Characterization of Geopolymer Paste based on Fly Ash and Bottom

Ash in PLTU Kaltim Teluk using Sodium Hydroxide (NaOH)

Andika Ade Indra Saputra, Adrian Gunawan, Latu Anggary Putri Sukandar, Yoel Gallaran Salurante,

Intan Dwi Wahyu Setyo Rini

Institut Teknologi Kalimantan

intan@lecturer.itk.ac.id

Keywords: Bottom Ash, Fly Ash, Geopolymer Paste, Replacement Cement

Abstract: Cement Industry in Indonesia has grown significantly every year. Limestone is one of the raw cement

substitution material which has rapidly grown. The cement production process released carbon dioxide (CO2),

which resulted in global warming. As an alternative material substitution, fly ash (FA) and bottom ash (BA)

as the remained coal was generally used for cement production. PLTU Kaltim Teluk, one of the steam power

plant which located in Balikpapan, East Kalimantan, produced 150 tons of FA in a day. However, FA and BA

were laid out in the landfill and had not managed well. Actually, FA and BA had potential material as a

substitution of cement in the paving block ingredients. Adding an alkaline activation, which consists of

sodium silicate (Na2SiO3) and sodium hydroxide (NaOH), could be increased the compressive strength,

especially for paste using 100% FA. The property of FA was characterized by Scanning Electron Microscope

(SEM) and X-Ray Fluorescence (XRF). A compressive strength test was carried out on paste at the age of 3

and 14 days. The result showed that the highest compressive strength at 14 days was 13.93 MPa with 12 M

NaOH. This research was conducted as an alternative solution to the waste of PLTU Kaltim Teluk as a

substitute for cement in Balikpapan.

1 INTRODUCTION

Cement is a binder that is able to bind solid materials

such as sand and stone into a compact unit when it

mixed with water. The main raw materials in the

process of making cement are limestone and clay; the

main compounds in cement come from both of the

materials (Rahadja, 2010). The ancillary materials of

cement are silica sand, contributing to correct low

level of silica (SiO2) in clay and iron sand as

correction material of low-level Fe2O3 in main raw

material (Farhan, 2016). The components of cement

are lime (CaO), SiO2, alumina (Al2O3), ferric oxide

(Fe2O3), magnesite (MgO), and a small number of

other oxides (Rahadja, 2010).

The cement industry in Indonesia has experienced

rapid development. The Ministry of Industry (2016)

states that currently, the consumption of domestic

cement is 62,4 million tons, with a total of national

cement production reaching 68,7 million. The

increased cement production causes cement raw

materials needs also increasing; one of them is lime.

Nur et al. (2015) stated that the use of lime to produce

cement is the largest use of raw material from total

raw material for 87,4% or 5.047.263,31 tons. The

increasing consumption of limestone affects mining

in the karst area, such as reduced water supply

sources and environmental damage to the needs of the

surrounding communities. On the other hand, the

production process or forming karst to become

cement results or releases carbon dioxide (CO2),

where the CO2, itself, gas can cause the increase of

global warming.

As an alternative to reduce mining in karst areas

and to cope with increasingly high CO2 gas, other

materials are required for replacing cement as a

solution. There are various solutions or alternatives to

substitute cement, including copper slag (Kadhafi,

2015), Lapindo mud (Susanto and Nugroho, 2012),

rice husk ash (Anam and Sumarno, 2018), eggshell

powder (Hibur, 2017), fly ash (FA), and bottom ash

(BA). From all of those alternative materials, FA is

able to become the best one because of the content of

pozzolan as cement replacement with the highest

level of SiO2, Al2O3, and Fe2O3.

252

Saputra, A., Gunawan, A., Sukandar, L., Salurante, Y. and Rini, I.

Characterization of Geopolymer Paste based on Fly Ash and Bottom Ash in PLTU Kaltim Teluk using Sodium Hydroxide (NaOH).

