Experimental Study of Aluminum Composite Material by the Percentage

Variation of Volcanic Ash Reinforcement

Juriah Mulyanti

1

, Sukamto

1

, Novi Arviyanto

2

, Sazkia Noor Anggraini

3

and Muhammad Kunta

Biddinika

4

1

Department of Mechanical Engineering, Janabadra University, Yogyakarta 55231, Indonesia

2

PT. Kereta Api Indonesia, Yogyakarta, Indonesia

3

Indonesian Art Institute of Yogyakarta, Indonesia

4

Department of Civil Engineering, Janabadra University, Yogyakarta 55231, Indonesia

Keywords:

Aluminum composite, volcanic ash, percentage of reinforcement, stir casting, material testing.

Abstract:

This research is using the volcanic ash from the eruption of Mount Kelud as material composite reinforcement.

Information about large amounts of Silica (SiO2) on Mount Kelud volcanic ash and its abundant amounts in

Yogyakarta after the eruption, were the reason for choosing this material as reinforcement in the making of

aluminum metal composite. This composite is using the recycled aluminum material as their matrix. Stir

casting method used during the experiment. 1%, 3%, 5% of volcanic ash used with 300 rpm stirring rotation

and 4 minutes stirring rotation. Microstructure testing, hardness testing, impact testing and tensile testing

were carried out to determined changes in material characteristic. The result showed that the addition of 1%

volcanic ash reinforcement gives the highest hardness and toughness number to aluminum composite material,

but the lowest ductility value. The highest aluminum composite material ductility value reached in the addition

of 3% volcanic ash reinforcement.

1 INTRODUCTION

Aluminum material is widely used because it has

several advantages, including formability and tensile

strength which can be improved through cold work-

ing processes or a heat treatment process (Callister,

2007)) . In the aluminum industry, it is usually com-

bined with other elements to get better product char-

acteristic. Composite is a material that composed

from a combination of two or more types of material

which are differentially macro in shape and compo-

sition(Waddoups and Halpin, 1974). It is produces

new material which is very different from the ba-

sic material. Al-Si-Cu-Mg is the aluminum compos-

ites that quite widely used in the industrial world be-

cause of their pour ability and good mechanical char-

acteristic in heat treatment conditions (Runxia et al.,

2010). The Stir casting method is the process of cast-

ing by melting the metal until it boils and then stirring

continuously until a vortex is formed (Hashim et al.,

1999). The reinforcement (in the form of powder) is

mixed gradually through the edges of the formed vor-

tex (Ajiriyanto, 2010).

Bhushan and Kumar (Bhushan and Kumar, 2011)

have conducted research on the the distribution ef-

fect of SiC particles on Al-7075 with the stir cast-

ing method and maintained temperature in the range

of 750 to 800o C. This experiment result shows that

the 5 to 15% SiC reinforcement added will increase

the 10.48% hardness value. In stirring with a rotation

of 500 rpm, metallographic result shows a uniform

distribution of granule structure with clearly visible

granule boundaries. This study took the stir casting

method from Bhushan and Kumar experiment by us-

ing the volcanic ash as a reinforcement material. The

stir casting method are suggested to reduce the poros-

ity in material composite (Wilastari et al., 2011).

Volcanic ash often referred to volcanic sand or

pyroclastic fall. It is a falling volcanic material that

sprayed into the air during an eruption, consisting of

large to fine-sized rocks. The volcanic ash that usedon

this experiment coming from the eruption of Mount

Kelud. Mount Kelud erupted on February 13th 2014

and sent wind-erupted volcanic ash in the form of fine

material falling in Yogyakarta. The result from Eu-

ropean Satelite Agency shows the chemical analysis

of Kelud volcanic ash which contains minimum of

55.05% silica (SiO2) (Guidebook et al., 2000). This

134

Mulyanti, J., Sukamto, ., Arviyanto, N., Anggraini, S. and Biddinika, M.

