Failure Risk Analysis on Screw Compressor

using Failure Mode and Effect Analysis (FMEA) Method

Hendrik Elvian Gayuh Prasetya, Joke Pratilastiarso, Radina Anggun Nurisma, Sulkan Efendi and Fifi

Hesty Sholihah

Powerplant Engineering Department, Politeknik Elektronika Negeri Surabaya, Surabaya

Keywords: Screw compressor, FMEA, LTA, MTTF.

Abstract: Screw compressor is a compressor that uses impeller media to compress air. This compressor is included in

the type of rotary compressor. In the work process, the screw compressor is equipped with several supporting

components. The screw compressor consists of 5 components, namely: intake filter, main motor, v-belt, screw

compressor, and oil filter. To maintain the performance of the screw compressor, it requires a method that can

predict the critical time in screw compressor components and can determine the impact of damage on an

operation. In this study, qualitative analysis and quantitative analysis will be conducted to predict and

determine the time and effect of screw compressor components failure. The method used in qualitative

analysis is Failure Mode and Effect Analysis (FMEA) and Logic Tree Analysis (LTA) methods. While the

quantitative analysis uses the reability function (Rt), hazard rate function (ht), and mean time to failure

(MTTF) parameters. By using qualitative FMEA analysis, the repair priority order in the screw compressor

is the oil filter, and oil filter is C category using LTA analysis, it means if the failure mode does not have an

impact on safety or operational plant and only causes relatively small economic losses for repairs. While

quantitative methods results recommended treatment time, intake filter must be maintained 25 - 27 days, oil

filter must be maintained 28 - 29 days, V-belt must be maintained 105 - 125 days, the main motor must be

maintained 330 - 335 days, and screw must be maintained 292 - 313 days.

1 INTRODUCTION

The screw compressor is a compressor that uses

impeller media to compress air. This compressor is

included in the type of rotary compressor. In the work

process, the screw compressor is equipped with

several supporting components. The main component

of the screw compressor is two pieces of the screw,

which rotate in the opposite direction, causing low

pressure on the suction side and high pressure on the

discharge side. Screw rounds are obtained from the

main motor components distributed through the V-

belt. To maintain its reliability, the screw compressor

is equipped with an oil cooling system that can

prevent overheating. In addition, the screw

compressor is also equipped with an air filter that can

prevent dust particles from entering the screw

compressor system.

However, in the work process, screw compressors

often experience several constraints on their

components. The lightest obstacle experienced by

screw compressors is the blockage of air-water by

dust or dirt. This can cause a decrease in the amount

of air entering the screw compressor. It can lead to a

decrease in the efficiency of the screw compressor.

Another obstacle that may occur is the clogging of the

oil filter due to the dirt in the oil. This can lead to

overheating so that it can reduce the performance of

the screw compressor work system. The hardest

obstacle found in a screw compressor is the damage

in the main motor that can cause a decrease in screw

rotation so that it can reduce the amount of

compressed air. In addition, screw damage caused by

the poor quality of fluid can decrease the efficiency

of the screw compressor. To maintain the

performance of the screw compressor, it requires a

method that can predict the critical time in screw

compressor components and can determine the

impact of damage on an operation.

In this study, qualitative analysis and quantitative

analysis will be conducted to predict and determine

the time and effect of screw compressor components

failure. The method used in qualitative analysis is

Failure Mode and Effect Analysis (FMEA) and Logic

226

Prasetya, H., Pratilastiarso, J., Nurisma, R., Efendi, S. and Sholihah, F.

Failure Risk Analysis on Screw Compressor using Failure Mode and Effect Analysis (FMEA) Method.

DOI: 10.5220/0009445202260232

In Proceedings of the 1st International Conference on Industrial Technology (ICONIT 2019), pages 226-232

ISBN: 978-989-758-434-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Tree Analysis (LTA) methods. FMEA method is a

failure analysis method to determine the level of

damage so that the repair priority in a tool is known.

While the LTA method is a method used to give

priority to each damage mode and conduct a review

toward functions and malfunctions. While the

quantitative analysis uses the reability function (Rt),

hazard rate function (ht), and mean time to failure

(MTTF) parameters. The damage constant needed to

get those three parameters above is obtained from the

Weibull 6 ++ software based on the data that has

occurred.

