (3) adsorp-

tion on solids, (4) permeation through a membrane,

and (5) changes in chemical compounds into other

compounds (Kohl and Nielsen, 1997)(Seader et al.,

1998). The direct chemical change in CO

2

which is

currently under study is an example of dry reforming

process, namely CO

2

reacts with CH

4

to form syn-

gas (mixture of H2 and CO

2

) which can later be used

to produce liquid fuel through a Fischer-Tropsch re-

action (Rufford et al., 2012) Then the selection for

selecting an acid gas treating process can be viewed

from the gas partial pressure, based on references

from Aden (Nexant, 2011) and shown in Figure 2.

Figure 2: CO

2

Removal Chart Based on Partial Pressure

(Aden, 2009).

Based on the results of Revolin’s (2016) research,

the selection of the CO

2

method can be done with

the help of the separation process selection diagram

shown in Figure 10. In addition, in this thesis a selec-

tion of CO

2

separation methods was carried out with

references from (Rufford et al., 2012) based on sev-

A Solution to Increase Natuna D Alpha’s Resource Utilization by Cryogenic Distillation: Conceptual Design Sensitivity Study

343

eral influential parameters in Table 1. In this study, the

factors that were considered to be the most influential

in the process of selecting CO

2

separation methods

from natural gas include:

• The presence or absence of H

2

S gas content

• Concentration of feed gas CO

2

• Feed gas flow rate

• The purity of CH

4

and CO

2

products

From the Natuna Field case, there are several

characteristics that are owned as consideration of the

choice of methods including:

• The H

2

S content is small

• The concentration of the gas content is 29%

methane and 71% CO

2

• Flow rate is very high (more than 1 BSCF, de-

pending on the duration of the contract)

• The desired purity of the product is at least 95%

methane, in this case it is targeted to be 99%.

From the parameters of CO

2

inlet concentration

above 50%, then based on a summary of the techno-

logical characteristics in Table 1 that may be used are

membrane technology, absorption with amine, and

cryogenic distillation. Then the selection process is

also carried out with the help of a selection diagram

in Figure 3 with the results of technology suitable for

use, namely cryogenic absorption and distillation. In

this study, membrane technology and absorption were

not chosen because there were several considerations

based on (Rufford et al., 2012). Membrane technol-

ogy requires pretreatment processes to remove heavy

liquids or hydrocarbons because it can cause damage

to membranes and blockages. Membrane quality de-

pends on permeability and selectivity that cannot be

obtained simultaneously. In addition, membranes are

sensitive to feed conditions and hydrocarbon loss is

also higher than other technologies. In the absorption

method another unit is needed to regenerate solvents

in the process of CO

2

gas separation. In this method

it is also often formed loading, foaming, and channel-

ing so that mass transfer is not good. Then, the ab-

sorption method requires a large amount of solvents

to separate the volume of high CO

2

gas, which makes

energy consumption also higher especially for regen-

erating solvents. Conformity between the character-

istics of the cases and categories in this study resulted

in the selection of cryogenic distillation.

