The Effect of Environmental Management Practices and Integrated

Supply Chain on Technology Innovation Performance in

Manufacturing Companies

Gatronado Garaika

1

, Rahmania Ayu Handyta Putri

2

, Yuli Liestyana

2

, and Yekti Utami

2

1

Department of Management, Sekolah Tinggi Ilmu Ekonomi Trisna Negara, Sumatera Selatan

2

Universitas Pembangunan Nasional Veteran Yogyakarta

Keywords: Management practices, supply chain, knowledge sharing, and performance.

Abstract: This study aims to analyze the effect of environmental management practices and integrated supply chain on

the performance of technological innovation in manufacturing companies in the Special Region of

Yogyakarta and South Sumatera. The list of manufacturing companies was obtained from the Directory of

Large and Medium Processing Industries in Yogyakarta and South Sumatera. The variables used in this

study are environmental management practices, integrated supply chain, supply chain knowledge sharing,

and technological innovation performance. The data used in this study are primary data. The data collection

method used was a questionnaire. The analytical tool used is a simple regression model, multiple regression,

and path analysis. The results of this study indicate that environmental management practices have no

positive and no significant effect on the performance of technological innovation, integrated supply chain

has a positive effect on the performance of technological innovation, integrated supply chain has a positive

effect on supply chain knowledge sharing, supply chain knowledge sharing has a positive effect on the

performance of technological innovation, and supply chain knowledge sharing is able to mediate the effect

of integrated supply chain on the performance of technological innovation.

1 INTRODUCTION

In the time of globalization with a great deal of

rivalry and advances in innovation and data as it is

today, organizations will consistently contend to

address the issues of their clients regarding speed,

capacity, fulfillment, and precision in an item. Client

request additionally changes from easy to

increasingly unpredictable. This makes the

organization flawless the generation procedure that

includes the majority of the organization's

accomplices, from the acquisition of crude materials

to the end-client or the end-client, which is the place

inventory network the board is required here.

Networks in Indonesia have pursued the

improvement of science, innovation, and expressions

(IPTEKS), which affects individuals' lives,

particularly in mechanical social orders. This

additionally affects the assembling business. As per

BPS (2008), the assembling business is an

assembling industry, which is a business that

procedures or changes over crude materials into

completed merchandise or semi-completed products

that have included worth, which is done precisely

with machines, or without utilizing machines.

Nearly in each district in Indonesia, there are

assembling organizations. This can be brought about

by a great deal of completed merchandise required

by the network.

A few exact examinations have endeavored to

analyze the impact of natural administration on

advancement following the Porter Hypothesis at the

business level. (Jaffe and Palmer, (1997);

Chudnovsky et al., (2005); Kneller and Manderson,

(2012)). In any case, Portney (2008) demonstrates

that the impacts of natural guidelines on

organizations can be altogether different, and

varieties in the organization level are significant

viewpoints. Therefore, a few scholastics and

analysts broke down the connection between

ecological administration rehearses and mechanical

developments at the organization level, for instance,

the utilization of natural administration frameworks

(ISO14001, Gold), earth well-disposed advertising,

clean creation, and interior approaches for

560

Garaika, G., Putri, R., Liestyana, Y. and Utami, Y.

The Effect of Environmental Management Practices and Integrated Supply Chain on Technology Innovation Performance in Manufacturing Companies.

DOI: 10.5220/0009965705600566

In Proceedings of the International Conference of Business, Economy, Entrepreneurship and Management (ICBEEM 2019), pages 560-566

ISBN: 978-989-758-471-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

improving natural execution. Ecological

administration practices have demonstrated their

impacts on procedure advancement and item

development (Wagner, 2008) (Rennings et al.,

2006). The extent of current investigations in this

field is restricted to the impact of a couple of

ecological administration rehearses on mechanical

development. In this way, it is important to

investigate the instrument by which natural

administration practices can advance mechanical

development.

Numerous observational examinations (e.g.,

Gemünden, 1996) locate that drawing in providers

for past item development ventures can maintain a

strategic distance from expensive plan changes later.

Provider interest in mechanical development has a

critical constructive outcome on operational

execution and creative execution. Client investment

in new item advancement ventures can help

organizations get request data, which can expand

consumer loyalty at lower costs but then with higher

caliber. The client request is a significant

predecessor of development and significant for item

plan, so client inclusion in advancement contributes

emphatically to the nature of execution and

development execution.

