Numerical Simulation of Combustion Characteristics on Tangentially

Fired Boiler with Different Yaw Angle

Rindra Hosanova

1

, Devy Setiorini Sa’adiyah

1,2

and Diniar Mungil Kurniawati

1

1

Insitut Teknologi Kalimantan

2

Department of Mechanical Engineering, Graduate School of Engineering, Kobe University, Japan

Keywords: Computational fluid dynamics, yaw angle, tangentially fired boiler

Abstract: Coal is one of the energy sources that widely used for electricity. Nonetheless, the high demand for coal is

not comparable with the remaining coal in the world, so it is necessary to make a study to reduce the

consumption rate of coal. Increase the efficiency of the tangentially fired boiler with improvement in the

burner is one of the right options. In some cases, because of the uneven distribution of coal type, blended of

mixing coal of higher and lower rank coal is necessary. This condition will affect the combustion behavior in

the boiler, also emission production. This research will study the effect of yaw angle modification to

combustion behavior and emission analysis in the tangentially-fired boiler with the condition of fuel 30%

MRC and 70% LRC. Computational fluid dynamics has been used in this study with validation. The yaw

angle diverse from +5º, 0º, -5º, -10º, dan -15º. The results show that the wider yaw angle increases the

temperature deviation and NOx concentration. Coal burner with -5º has the least temperature deviation and

the lowest NOx emission, which has 83,07 ppm of NOx, then -5º yaw angle is chosen.

1 INTRODUCTION

Coal is one of the most used energy sources,

especially in power plants, according to data obtained

from PT Bukit Asam (Indonesian mining company)

at least 27 percent of the total energy produced in the

world. While coal-fired power plants produce more

than 39 percent of all electricity created in the world,

this is because coal has a relatively easy and

inexpensive extraction process, and infrastructure

requirements are cheaper than other energy resources

(BUMN, 2017). Based on the latest data obtained

from the Geological Agency of the Ministry of

Energy and Mineral Resources (ESDM), Indonesia's

coal reserves amounted to 26.2 billion tons. With coal

production of 461 million in 2017, the remaining coal

reserves are 56 years old if there are no new reserves

found (KESDM, 2016).

The level of coal consumption should reduce, so

further research and innovation are needed. Much

research has been done to reduce the level of coal

consumption by increasing the efficiency of the

boiler. One widely used boiler is a tangentially-fired

boiler because it has the advantage of better

combustion and can be used for broader classes of

coal (Y.C. Liu et al., 2016). Although tangentially

fired boilers have better combustion, there are still

some problems such as carbon that does not burn in

ash, unbalanced heat and there is a temperature

deviation in the super-heater and reheater, numerical

simulations can be successfully used to assess coal

combustion and can observe the behavior of exhaust

emissions from boilers on a large scale (Ho Young

Park et al., 2012).

In coal-production, Indonesia is one of the coal-

producing countries, with the majority of the quality

of coal produced is medium calorie coal, whereas

there are still many old plants that still use low-calorie

coal. Under certain conditions, low-calorie coal

supply cannot meet the needs of the generator, so that

low-calorie coal will be mixed with medium quality

coal, which is more widely available in other

generating units (MEMR, 2016). In a numerical

simulation study, it was shown that tangentially fired

boilers with coal composition of 70% low-calorie

coal with 30% medium calorie coal showed that there

was a high-temperature build-up at the bottom of the

boiler (Sa'adiyah et al., 2017).

To reduce the occurrence of gas temperature

deviations in the boiler can be done by changing the

yaw angle of over-fire water. This is indicated by the

numerical simulation results, which show that

184

Hosanova, R., Saadiyah, D. and Kurniawati, D.

Numerical Simulation of Combustion Characteristics on Tangentially Fired Boiler with Different Yaw Angle.