In this study the simulation of CO

2

separation us-

ing the cryogenic distillation method was carried out

using the Aspen Hysys V10 software. Simulation

of CO

2

separation was carried out by applying refer-

ence to the cryogenic distillation process by Pellegrini

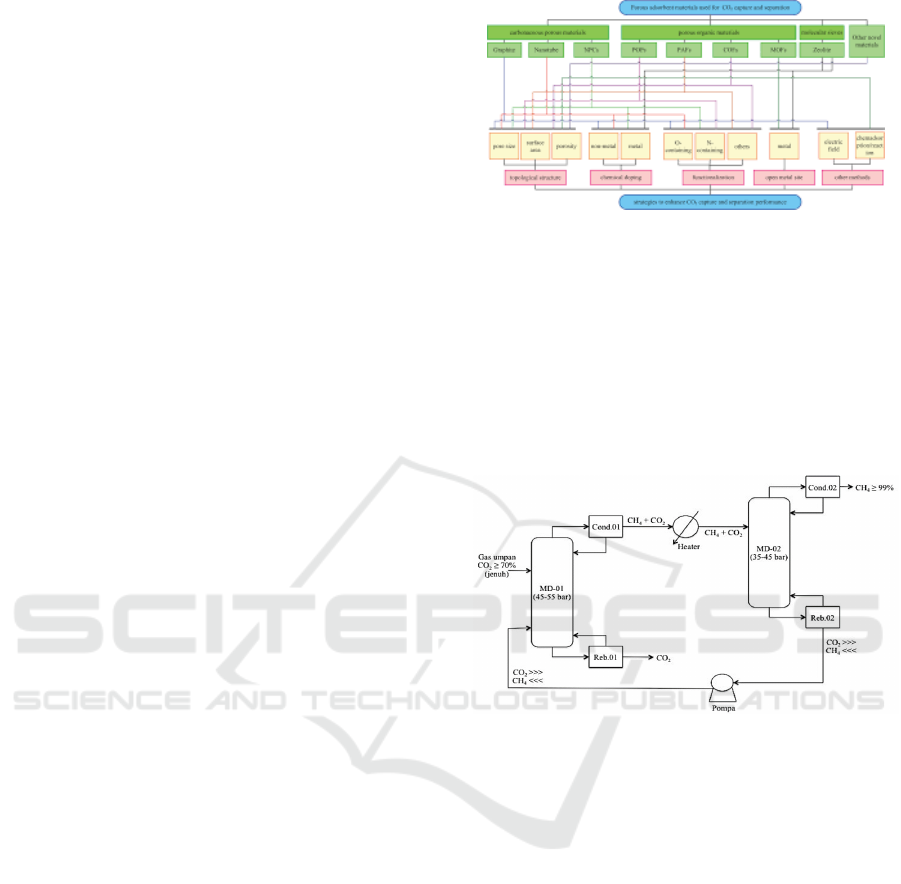

Figure 3: CO

2

Separation Guideline (Liu et al., 2015).

(Pellegrini et al., 2015) with simplification of one dis-

tillation column and reference from Revolin (2016) as

a simulation baseline with several assumptions used

in the process including simplified feed gas compo-

nents in the form of binary mixture namely CO

2

and

methane, and the vapor and liquid phases are consid-

ered ideal. The scheme of the distillation process can

be seen in Figure 4.

Figure 4: Cryogenic CO

2

Separation (Pellegrini et al.,

2015).

In this CO

2

separation simulation the most im-

portant component observed is the distillation col-

umn. The distillation design process consists of de-

signing processes and mechanical design. Simulation

with shortcut distillation is used in the design pro-

cess to find out the mass balance and the variables

needed. Then, some parameters generated from this

simulation that are needed for mechanical design in-

clude pressure and temperature on the top product (in

the condenser) and the bottom product (in reboiler)

needed, the minimum and actual stage number, the

position of the feed gas stage, and reflux ratio early. In

this stage data on composition, pressure, temperature,

and feed gas flow rate are needed, as well as the speci-

fications of the condenser output and reboiler needed.

The feed gas flow rate obtained also makes the flow

rate data for each component in the feed known.

In mechanical design, rigorous methods are used

(with the distillation column) for more detailed and

detailed simulations to determine and determine the

profile of pressure and temperature in each stage, con-

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

344

denser and reboiler condition profiles, and the com-

position of CO

2

and methane from separation. It is

necessary to know the variables needed in the distilla-

tion column, including the composition and flow rate

of the feed gas, the pressure and temperature of the

feed gas, the position of the feed gas stage, the num-

ber of stages and the pressure profile, and the spec-

ifications of the desired product or product. Some

of the assumptions used in the distillation column

include each plate in the column having an equilib-

rium with constant pressure reduction with a rule of

thumb of 0.2 psi per plate. The pressure and tem-

perature of the feed gas entering the distillation col-

umn need to be adjusted to match the column op-

erating conditions. The high CO

2

content is cooled

to a certain temperature and pressure on the distilla-

tion column so that the CO

2

concentration decreases

to the desired level, which increases the concentra-

tion of methane. Pressure and temperature specifi-

cations are important factors that influence gas sep-

aration(Suarsana et al., 2010). The column operating

conditions are assumed to be in ideal conditions or in

the sense that the amount of feed gas to the distillation

column is equal to the number that exits the column.