DOI: 10.5220/0009445802520258

In Proceedings of the 1st International Conference on Industrial Technology (ICONIT 2019), pages 252-258

ISBN: 978-989-758-434-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All r ights reserved

Furthermore, FA and BA able to be used in this

research are the waste from the coal combustion

process at Kaltim Teluk Steam-electric Power Station

(PLTU). Everyday PLTU Kaltim Teluk produces FA

of 150 tons (Rini et al., 2018). According to

Government Regulation (PP), Number 101, the Year

2014 large amount of resulted waste in a period is

categorized as specific hazardous and toxic material

waste (B3). Therefore, FA and BA from PLTU

Kaltim Teluk are categorized as specific hazardous

and toxic waste.

So far, FA and BA of PLTU Kaltim Teluk are

managed by using the third party. The increasing total

amount of FA and BA in every year requires

management in order to not causing environmental

issues, for example, air or water pollution and

decreased quality of the ecosystem. Due to that, one

solution or alternative measure that is able to be

conducted is to process FA and BA as substitution or

replacement of cement in a mixture of pozzolan

concrete, causing them to become good additive

mineral for concrete (Adibroto et al., 2018).

2 MANUSCRIPT PREPARATION

2.1 Materials

Materials used in this research are FA and BA wastes,

which were collected from PLTU Kaltim Teluk on

February 4, 2019, solid Sodium Hydroxide (NaOH)

pro analyst (PA) type from Ensure ISO brand, and

solution of Sodium Silicate (Na2SiO3) from Pudak

Scientific brand.

2.2 FA Characterization

FA raw material is tested by using a Scanning

Electron Microscope (SEM) of FEI type from

Inspect-S50 brand and X-Ray Fluorescence (XRF)

from Panalytical brand with Minipal 4 type. SEM is

intended to determine shape, size, and surface

structure of FA grain, meanwhile XRF is intended to

analyze chemical composition and element

concentrate in FA.

2.3 The Making and Vicat Test on

Portland Cement Paste

In this procedure, making and Vicat test is conducted

on the cement paste. The purpose of this procedure is

to find out the effect of setting the time on the cement

paste. In order to figure out the setting time of a

cement paste, the normal consistency of a cement test

should be carried out first so that the need for water is

able to be determined. Steps of implementation in

normal consistency of a cement paste test are in

accordance with SNI 03-6827-2002 (Normal

Consistency Test Method of Portland Cement Using

Vicat Apparatus for Civil Work) that the object of

cement test is prepared with the composition of

cement and water in table 1. Afterward, cement is put

in, and water is added into the mixing pan to form

cement paste. After mixing has been completed, it is

formed into ball-shaped by using a hand. Then, the

cement paste is put into Vicat mold through its base

hole until fully filled and place it on the glass plate.

Next, the Vicat mold filled with cement paste is

positioned on the Vicat apparatus, and then the tip of

the Vicat rod is contacted to the center of cement

paste surface, and the position of the Vicat rod is

tightened.

Table 1: Composition of portland cement paste for the Vicat

test.

Cement (gram) Water (mL)

300 76,95

Steps of setting time tests are in accordance with

SNI 03-6827-2002 (Initial Setting Time Test Method

Using Vicat Apparatus for Civil Work) that 300

grams of cement and volume of water required for

normal consistency in accordance with normal

consistency of a cement paste test method are

prepared. Next, cement is put in, and water is added

into the mixing pan to form cement paste. Afterward,

a vicat mold filled with cement paste is stored along

with the glass plate in a humid cabinet, and the

concrete thermometer is positioned on the Vicat mold

and counted for 30 minutes by using a stopwatch.

After that, the vicat mold filled with cement paste is

positioned on the Vicat apparatus, then the tip of the

Vicat rod is contacted on the center of the cement

paste surface, and the Vicat rod is tightened. This

process is repeated every 15 minutes for other

different holes on the cement paste surface. The space

between penetration points is no less than 5 mm to the

inner sidewall of mold, and the space between 2

penetration points is no less than 10 mm.

2.4 The Making and Vicat Test on

Geopolymer Paste

In this research, the used composition of FA and

alkaline activation to form geopolymer paste is

determined by the Vicat test result. The mass ratio

between Na

2

SiO

3

solution and NaOH solution used

Characterization of Geopolymer Paste based on Fly Ash and Bottom Ash in PLTU Kaltim Teluk using Sodium Hydroxide (NaOH)

253

for alkaline activator is 3: 2. The composition of FA

and alkaline activation used on the Vicat test are

shown in table 2.

