Optimizing the Pyrolysis Process and Modelling the Calorific Value of

Sawdust Charcoal as Composing Materials of Quality Briquettes

Musabbikhah

1

, Samsul Bakri

2

1

Mechanical Engineering Department, Akademi Teknologi Warga Surakarta

2

Accounting Department, Universitas Widya Mataram Jogjakarta

Keywords:

Optimization, Pyrolysis, calorific value, sawdust charcoal, model, briquettes.

Abstract:

This study aims to optimize the pyrolysis process and build calorific value model of sawdust charcoal as

composing materials of quality briquettes to fulfill the need of renewable fuels. The results showed that the

calorific value of sawdust increased by 2344 Cal/g after pyrolysis. The optimum conditions of calorific value

were achieved at drying temperature parameters of 60°C, pyrolysis temperature of 600°C, holding time of

120 minutes, and particle size of 100 mesh. The linearity test results between the value of R, R Square, and

Adjusted R Square of the calorific value showed there is a strong correlation between drying temperature,

pyrolysis temperature, holding time, and particle size. Based on validation test, the calorific value model

showed that the residual normality distribution (P-value) was > 0.05 which did not form a certain pattern

on the assumption of homoscedasticity, no multicollinearity (T OL > 1; V IF < 10) and the DW value was

between the specified range. The model was declared valid. Based on the feasibility test model, P-value was

(0.000) < α (0.05). This means the model of proper calorific value was reliable to be used to predict the

sawdust charcoal calorific value.

1 INTRODUCTION

Energy demand is increasing every year with increas-

ing population. One of the main energy sources

needed by humans is the energy source from fossils.

The availability of this fossil energy source will grad-

ually run out, so that it becomes a serious problem be-

cause it cannot be renewed. High dependency on fos-

sil resources combined with the need to reduce CO

2

emissions due to the climate change force people to

utilize renewable energy sources, including biomass.

Biomass is a renewable energy source required to

meet the energy needs, and is also used for carbon

neutrality as a means of preventing climate change.

Vargas (Vargas-Moreno et al., 2012) states that ad-

vanced societies have replaced the use of fossil fuels

with biomass. Wisakha (Wisakha, 2015) explains that

biomass is able to produce continuous heat, therefore

it can be used to replace fossil fuel. One of the renew-

able energy from biomass as a constituent material for

briquettes is sawdust (Lela et al., 2016).

Pyrolysis is needed by sawdust used to make bri-

quettes. Pyrolysis is a thermal degradation process of

solids in the absence of oxygen which allows the oc-

currence of several thermochemical conversion path-

ways so that the solid changes into gas, liquid, then

back to its solid form (Blasi, 2008). Furthermore,

Basu (Basu, 2013) explains that the pyrolysis reaction

from biomass is as follows:

CnHmOp

∑

liquid → CxHyOz +

∑

gasCaHbOc +

H

2

O +C (1)

Heat pyrolysis (thermolysis) decomposition is of

organic matter, such as coal heated more than 300

C°without atmospheric air. The selection of biomass

materials to produce carbon is based on the avail-

ability of materials, costs and the ability to be con-

verted into porous carbon powder after carbonization

(Kalyani and Anitha, 2013). In this study, the qual-

ity of sawdust charcoal is in terms of calorific value

which indicates the energy contained in the fuel per

unit mass of fuel (cal/g). This research is in accor-

dance with the development of solid bio-fuel using a

wood pellet model (Giacomo and Taglieri, 2013).

The research conducted (Lela et al., 2016) con-

cerning the physical, mechanical and thermal proper-

ties of sawdust briquettes is used as a reference for

fuel quality. The optimal value obtained for the bri-

quette making process parameters is the compression

strength of 588.6 KN, sawdust mass of 46.66% and

drying temperature of 22 C°. Based on the mathemat-

Musabbikhah, . and Bakri, S.

Optimizing the Pyrolysis Process and Modelling the Calorific Value of Sawdust Charcoal as Composing Materials of Quality Briquettes.