DOI: 10.5220/0009443501840190

In Proceedings of the 1st International Conference on Industrial Technology (ICONIT 2019), pages 184-190

ISBN: 978-989-758-434-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

changing the yaw angle of Secondary Over-Fire

Water (SOFA) is a sufficient way to reduce gas

temperature deviation. Numerical simulations show

that changing the angle of SOFA and Closed Couple

Over-Fire Water (CCOFA) can affect gas

temperature and flow in the area around the

superheater and reheater (Ho Young Park et al.,

2015). Horizontal exhaust gas deviation decreases by

changing the yaw angle from SOFA to negative

direction, with Concentric Firing Secondary (CFS)

water at an angle of 22º (Y.C. Liu et al., 2016). To

reduce the occurrence of temperature deviation, it

necessary to optimize airflow in the opposite

direction from the secondary air (Ho Young Park et

al., 2012). So based on this research, it is necessary to

study the effect of the yaw burner angle which is

expected to be able to overcome the temperature

deviation at the bottom of the boiler which can

determine the quality of coal combustion in the boiler

which can affect the exhaust emissions produced, and

also overcome future conditions if Indonesia lacks

low coal calories. So from that, a numerical

simulation study of the combustion characteristics of

tangentially fired boilers with yaw angle variations

was carried out.

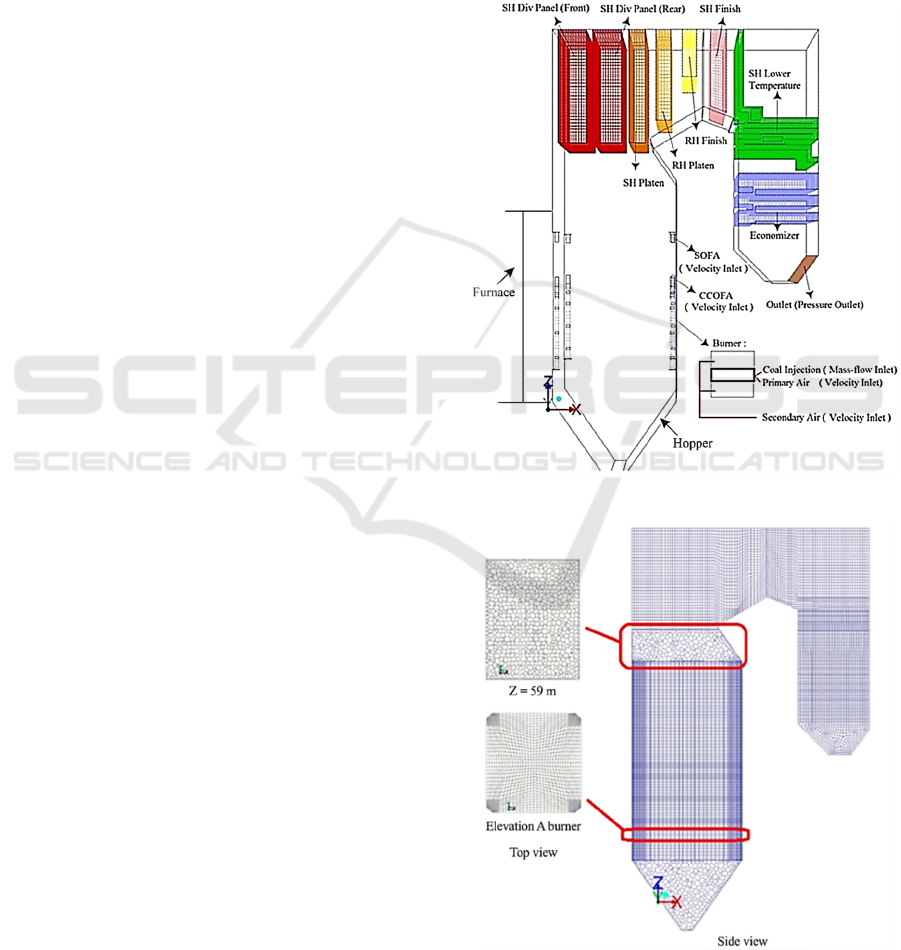

2 NUMERICAL METHOD

The numerical simulation in this study using

Computational Fluid Dynamics, which started with

geometry build and meshes formation before setting

the solving method. The geometry of the tangentially-

fired boiler that will be used in this study is shown in

Fig. 1(a). The furnace section will have 7 (seven)

elevation, namely A, B, C, D, E, F, and G, with 1

(burner) at each corner of the elevation, or it can be

said for each elevation there would be 4 (four) burner.

Furthermore, this boiler also included CCOFA

(Closed-coupled Over-Fire Air) near elevation G and

SOFA (Separated Over-Fire Air) on the higher

elevation.