The significance of raising this subject is so

assembling organizations in the Special Region of

Yogyakarta, and South Sumatera can improve their

production network combination so they can get by

in progressively savage business rivalry and have the

option to contend with the best procedures to win the

challenge from their rivals, so it is trusted that by

actualizing ecological administration rehearses,

inventory network incorporation, store network

learning sharing can influence the presentation of

mechanical development in assembling

organizations in the Special Region of Yogyakarta

and South Sumatera. In light of the foundation over,

the creators are keen on looking into with the title

Effect of Environmental Management Practices and

Supply Chain Integration on Technology Innovation

Performance in Manufacturing Companies in

Special Region of Yogyakarta and South Sumatera.

2 LITERATURE REVIEW

2.1 Environmental Management

Practices and the Performance of

Technological Innovation

In ongoing years, the connection between the board

rehearses deliberate condition and the presentation

of mechanical advancement in an organization have

turned into the focal point of consideration. Wanger

(2008) found that natural administration rehearses in

organizations can not just decrease negative

ecological effects and asset utilization yet, in

addition, to advance natural procedure development

and item advancement through authoritative

learning. Rennings et al. (2006) demonstrate that

intentional natural administration works on,

including life cycle investigation and ISO14001

accreditation, have a critical positive effect on item

advancement and procedure development.

H1: Environmental administration practices have

a critical and beneficial outcome on the presentation

of mechanical development in assembling

organizations.

2.2 Integrated Supply Chain and the

Performance of Technological

Innovation

Both production networks and mechanical

development centers around business techniques,

associations, and procedures. The inventory network

is focused on making an incentive for end clients.

For organizations, individuals' inventory network

(counting clients and providers) are the fundamental

wellsprings of mechanical development as well as

significant wellsprings of thoughts and information.

Data sharing, common trust, and joint critical

thinking among individuals are things that

incorporation store network underlines, and this can

increment immediate or roundabout communications

among organizations and their production network

accomplices. Things like this can prompt new and

alternate points of view and can help create new

thoughts and various options that are significant for

the advancement of assembling organizations in the

Special Region of Yogyakarta.

Bellamy et al. (2014) attested that store network

combination system and learning coordinated effort

could improve item quality and administration levels

as well as are the principal assets of business

development. Lee et al. (2014) found that store

network mix had a positive and noteworthy impact

The Effect of Environmental Management Practices and Integrated Supply Chain on Technology Innovation Performance in Manufacturing

Companies

561

on advancement execution in Malaysian assembling

organizations.

H2: Supply chain mix has a positive and

noteworthy impact on the exhibition of mechanical

development in assembling organizations.

2.3 Integrated Supply Chain and

Supply Chain Knowledge Sharing

With the change of business, the board from shut

end the board to open administration, production

network systems have turned into a significant route

for organizations to share information. The impact

of store network incorporation on learning sharing is

for improvement, and organizations ought not just to

depend on their rare assets (counting information)

yet in addition, effectively gain new information

from outer sources. At that point, it can invigorate

information sharing. A tight system of connections

between organizations can advance learning sharing.

Store network joining gives its individuals

neighborly correspondence openings that encourage

agreement building, which adds to open learning

sharing and the viable utilization of implied

information to assembling organizations in the

Special Region of Yogyakarta. Lee et al. (2014)

additionally found that inventory network systems

are significant wellsprings of learning and assets for

organizations.

H3: Supply chain reconciliation has a positive

and critical impact on production network learning

partaking in assembling organizations.

2.4 The Influence of Supply Chain

Knowledge Sharing on

Technological Innovation

Performance

Nonaka (1991) says that learning sharing is a

fundamental phase of development. An association

can't make learning without anyone else, just when

the information controlled by its staff is shared,

talked about, and whenever broke down, the

association or organization will be able to advance.

Learning sharing between associations can not just

mitigate the troubles of restricted inside information

assets and decrease advancement costs yet

additionally increment the degree of execution of

development.

H4: Supply chain information sharing has a

positive and critical impact on the presentation of

mechanical advancement in assembling

organizations.

2.5 The Influence of Supply Chain

Integration on the Performance of

Technological Innovations

Mediated by Supply Chain

Knowledge Sharing

Organizations, when offering to learn to an

accomplices production network, will have the

option to comprehend cutting edge innovation

instantly and the most recent imaginative

accomplishments that are basic for mechanical

advancement.

H5: Supply chain learning sharing emphatically

intervenes in the impact of production network

combination on the presentation of mechanical

development in assembling organizations.