DOI: 10.5220/0009882402630267

In Proceedings of the 2nd International Conference on Applied Science, Engineering and Social Sciences (ICASESS 2019), pages 263-267

ISBN: 978-989-758-452-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

263

ical model, the optimal values generated are calorific

values increased to 17.41 MJ/kg, ash content de-

creased to 6.62% and maximum compressive strength

is of 149.54 N/mm2. Research on sawdust briquettes

was also carried out by (Stolarski et al., 2013) which

showed that the highest calorific value in sawdust bri-

quettes was 18.144 MJ/kg. Moreover, sawdust bri-

quettes have an effect of 0.40% on ash content.

2 MATERIAL AND METHOD

2.1 Material

The material used in pyrolysis is sawdust powder

from teak wood.

2.2 Method

Data collection of pyrolysis process and calorific

value refers to orthogonal L9(3)4 arrays. The in-

dependent variables used in the study were drying

temperature, pyrolysis temperature, holding time, and

particle size. The dependent variable to determine

the quality of sawdust charcoal is the calorific value.

The method for optimizing pyrolysis parameters is

Taguchi, while for modelling of calorific value is mul-

tiple linear regression model (MLRM) analysis.

3 RESULTS AND DISCUSSION

The effect of level factor differences on the sawdust

charcoal calorific value which has the highest aver-

age calorific value of 6231 cal/g was achieved at dry-

ing temperatures of 60 C°, pyrolysis temperature of

600 C°, holding time of 120 minutes, and particle

size of 100 mesh. The calorific value is influenced

by water content and carbon content. This study is

in line with the research of (Sundaram et al., 2016)

which states the water content of the particles changes

with the variation of drying time in fluidized bed dry-

ing. The same study was also carried out by (Wilk

et al., 2016) who stated that the carbonization of wood

residue into charcoal occurred during the low temper-

ature process.

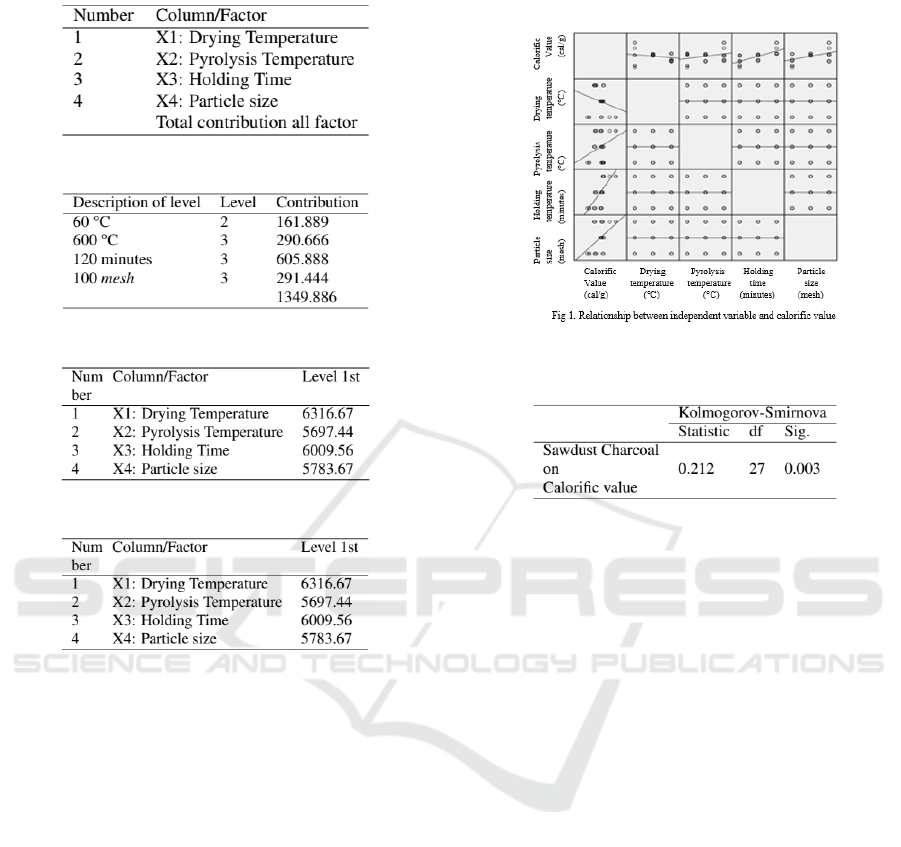

3.1 Normality Test

The normality test of the Sawdust Charcoal calorific

value variable uses a significance level of α = 0.05

and the Shapiro-Wilk statistical test shows that P −

value = 0.915. Therefore, H0 is accepted. It means

that Calorific value of sawdust charcoal variables are

normally distributed and are presented in Figure 1 and

Figure 2.