Then the separation simulation is carried out using

two stages of design with several sensitivity studies

that refer to a predetermined base case condition.

From the base case that has been determined, pres-

sure sensitivity and the rate of gas feed production are

carried out into the distillation column. After a simu-

lation and sensitivity study, the reflux ratio results and

the number of stages needed to obtain the desired cri-

teria for the methane and CO

2

content are obtained.

Variations in the condition of the feed gas are carried

out with the condition of the condenser and the re-

boiler being fixed.

3 CASE STUDY

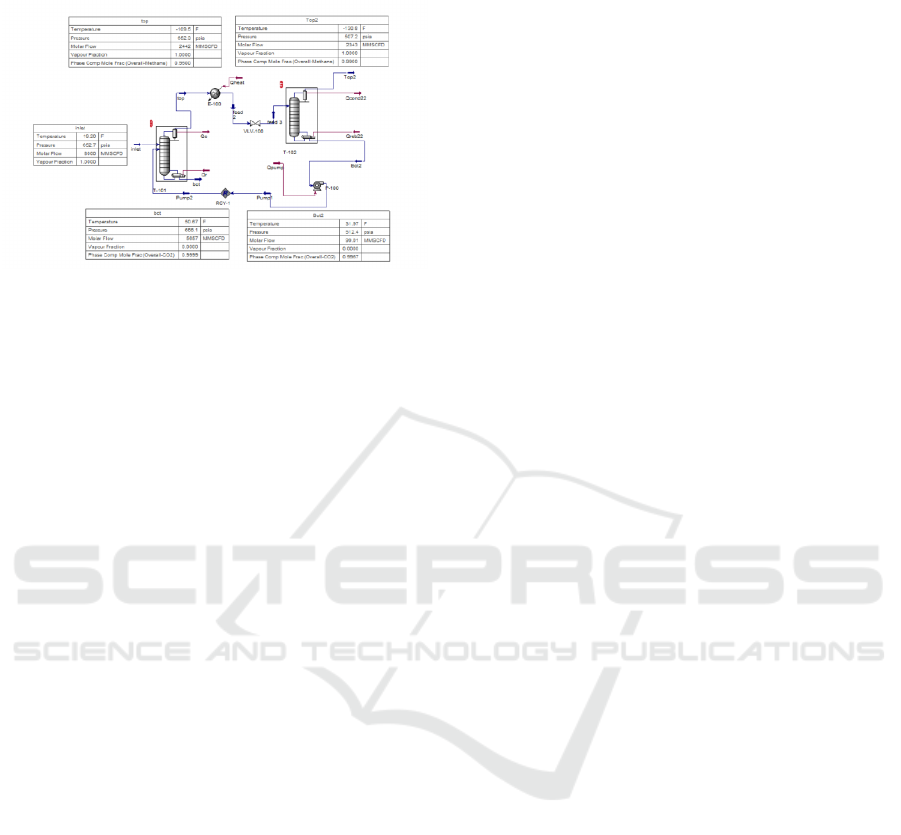

Before the sensitivity study, a base case was sim-

ulated with a composition of 71% CO

2

and 29% CH

4

, feed gas flow rate of 8 BSCFD, pressure of 652.7

psia, and temperature of 19.19 oF (at the dew point

point) with the result specifications in the CH

4

con-

denser with purity of ≥ 95% and the result of reboiler

CH

4

≤ 0.001%. From the variable reference shortcut

distillation method obtained, the minimum number of

stages required is 9,643 with rounded up to 10 stages,

the actual number of stages is 17, and the feed gas

flow is optimal in the second stage. Then the results

of the condenser namely CH

4

composition has a flow

rate of 2,442 BSCFD and from the reboiler obtained

a flow rate of 5,558 BSCFD. The shortcut distillation

operation scheme in the base case can be seen in Fig-

ure 5.