From the analysis carried out, it is expected to be

able to know the time of damage and the type of

damage that occurs in screw compressor components.

Therefore, it can determine the damaging impact of

the screw compressor unit operating system and the

correct repair

2 LITERATURE REVIEW

The screw compressor is a compressing or

compressing fluid (gas or air) device with a screw-

shaped cross-section. The screw compressor system

uses a screw system, and the incoming air will be

filtered using an air filter, then the air will enter the

compressor inlet side. The air will spin following the

screw compressor. Both screws in the compressor

cause the air to compress so that at the outlet side, the

air pressure will rise.

Figure 1. Component screw compressor

Based on picture 1 screw compressor component

consists of 5 components, namely: intake filter, main

motor, v-belt, screw compressor, and oil filter.

a.

Intake Filter

The function is filtering outside air that enters the

compressor system

b.

Main motor

The function is driving Compressor via V-belt

c.

V-belt

The function is distributing motor rotation to the

compressor

d.

Screw compressor

The function is increasing air pressure with the

compression method

e.

Oil filter

The function is filtering oil from dirt

3 RESEARCH METHODOLOGY

To predict a failure, qualitative and quantitative

methods can be used. Qualitative method is a failure

prediction method by collecting information from

various informants, which later we can consider as a

damage analysis. While the quantitative method is a

statistical failure prediction of a system by utilizing.

Various types of data distribution. The following are

the steps used to analyze the failure of the screw

compressor unit

Figure 2. Research methodology

3.1 Qualitative Method

3.1.1 Failure Mode and Effect Analysis

Method (FMEA)

FMEA is a methodology used to analyze and find all

potential failures that occur in a system and find the

effects of failures which occur on the system and how

to improve or minimize failures or their effects on the

system (improvement and minimalism is conducted

based on a ranking of the severity and probability of

Failure Risk Analysis on Screw Compressor using Failure Mode and Effect Analysis (FMEA) Method

227

failure). To analyze the potential failure system using

the FMEA method, it requires 3 data, namely

severity, assurance, and detection. Data severity,

occurrence, and detection are obtained from various

types of literature, which state the level of failure

cause, the impact, and the instrument capability to

read the potential failure.

Table 1: Screw compressor component and failure effect

3.1.2 Logic Tree Analysis (LTA) Method

The compilation of Logic Tree Analysis (LTA) has

the purpose of giving priority to each damage mode,

showing the type of hazard category, and

recommending steps that must be taken if a failure

occurs. There are four important things in critical

analysis as follows:

1)

Evident, whether the operator knows that

under normal conditions, there has been a

disturbance in the system?

2)

Safety, whether this failure mode causes

safety problems?

3)

The outage, whether this failure mode

causes the whole or part of the machine

stops?

4)

The category is categorization obtained after

answering the questions. In this section, the

components are divided into four categories,

namely:

Category A (Safety problem) if the

failure mode has safety consequences for

personnel and the environment.

Category B (Outage problem) if failure

mode has consequences for plant

operations (affecting the quantity or

quality of output) that can cause

significant economic losses.

Category C (Economic problem), if the

failure mode does not have an impact on

safety or operational plant and only

causes relatively small economic losses

for repairs.

Category D (Hidden failure) if the

failure mode is classified as a hidden

failure, which is then classified into D /

A categories, D / B categories, and D / C

categories.