Table 2: Composition of FA and alkaline activation for

Vicat test

Variable

FA

(gram

)

Alkaline

Activation

FA:

Alkaline

Activation

Ratio

Na

2

SiO

3

(gram)

NaOH

(gram

)

100% FA 300 159,62

106,4

2

53% : 47%

100% FA 300 166,15

110,7

7

52% : 48%

100% FA 300 172,94

115,2

9

51% : 49%

In this procedure, forming and Vicat test on the

geopolymer paste are conducted. The purpose of this

is to figure out the effect of setting the time on

geopolymer paste. Steps of implementing setting time

tests are in accordance with SNI 03-6827-2002

(Initial Setting Time Test Method on Portland

Cement Using Vicat Apparatus for Civil Work) FA

and alkaline activation mass are prepared in

accordance with table 2. Afterward, FA is put in, and

alkaline activation is added into mixing pan to form a

paste. Then, the geopolymer paste is put into Vicat

mold. The top surface of geopolymer paste is leveled

with one movement using the scoop and smooth off

the surface of geopolymer paste using the tip of scoop

without applying pressure on geopolymer paste. After

that, the vicat mold filled with a geopolymer paste is

stored in the humid cabinet along with a glass plate,

and the concrete thermometer is positioned on the

Vicat mold and count for 30 minutes using the

stopwatch. And after that, Vicat mold filled with

geopolymer paste is positioned on the Vicat

apparatus, then the tip of the Vicat rod is contacted on

the center of the geopolymer paste surface, and Vicat

rod is tightened. This process is repeated every 15

minutes for other different holes on the geopolymer

paste surface. The space between penetration points

is no less than 5 mm on the inner sidewall of mold,

and the space between 2 penetration points is no less

than 10 mm. Every time this penetration is carried

out, the Vicat needle shall be cleaned and always

align, and there should be no vibration. The steps are

repeated for Vicat mold with a composition ratio of

FA and alkaline activation.

After the Vicat test on geopolymer paste is

conducted, the result which is close to the result of the

Portland cement Vicat test, the ratio of FA and

alkaline activation are acquired with the percentage

of 51 %: 49%. The making of paste is carried out to

find out the maximum compressive strength acquired

on concentrate variation of NaOH solution. The

composition of making geopolymer paste for six

Vicat molds is shown in table 3.

Table 3: Composition of making geopolymer paste

Vicat

Mould

Code

FA

(51%)

(gram)

Alkaline Activation (49%)

Na2SiO3

(gram)

NaOH solution

(gram)

(molarity)

P-8 600 345,87 230,58 (8 M)

P-9 600 345,87 230,58 (9 M)

P-10 600 345,87 230,58 (10 M)

P-11 600 345,87 230,58 (11 M)

P-12 600 345,87 230,58 (12 M)

2.5 Curing Geopolymer Paste

In this research, after a geopolymer is removed from

the mold, it is continued by curing the geopolymer

paste. The type of curing that is used is a process of

treatment by placing a geopolymer paste in open

space with the specified time. Curing is conducted on

normal curing temperatures for 3 days and 14 days.

2.6 Compressive Test

On the paste compressive strength test, a compressive

test machine is used. The first step of the compressive

paste test is to clean the test object from any attached

dirt using a wet cloth. Afterward, the paste is weighed

to determine the mass of the test object. After that, it

is placed on a compressive test machine centrally.

Then, the compressive test machine is turned on and

compress the test object until it is cracked or splinter.

After that, record the maximum load of the test

objects displayed on the compressive test machine.

And then, calculate the paste compressive strength,

which is the load per metric unit in N/mm2 or MPa.

3 RESULTS AND DISCUSSION

3.1 XRF Test on FA

XRF test is conducted to find out the chemical

composition in FA.