3 RESEARCH METHOD

This research concentrate utilizes quantitative

research, and the information source utilized in this

investigation is the wellspring of essential

information acquired from surveys. The testing

procedure utilized is Purposive Sampling. The

example in this investigation was assembling

organizations in the Special Region of Yogyakarta

and South Sumatera, with the respondent criteria

being assembling organizations. The information

recorded in the Large and Medium Manufacturing

Industry Directory Daerah Istimewa Yogyakarta and

South Sumatera in 2016 is still in activity until this

examination is completed, having executed

ecological administration, having in excess of 200

workers, producing organizations that have the type

of a Limited Liability Company or PT.

4 RESULTS AND DISCUSSION

4.1 Simple Regression Analysis

Hypothesis testing utilizing a basic relapse

examination in this investigation is utilized to test

one theory. Basic relapse depends on the utilitarian

or causal relationship of a free factor with a needy

variable. Test results with straightforward relapse

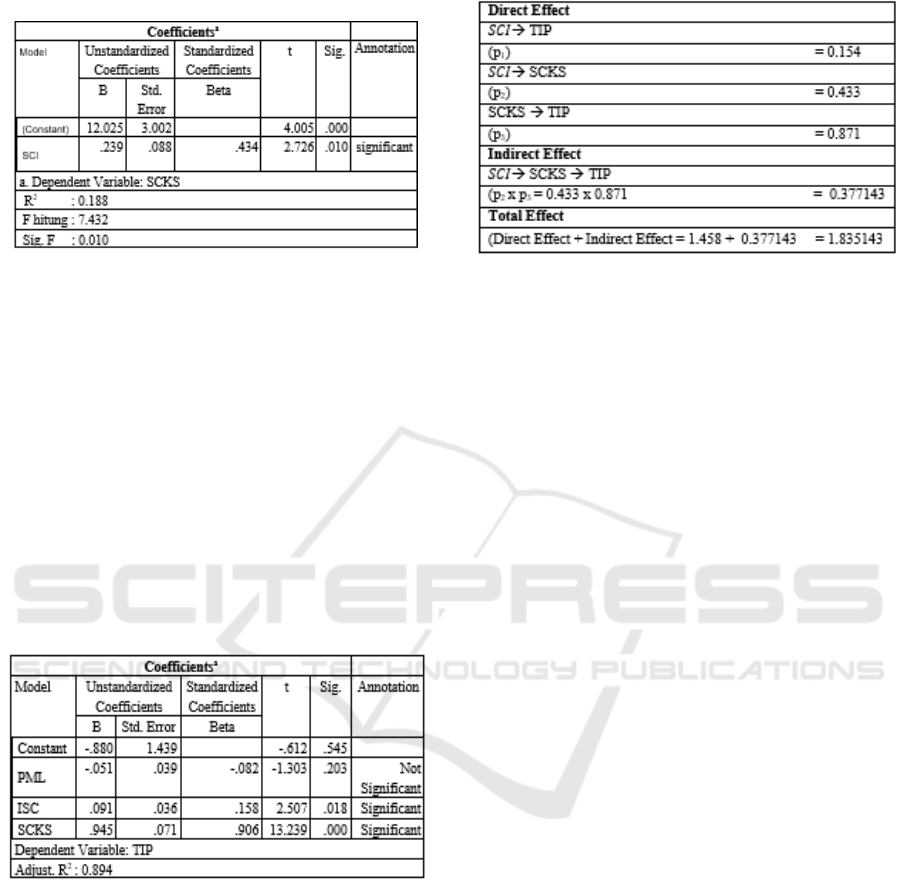

examination can be found in Table 1:

ICBEEM 2019 - International Conference on Business, Economy, Entrepreneurship and Management

562

Table 1: Hypothesis Testing Results with Simple

Regression Analysis

Source: Data processing with simple regression analysis,

2019

4.2 Multiple Regression Analysis

Numerous relapse investigation expects to foresee

how the state (high points and low points) of the

needy variable (measure) if at least two free factors

as an indicator factor are controlled (expanded in

worth). So different relapse examinations will be

done if the quantity of autonomous factors is at any

rate two. Hypothesis testing utilizing a

straightforward relapse examination in this

investigation was utilized to test three hypotheses.

Table 2: Hypothesis Testing Results with Multiple

Regression Analysis

4.3 Path Analysis

Path analysis is an expansion of various relapse

investigations, or way investigation is the utilization

of relapse examination to appraise causality

connections between factors that have been

foreordained dependent on the hypothesis ( Ghozali,

2013).