Figure 1: Normality Test of calorific value.

Figure 2: Normality Test of calorific value (extension).

a Lilliefors Significance Correction

3.2 ANOVA

Based on ANOVA calculations, the four variables

namely drying temperature, pyrolysis temperature,

holding time, and particle size have a significant in-

fluence on the sawdust charcoal calorific value with

the percentage value of the contribution consecutively

is 7.877%; 54.77%; 11.534%; and 25.817%. In this

case, the pyrolysis temperature has the greatest influ-

ence on the sawdust charcoal calorific value because

the higher the pyrolysis temperature is, the lower the

water content and the higher the calorific value. The

results of this study was in line with the research of

(Mandala et al., 2016) which states that pyrolysis tem-

perature is varied from 200 C°to 500 C°and in using

the random wood powder size, there is 29% bio-oil

yield occurs at a temperature of 400 C°.

3.3 Optimization

The optimum conditions of calorific value on sawdust

charcoal obtained were material drying temperature

of 60 C°, pyrolysis temperature of 600 C°, holding

time of 120 minutes, and particle size is of 100 mesh

as shown in Figure 3 and Figure 4. The difference in

mean values between factor effects is shown in Figure

5 and Figure 6. Research on optimization using the

Taguchi method was also conducted by ((Azadi et al.,

2011) and (Roy, 2010).

ICASESS 2019 - International Conference on Applied Science, Engineering and Social Science

264

space

Figure 3: Optimum condition of calorific value.

Figure 4: Optimum condition of calorific value (extension.).

Figure 5: Factor Effects of calorific valu.

Figure 6: Factor Effects of calorific value (extension).

The average sawdust calorific value obtained be-

fore pyrolysis was 3887 cal/g, and after pyrolysis the

average sawdust charcoal calorific value was 6231

cal/g. The effect of drying and pyrolysis are very sig-

nificant in increasing the sawdust calorific value. This

sawdust charcoal has fulfilled the Indonesia National

Standard so that sawdust charcoal is suitable as a high

quality briquette maker. This study is in accordance

with the results of (Wilk et al., 2016) which used py-

rolysis of wood waste material by varying carboniza-

tion temperatures of 230, 260 and 290 C°and car-

bonization times of 0.5, 1.0 and 1.5 hours. The same

study was also carried out by (Al-Refaie et al., 2010)

who explained that the HHV from torrefied samples

increased with increasing temperature. The highest

HHV was found at 26.09 MJ/kg obtained at 60 min-

utes and 300 C°.

3.4 Building a Calorific Value Model

Linearity test is a procedure to find out whether linear

data distribution is or not. The relationship of the re-

sponse variable sawdust charcoal calorific value and

predictor variables is shown in Figure 7 and Figure 8.

Figure 7: Relation between independent variable and

calorific value

Figure 8: Model Summary

b

.

Based on Figure 8, the value of R=0.935 shows a

fairly close degree of linear relationship between the

response variable of the calorific value and the pre-

dictor variable. The R Square=0.875 and Adjusted R

Square=0.852 showed that 85.2% of the variance in

the calorific value variable can be explained by the

independent variable. Meanwhile, St. Error=1.682

states the magnitude of the variance of the regression

model. Thus, there is a linear relationship between the

variables sawdust charcoal calorific value with drying

temperature, pyrolysis temperature, and holding time

and particle size. This modelling research is in accor-

dance with the results of (Sundaram et al., 2016) that

describe the process of drying materials using tem-

perature variations of 55, 60 and 65 C°; speeds of 2.2,

2.4 and 2.6 m/s and moisture content of 27.5, 30 and

32.5% of the total weight.