Experimental Study of Aluminum Composite Material by the Percentage Variation of Volcanic Ash Reinforcement.

DOI: 10.5220/0009879501340138

In Proceedings of the 2nd International Conference on Applied Science, Engineering and Social Sciences (ICASESS 2019), pages 134-138

ISBN: 978-989-758-452-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

information and abundant amount of Kelud volcanic

ash are the reason for choosing this material as rein-

forcement for Aluminum metal composite.

Few research on Mt. Kelud volcanic ash utiliza-

tion has been done particularly on the agriculutre and

building material (concrete and brick) (Bahri, 2015),

(Saputra, 2011). The chemical characteristic of In-

donesia volcanic ash has been research with SEM-

EDS test. This research obtained Si content of the

three types of volcanic ash ranges 45-60% and ele-

ments of Al ranges 14-20% (Latif et al., 2016). The

research on the field of metal composite material just

has been done in this research. The volcanic ash con-

tain mineral and silica that never change into time.

This material expected to improve the aluminum com-

posites characteristic, such as tensile strength, hard-

ness and toughness value.

2 METHODOLOGY

This experimental study was conducted to determine

the physical and mechanical characteristic of Alu-

minum metal composite material with volcanic ash

reinforcement by the stir casting process (Bhandare

and Sonawane, 2013).

2.1 Material Preparation

The main material used in this study was recycled alu-

minum bars, with 80% aluminum and Kelud volcanic

ash.

Figure 1: Aluminum bars and mount Kelud volcanic ash.

2.2 The Making of Composite Material

1. Smelting Process

This smelting process used the smelting furnace

with the LPG fuel. Heat the crucible then put the

aluminum until its melt.

2. Mixing process

Mixing Process is the mixture process of alu-

minum composite matrix with the volcanic ash

as reinforcement, strain the volcanic ash with

smooth sieve, then heat to 600

◦

C nearly the

molten aluminum temperature. The little amount

of volcanic ash was put gradually into the molten

aluminum. This mixture done with the stir casting

method, by the 300 rpm stirring speed and 4 min-

utes stirring time. This mixing process was done

with three variation of volcanic ash reinforment

percentage (1%, 3%, and 5%). The percentage of

volcanic ash was have to be under 5% to avoid

mixture clotted.

Figure 2: Stir Casting furnace

Figure 3: Material Mixing Process

3. Pouring & Dismantling Process

Pouring process used crucibles ladel, molding

pattern with gating system, green sand, and mold-

ing frame. Pour the molten aluminum on 650oC

temperature. The molding dismantling process

took after 15 minutes.

Figure 4: Material Casting Process and Casting Results

Experimental Study of Aluminum Composite Material by the Percentage Variation of Volcanic Ash Reinforcement