The following is the LTA analysis obtained in this

study, where the information is broken down into

each type of damage in the screw compressor

Table 2 LTA analysis

Component Damage E S O

Intake Filter The filter

element is

clogged with

dust/dirt,

No No No

Broken /

torn filter

element

No No No

Main motor The motor

RPM is

decreasing

Yes No Yes

Motor

overheat

Yes No Yes

Supply

current is

low

Yes No Yes

V-belt V belt slip No No Yes

V belt is

broken

No No Yes

V belt is

dirty

No No No

Screw broke No No No

Component Function Failure Effect

Intake Filter Filtering

outside air that

enters the

compressor

system

The

accumulation

of dust/dirt on

the air filter so

that there is

clogging in the

inlet

Airflow

decreases so

the risk of

plugging on

the tube and

hopper in the

ash handling

system

Main motor Driving

Compressor

via V-belt

Motor RPM

decreases,

Motor

overheats, Low

current

supply

Decreasing

air capacity

interferes

motor work

V-belt Distributing

motor rotation

to the

compressor

V-belt

breaking

The motor

cannot

transmit

rotation to

the

compressor

Screw

compressor

Increasing air

pressure with

the

compression

method

the screw is

worn and

jammed

Air pressure

decreases

Oil filter Filtering oil

from dirt

Clogged up

dirt

Cooling oil

circulation is

disrupted

ICONIT 2019 - International Conference on Industrial Technology

228

Screw

compressor

Screw

stuck

No No Yes

Oil filter Oil filter t

clogged up

Yes No Yes

Oil filter

leak

out

No No Yes

Information: E (Evident), S (Safety), and O

(Outage )

3.2 Quantitative Method

The quantitative analysis method is a failure risk

analysis method that uses a numerical approach to

show the impact of damage to the tool. The data used

determines TTF (time to failure) and TTR (time to

repair) value than the Screw compressor operation.

Then the data is processed using Weibull 6 ++

software, which serves to determine the suitable

distribution used to determine the reliability function.

From the data processing carried out, the results are

as follows:

Table 3 Quantitative Methods result

Component Distribution Constant

Intake Filter Lognormal

μ = 6,6553

σ = 0,1467

Main motor Weibull

λ = 1.54275

γ = 0.9736

β = 5.1736

η =10757

V-belt Lognormal

μ = 8,4586

σ = 0,6823

Screw

compressor

Weibull

λ = 2.4735

γ = 1

β = 3,716

η

=10813

Oil filter Lognormal

μ = 6,6553

σ = 0,1467

Information :

t : failure time μ : mean

ɸ: normal distribution data

σ : deviation standart

Distribusi Weibull

Reliability function :

ܴ(ݐ)=݁[−(ݐ−ߛߠ)ߚ]

Information :

t : failure time

λ : lambda Weibull parameter

γ : gamma Weibull parameter

ߚ : betha Weibull parameter

θ : tetha Weibull parameter

4 RESULT AND DISCUSSION

4.1 Analysis Results of Failure Mode

and Effect Analysis (FMEA)

FMEA analysis is used to analyze all potential

failures that occur in each component, to arrange the

system, and determine the priority of damage in

equipment. FMEA analysis is in the form of a risk

priority number (RPN) value obtained from the

multiplication between the value of severity,

occurrence, and detection. The severity, occurrence,

and detection values are obtained from the value

scorers from value 1 to value 10. Severity has value 1

if the failure does not cause any effect, while value 10

if a dangerous condition occurs without warning after

a failure occurs. The occurrence has value 1 if there

is almost no failure in a component, while it is worth

10 if a component often fails. Detection has value 1 if

preventive maintenance will always detect the

potential cause of failure and failure mode while

having value 10 if preventive maintenance is unable

to detect potential causes of failure and failure mode.

In this study, there are 10 respondents, where each

respondent was an expert in the field of screw

compressor. Each respondent will assess the FMEA

table according to the scale of the severity value,

assurance, and detection that is in accordance with the

facts in the field. After obtaining severity, assurance,

and detection values, the value of the risk priority

number (RPN) is calculated, which is a multiplication

of the severity, occurrence, and detection values. To

easily determine which component is the priority of

improvement, a Pareto chart is made.