Optimizing the Pyrolysis Process and Modelling the Calorific Value of Sawdust Charcoal as Composing Materials of Quality Briquettes

265

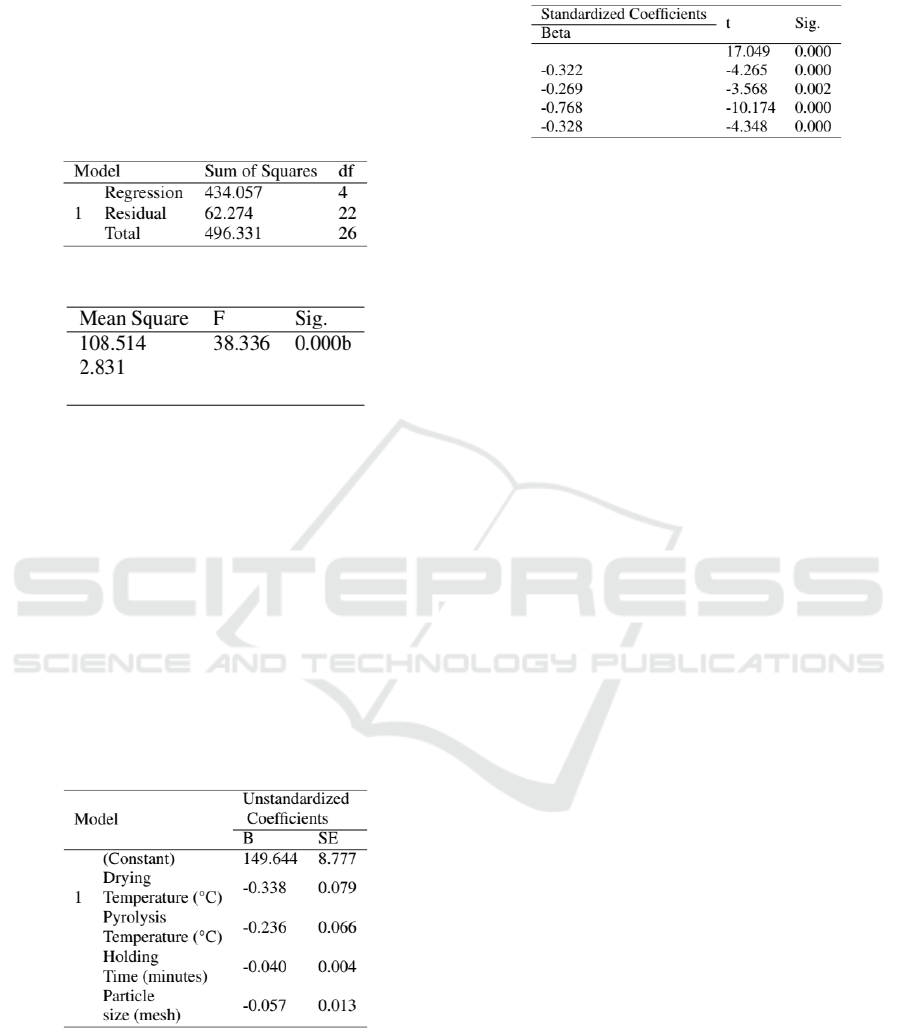

3.5 Overall Test (Model Feasibility)

The feasibility test of multiple regression models at

the level of significance: α0.05 using the F test is

shown in Figure 9 and Figure 10. Based on ANOVA

in Figure 9, P-value (0.000) < α (0.05). H0 is re-

jected, meaning the sawdust charcoal calorific value

model is suitable for use.

Figure 9: ANOVA

a

.

Figure 10: ANOVA

a

(Extension).

a Dependent Variable: calorific value (cal/g)

b Predictors: (constant), drying temperature (°C),

pyrolysis temperature (°C), holding time (min-

utes) and particle size (mesh)

3.6 Coefficient Feasibility Test

The coefficient feasibility test is used to determine the

level of feasibility of the independent variable coeffi-

cients in the formation of a model of calorific value.

The output of the coefficient feasibility test of the

sawdust charcoal calorific value is presented in Fig-

ure 11 and Figure 12.

Figure 11: Coefficient feasibility test

a

.

space

Figure 12: Coefficient feasibility test

a

(extension).

a Dependent Variable: calorific value (cal/g)

Based on Figure 11 and 12, all the independent

variables in the model significantly affect the sawdust

charcoal calorific value variable. The mathematical

model to predict sawdust charcoal calorific value as

a function of drying temperature, pyrolysis tempera-

ture, holding time and particle size are:

ˆ

Y (cal/g) = 4708.58–33.23X

1

+ 42.71X

2

+

5.70X

3

+ 12.32X

4

(2)