135

3 RESULT AND DISCUSSION

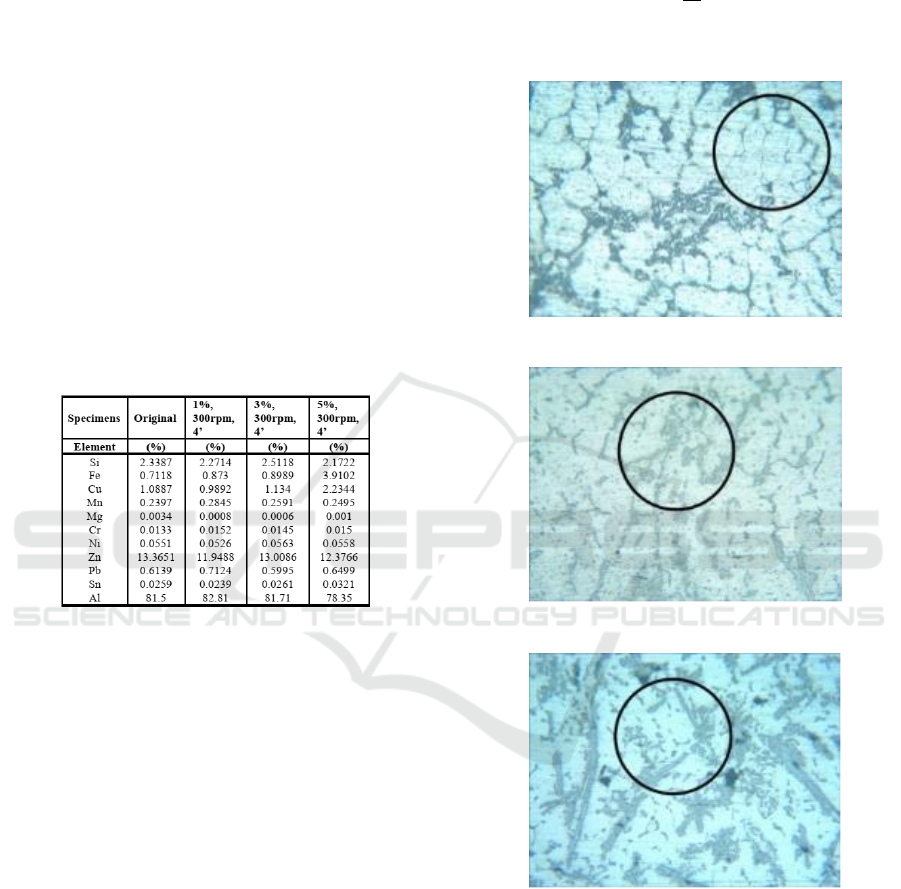

3.1 Composition Test Result

The result obtained from Spectrometer at the En-

gineering Materials Laboratory, Department of Me-

chanical and Industrial Engineering, Faculty of En-

gineering, Gajah Mada University. From the table

above, we can see that the raw material of aluminum

contains 13,3651% of Zn element. It means, the raw

material itself was Al-Zn alloy. From the results of

the composition test, it can be seen that the silica con-

tent addition does not addded Si composition to the

composite material. A large percentage of Zn (Zinc)

element will affect the nature of the composite mate-

rial. The higher content of Zn (Zinc) in the composite

soften the granule of the matrix but it will increase the

composite brittleness (E8, 1992). The addition of 5%

volcanic ash reinforcement decreased Al content until

78.35%.

Figure 5: Composition Testing Result.

3.2 Microstructure Testing Result

The microcrostructure testing in this experiment us-

ing 200x magnifition. The size and granule form ob-

servation method are using in the discussion of this

microstructure result. Planimetri method is used to

observe the granule size, which a circle with the cer-

tain size made on the microscope photograph.

The amount of granule on the circle, measured

with the formula :

n

eq

=

n

c

2

+ n

i

(1)

n

i

= the amount of granule on the circle n

c

= the

amount of granule cut in circles

Figure 6: 1% of volcanic ash (Amount of granules = 12)

Figure 7: 3% of volcanic ash (Amount of granules = 6)

Figure 8: 5% of volcanic ash (Amount of granules = 4)

The number of granule affects the material me-

chanical characteristic. The more number of granule,

the higher value of material hardness and toughness.

ICASESS 2019 - International Conference on Applied Science, Engineering and Social Science