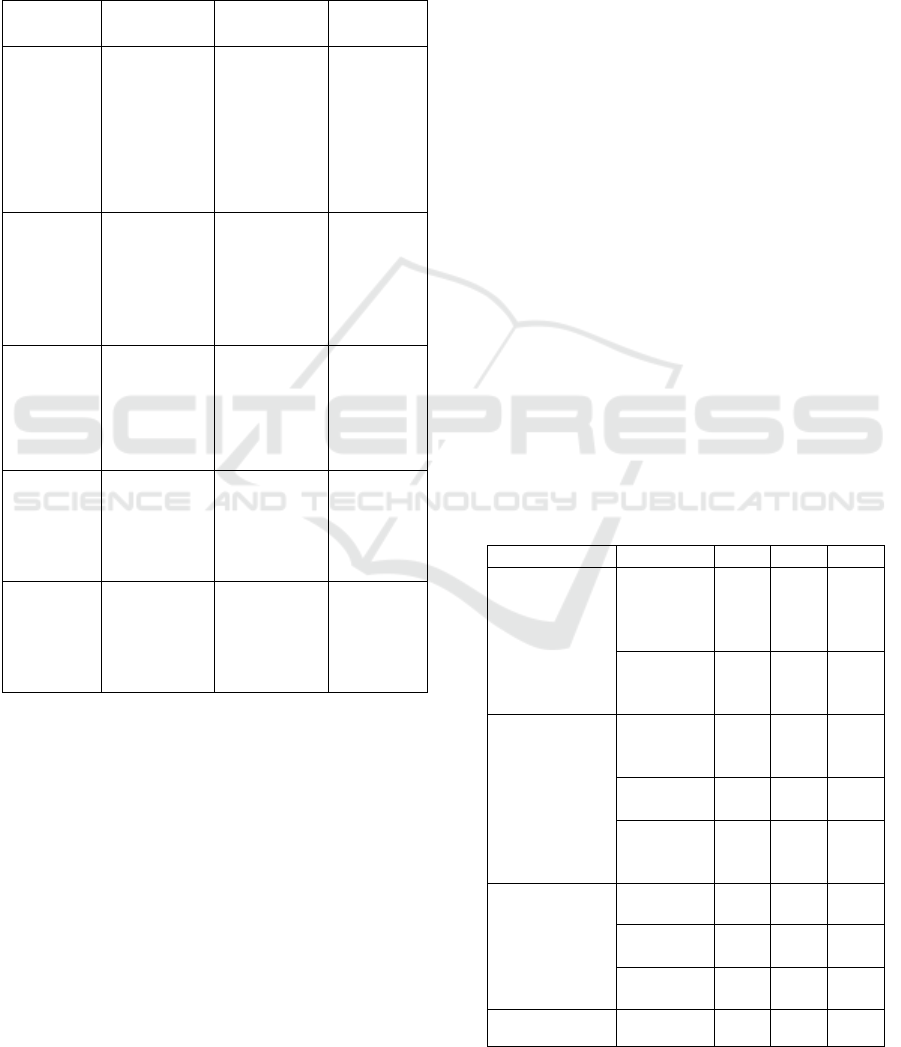

Figure 3. Pareto chart

From figure 3, it can be seen that by using the

FMEA method, the RPN value is obtained from the

highest one, such as oil filter, intake filter, v-belt,

Failure Risk Analysis on Screw Compressor using Failure Mode and Effect Analysis (FMEA) Method

229

main motor, and screw. The higher the value of RPN,

the component has a higher priority to be replaced

when damage occurs because it has a very high

urgency. This indicates that the oil filter and intake

filter have low reliability and a high rate of damage

so that it requires periodic checks. The low level of

reliability and the high rate of damage to the oil filter

can be caused by several things, including the low

quality of oil filter, the work of the oil filter, which is

too heavy because the oil is too dirty and inconvenient

repair techniques.

4.2 Logic Tree Analysis (LTA) Analysis

Results

LTA analysis shows the types of hazard categories

and recommends steps that must be taken when a

failure occurs. Table 4 below shows the hazard level

category for each screw compressor.

Table 4 LTA Methode Analyze

Component Damage Category

Intake Filter The filter element is

clogged with dust/dirt,

C

Broken/torn filter

element

D

Main motor The motor RPM is

decreasing

B

Motor overheat B

Supply current is low C

V-belt V belt slip C

V belt is broken

B

V belt is dirty

D

Screw broke C

Screw compressor Screw stuck B

Oil filter Oil filter t clogged up C

Oil filter leak out C

Based on table 4, each component has a different

category of damage. Oil filters and intake filters

belong to the C / D category because the damage does

not have an impact on the safety and operational unit,

even the damage that occurs can be hidden accident.