Based on the above equation (2), the higher of

pyrolysis temperature, holding time and particle size

are significant to the higher the calorific value. This

happens because the higher the pyrolysis tempera-

ture, the higher the water content lost, the material

becomes dry so that the water content becomes low

and the carbon is bound as high which results in a

high calorific value. The results of this study is in

accordance with (Lela et al., 2016) which states that

the mathematical model and optimal value produces a

calorific value increased to 17.41 MJ/kg, ash content

decreased 6.62% and maximum compressive strength

of 149.54 N/mm

2

. The same study was alsocarried

out by (Al-Refaie et al., 2010) which explained that

the optical mal parameter design with regression tech-

nique and grey relational analysis. Research on op-

timization and regression modelling were also con-

ducted by (Vishwakarma et al., 2012).

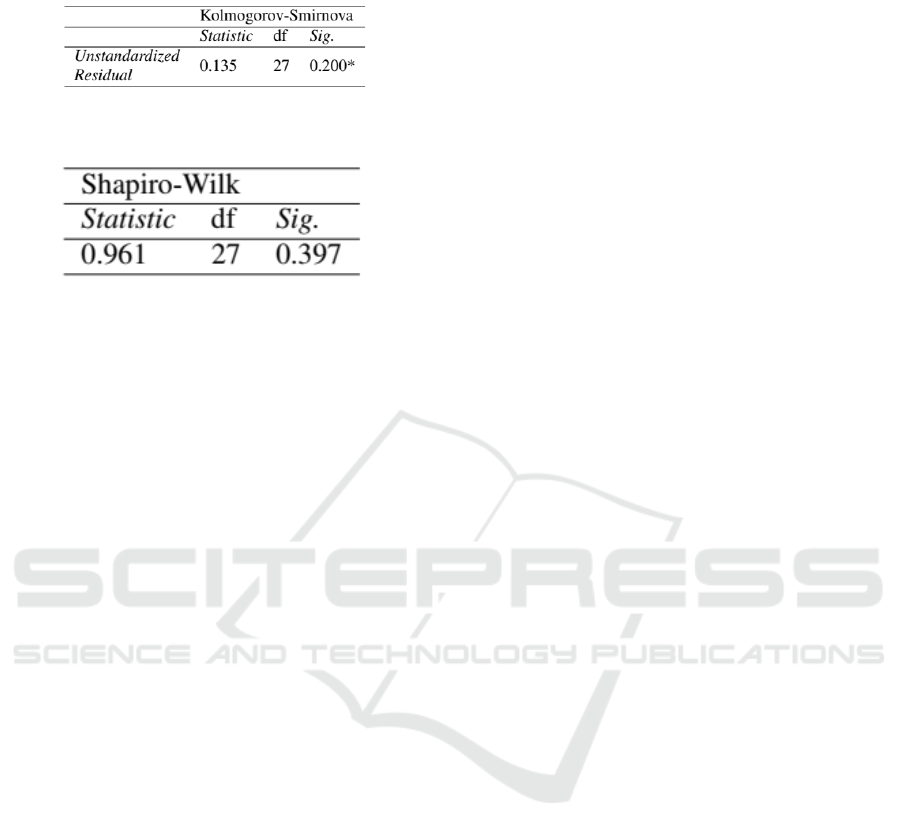

3.7 Model Validation

Residual analysis is a way to validate the sawdust-

charcoal calorific value model. The results of resid-

ual analysis summary to determine the validity of

the response model to the sawdust charcoal calorific

value is presented in Figure 13. The model validation

test results show that the residual normality distribu-

tion (P-value) is 0.563> 0.05, no particular pattern is

formed on the assumptions of homoscedasticity, no

multicollinearity (T OL > 1;V IF < 10) and the DW

value is in the range of 0.878<1.456 <1.514.

ICASESS 2019 - International Conference on Applied Science, Engineering and Social Science

266

space

Figure 13: Residual normality test of calorific value.

Figure 14: Residual normality test of calorific value (exten-

sion).

Based on Figure 13 and Figure 14, it can be con-

cluded that the sawdust charcoal calorific value model

has met the eligibility requirements, and model vali-

dation, so that the resulting model is declared feasible

and valid and can be used to predict the sawdust char-

coal calorific value. The drying and pyrolysis treat-

ment has a positive effect on increasing the calorific

value. It is proved because the initial sawdust calorific

value of 3887 cal/g increased to 6231 cal/g after dry-

ing and pyrolysis. Therefore, there was an increase in

the calorific value of 2344 cal/g.