Figure 5: Cryogenic CO

2

Separation (Pellegrini, 2014).

The results of the number of stages and reflux ra-

tios obtained from the shortcut distillation simulation

are entered into the distillation column for rigorous

distillation simulation and the results for this base

case condition are reflux ratios of 12.08. Comparison

of reflux ratio calculations with the shortcut distilla-

tion method and rigorous distillation gives different

values. This is due to the rigorous distillation simula-

tion, the calculation is done in more detail and detail

that considers many variables and results until the de-

sign of column sizes. The results obtained are in the

form of a static plant simulation and even dynamic

if added to the addition of controls (Biyanto, 2007).

While the distillation shortcut is still a rough calcula-

tion or not done in detail. The CO

2

separation scheme

uses rigorous distillation in the base case distillation

column attached to Figure 6.

Figure 6: Cryogenic CO

2

Separation (Pellegrini, 2014).

A Solution to Increase Natuna D Alpha’s Resource Utilization by Cryogenic Distillation: Conceptual Design Sensitivity Study

345

Then a sensitivity study is carried out by review-

ing the variable pressure and feed gas flow rate. The

temperature conditions of the feed gas, gas specifica-

tions produced, and variations in flow rates are made

the same in each case. The feed gas flow rate and

the flow rate of the separation results for each rate are

shown in Table 1.

Table 1: Gas Flow Rate on Distillation Column.

Flow Rate (MMSCFD)

Feed Gas Condenser (Top) Reboiler (Bottom)

8000 2442 5558

1000 305.2 694.8

2000 610.4 1389.6

3000 915.6 2084.4

4000 1221 2779

5000 1526 3474

6000 1831 4169

7000 2136 4864

From Table 2, the flow rate of CH

4

generated

from the condenser is smaller than the flow rate of

CO

2

generated from the reboiler because the fraction

of the CO

2

component in the feed gas is greater than

CH

4

. And also in this study, the calculation in the

simulation uses the assumption of a 100% efficiency

level in the separation process so that the total flow of

the feed gas entering is equal to the amount that comes

out. The following are the operating conditions of the

distillation tower for each case shown in Table 2.

Table 2: Gas Condition in Distillation Column.

Case

Operating Condition

Feed Gas Condenser Reboiler

Base

P = 652.7 psi

T =19.19 F

Pcond = 652.3 psi

Tcond = -109.5 F

Preb = 656.1 psi

Treb = 50.67 F

Case 1

P = 507.6 psi

T =19.19 F

Pcond = 507.2 psi

Tcond =-120.9 F

Preb = 510.2 psi

Treb = 33.3 F

Case 2

P = 362.6 psi

T =19.19 F

Pcond = 362.4 psi

Tcond = -130.1 F

Preb = 364.6 psi

Treb = 33.3 F

Case 3

P = 217.6 psi

T =19.19 F

Pcond = 217.4 psi

Tcond =-140 F

Preb = 219.4 psi

Treb = -17.5 F

Case 4

P = 72.52 psi

T =19.19 F

Pcond = 217.4 psi

Tcond = -163.3 F

Preb = 73.92 psi

Treb = -69.13 psi

In terms of operating conditions, the pressure on

the condenser needs to be made smaller than the re-

boiler pressure. This is so that the steam formed can

rise to the top of the column, according to the prin-

ciple of fluid flow that the gas will flow from high

pressure to low pressure.

From the sensitivity results obtained that the

greater the pressure of the feed gas into the distilla-

tion column, with the same flow rate and tempera-

ture of the feed gas, the more reflux ratio is needed.