ICONIT 2019 - International Conference on Industrial Technology

254

Table 4: The result of the XRF test on FA from PLTU

Kaltim Teluk

Element

Concentrate

(%)

Compound

Concentrate

(%)

Al 5,60 Al2O3 7,80

Si 11,50 SiO2 18,00

S 1,60 SO3 2,80

Ca 27,10 CaO 24,70

Fe 42,30 Fe2O3 35,80

In research, Akinyemi and Mugera (2018)

specified that class C FA has SiO

2

+ Al

2

O

3

+ Fe

2

O

3

with the amount of 50% - 70%, a maximum of 5% of

SO

3

, and more than 10% CaO. In Table 5, the result

of the XRF test on FA of PLTU Kaltim Teluk has

SiO

2

of 18%, 7,8% of Al

2

O

3

, and 35,8% Fe

2

O

3

. This

indicates the total of SiO

2

+ Al2O

3

+ Fe

2

O

3

for 61,6%,

2,8% of SO

3

, and 24,7% of CaO. Thus, it can be

inferred that the FA at Kaltim Teluk can be classified

as class C FA.

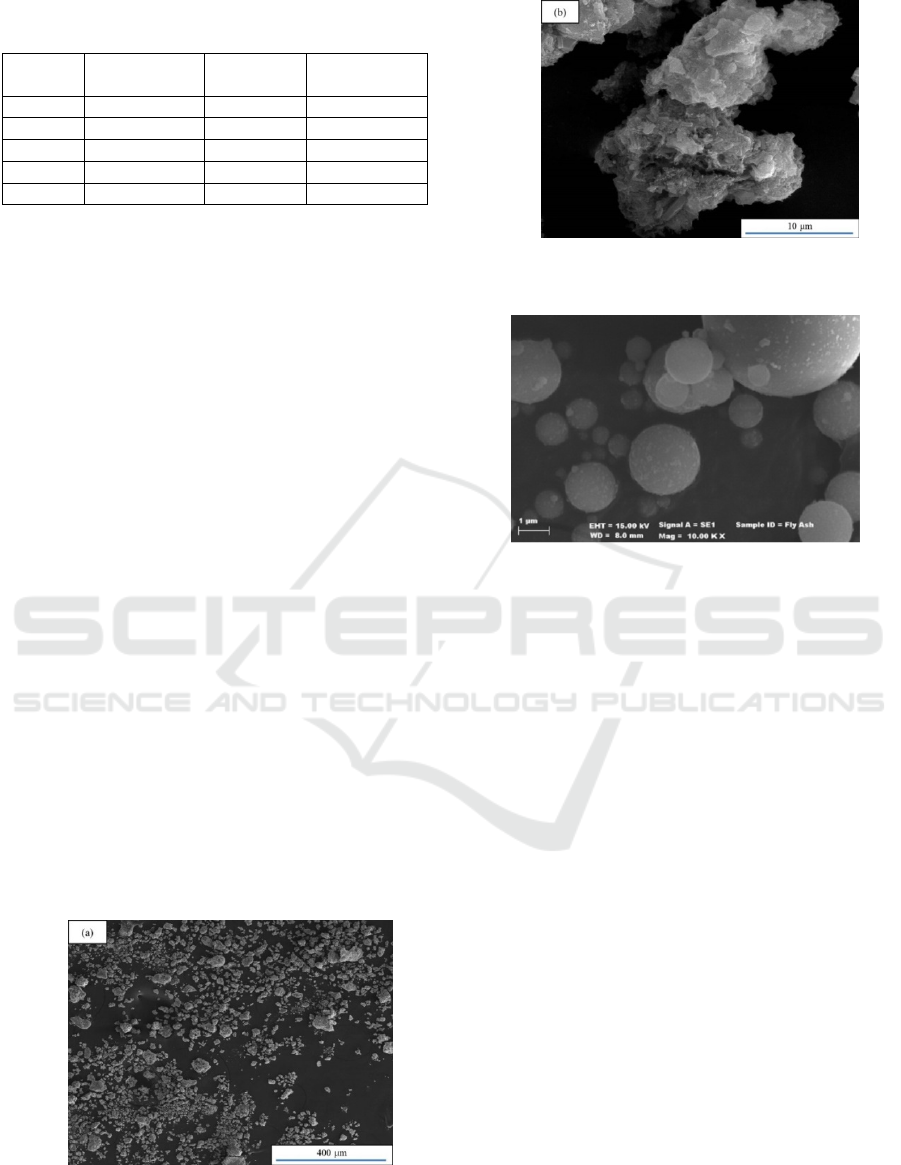

3.2 SEM Test on FA

SEM is conducted to acquire an overview of

morphological conditions on FA, which is used as a

basic material in synthetizing geopolymer paste

activated by an alkaline activation solution. In

research conducted by Akinyemi and Mugera (2018),

it is stated that generally, the FA particle has irregular

and porous microscopic structures. The result of

observation on the FA particle of PLTU Kaltim Teluk

using the SEM test in figure 1 with a magnification

value of 250x and 10.000x shows that FA of PLTU

Kaltim Teluk has an irregular particle. In research

conducted by Sinaga (2018), it is said that irregular

FA particles will decrease workability because FA is

unable to enter through the paste, causing the