While the damage in the v-belt is in the B / C

category. Failure will be classified as category B if

the belt breaks because it will affect the screw

compressor operating system. While the damage will

be classified as category C if the damage is only

minor damage such as v-belt dirty and slippage.

Whereas damage to motorbikes and screws is

included in the B/ C category. Damage is included in

category B if there is a decrease in RPM and

overheats on a motorbike, or when the screw jams.

Category C occurs when the supply of electric current

is reduced at the main motor, or when there is wear

screw so that it can cause a decrease in screw

compressor performance

4.3 Reliability Function Analysis

The reliability function analysis is used to determine

the reliability value based on quantitative operational

time. Quantitative data is obtained from operational

data of the tool, which is then processed using

Weibull 6 ++ software, which displays the value of R

(t) using each distribution. Figure 4 below shows a

graph of the reliability function R (t) of each

component.

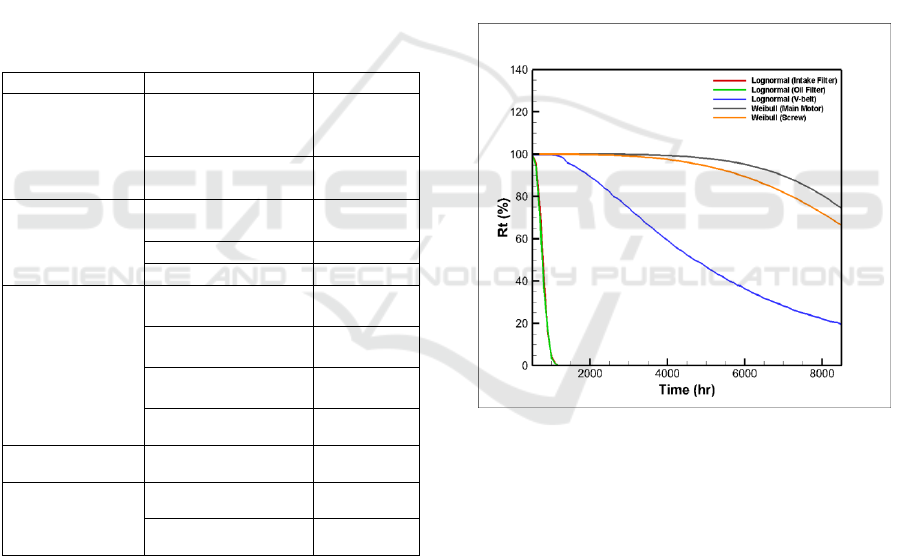

Figure 4. Graph of the reliability function R (t) of each

component

From this graph, it can be seen that the

components of the intake filter, oil filter, and V-belt

have the same Lognormal failure distribution

equation, while Main Motor and Screw have the

Weibull failure distribution equation. To reach Rt =

0%, the intake filter and oil filter need 1500 hours.

The V-belt component, at variable (t) maximum

(8500 hours), reaches Rt = 19.49%. While the Main

Motor and Screw Components, the variable (t)

maximum (8500 hours), each reach Rt = 74.41% and

Rt = 66.45%.

ICONIT 2019 - International Conference on Industrial Technology

230

4.4 Recommendation Maintenance

After analyzing the damage to the screw compressor

subcomponent, the next step is the recommendation

for proper maintenance and repair. Appropriate

improvement recommendations for each component

are as follows:

a. Intake Filter

From the results of both qualitative and

quantitative analyses, the intake filter shows a low

level of endurance. So that the right maintenance

schedule is needed to be more efficient. The

recommended treatment schedule is 25-27 days.

From the calculation results, the reliability obtained

when 25-27 days is 77.04% - 89.07%. The

recommended types of maintenance are preventive

maintenance and corrective maintenance.

-

Preventive maintenance, what can be done is

cleaning the intake filter using compressed air

to reduce the accumulation of dust attached to

the intake filter element.

-

Corrective maintenance, what can be done, is

to replace the intake filter periodically.

b. Oil Filter

From the results of qualitative and quantitative

analysis, the level of reliability in the oil filter is the

lowest compared to other sub-components. The

recommended treatment schedule is 28-29 days.