The formation of boiler meshing is depicted in

Figure 1 (b), which are using hexahedral at the

rectangular shape and polyhedral at the non-

rectangular shape to minimize the error due to

unbalanced mesh size ratio. Meshing is a process of

breaking domains into smaller volumes/forms that

can facilitate stream domain discretization and can

apply control equations to the flow domain. The

domain of the coal burner is mass flow inlet, while

CCOFA, SOFA, primary air, and secondary air are

velocity inlet. The water wall-tubes on wall furnace

are modeled as a heat sink that absorbs heat from flue

gas (heat flux). All heat exchangers, from superheater

to economizer, are modeled as a porous medium that

also absorbs heat (heat generation). The last, the

outlet will be modeled as a pressure outlet.

In this study 70% LRC type coal will be injected

through the elevation of B, D, E, G burners and MRC

type coal with a composition of 30% will be injected

through elevations A and C, as suggested in

Sa’adiyah et al. research, while at elevation F is in

stand by position (deactivated).

(a)

(b)

Figure 1: (a) Boiler geometry and (b) boiler mesh.

Numerical Simulation of Combustion Characteristics on Tangentially Fired Boiler with Different Yaw Angle

185

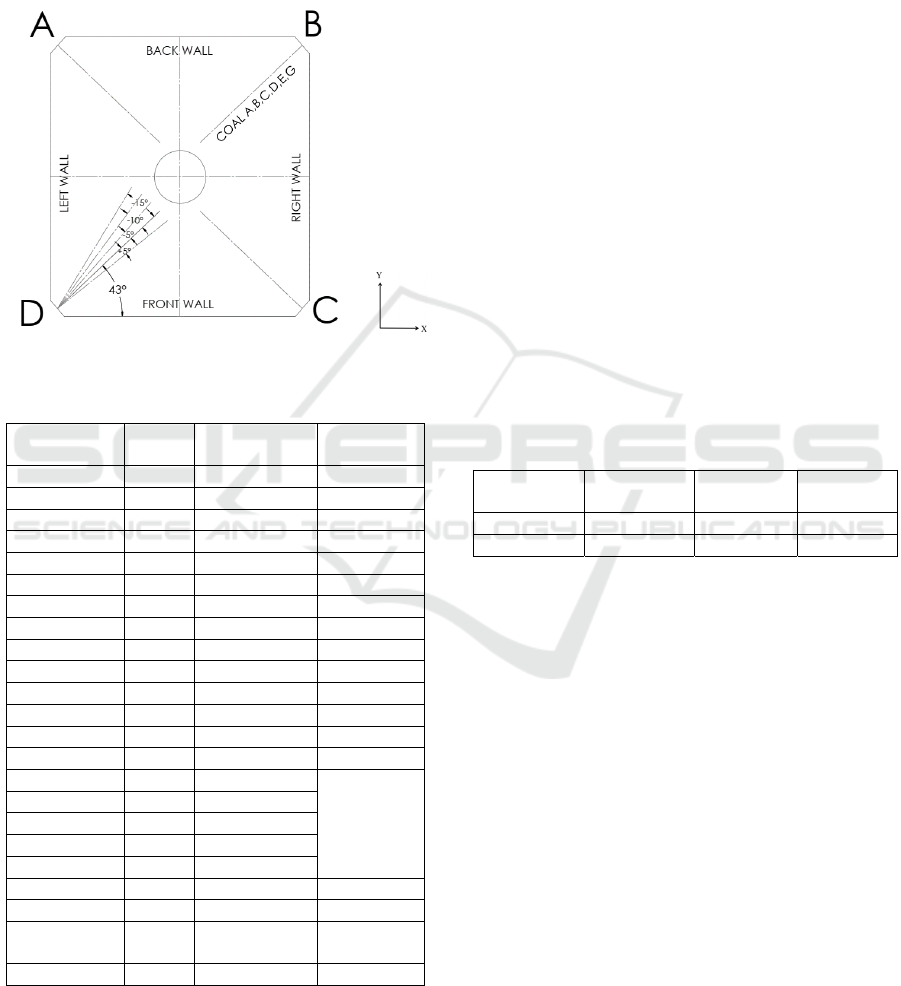

The original angle configuration for each coal

injection and auxiliary air can be seen in figure 2 and

Table 1. The change of yaw angle in this study is

focused on secondary air injection angle, which will

vary from + 5º, 0º, -5º, -10º, and -15º. The specific

condition of coal injection and auxiliary air, including

CCOFA and SOFA, are presented in Table 1.