136

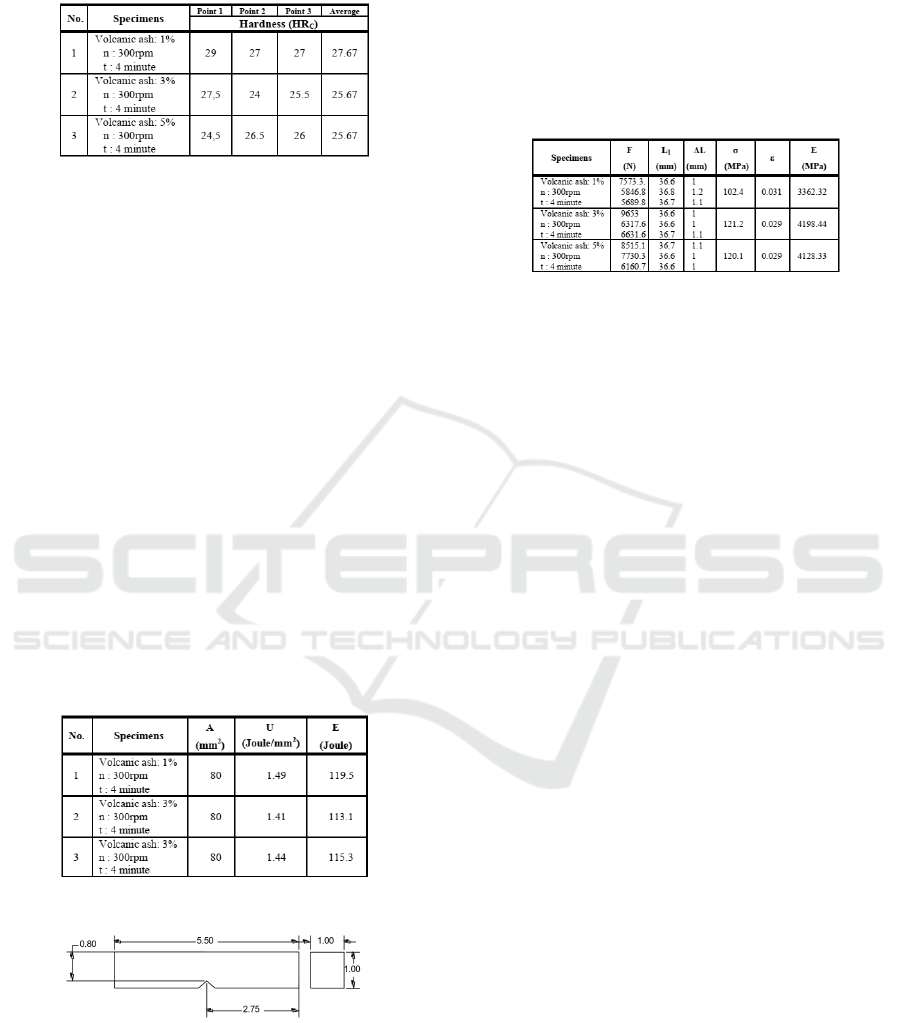

3.3 Hardness Testing Result

Figure 9: Hardness Testing Result.

This hardness test uses Rockwell scale C (HRC)

hardness method. The highest hardness value was ob-

tained on aluminum composites with 1% volcanic ash

reinforcement of 27.67 HRC. The addition of rein-

forcement with a percentage of 3% and 5% reduces

the hardness of the composite. Another research

shows that the SiC added will increase the hardness

value. This contary results shows from the existance

of Silicone Carbida as reinforcement addition (Nu-

groho et al., 2014).

The microstructure test calculation result shows

that the highest amount of granule were obtained from

1% volcanic ash reinforcement which reach 12 gran-

ule. The amount of granule on 3% volcanic ash rein-

forcement addition is 6 and on 5% volcanic ash rein-

forcement is 4 granule. The higher addition amount of

granule, addition the higher material hardness value.

On contrary, the fewer amount of granule, the lower

material hardness value.

3.4 Impact Test Result

Figure 10: Impact Testing Result.

Figure 11: Impact Testing Result.

The result on the Figure 10 shows that absorbed

energy to break the specimen are not much different

among others. The calculation shows that the highest

value from 1% volcanic ash reinforcement addition is

equal to 119.5 Joules, while the lowest of 3% volcanic

ash reinforcement addition is equal to 113.1 Joule.

The microstructure testing shows that 1% of vol-

canic ash reinforcement have the highest amount of

granule and the highest energy to break the specimen.