4 CONCLUSIONS

The optimum condition of the pyrolysis process

which can increase the calorific value of sawdust is

the drying temperature of 60 C°, the pyrolysis temper-

ature of 600 C°, holding time of 120 minutes, and par-

ticle size of 100 mesh. The linearity test results show

that the value of R; R Square; and Adjusted R Square

at the calorific value to have a strong correlation with

drying temperature, pyrolysis temperature, holding

time, and particle size. The result calorific value

model is

ˆ

Y(cal/g) = 4708.58–33.23X1 + 42.71X2 +

5.70X3 + 12.32X4. The validation test results of the

heat value model show that the residual normality dis-

tribution (P-value)> 0.05 does not form a certain pat-

tern on the assumption of homoscedasticity, no mul-

ticollinearity (TOL> 1; VIF <10) and the DW value

is within the specified range so the model is declared

valid. The model feasibility test results in a P-value

(0.000) < α (0.05) so that the calorific value model

is declared feasible and can be used to predict the

calorific value of sawdust charcoal to produce a qual-

ity briquette.

ACKNOWLEDGEMENTS

This research was funded by the Directorate Gen-

eral of Research and Development, Ministry of Re-

search, Technology and Higher Education for the pe-

riod 2017-2019.

REFERENCES

Al-Refaie, A., Al-Durgham, L., and Bata, N. (2010). Op-

timal parameter design by regression technique and

grey relational analysis. volume 3. Proceedings of the

World Congress on Engineering.

Azadi, M. M., Kolahan, F., and Golmezerji, R. (2011).

Multi objective optimization of turning process using

grey relational analysis and simulated annealing algo-

rithm. pages 2926–2932.

Basu, P. (2013). Biomass Gasification, Pyrolysis and Tor-

refaction: Practical Design and Theory. Elsevier Inc,

2nd edition.

Blasi, C. D. (2008). Modeling chemical and physical pro-

cesses of wood and biomass pyrolysis. 34:47–99.

Giacomo, G. D. and Taglieri, L. (2013). Modeling chemical

and physical processes of wood and biomass pyroly-

sis. 2(3):255–260.

Kalyani, P. and Anitha, A. (2013). Biomass carbon

& its prospects in electrochemical energy systems.

38:4034–4045.

Lela, B., Bari

ˇ

sic, M., and Nizˇetic, S. (2016). Card-

board/sawdust briquettes as biomass fuel: Physical–

mechanical and thermal characteristics. 47:236–245.

Mandala, W. W., Cahyono, M. S., Sukarjo, S., and War-

doyo, H. B. (2016). Influence of temperature to yield

and caloric value of plastic waste pyrolysis oil. 1.

Roy, R. K. (2010). A primer on the taguchi method: Society

of manufacturing engineers. 21.

Stolarski, J. M., Szczukowski, S., Tworkowski, J., Zaniak,

K., Gulczynski, P., and Mleczek, M. (2013). Compar-

ison of quality and production cost of briquettes made

from agricultural and forest origin biomass. 57:20–26.

Sundaram, P., Sudhakar, P., and Yogeshwaran, R. (2016).

Experimental studies and mathematical modeling of

drying wheat in fluidized bed dryer. 9(36):1–8.

Vargas-Moreno, J. M., Callej

´

on-Ferre, A. J., P

´

erez-

Alonsoa, J., and Vel

´

azquez-Mart

´

ı, B. (2012). A review

of the mathematical models for predicting the heating

value of biomass materials. 16:3065–3083.

Vishwakarma, M., Parashar, V., and Khare, V. (2012).

Regression analysis and optimization of material re-

moval rate on electric discharge machine foren-19 al-

loy steel using tungsten copper electrode. 2(6):785–

792.

Wilk, M., Magdziarz, A., Kalemba, I., and Gara, P. (2016).

Carbonisation of wood residue into charcoal during

low temperature process. pages 507–513.

Wisakha, P. (2015). Sustainability approach for energy pro-

duction using biomass at household and community

levels. a case study in thailand. 5(3):859–872.

Optimizing the Pyrolysis Process and Modelling the Calorific Value of Sawdust Charcoal as Composing Materials of Quality Briquettes

267