Figure 2: Yaw angle configuration.

Table 1: Auxiliary Air Boundary Condition.

Auxiliary

Air

Angle

(º)

Temperature

(º C)

Velocity

(m/s)

AA 0 359 59,749

A 0 66 22,8

AB 4.5 359 59,749

B 0 66 22,8

BC1 4.5 359 59,749

BC2 15 359 59,749

C 0 66 22,8

CD1 15 359 59,749

CD2 4.5 359 59,749

CD3 15 359 59,749

D 0 66 22,8

DE1 15 359 59,749

DE2 4.5 359 59,749

E 0 66 22,8

EF 4.5 359

Not

activated

(assumed

as a wall)

F 0 66

FG1 -20 359

FG2 (LDO) 4.5 359

FG3 -20 359

G 0 66 22,8

GG -25 359 59,749

CCOFA 1 &

2

-25 359 15,438

SOFA 1 & 2 0 359 11,8197

The solution used in this study is using the

SIMPLE (Semi-Implicit Method for Pressure-Linked

Equations) algorithm, where least squares are cell-

based for gradients, standard for pressure, first-order

upwind for turbulent kinetic energy and turbulent

dissipation rate, and second-order upwind for

momentum, lig-vol, O

2

, CO

2

, H

2

O, H

2

, and CO. The

use of these solutions is based on research by

Chungen et al. (2003) and Choi and Kim (2009). The

viscous model to simulates the turbulence flow inside

the boiler is the standard k-ε model, while the coal

combustion process using the species transport

model.

3 RESULTS AND DISCUSSION

In the numerical simulation, before it can be

continued to do further research, it should be relevant

to the original condition called validation. The

simulation results with the original condition have to

be in the same line with minimal error. However,

because the actual measured results only have CO

2

and O

2

emission percentages, then in this study, Table

2 points out the difference value O

2

and CO

2

concentration at the outlet in both actual and

simulation data/ Computational Fluid Dynamic

(CFD).

Table 2: Auxiliary Air Boundary Condition.

Emission at

boiler exit

Plant Data

(%)

CFD (%) Error

O2 5,4 5,9 9%

CO2 14,8 15,5 4,7%

Table 2 shows that there is a reasonably small

error in CO2 exhaust emissions which is below 5%,

whereas in O2 exhaust emissions there is a difference

of 9%, the simulation results show that the exhaust

emissions data obtained at the outlet is entirely

consistent with the actual data because the error is still

below 10%, this refers to previous research where

errors that occur in exhaust emissions between actual

and simulated data have an error of 16% (Ho Young

Park et al., 2012) and an error of 11% (Tan et al., 2017

) So that this simulation can be used for further

research.