occurrence of pores or tiny holes on paste and slowing

down the hydration process.

Figure 1: SEM of FA (100 wt%) with magnification value

of (a) 250x and (b) 10.000x (Writer, 2019)

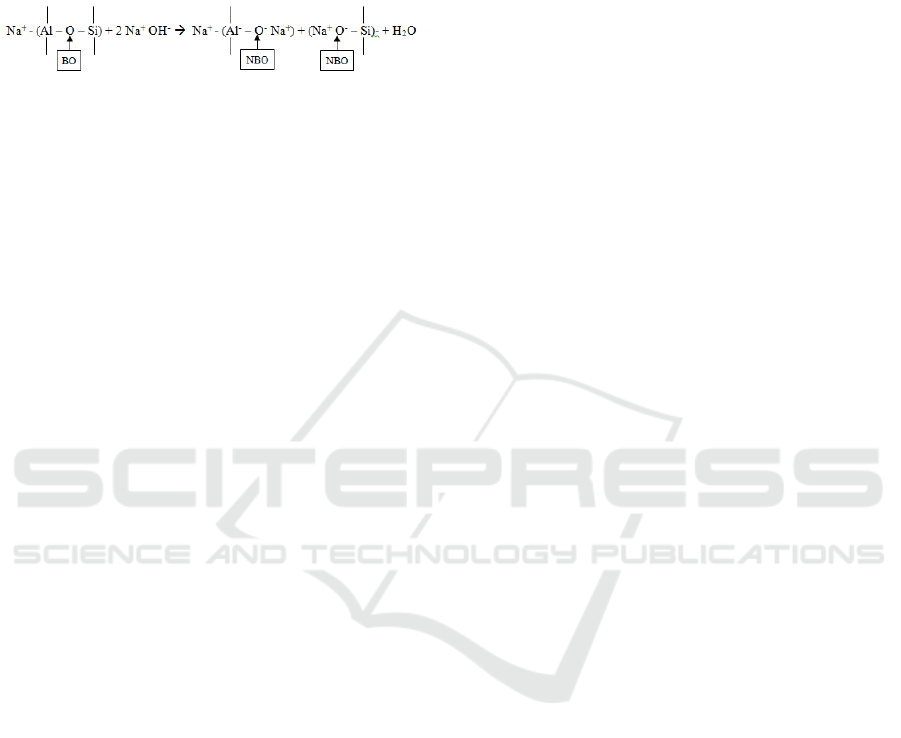

Figure 2: SEM of FA (Ilmiah, 2017)

In research conducted by Rommel, et al. (2014),

as well as Ilmiah (2017), displayed in figure 2, also

specified that the smoothness of the particle is able to

affect the hydration process and setting time.

Reactions between pozzolan and water are

commenced from the pozzolan particle surface, so the

more area of particle surface is, the quicker is its

hydration process. This means that a smooth particle

will strengthen and generate faster hydration heat

than the rougher one. In addition, the spherical

particle will increase workability resulting in the

reduced need for water, easily bind each other, and

also narrow the space between mixed materials. In

conclusion, the best shape of FA farticle to be used

for making geopolymer paster is spherical and

possess a smooth surface.

3.3 Normal Consistency Test and Vicat

Test

The steps of normal consistency test of a cement paste

are in accordance with SNI 03-6827-2002 (Normal

Consistency Test Method of Portland Cement Using

Vicat Apparatus for Civil Work) which is conducted

in order to make the requirement of water in forming

cement paste on setting time test is able to be

determined. Cement paste reaches normal

Characterization of Geopolymer Paste based on Fly Ash and Bottom Ash in PLTU Kaltim Teluk using Sodium Hydroxide (NaOH)

255

consistency when the depth of cement paste

penetration is 10 ± 1 mm.