Therefore higher volcanic ash reinforcement will de-

crease the thoughness value.

3.5 Tensile Test Result

Figure 12: Tensile Testing Result.

The test was carried out with a Servopulser ma-

chine using 4 tons load. With data spesimens are:

L0=35.6mm, D=8.9mm, A=62.18mm2. The test

founded that the highest average tensile on 3% vol-

canic ash reinforcement addition was 121.2 MPa and

the smallest was 1% volcanic ash reinforcement addi-

tion was 102.4 MPa. The tensile value increases with

the addition of volcanic ash reinforcement. The mi-

crostructure test and granule amout calculation shows

the amount of granule on the 3% and 5% volcanic

ash reinforcement added has less granule from 1% of

volcanic ash reinforcement added. It means the less

amount of granule, the higher tensile strength.

4 CONCLUSIONS

This research result shows that the composition of

raw material is known as Al-Zn alloy. The addition

of volcanic ash reinforcement does not add Silica ele-

ments to the composite material significantly. The ad-

dition of 1% volcanic ash reinforcement produces the

highest hardness and toughness of aluminum compos-

ite material and provides the lowest tensile strength

value. The addition of 3% and 5% volcanic ash re-

inforcement decreases the hardness and toughness of

aluminum composites, but its increases the tensile

strength.

ACKNOWLEDGEMENTS

Thanks to the team of PT. Kereta Api Indonesia who

collaborate in this research.

Experimental Study of Aluminum Composite Material by the Percentage Variation of Volcanic Ash Reinforcement

137

REFERENCES

Ajiriyanto, M. K. (2010). Fabrikasi komposit al/al2o3 (p)

coated dengan metode stir casting dan karakterisas-

inya= fabrication of composite al/al2o3 (p) coated us-

ing stir casting method and its characteristics.

Bhandare, R. G. and Sonawane, P. M. (2013). Preparation

of aluminium matrix composite by using stir casting

method. International Journal of Engineering and Ad-

vanced Technology (IJEAT), 3(3):61–65.

Bhushan, R. K. and Kumar, S. (2011). Influence of sic par-

ticles distribution and their weight percentage on 7075

al alloy. Journal of materials engineering and perfor-

mance, 20(2):317–323.

Callister, W. D. (2007). An introduction to materials science

and engineering. John Wiley and Sons Inc.

Guidebook, E., Sriwana, T., and Sitorus, K. (2000). Crater

lakes of java: Dieng, kelud and ijen.

Hashim, J., Looney, L., and Hashmi, M. (1999). Metal

matrix composites: production by the stir casting

method. Journal of materials processing technology,

92:1–7.

Latif, D. O., Rifa’i, A., and Suryolelono, K. B. (2016).

Chemical characteristics of volcanic ash in indonesia

for soil stabilization: Morphology and mineral con-

tent. International Journal, 11(26):2606–2610.

Nugroho, S. et al. (2014). Pengaruh komposisi mg dan

sic terhadap sifat kekerasan komposit alsi-sic yang

dibuat dengan proses semi solid stir casting. Prosiding

SNATIF, pages 165–172.

Runxia, L., Yujin, C., Xiaoguang, Y., Yingdong, Q., and

Rongde, L. (2010). Effects of cd and sn on double-

peak age-hardening behaviors of al-si-cu-mg cast al-

loys. Research & Development, 7(1):1–5.

Waddoups, M. and Halpin, J. (1974). The fracture and fa-

tigue of composite structures. Computers & Struc-

tures, 4(3):659–673.

Wilastari, S., Bayuseno, A., and Nugroho, S. (2011). Pen-

garuh variasi kecepatan putar dalam metode stir cast-

ing terhadap sifat kekerasan al-sic untuk aplikasi blok

rem kereta api. Majalah Ilmiah Gema Maritim,

13(1):1–7.

ICASESS 2019 - International Conference on Applied Science, Engineering and Social Science

138