Table 3: Hypothesis Testing Results with Path Analysis

Source: Data processing

with path analysis, 2019

4.4 Hypothesis Testing Results 1

In light of the legitimacy test hypothesis (Ghazali,

2011) utilized in this investigation, where the rule of

noteworthiness esteem α ≤0.05 is pronounced

substantial. From the relapse, investigation, results

got noteworthy outcomes found in the Significant

Coefficient table of 0.203. With this, it doesn't

demonstrate that the worth is 0.000 ≤ 0.05, and it

very well may be presumed that PML doesn't impact

KIT. This is since there are as yet many assembling

organizations in the Special Region of Yogyakarta

and South Sumatera that have not actualized natural

administration appropriately, truth be told, there are

no organizations that have explicit ecological

models, for example, ISO14001 with the goal that

the impact that emerges on the exhibition of

mechanical advancement isn't yet there. In this

manner, theory 1 isn't acknowledged.

4.5 Hypothesis 2 Testing Results

In view of the legitimacy test hypothesis (Ghazali,

2011) utilized in this examination, where the rule of

centrality esteem α ≤ 0.05 was announced

substantial. From the relapse examination results

acquired noteworthy outcomes found in the

Significant Coefficient table of 0.018. With this, it

demonstrates that the estimation of 0.018 ≤ 0.05, and

it very well may be inferred that the ISC positively

affects KIT, implying that on the off chance that the

ISC is higher, at that point the KIT in assembling

organizations in the Special Region of Yogyakarta

and South Sumatera will likewise be higher.

In improving inventory network incorporation, to

have the option to connect with clients through data

systems, speak with clients, increment piece of the

pie data from clients, trade data with providers and

The Effect of Environmental Management Practices and Integrated Supply Chain on Technology Innovation Performance in Manufacturing

Companies

563

clients, take an interest with providers during the

time spent obtaining crude materials, and so forth

improve the exhibition of mechanical development.

In the inventory network, the joining procedure

can help improve item data that is available,

discover what item advancements are going on, and

the market needs, and can help organizations in

amplifying generation and expanding productivity in

the organization. Furthermore, with this, it can

likewise be expressed that hypothesis 2 (H2) is

acknowledged.

4.6 Hypothesis Testing Results 3

In light of the legitimacy test hypothesis (Ghazali,

2011) utilized in this investigation, where the

foundation of importance esteem α ≤ 0.05 is

announced legitimate. From the relapse investigation

results acquired huge outcomes found in the

Significant Coefficient table of 0.010. With this, it

demonstrates that the estimation of 0.010 ≤ 0.05, and

it tends to be reasoned that ISC positively affects

SCKS, implying that if ISC is higher than SCKS in

assembling organizations in the Special Region of

Yogyakarta and South Sumatera will likewise be

higher. The significance of inventory network

coordination in-store network learning sharing is

that the production network mix gives data about

conditions and openings that are entirely appropriate

for organizations in picking up information in the

inventory network.

Production network combination carries the

organization closer to inventory network

accomplices, so this can invigorate data sharing or

learning sharing, set up store network connections

both inside and outside the organization, expanding

income and income as well as expanding union to

improve proficiency inside the organization. So the

execution of inventory network reconciliation in

assembling organizations in the Special Region of

Yogyakarta and South Sumatera can confront the

tight local challenge and can impact the degree of

offers inside the organization. Furthermore, with

this, it can likewise be expressed that hypothesis 3

(H3) is acknowledged.

4.7 Hypothesis 4 Test Results

In light of the legitimacy test hypothesis (Ghazali,

2011) utilized in this investigation, where the

paradigm of noteworthiness esteem α ≤ 0.05 was

proclaimed substantial. From the relapse

investigation results acquired huge outcomes found

in the Significant Coefficient table of 0,000. With

this, it demonstrates that the estimation of 0,000 ≤

0.05, and it tends to be reasoned that SCKS

positively affects KIT, implying that if SCKS is

higher, the KIT in assembling organizations in the

Special Region of Yogyakarta and South Sumatera

will be higher. An organization can be said to be

fruitful in advancement if the whole arrangement of

organizations from upstream to downstream as of

now comprehends and comprehends the learning

gave. With so advancement in the organization will

go connected at the hip with the talk and

investigation, so the procedure of store network

information sharing can emphatically impact the

presentation of mechanical development in

improving execution and expanding the greatness of

assembling organizations in Special Region in

Yogyakarta and South Sumatera. What's more, with

this, it can likewise be expressed that hypothesis 4

(H4) is acknowledged.

