Semantic Web Services for AI-Research with Physical Factory

Simulation Models in Industry 4.0

Lukas Malburg

1 a

, Patrick Klein

1 b

and Ralph Bergmann

1,2 c

1

Business Information Systems II, University of Trier, 54296 Trier, Germany

2

German Research Center for Artificial Intelligence (DFKI), Branch University of Trier,

Behringstraße 21, 54296 Trier, Germany

Keywords:

Semantic Web Services, Industry 4.0, Artificial Intelligence, Flexible Cyber-Physical Workflows, OWL-S,

WSMO.

Abstract:

The transition to Industry 4.0 requires smart manufacturing systems that are easily configurable and provide

a high level of flexibility during manufacturing in order to achieve mass customization or to support cloud

manufacturing. To realize this, Cyber-Physical Systems (CPSs) combined with Artificial Intelligence (AI)

methods find their way into manufacturing shop floors. For using AI methods in the context of Industry 4.0,

semantic web services are indispensable to provide a reasonable abstraction of the underlying manufacturing

capabilities. In this paper, we present semantic web services for AI-based research with physical factory sim-

ulation models in Industry 4.0. Therefore, we developed 70 semantic web services based on Web Ontology

Language for Web Services (OWL-S) and Web Service Modeling Ontology (WSMO) and linked them to an

already existing domain ontology for intelligent manufacturing control. Suitable for the requirements of CPS

environments, our pre- and postconditions are verified in near real-time by invoking other semantic web ser-

vices in contrast to complex reasoning within the knowledge base. Finally, we examine the feasibility of our

approach by executing a cyber-physical workflow composed of semantic web services using a state-of-the-art

workflow management system.

1 INTRODUCTION

Nowadays, the industry is in a transformation to-

wards the fourth industrial revolution, also known

as Industry 4.0 in the German-speaking area (Lasi

et al., 2014). The predominant application of Ar-

tificial Intelligence (AI) methods in Cyber-Physical

Systems (CPSs) (Broy et al., 2012) is a typical char-

acteristic of this transformation (Lee et al., 2014).

In this context, flexibility is one of the central as-

pects for manufacturing companies particularly be-

cause of ever shorter market launch times and increas-

ing customer demands for individualization (Cheng

et al., 2017; Lasi et al., 2014). In order to con-

duct close to reality Industry 4.0 research, we use

a physical Fischertechnik (FT)

1

factory simulation

model because companies are often not willing to pro-

vide data from and access to their production lines

a

https://orcid.org/0000-0002-6866-0799

b

https://orcid.org/0000-0002-5077-2645

c

https://orcid.org/0000-0002-5515-7158

1

https://www.fischertechnik.de/en/simulating/industry-4-0

for research purposes. To use AI applications in

practise, knowledge must necessarily be available in

formal and machine-readable representations (Humm

et al., 2020). Semantic Web Services (SWSs) ad-

dress the problems of automatic discovering, com-

posing, and executing by providing a declarative, on-

tological framework for describing them. Using AI

methods (e. g., automated planning such as Marrella,

2018; Marrella and Mecella, 2018, multi-agent sys-

tems for decentralized manufacturing control such as

Ciortea et al., 2018; Ocker et al., 2019, Case-Based

Reasoning (CBR) such as Minor et al., 2014; Müller,

2018) to enhance flexibility in cyber-physical produc-

tion workflows (Bordel Sánchez et al., 2018; Seiger

et al., 2018) inevitably require such semantic annota-

tions. Several related work (e. g., Lastra and Delamer,

2006; Puttonen et al., 2010, 2013) exist that already

address these issues by using SWSs. However, the

currently available approaches that use SWSs in the

context of Industry 4.0 focusing only on specific as-

pects and do not consider the entire context of man-

ufacturing environments. Furthermore, the complex

32

Malburg, L., Klein, P. and Bergmann, R.

Semantic Web Services for AI-Research with Physical Factory Simulation Models in Industry 4.0.