This is because with high pressure the more steam

formed. Even though the reflux system is condens-

ing steam, so if the steam is high then the reflux ra-

tio is also high. This applies also with the increasing

pressure of the feed gas, the greater the number of

stages needed. The principle of the stage is to sep-

arate the components in the gas feed, if the pressure

is high then the interaction of the gas component is

also higher, then more stages will be needed for the

separation process. In this study the magnitude of the

feed gas flow rate does not directly affect the magni-

tude of the relux ratio and the number of stages. For

each case carried out, the value of reflux ratio and the

number of stages are the same, but the magnitude of

the feed gas flow rate affects the diameter of the dis-

tillation column more and the energy needed, in this

case the condenser duty and reboiler duty. The greater

the feed gas flow rate, the greater the dimension (di-

ameter and height) of the distillation column and the

energy needed. This is because a large flow rate re-

quires a large capacity.

After the sensitivity to the influential parameters

it was found that in distillation using distillation is

strongly influenced by pressure and rate feed gas flow.

The smaller the condenser duty feed gas pressure and

the reboiler duty is also greater, but it needs to be ad-

justed again with the existing capacity. In the low

temperature process carried out on the separation of

the natural gas flow with high CO

2

concentration the

cooling cycle is required in the process. In this condi-

tion, electrical energy needs are one of the important

factors because they are needed in the cooling cycle.

Therefore it would be better to choose the lowest pres-

sure energy conditions, especially in this study the

condenser and reboiler. From the results of the sensi-

tivity obtained the selection of pressure is taken at the

greatest value. In this study the pressure was in the

range of 5-45 bars. In this study cryogenic distillation

was not carried out by a higher pressure review be-

cause of the limitation of temperature determination

of 19.20 F and the feed gas vapor fraction 1 which

could be achieved with higher pressure when the tem-

perature was also raised. Therefore it was chosen, the

feed gas pressure was 45 bar in this study.

The design of the CO

2

separation process in this

study used the method in the Pellegrini (Pellegrini

et al., 2015) patent with separation using two distil-

lation columns. The feed gas pressure entering in the

first column is 45 bar and in the second column 35

bar. The purity results obtained in this study were

99% CH

4

at the end of the second column. From the

first column to the second column a heater and valve

are given to reduce pressure. Then the output of CO

2

in the second column is pumped back to the first col-

umn for re-separation. The design of this process can

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

346

be seen in Figure 7.

Figure 7: Overall Design of Cryogenic Process.

To validate the results of the calculation of the dis-

tillation column, a reference is needed for compari-

son. In this study a reference to the size of the dis-

tillation column from the RCC Regenerator Column

was used, Balongan refinery with a diameter of about

9 meters and a height of more than 20 meters. Then

the feed gas rate is determined by the length of the

agreed contract. In this study the reference of feed

gas flow rate uses a reference from Nainggolan (2016)

with a flow rate of 8 BSCFD. From these references,

determining the size of the distillation column can be

done.

The variation in flow rate from 1-8 BSCFD pro-

duces a diameter of more than 11 meters. Whereas

the flow rate of 100-800 MMSCFD has the largest di-

ameter at the rate of 800 MMSCFD with a value of

10 meters. For the rate of 8 BSCFD, a diameter of

52.5 meters is produced, in the field this condition is

not possible so there is a need for a scenario to di-

vide the flow rate in the column in parallel, more than

one in each column. In the first column the maximum

rate that can be accommodated is 500 MMSCFD with

a diameter of 7.4 meters, while for the second col-

umn the maximum rate that can be accommodated is

610.4 MMSCFD from the results of the first column

with a diameter of 8 meters. The scenario is based

on the smallest condenser duty and reboiler duty to-

tal requirements is selected so that the first scenario

with column 1 (7.4 meters in diameter and 17.66 me-

ters in height) is obtained and 16 pieces are needed

column 2 (with a diameter of 8 meters and a height

of 22.38 meters) requires 4 pieces. From these results

for the next process, it is necessary to consider the ap-

plication of the distillation column in the field, with

the limitation of the location of the Natuna Gas Field

which is offshore resulting in the availability of land

and installation of the distillation column equipment

that needs to be reviewed.