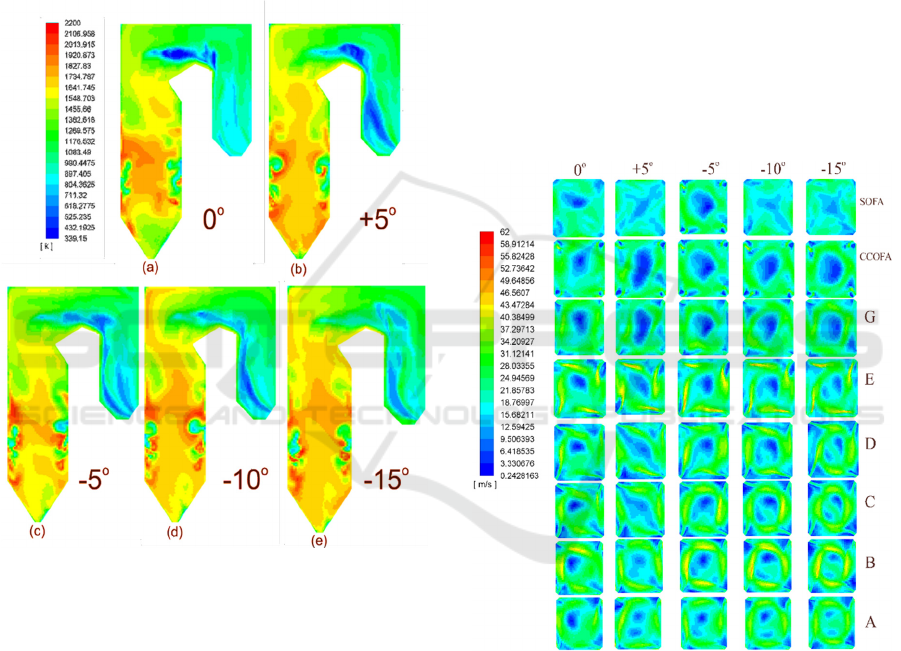

3.1 Temperature and Velocity

Distribution

The temperature distribution at the y-center cross-

section is shown in Figure 3. The original case with

default yaw angle 0˚ is depicted in Figure 3 (a). Based

on the default configuration, the fire-ball swirling to

clockwise direction. The injection of MRC to burners

ICONIT 2019 - International Conference on Industrial Technology

186

at elevation A and C makes high-temperature

distribution above the hopper zone because MRC has

a high heating value. Then the heat from MRC

combustion accelerates the burning rate of LRC at the

other burner elevation. The high temperature

increases the devolatilization process, so the char of

LRC burned faster. Therefore the combustion process

complete right before entering the superheater and

reheater area. However, the temperature before

entering the superheater area is still relatively high

that needs to be considered to prevent the damage of

the superheater tube from overheated.

Figure 3: Temperature distribution at the y-center cross-

section.

The first case which uses +5˚ yaw angle has the

opposite direction of fire-ball, this condition weakens

the fire-ball. Rather than moving upward, the fire-ball

tends to move to the hopper zone. The combustion

process then also takes place in the hopper zone; that

is why the red color shown in Figure 3 (b). However,

because almost all MRC get burned at hopper zone

and at a lower elevation, the LRC at higher elevation

did not get enough heat to speed up the burning time,

then the uncomplete combustion of LRC moving

upward to superheater area and get burned in that

area.

The observation of temperature distribution with

yaw angle -5˚, -10˚, and -15˚ showed in Figure 3 (c-

e). For these cases, the yaw angle sprays air in the

same direction with fire-ball rotation. The increasing

of yaw angle makes the fire-ball become wider to the

vicinity of wall-burner also decrease the turbulence.

The wider fire-ball expands the combustion area and

let the coal get complete combustion before entering

the next elevation and the superheater area. However,

for numerical simulation with -10˚ shows, the

combustion process delayed until the superheater area

and got worse when using -15˚. This can happen

because after increasing the yaw angle, the air

injection also directing some coal to the wall-furnace

and get burned. The red color occurs in the vicinity of

the burner, which indicated a very high temperature.

While the combustion takes place near the wall

furnace, the intake of air becomes insufficient at the

center, causing uncomplete combustion, the flow

with uncomplete combustion coal moving upward,

and get burned at the superheater area and damage

superheater tubes.

Figure 4: Velocity distribution at each elevation.

The phenomena that happened in the distribution

of temperature at each elevation strengthened with the

distribution of velocity, as shown in Figure 4.

Simulation with +5° yaw angle made the velocity

distribution spread and dispersed the fire ballet

elevation C & D. While on the negative yaw angle,

the velocity distributes evenly from bottom elevation,

elevation A, until SOFA elevation, especially with the

case -5° yaw angle.

Numerical Simulation of Combustion Characteristics on Tangentially Fired Boiler with Different Yaw Angle

187

Table 3: Height for each elevation.

Elevation Height (m)