DOI: 10.5220/0010135900320043

In Proceedings of the International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2020), pages 32-43

ISBN: 978-989-758-476-3

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

reasoning within the knowledge base makes real-time

execution and monitoring of manufacturing processes

difficult. In particular, we experienced these problems

already in our physical simulation factory and thus it

is probably not possible to use these approaches in

real production settings efficiently. For this reason,

we present an approach for applying SWSs to avoid

complex reasoning in the knowledge base and that

is therefore suitable for near real-time AI-based ap-

plications. We present three exemplary AI use cases

namely multi-agent systems, automated planning, and

business process management in CPSs that demand

for semantically enriched Service-Oriented Architec-

tures (SOAs). Afterwards, we identify requirements

from the use cases that should be fulfilled by the pro-

posed architecture and show why SOAs are indispens-

able. In the following, Section 2 describes the layout

of our used physical Fischertechnik (FT) simulation

factory and presents use cases in which the applica-

tion of semantic information provided by semantic

web services could be important. Furthermore, re-

lated work concerning the use of web services in man-

ufacturing and a domain ontology for physical simu-

lation factories are presented. The developed seman-

tic web services themselves are described in detail in

Section 3 and a feasibility test is presented in Section

4. Finally, a conclusion is given and future work is

discussed in Section 5.

2 FOUNDATIONS AND RELATED

WORK

2.1 Semantic Web Services for Flexible

Production

The paradigm of Service-Oriented Architectures

(SOAs) can be used to achieve manufacturing flexibil-

ity as it is needed for Industry 4.0 mass customization

(Lasi et al., 2014) and reconfigurability by decoupling

functionality from the underlying implementation and

location (Lu and Ju, 2017). For implementing SOAs,

web service technologies can be used (Jammes and

Smit, 2005) and, in particular, in the context of AI,

these are semantically enriched, resulting in Semantic

Web Services (SWSs). Therefore, semantic technolo-

gies such as Web Ontology Language for Web Ser-

vices (OWL-S) (Martin et al., 2007) for expressing the

meaning of the web service interface can be used. In

general, this enables automatic discovering, compos-

ing, and executing that are required for using AI meth-

ods.

Several works propose the use of SWSs for smart

manufacturing in Industry 4.0 but focusing only on

partial aspects and do not consider the entire context

of the shop floor. For instance, Puttonen et al. (2013)

present an approach to use SWSs for executing manu-

facturing processes by means of three software agents

represented as web services. One of these agents, re-

ferred to as Service Monitor, is a specialized web ser-

vice that carries out semantic web service composi-

tion by using planning techniques w. r. t. a given pro-

duction goal and the current state of the world that

is provided by a domain ontology. Therefore, they

use OWL for describing the state of the production

system as well as OWL-S and SPARQL expressions

for semantically describing the available web services

that offer production capabilities. In our work, we use

a digital representation connected to a corresponding

physical simulation model instead of exclusively us-

ing artificially simulated data. Additionally, we focus

on semantic descriptions of the underlying web ser-

vices that are remotely accessible via REST in order

to control manufacturing resources directly in con-

trast to use agents. Furthermore, we combine our

SWSs with a comprehensive domain ontology of our

production environment, whereas their modeled do-

main knowledge is limited to product definitions. Our

work also focuses on a cyber-physical environment in

which real-time sensor values are retrieved as part of

service pre- and postconditions. Moreover, they just

have two OWL-S processes, which result in 126 pro-

cess variants after considering all possible permuta-

tions of descriptions.

Since modern Cyber-Physical Production Systems

(CPPSs) (Monostori, 2014) consist of many different

components and therefore many stakeholders are in-

volved in their development process up to the later use

in the manufacturing of products, Lobov et al. (2008)

investigated the application of SWSs for orchestration

of a flexible control. They propose OWL for model-

ing a Process Taxonomy, Product Ontology, Equip-

ment Ontology, and Service Ontology and mainly

discuss the responsibilities of involved persons for

knowledge acquisition and maintenance rather than

present their detailed semantic specification.