Based on the designs presented above, it can be

proposed to be two main distribution/processing hub,

namely the platform based unit processing and on-

shore facility, connected with underwater pipeline. It

is worth noting that applying platform based process-

ing facility requires massive capital due to the size

of the processing facility, while using onshore facil-

ity would require very large pipe with high corrosion

potential. Further study should be done to assess the

economic and technical feasibility of these projects.

4 CONCLUSIONS

The choice of CO

2

separation technology from natu-

ral gas is based on several factors that are highly de-

pendent on the conditions and characteristics of the

gas field being reviewed.

Under pressure and gas flow rates based on the

case of the Natuna Gas Field, the cryogenic distilla-

tion process is chosen in the separation of CO

2

con-

tent at high flow rates, and is considered capable of

obtaining specifications of CO

2

content of less than

or equal to 1%.

In designing CO

2

separation using cryogenic dis-

tillation at a very high flow rate, a flow rate distri-

bution scenario in parallel with different columns is

needed to meet these needs due to limited location

availability.

With the content of 71% CO

2

and 29% methane,

the results of separation using two-column cryogenic

distillation obtained by the case of 8000 MMSCFD

flow rate obtained the number of the first column as

much as 16 with a diameter of 7.4 meters and height

of 17.66 meters, while the number of second columns

was 4 in diameter 8 meters high and 22.38 meters.

REFERENCES

Biyanto, T. R. (2007). Cascade control using soft sensor for

aldehide column energy saving. IPTEK The Journal

for Technology and Science, 18(4).

Burgers, W., Northrop, P., Kheshgi, H., and Valencia, J.

(2011). Worldwide development potential for sour

gas. Energy Procedia, 4:2178–2184.

Fenter, D., Hadiatno, D., et al. (1996). Reservoir simulation

modeling of natuna gas field for reservoir evaluation

and development planning. In SPE Asia Pacific Oil

and Gas Conference. Society of Petroleum Engineers.

IEA (2017). WEO 2017.

Kohl, A. L. and Nielsen, R. (1997). Gas purification. Else-

vier.

Liu, X., Jin, D., Wei, S., Wang, Z., An, C. G., and W.

(2015). Strategies to enhance CO2 capture and sepa-

A Solution to Increase Natuna D Alpha’s Resource Utilization by Cryogenic Distillation: Conceptual Design Sensitivity Study

347

ration based on engineering absorbent materials. Jour-

nal of Materials Chemistry A. 3, 3.:12118–12132.

Nexant, Inc., S. F. C. (2011). Survey and Down-Selection

of Acid Gas Removal Systems for the Thermo-

chemical Conversion of Biomass to Ethanol with a

Detailed Analysis of an MDEA System. Techni-

cal report, National Renewable Energy Laboratory

(NREL), Golden, CO (United States).

Pellegrini, L. A., Oldrich, M., Lange, S., and Picutti, B.

(2015). A New Cryogenic Technology for Natural Gas

Sweetening. Presented at SOGAT 2015, Abu Dhabi.

Rufford, T. E., Smart, S., Watson, G. C., Graham, B.,

Boxall, J., Da Costa, J. D., and May, E. (2012).

The removal of co2 and n2 from natural gas: A re-

view of conventional and emerging process technolo-

gies. Journal of Petroleum Science and Engineering,

94:123–154.

Seader, J. D., Henley, E. J., and Roper, D. K. (1998). Sepa-

ration process principles.

Suarsana, I. P. et al. (2010). Producing high co2 gas content

reservoirs in pertamina indonesia using multi stage

cryogenic process. In SPE Asia Pacific Oil and Gas

Conference and Exhibition. Society of Petroleum En-

gineers.

ICoSET 2019 - The Second International Conference on Science, Engineering and Technology

348