Figure 3: Graphic of normal consistency on cement paste

(Writer, 2019)

It is showed in figure 3 that the linear equation that

can be used as a measurement of required water to

reach normal consistency of a cement paste with a

penetration of 10 mm. In normal consistency, cement

paste, when penetrated 10 mm, is 25,7%. The total

amount of water required in setting the time test of a

cement paste is 76,9 grams. In accordance with SNI

03-6827-2002 (Initial Setting Time Test Method

Using Vicat Apparatus for Civil Work), the setting

time test is conducted to find out the effect of initial

setting time and final setting time of a cement paste.

Initial setting time is the time required for a cement

paste to change its property from liquid to solid, while

final setting time is the time where penetrated Vicat

needle is visually visible. The initial setting time is at

least 45 minutes, and the final setting time is 375

minutes in maximum. Initial setting time is reached

when the Vicat needle enters into the paste in 30

seconds with penetration of 25 mm. Meanwhile, the

final setting time is reached when the Vicat needle

does not come into the paste in 30 seconds or does not

penetrate the surface of paste at all.

Figure 4: Graphic of Vicat test result on cement paste

(Writer, 2019)

In figure 4, during the penetration of 25 mm, the

initial setting time is acquired in the 74th minute, and

the final setting time is in the 135th minute. Setting

the time on a cement paste is used as a reference in

creating geopolymer paste (Manuahe et al., 2014).

3.4 Compressive Strength Test on

Geopolymer Paste

The purpose of this compressive strength test on the

geopolymer test is to find out the concentrate of

NaOH solution optimally required. In figure 5, it is

showed that the compressive strength of geopolymer

paste with the concentrate of 12 M NaOH has a

maximum compressive strength value of 9,51 MPa on

the 3rd day and 13,93 MPa at the 14th day. It means

that there is an increased value of 31,78% for 14 days.

From the compressive strength test on geopolymer

paste showed in figure 5, then the optimal NaOH

concentrate required is 12 M with the ratio of alkaline

activation solution of 3: 2.

Similarly with researches conducted by Setiadji

(2011), Yuanda, et al. (2015), Qomaruddin, et al.

(2018), Abdullah, et al. (2011), and Irawan, et al.

(2015) stated that the higher is the concentrate of

NaOH solution, and the increased age of the paste is,

the higher is the resulted compressive strength. And

also, the concentrate of the NaOH solution produces

the highest compressive strength of 12 M. These are

caused because of the effect of FA on the paste

compressive strength. Reactions between calcium

hydroxide (Ca(OH)2) with SiO2 in FA form calcium

silicate hydrate (CSH) compound with the property of

increasing strength.

3Ca(OH)

2

+ 2SiO

2

+ H

2

O 3CaO.2SiO

2

.3H

2

O

Figure 5: Graphic of NaOH solution concentrate on

compressive strength (Writer, 2019)

ICONIT 2019 - International Conference on Industrial Technology

256

Ferdy (2010) and Ren (2015) explained that on

FA geopolymer and alkaline activation solution

would synthesize, forming solid material through the

polymerization process. In this polymerization

process, there are 3 phases, where there is the

dissolution of Si and Al at the first phase.

In accordance with the reactions, NaOH solution

in polymerization has a role in dissolution Si and Al

of FA, and as a supplier of Na+ to make the charge

remains balance. On high concentrate, NaOH

solution has more Na+ and is able to cause flash

setting, because of high alkalinity and prompt

dissolution of Ca-Si. The Na+ cation strikes the

surface of the solid phase to dissolve Si and Al. High

OH concentrate in NaOH solution is able to

accelerate the dissolve of Si and Al in FA to make it

more optimal. Alkaline activation solution of

aluminosilicate involves chemical reaction where an

atom of bridging oxygen (BO) in the structure of

aluminosilicate is transformed into non-bridging

oxygen (NBO), which leads to Si and Al isolation.