Most similar to our work, Cheng et al. (2017) pre-

sented an architecture and knowledge model for the

integration of web services for flexible manufactur-

ing systems. Their model includes ontologies that are

similar to Lobov et al. (2008). However, the web ser-

vices themselves are not semantically modeled, while

Puttonen et al. (2013) develop semantic web services

but do not link them to a comprehensive domain on-

tology of the manufacturing environment. Based on

our experiments, we assume that the continuous rea-

soning to evaluate the pre- and postconditions is too

Semantic Web Services for AI-Research with Physical Factory Simulation Models in Industry 4.0

33

complex and time consuming for real world applica-

tions due to ongoing updates of the state of a CPPS

and the huge number of axioms considered during the

inference process.

Most recently, Järvenpää et al. (2019) present

the Manufacturing Resource Capability Ontology

(MaRCO) that aims to provide a semantic description

of the capabilities of manufacturing resources. Ca-

pability parameters as configuration settings of man-

ufacturing resources are also modeled and the capa-

bilities are divided into simple capacities and aggre-

gated combined capacities composed of several sim-

ple capacities. However, their approach is not re-

lated to a SOA and does not directly offer SWSs for

the corresponding capacities to invoke them remotely.

Thus, there is no direct connection between the mod-

eled knowledge and the physical resources to control

manufacturing. Furthermore and in contrast to our

work, no preconditions and effects have been mod-

eled for the capacities, which makes it difficult to use

AI methods directly for intelligent control. Similarly,

Schnicke et al. (2020) present a SOA in which ser-

vices are described by their capabilities, the associ-

ated costs, and the achievable quality of the service

invocation (e. g., time, costs etc.). For discovering a

proper service, a match making by using tags that are

linked to the services is applied. The approach does

not use already established techniques to enrich web

services with semantic descriptions. Thus, it is also

difficult to use AI techniques directly.

All in all, there is a lack of research regarding

the integration of semantically enriched web services

with an existing domain ontology of a manufacturing

environment to make production control more flexi-

ble as well as of research that considers the reasoning

complexity in real-time applications sufficiently.

2.2 Industry 4.0 Simulation Factory

Model

Similar to Cheng et al. (2017), we use a physical Fis-

chertechnik (FT) factory model for the simulation of

an Industry 4.0 manufacturing environment

2

. Such

models are referred to as Learning Factories (Abele

et al., 2017) and are used for education and Industry

4.0 research purposes (e. g., Calà et al., 2016; Klein

and Bergmann, 2019). By using such physical simu-

lation models, it is possible to conduct research under

laboratory conditions and to assess the suitability of

AI methods and prototypical implementations before

they are potentially used in practice. Furthermore, the

direct impact on the physical world can be investi-

2

See www.iot.uni-trier.de for more details.