4.8 Hypothesis Testing Results 5

Hypothesis intervention testing should be possible

by a strategy created by Sobel (Ghozali, 2011) and is

known as the Sobel test or Sobel test. The Sobel test

is completed by testing the quality of the

backhanded impact of the autonomous variable

(ISC) on the needy variable (KIT) through

interceding factors (SCKS) or the circuitous impact

(ISC) on (KIT) through (SCKS).

The way coefficient demonstrates the immediate

impact of a free factor on the needy variable on

away. Testing this hypothesis has an ISC variable

coefficient of 0.433 duplicated by an SCKS variable

coefficient of 0.871 will give an aftereffect of

0.377143. Inventory network reconciliation has an

immediate application that has great outcomes to

improve the presentation of mechanical

developments to be applied to the organization. At

that point with the job of production network

learning sharing as intervention can make inventory

network incorporation persuasive and assume a

more noteworthy job in improving the presentation

of mechanical advancement.

Where the store network of information sharing

has a major job to improve correspondence and to

learn to share on everything that is engaged with the

production network process in the organization, this

implies the production network learning sharing

gives a superior and more prominent impact in the

mix of the store network on the exhibition of

mechanical advancement if the reconciliation of the

inventory network through the production network

information sharing.

ICBEEM 2019 - International Conference on Business, Economy, Entrepreneurship and Management

564

5 CONCLUSIONS

Based on the results of the study, as outlined in the

previous chapter, some conclusions can be drawn as

follows:

1) Natural administration practices are not huge

with the goal that they don't have any effect

on the presentation of mechanical

development in assembling organizations in

the Special Region of Yogyakarta and South

Sumatera.

2) Production network combination has a

positive and noteworthy impact on the

presentation of mechanical advancement in

assembling organizations in the Special

Region of Yogyakarta and South Sumatera

3) Inventory network combination has a positive

and noteworthy impact on production

network information partaking in assembling

organizations in the Special Region of

Yogyakarta and South Sumatera.

4) Production network learning sharing has a

positive and huge impact on the presentation

of mechanical development in assembling

organizations in the Special Region of

Yogyakarta and South Sumatera.

5) Store network information sharing

emphatically intercedes the impacts of the

joining of the inventory network to the

presentation of innovation development in

assembling organizations in Yogyakarta and

South Sumatera.

6 SUGGESTIONS

Suggestions from this study based on the results of

research hypothesis testing are as follows:

1) Following the aftereffects of the investigation,

ideally, every assembling organization

proceeded with consideration will rehearse

ecological administration around the

organization. Seeing the realities on the ground

that there are as yet numerous organizations

that have not executed natural administration

appropriately, this won't influence the

exhibition of the organization's mechanical

advancement. Organizations are additionally

urged to keep up and increment production

network reconciliation and are joined by a

superior inventory of information sharing

stockpile chains. Since by actualizing

production network mix together with the

usage of store network learning sharing, there

is a huge constructive outcome on improving

the exhibition of mechanical development.

With the presentation of inventory network

mix, store network information sharing, and the

exhibition of this great mechanical

development will have the option to expand the

upper hand of assembling organizations in the

Special Region of Yogyakarta and South

Sumatera.

2) Future specialists who utilize this exploration

as a source of perspective ought to create

research models so they can find or

demonstrate new things from ecological

administration rehearses, production network

mix, inventory network information sharing,

and mechanical development execution.

REFERENCES

Argote, L., Ingram, P. 2000. Knowledge transfer: A basis

for competitive advantage in firms. Organizational

Behavior and Human Decision Processes. 82, 150–

169.

Avadikyan, A .; Llerena, D .; Ostertag, K. 2001.

Organizational mechanisms in environmental

management: An evolutionary analysis confronted

with empirical facts. International Journal of

Technology Management Environment. 1, 45–60.

Cai, W .; Zhou, X. 2014. On the drivers of eco-innovation:

Empirical evidence from China. Clean Production

Journal. 79, 239–248

Chen, J .; Chen, YF 2006. The study of systems on

technological innovation performance in enterprises.

Science Management. S&T 27, 86–91.

Flynn, BB; Huo, B .; Zhao, X. The Impact of Supply

Chain Integration on Performance: A Contingency and

Configuration Approach. Journal of Operations

Management. 2010, 28, 58–71.

Frohlich, MT; Westbrook, R. 2001. Arcs of integration:

An international study of supply chain strategies.