Adding Na

2

SiO

3

also helps to slow the setting on

a paste, providing more time for the Si and Al

dissolution. Zhang et al. (2015), said that Si on FA is

dissolved by NaOH solution and becomes one of Si

sources. Then, other sources of Si are provided by

Na

2

SiO

3

directly. Moreover, Na

2

SiO

3

in alkaline

activation solution accelerates the polymerization.

The second phase is the hydrolysis of s and Al,

where this process causes the forming of Si-OH and

Al-OH bond.

Al

2

O

3

+ 3H

2

O + 2OH

-

2[Al(OH)

4

]

-

SiO

2

+ H

2

O + OH

-

[SiO(OH)

3

]

-

SiO

2

+ 2OH

-

[SiO

2

(OH)

2

]

2-

In this stage, there is the decomposition of Si and

Al in FA to become monomer, then followed by a

polycondensation process from monomer into

polymer structure with a three-dimensional molecule

network. On a high ratio of Si/Al, there will be

condensation between silica and will form polymer

silicate with Al. Adding Na

2

SiO

3

into a geopolymer

mixture will help increase the ratio of Si/Al

inactivation phase. When the polycondensation

process is ongoing, which is endothermic, where the

heat is acquired from the curing process determined

by temperature. In this process, a geopolymer will

absorb the aluminosilicate compound.

4 CONCLUSIONS

This research shows that the highest compressive

strength on geopolymer paste is acquired when the

alkaline activation solution is used with a NaOH

solution of 12 M concentrate with a compressive

strength of 13,93 MPa at 14 days.

ACKNOWLEDGMENTS

The authors gratefully acknowledge for Kalimantan

Institute of Technology and LPPM Kalimantan

Institute of Technology for the 2019 research grant to

support this research.

REFERENCES

Abdullah, M.M.A., Kamarudin, H., Mohammed, H., Nizar,

I. Khairul, Rafiza, A.R., dan Zarina, Y. (2011), “The

relationship of NaOH Molarity, Na2SiO3/NaOH Ratio,

Fly Ash/Alkaline Activator Ratio, and Curing

Temperature to the Strength of Fly Ash-Based

Geopolymer”, Advanced Materials Research, Vol. 328-

330, hal. 1475-1482.

Adibroto, Fauna, Suhelmidawati, Etri, dan Zade, Azri

Azhar Musaddiq. (2018), “Eksperimen Beton Mutu

Tinggi Berbahan Fly Ash Sebagai Pengganti Sebagian

Semen”, JIRS, Vol. 15, No. 1, hal. 11-16.

Akinyemi, Segun A., dan Mugera, W Gitari. (2018), “Coal

Fly Ash Beneficiation – Treatment of Acid Mine

Drainage With Coal Fly Ash”, National and University

Library in Zagreb, Croatia.

Anam, Syaiful, dan Sumarno, Agung. (2018), “Pengaruh

Kombinasi Abu Sekam Padi Sebagai Binder Alternatif

Dan Fly Ash Pada Tinjauan Kuat Tekan Beton

Geopolimer”, Universitas Mercubuana, Bekasi.

Badan Standarisasi Nasional. (2002), “Metode Pengujian

Waktu Ikat Awal Semen Portland dengan

Menggunakan Alat Vicat Untuk Pekerjaan Sipil”, BSN,

Jakarta, SNI 03-6827-2002.

Farhan, Muhammad. (2016), “Penambahan Abu Batubara

Sebagai Bahan Campuran Untuk Proses Pembuatan

Semen”, Politeknik Negeri Sriwijaya, Palembang.

Ferdy. (2010), “Pengaruh Temperatur dan Waktu Curing

Terhadap Kuat Tekan Pasta Geopolimer Berbahan

Dasar Abu Terbang”, Universitas Indonesia, Depok.

Hibur, Yohanes Berkhemans. (2017), “Pengaruh Serbuk

Cangkang Telur Substitusi Semen Terhadap

Karakteristik Beton”, Universitas Atma Jaya

Yogyakarta, Yogyakarta.

Ilmiah, Rihnatul. (2017), “Pengaruh Penambahan Abu

Sekam Padi Sebagai Pozzolan Pada Binder Geopolimer

Menggunakan Alkali Aktivator Sodium Silikat

(Na

2

SiO

3

) serta Sodium Hidroksida (NaOH)”, Institut

Teknologi Sepuluh Nopember, Surabaya.