gated and the step towards transferability to real fac-

tories is closer. When using a digital twin (Boschert

and Rosen, 2016) or simulated data exclusively, this

is only possible to a limited extent and with greater

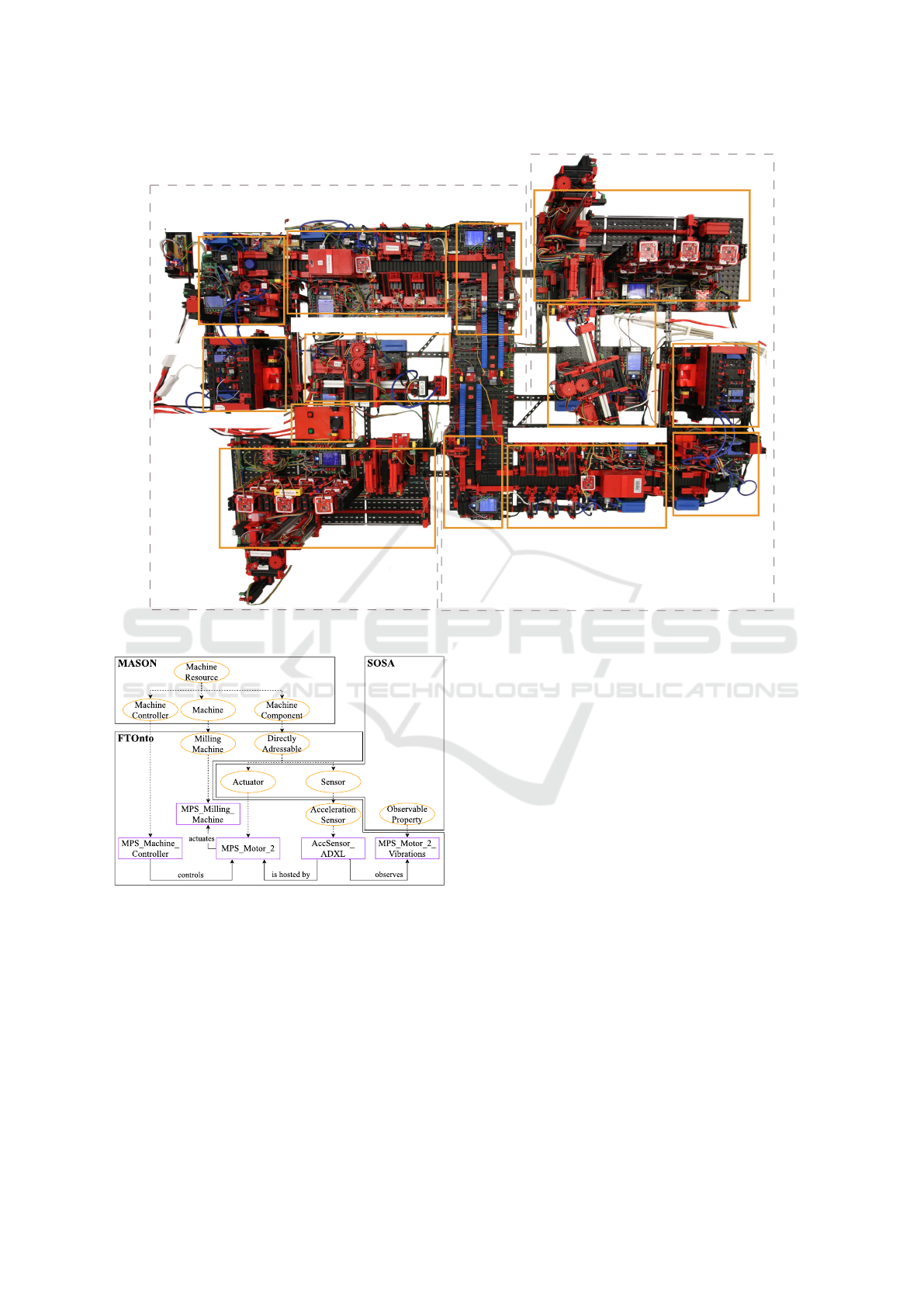

obstacles. Our factory consists of two identical shop

floors that are linked for the exchange of workpieces

as shown in Figure 1. Each shop floor consists of 4

workstations with 6 identical machines: a sorting ma-

chine with color detection, a multi-processing work-

station with an oven, a milling machine, and a work-

station transport that connects both of them, a high-

bay warehouse, and a vacuum gripper robot. Addi-

tionally, each shop floor has individual machines, i. e.,

a punching machine and a human workstation in the

first and a drilling machine in the second shop floor.

Each shop floor is equipped with several light barri-

ers, switches, and capacitive sensors for control pur-

poses. Additionally, the first shop floor is enhanced

with dedicated sensors such as acceleration, differen-

tial pressure, and absolute orientation sensors. RFID

reader/writers are integrated in workstations on both

shop floors and in the high-bay warehouse resulting

in 28 communication points. This allows each work-

piece to be tracked and the required manufacturing

operations and parameters to be retrieved and adjusted

during production as necessary. Furthermore, a cam-

era is placed above the two shop floors to detect and

track the workpieces.