From the calculation results, the reliability obtained

when 28-29 days is 79.95% -72.57%. The

recommended types of maintenance are preventive

maintenance and corrective maintenance.

-

Preventive maintenance, what can be done is to

clean the area around the oil filter to find out

whether there is oil leakage or not.

-

Corrective maintenance, what can be done, is

to replace the oil filter periodically.

c. V-belt

From the results of qualitative and quantitative

analysis, the reliability value of 99.7% when t = 30

days. The recommended treatment schedule is 105 -

125 days. From the calculation results, the reliability

obtained when 105 - 125 days is 82.38% - 74.54%.

The type of maintenance recommended is preventive

maintenance.

-

Preventive maintenance, what can be done is to

clean the v-belt from dirt or dust, which also

checks the visual condition.

d. Main Motor

From the results of qualitative and quantitative

analysis, the reliability value of 99.92% when t = 30

Days. The recommended treatment schedule is 334 -

355 days. From the calculation results, the reliability

obtained when 334-355 days is 80.57% - 74.41%. The

type of maintenance recommended is preventive

maintenance.

-

Preventive maintenance, what can be done is to

do the cleaning on the motorbike to remove

dust or dirt on the body of the main motorbike

and also check the condition of the motorbike

visually.

e. Screw

From the results of qualitative and quantitative

analysis, the reliability value is 99.99% when t = 30

days. The recommended treatment schedule is 292 -

313 days. From the calculation results, the reliability

obtained when 292 - 313 days is 80.57% - 74.41%.

The recommended types of maintenance are

preventive maintenance, predictive maintenance, and

corrective maintenance.

-

Preventive maintenance, what can be done is to

change the intake filter regularly because

damage to the intake filter can cause damage to

the screw. In addition, oil filter replacement can

also extend the lifetime of the screw.

5 CONCLUSION

Based on failure risk analysis discussion in screw

compressors using qualitative and quantitative

methods, the following conclusions are obtained:

1.

By using qualitative FMEA analysis, the repair

priority order in a screw compressor ash

handling system based on the RPN rating is the

oil filter, intake filter, v-belt, main motor, and

screw. This means that if there is damage to the

screw compressor, the component that must be

corrected first is the oil filter component.

2.

By using qualitative LTA analysis, the damage

categories for each sub-component are as

follows :

a. Oil filters are C category

b. The intake filter is C/D category

c. V-belts are B/C/D category

d. The main motor is B/C category

e. The screw is B/C category

3.

Recommended treatment time to do is as

follows:

a. Intake Filter: 25 - 27 days

b. Oil Filter: 28 - 29 days

c. V-belt : 105 - 125 days

d. Main motor: 330 - 335 days

Screw : 292 - 313 days

Failure Risk Analysis on Screw Compressor using Failure Mode and Effect Analysis (FMEA) Method

231

REFERENCES

Yonemoto, R., Tsuchiya, T., Kato, E., Chiba, K., & Iizuka,

Y. (2018). U.S. Patent Application No. 10/145,374.

Carnero, M. C. (2005). Selection of diagnostic techniques

and instrumentation in a predictive maintenance

program. A case study. Decision support systems, 38(4),

539-555.

Kovacevic, A., Stosic, N., & Smith, I. K. (2002). CFD

analysis of screw compressor performance. Advances of

CFD in Fluid Machinery Design” edited by Elder, RL,

Tourlidakis, A, Yates MK, Professional Engineering

Publishing of ImechE, London.

Stamatis, D. H. (2003). Failure mode and effect analysis:

FMEA from theory to execution. ASQ Quality press.

Ericson, C. A. (1999). Fault tree analysis. In System Safety

Conference, Orlando, Florida (Vol. 1, pp. 1-9)

Kapur, K. C., & Lamberson, L. R. (1977). Reliability in

engineering design. New York, John Wiley and Sons,

Inc., 1977. 605 p.

Khan, F. I., & Haddara, M. M. (2003). Risk- based

maintenance (RBM): a quantitative approach for

maintenance/inspection scheduling and planning.

Journal of loss prevention in the process industries,

16(6), 561- 573.

ICONIT 2019 - International Conference on Industrial Technology

232