Characterization of Geopolymer Paste based on Fly Ash and Bottom Ash in PLTU Kaltim Teluk using Sodium Hydroxide (NaOH)

257

Irawan, Ranastra Rulli, Hardono, Setyo, Budiman, Yanu

Ikhtiar, Soeherman, Ogi, Triani, Desak Nyoman Deasy,

dan Gunawan, Gugun. (2015), “Beton Dengan Sedikit

Semen Portland dan Tanpa Semen Portland

Memanfaatkan Abu Terbang Dari PLTU Batu bara”,

Badan Penelitian dan Pengembangan, Bandung.

Kadhafi, Muhammad. (2015), “Pemanfaatan Copper Slag

Sebagai Substitusi Semen Pada Campuran Beton Mutu

K-225”, Jurnal Teknik Sipil dan Lingkungan, Vol. 3,

No. 1, hal. 734-740.

Kementerian Perindustrian. (2016), “Pasokan Semen

Nasional 102 Juta Ton pada 2017”,

http://www.kemenperin.go.id/artikel/12223/pasokan-

semen-Nasional-102-juta-ton-pada2017.

Manuahe, Riger, Sumajouw, Marthin D. J., dan Windah,

Reky S. (2014), “Kuat Tekan Beton Geopolymer

Berbahan Dasar Abu Terbang (Fly Ash)”, Jurnal Sipil

Statik, Vol. 2, No. 6, hal. 277-282.

Nur, Rasdiana Rahma, Hartanati, Firda Dwi, dan Sutikno,

Juwari Purwo. (2015), “Studi Awal Desain Pabrik

Semen Portland dengan Waste Paper Sludge Ash

Sebagai Bahan Baku Alternatif”, Jurnal Teknik ITS,

Vol. 4 No. 2, hal. F164-F168.

Qomaruddin, Mochammad, Munawaroh, Tri Hanafiah, dan

Sudarno. (2018), “Studi Komparasi Kuat Tekan Beton

Geopilimer Dengan Beton Konvensional”, Universitas

Islam Nahdlatul Ulama, Jepara.

Rahadja, Hasan. (2010), “Kursus Eselon III Produksi

Teknologi Semen”. Indonesia Cement Institute,

Padang.

Ren, Xin. (2015), “Complete Recycling and Utilization Of

Waste Concrete Through Geopolymerization”,

Universitiy of Arizona, Arizona.

Rini, Intan Dwi W. S., Sholikah, Umi, Saputra, Andika Ade

I., Fansuri, Hamzah, dan Gunawan, Adrian. (2018),

“Utilization of Hazardous Waste Fly Ash Coal from

Kariangau Thermal Power Plant as Substitution of

Portland Cement on Concrete”, 2nd Borneo

International Conference on Applied Mathematics and

Engineering (BICAME), hal. 253-257.

Rommel, Erwin, Kurniawati, Dini, dan Pradibta, Arman

Putra. (2014), “Perbaikan Sifat Fisik dan Reaktifitas Fly

Ash Sebagai Cementitious Pada Beton”, Media Teknik

Sipil, Vol. 12, No. 2, hal 111-118.

Setiadji, Rudi. (2011), “Sifat Mekanik Beton Geopolimer

Dengan Agregat Tailing”, Universitas Gadjah Mada,

Yogyakarta.

Susanto, Agus dan Nugroho, Prasetyo Agung. (2012),

”Pemanfaatan Lumpur Lapindo Sebagai Pengganti

Agregat Kasar Beton”, Universitas Muhammadiyah

Surakarta, Surakarta.

Yuanda, Dedi, Fadli, Ahmad, dan Drastinawati. (2015),

“Pemanfaatan Limbah Abu Terbang (Fly Ash)

Batubara Sebagai Bahan Pembuatan Beton

Geopolimer”, JOM FTEKNIK, Vol. 2, No. 2, hal. 1-7.

Zhang, Lianyang. (2015), “Molecular Dynamics Study of

Sodium Aluminosilicate Geopolymer Containing

Calcium”, University of Arizona, Arizona.

ICONIT 2019 - International Conference on Industrial Technology

258