The availability of a knowledge representation in

form of an ontology that represents the manufactur-

ing environment enables engineers to share, reuse,

and make knowledge in formal and machine-readable

way explicit. For Fischertechnik simulation facto-

ries, FTOnto (Klein et al., 2019) provides a seman-

tic description of resources such as sensors and ac-

tuators, products and raw materials, as well as op-

erations such as manufacturing capabilities and han-

dling. Each physical part of the factory is represented

as an individual and is ordered in a sub-class hier-

archy based on an established ontology for model-

ing a manufacturing system called MASON (Lemaig-

nan et al., 2006). Additionally, object properties are

used to model relations between individuals. More-

over, relationships between sensors and actuators are

modeled by the SOSA ontology (Janowicz et al.,

2019). Figure 2 depicts a part of the domain on-

tology FTOnto. Classes are surrounded by an or-

ange circle and instances by a purple rectangle. The

dashed arrow between both states a subclass rela-

tionship or that the instance is from the type of this

class. For example, MPS_MillingMachine is the in-

stance of the class MillingMachine. The statement

that MPS_MillingMachine is driven by MPS_Motor2

is modeled by the property actuates.

IN4PL 2020 - International Conference on Innovative Intelligent Industrial Production and Logistics

34

High-Bay Warehouse 1

Sorting Machine 1

Sorting Machine 2

Punching

Machine

Drilling

Machine

Shop Floor 1

Shop Floor 2

Milling

Machine 2

Vacuum Gripper Robot 2

Oven 2

Vacuum Gripper Robot 1

Milling Machine 1

Oven 1

Sorting Machine 2

Drilling

Machine

Human Workstation

Punching

Machine

High-Bay Warehouse 1

High-Bay Warehouse 2

Sorting Machine 1

Figure 1: The Two Fischertechnik Factory Simulation Models.

Figure 2: Subset of Domain Ontology FTOnto.

2.3 Use Cases

We now introduce three typical use cases by which

we want to demonstrate the potential of semantic

web services for AI-based research in the context of

CPPSs.

Multi-Agent Systems for Decentralized Control

Multi-Agent Systems (MASs) can be used to encapsu-

late functions, e. g., order processing, product design,

production planning, or to represent physical manu-

facturing resources with their manufacturing opera-

tions. For instance, a planning agent either uses man-

ually predefined plans that specify manufacturing op-

erations and their sequence or generates a plan under

consideration of the semantic descriptions of seman-

tic web services that represent the manufacturing ca-

pabilities in order to achieve a given production goal

such as a specific customer request (Ciortea et al.,

2018). We consider a use case in which Multi-Agent

Systems (MASs) utilize the SOA as an abstraction of

physical devices to obtain information from the shop

floor and to control the physical devices by invocation

of web services.

Workflow Planning of Manufacturing Processes

Similar to agent-based planning approaches, auto-

mated planning techniques can be used to build pro-

duction workflows, i. e., a sequence of actions, from

scratch or parts of them by using a complete domain

model, an initial state, and a goal state (Marrella,

2018; Marrella and Mecella, 2018). Semantic web

services enriched with preconditions and effects can

be used for workflow planning. The work of Chen

and Yang (2005) is one of the first in this area that

Semantic Web Services for AI-Research with Physical Factory Simulation Models in Industry 4.0

35

introduces the basic principle. Puttonen et al. (2013)

also use semantic web services and transfer the se-

mantic descriptions into the Planning Domain Def-

inition Language (PDDL) (McDermott et al., 1998)

for planning of manufacturing processes. Similar to

the latter approach, we propose a use case in which

automated planning techniques can be used to gener-

ate cyber-physical workflows enabled by the defini-

tion of semantic web services and the transformation

into PDDL.

Business Process Management for Cyber-Physical

Systems

The application of Business Process Management

(BPM) techniques in cyber-physical environments

can lead to numerous advantages. These are mainly

due to the automatic retrieval of sensor data or events

and are useful in determining the status of activities,

making decisions about future process flow, and de-

tecting deviations at an early stage (Janiesch et al.,

2020). The SOA provides the services that can be

used to execute process activities or to acquire sen-

sor data values. For our use case, we consider that

an intelligent system for BPM needs to access this

data in different process steps or within a specified

time frame in order to use it properly. For example,

Process-Oriented Case-Based Reasoning (POCBR)

(Minor et al., 2014; Müller, 2018) has shown great

potential as an experience-based activity in similar

research fields (e. g., in the cooking domain to repre-

sent cooking recipes as workflows in Müller (2018) or

in the domain of scientific workflows in Zeyen et al.

(2019)) by using best-practise workflows from a case

base. This approach can perhaps also be used to in-

crease workflow flexibility in CPPSs.