A 26.64

B 28.5

C 30.36

D 32.22

E 34.08

F 35.94

G 37.8

CCOFA 39.17

SOFA 45.73

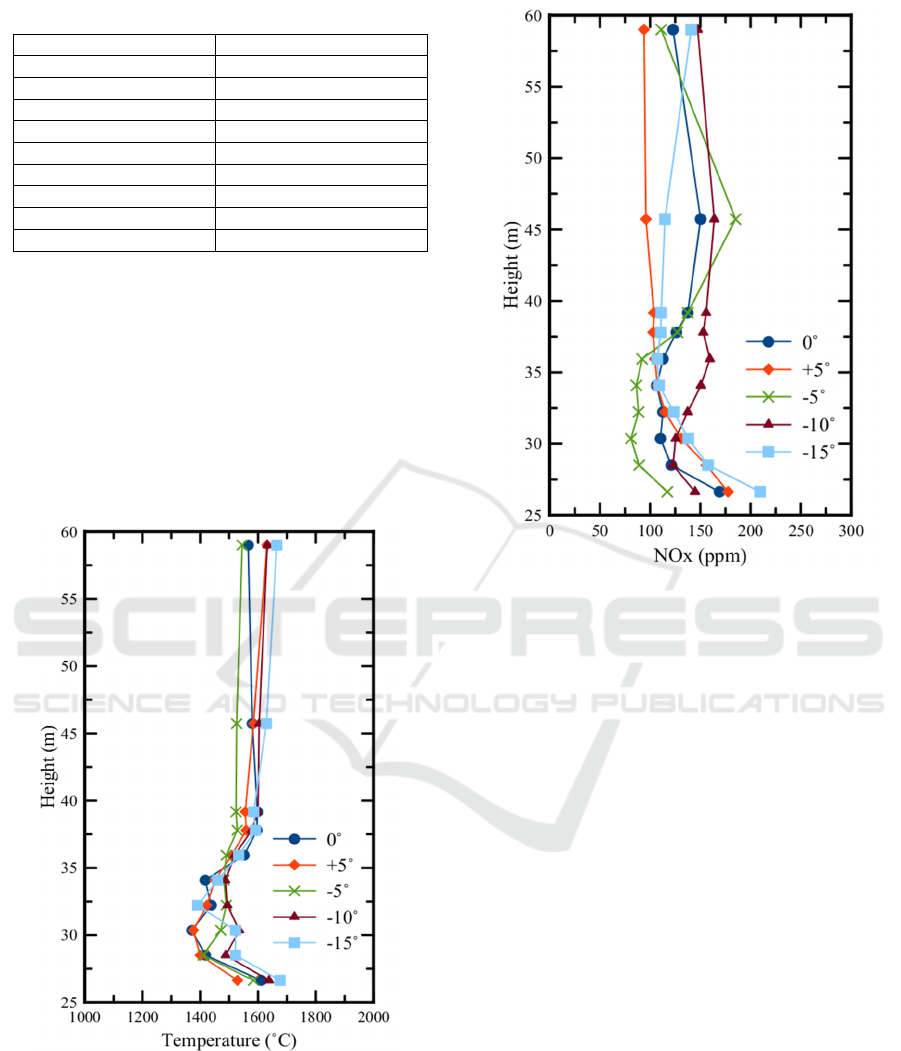

3.2 NOx Emission

The special condition of this study is the mixed fuel

that has been used, namely MRC and LRC, which

need modification of yaw angle to reduce the

consumption of coal. Furthermore, the emission also

needs to be considered, called NOx, to offer the best

yaw angle. Figure 5 depicted the average temperature

and NOx concentration. The height shown in the

graph is the height of each elevation, Table 3.

(a)

(b)

Figure 5: Velocity distribution at each elevation.

The higher temperature will have higher NOx

concentration. However, the average value for both

temperature and NOx concentration can not represent

the actual phenomena inside the boiler; the further

observation of NOx is need inside the boiler, Figure

6.

The NOx production relies on temperature and the

amount of nitrogen and oxygen in the flue gas. When

the temperature is higher than 1800K (El-Mahallawy,

2002), the nitrogen from air and coal will react with

oxygen to generate NOx emission. The original case

with 0˚ produced high enough NOx species in the

furnace area, Figure 6 (a). The NOx generation also

occurs until the outlet of the boiler, although only

with a small amount. This indicates still there is

enough heat, nitrogen, and oxygen to produce more

NOx.

The combustion with yaw angle +5˚, as shown in

Figure 6 (b), generated a high amount of NOx in the

hopper zone until the middle of the furnace area, and

this is happening because of the very high

temperature formed due to MRC combustion. Despite

high NOx production at the lower part of the furnace,

the other area includes the heat exchanger area

forming the only little amount of NOx since all

ICONIT 2019 - International Conference on Industrial Technology

188

combustion processes, which produce high heat ends

at the furnace zone.