Journal of Operations Management. 19, 185–200

Gemünden, HG; Ritter, T .; Heydebreck, P. 1996.

Network configuration and innovation success: An

empirical analysis in German high-tech industries.

International Journal of Market Research. 1996, 13,

449–462

Ghozali, Imam, 2011, Application of Multivariate

Analysis with the IBM SPSS 20 Program, Semarang:

Diponegoro University.

Hagedoorn, J .; Cloodt, M. 2003. Measuring Innovative

Performance: Is There an Advantage in Using

Multiple Indicators? Research Policy 2003, 32, 1365–

1379.

Hajmohammad, S .; Vachon, S .; Klassen, RD; Gavronski,

I. 2013. Lean management and supply management:

The Effect of Environmental Management Practices and Integrated Supply Chain on Technology Innovation Performance in Manufacturing

Companies

565

Their role in green practices and performance. Journal

of Clean Production., 39, 312-320.

Hart, SL; Ahuja, G. 1996. Does it pay to be green? An

empirical examination of the relationship between

mission reduction and firm performance. Business

Strategy Environment, 5, 30–37.

Heba, Suifan. 2017, The effect of supply chain integration

on technical innovation in Jordan: the mediating role

of knowledge management, Benchmarking: An

International Journal, Vol. 24 Issue 3 pp.

Klassen, RD; Whybark, DC 1999. Environmental

Management in Operations: The Selection of

Environmental Technologies *. Decision Science. 30,

601–631.

Lee, VH; Ooi, KB; Chong, AYL; Seow, C. 2014. Creating

technological innovation via green supply chain

management: An empirical analysis. Expert System

Application. 41, 6983–6994

Levary, RR 2000. Better supply chains through

information technology. Atlanta Industrial

Management, 43, 24-30.

Llerena, D. 1999. Integration of environmental issues in

the firm: Learning processes and coordination.

International Journal of Sustainable Development.

1999, 2, 263–282.

Mentzer, JT; Foggin, JH; Golicic, SL 2000. Collaboration:

The enablers, impediments, and benefits. Supply

Chain Management Review. 4, 52–58.

Narasimhan, R .; Kim, SW 2002. Effect of supply chain

integration on the relationship between diversification

and performance: Evidence from Japanese and Korean

firms. Journal of Operations Management. 20, 303–

323.

Nonaka, I. 1991 The knowledge-creating company.

Harvard Business Review. 169, 96–104.

Notoatmodjo, S. 2002, Health Research Methodology,

RinekaCipta, Jakarta

Rennings, K .; Ziegler, A .; Ankele, K .; Hoffmann, E.

2006. The influence of different characteristics of the

EU environmental management and auditing scheme

on technological environment innovations and

economic performance. Ecology Economy. 57, 45–59.

Roome, N. 1992. Developing environmental management

strategies. Business Strategy Environment. 1, 11–24.

Now, Uma. Bougie, Roger. 2017. Business Research

Methods. Issue 6, Jakarta: SalembaEmpat

Shrivastava, P .; Hart, S. 1995. Creating sustainable

corporations. The bus. Strategy Environ. 4, 154–165.

Sugiyono 2012. Qualitative Quantitative Research

Methods & RND. Bandung: Alfabeta

________. 2014. Educational Research Methods

Quantitative, Qualitative, and R&D Approaches.

Bandung: Alfabeta.

Swink, M .; Narasimhan, R .; Wang, C. 2007. Managing

beyond the factory walls: Effects of four types of

strategic integration on manufacturing plant

performance. Journal of Operations Management. 25,

148–164.

Vachon, S .; Klassen, RD 2008. collaboration in the

supply chain. International Journal of Production

Economy. , 111, 299–315

Wagner. 2008. M. Empirical influence of environmental

management on innovation: Evidence from Europe.

Ecology Economy. 66, 392–402.

Yang, J; Han, Q; Zhou, J; Yuan, C. 2015. The Influence of

Environmental Management Practices and Supply

Chain Integration on Technological Innovation

Performance — Evidence from China's Manufacturing

Industry. Journal of Sustainability. 15342 - 16361

Zhu, Q .; Sarkis, J .; Lai, K. 2012. Green Supply Chain

Management Innovation Diffusion and its

Relationship to Organizational Improvement: An

Ecological Modernization Perspective. Journal of

English Technology Management. 29, 168–185.

Barnes, James G. 2003. Secrets of Customer

Relationship Management. Andi, Yogyakarta.

ICBEEM 2019 - International Conference on Business, Economy, Entrepreneurship and Management

566