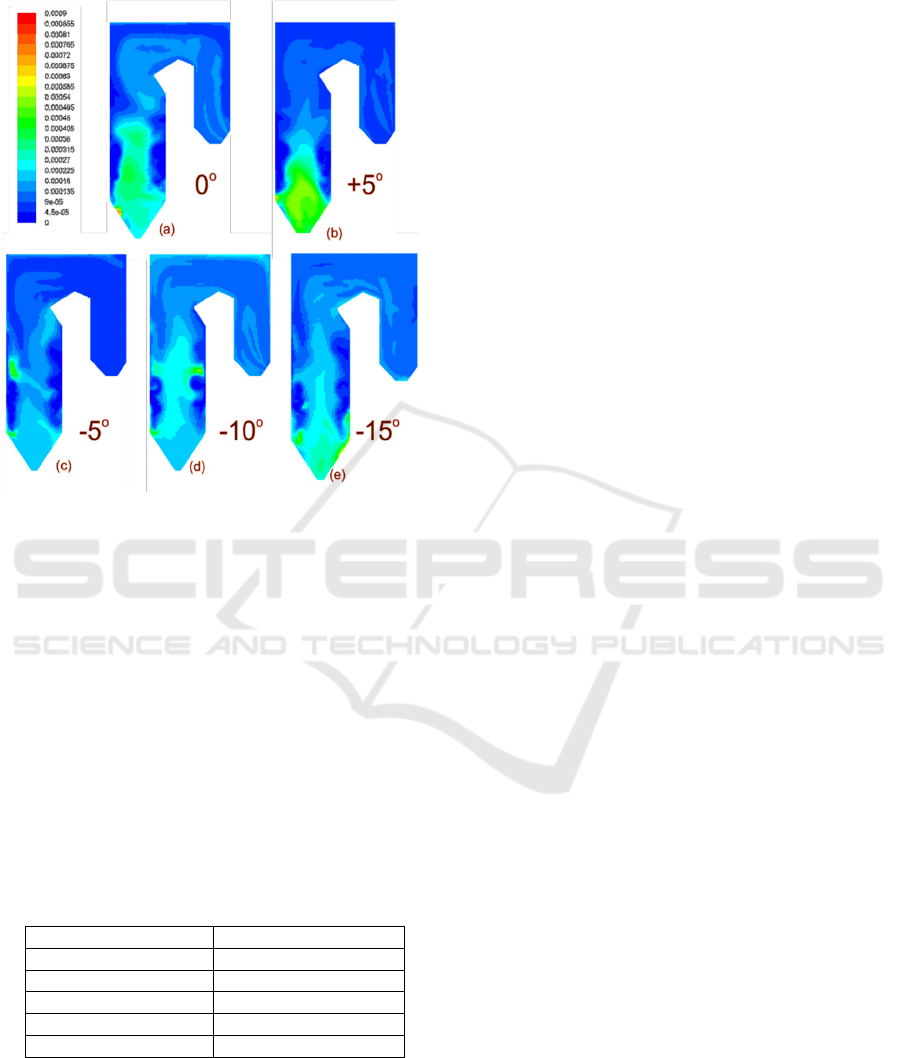

Figure 6: NOx distribution at the y-center cross-section.

The distribution of NOx with -5˚, -10˚, and -15˚,

which conceived in Figure 6 (c-e), shows that NOx

generation increased as the increasing of yaw angle.

The highest NOx formed at the lower part of the

furnace of -15˚ yaw angle simulation. Regardless of

the highest NOx amount at -15˚ yaw angle,

represented by green color, the simulation with -10˚

yaw angle actually generates more NOx. As can be

seen in Figure 6 (d), NOx formation also happens in

the upper part of the furnace and on the heat

exchanger area. While comparing to all cases with

negative yaw angle, the case with +5° yaw angle

produce a relatively small amount of NOx than

others.

Table 4: NOx emission at boiler exit

Yaw angle NOx (ppm)

0º 113,32

+5º 87,62

-5º 83,07

-10º 145,04

-15º 126,43

Observation of flue gas emission is also taken

place at the boiler exit to know how the yaw angle

variation affected the emission results before going

out to the atmosphere. Table 4 discloses the amount

of each emission for each variation of the yaw angle.

It shows the variation of the yaw angle really affects

the emission, with less emission is provided in -5°

yaw angle case.

4 CONCLUSION

In this study, Computational Fluid Dynamic

modelings were developed to investigate the effect of

the burner yaw angle on the combustion characteristic

and gas emission of a 625 MWe tangentially fired

boiler with mixed coal (70% LRC & 30 % MRC). The

Computational Fluid Dynamic model was validated

against measured results were found to be both

qualitatively and quantitatively consistent. As the

burner yaw angle going wider, the temperature

deviation also higher, which happened on the upper

furnace. The coal burner yaw angle that has the best

temperature distribution is at -5º because it has the

least temperature deviation on the upper furnace,

which minimizes the risk of overheat on superheaters

and reheaters. The least NOx is happened at -5º yaw

angle, with the result is 83,07 ppm because of the

NOx production process at the furnace effect the

results of NOx at the boiler outlet.

ACKNOWLEDGMENTS

The authors would like to thanks to all who help and

support the authors to finish this paper.

REFERENCES

Al-Abbas, Audai Hussein., Naser, Jamal., Hussein, Emad

Kamil., 2012. CFD modeling of air-fried and oxy-fuel

combustion in a large-scale furnace at Loy Yang A

brown coal power station. Fuel (2012). Elsevier.

Al-Abbas, Audai Hussein., Naser, Jamal., Hussein, Emad

Kamil., 2012. Numerical simulation of brown coal

combustion in a 500 MW tangentially-fired furnace

under different operating conditions. Fuel (2012).

Elsevier.

BUMN, (2017), Produksi Batubara Indonesia. [online]

available on http:// bumn.go.id/bukitasam/berita/2-

Batubara-di-Indonesia-Produksi-Ekspor-Batubara -

Indonesia- [accessed on July 22, 2018].

Chen, Shinan., He, Boshu., He, Di., Cao, Yang., Ding,

Guangchao., Liu, Xuan., Duan, Zhipeng., Zhang, Xin.,

Song, Jingge., Li, Xuezheng., 2017. Numerical

investigations on different tangential arrangements of

burners for a 600 MW utility boiler. Energy 122 (2017).

Elsevier.

Choi, Choeng Ryul., Kim, Chang Nyung., 2009. Numerical

investigation on the flow combustion and NOx

Numerical Simulation of Combustion Characteristics on Tangentially Fired Boiler with Different Yaw Angle

189

emission characteristics in a 500MWe tangentially fired

pulverized-coal boiler. Fuel 88 (2009). Elsevier.

Chungen, Yin., Rosendahl, Lasse., Condra, Thomas J.,

2003. Further study of the gas temperature deviation in

large-scale tangentially coal-fired boilers. Fuel 82

(2003). Elsevier.

El-Mahallawy, F,. El-Din Habik, S., 2002. Fundamentals

and Technology of Combustion, Elsevier Science Ltd.

Oxford

KESDM., 2016. Laporan Kinerja Direktorat Jenderal

Mineral dan Batubara, KESDM. Jakarta.

Li, D., Lv, Q., Feng, Y., Wang, C., Liu, X., Chen, K., Xu,

K., Zhong, J., Che. D., 2017. Effects of coal blending

and operating conditions on combustion and NOx

emission characteristics in a tangentially-fired utility

boiler. Energy Procedia 105 (2017), Elsevier.

Liu, Y.C., Fan, W.D., 2017. Experimental and numerical

studies on the gas velocity deviation in a 600 MWe

tangentially fired boiler. Applied Thermal Engineering

110 (2017). Elsevier.

Park, Ho Young., Baek Se Hyun., Kim, Young Joo., Kim,

Tae Hyung., Kang, Dong Soo., Kim, Dong Woong.,

2012. Numerical and experimental investigations on the

gas temperature deviation in a large scale, advanced

low NOx, tangentially fired pulverized coal boiler. Fuel

104 (2013). Elsevier.

Park, Ho Young., Baek Se Hyun., Kim, Hyun Hee., Kim,

Young Joo., Kim, Tae Hyung., Lim, Hyun Soo., Kang,

Dong Soo., 2016. Reduction of main steam temperature

deviation in a tangentially coal-fired, two pass boiler.

Fuel 166 (2016). Elsevier.

Sa’adiyah, Devy., Bangga, Galih., Widodo, Wawan.,

Ikhwan, Nur., 2017. Numerical study of flow,

combustion and emissions characteristics in a 625

MWe Tangentially Fired Boiler with the composition

of Coal 70% LRC and 30% MRC. AIP Conference

Proceedings 1867, 020007 (2017). AIP Publishing.

ICONIT 2019 - International Conference on Industrial Technology

190