3 SEMANTIC WEB SERVICES

FOR AI-BASED RESEARCH

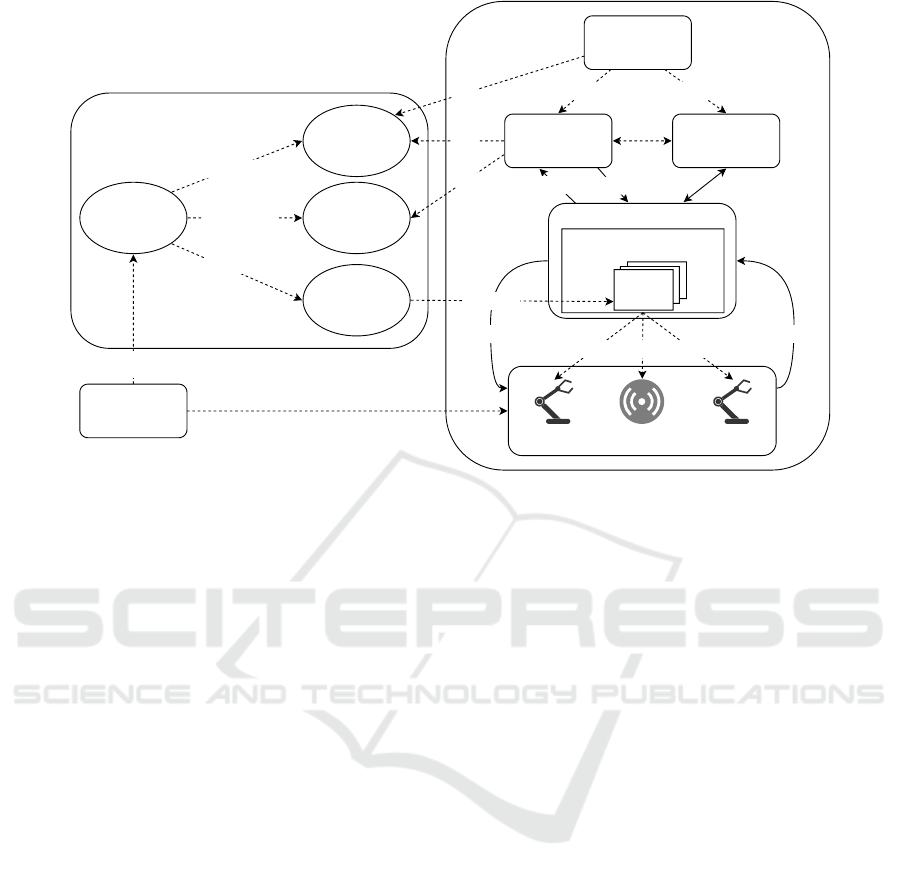

In this chapter, our Service-Oriented Architecture

(SOA) with semantically enriched web services for

applying them in the use cases previously described

is presented. Note that the SOA provides the ser-

vices to retrieve data for implementing a digital twin

(Boschert and Rosen, 2016). The development pro-

cess of our SOA follows the well-known ontology

development methodology by Sure et al. (2009) that

contains the four steps Kickoff, Refinement, Evalua-

tion, and Application & Evolution (see Figure 3) and

that can also be applied for developing semantic web

services. The steps are described in detail in the fol-

lowing.

Kickoff Refinement Evaluation

Application&

Evolution

Figure 3: The Ontology Development Process by Sure et al.

(2009).

3.1 Requirements

In this section, we introduce as part of the Kickoff

phase requirements (RQs) that a SOA should meet in

order to be suitable for AI-based research activities in

Industry 4.0. The requirements have been primarily

derived from the use cases presented in Section 2.3.

We do not divide the requirements according to these

use cases, because most requirements are essential for

more than one use case.

RQ 1 – Provide Interoperability and Interconnec-

tivity. The SOA should be developed to achieve

interoperability and interconnectivity from sev-

eral controller types and programming languages

(Burns et al., 2019; Puttonen et al., 2013).

RQ 2 – Connect to Existing Knowledge Represen-

tations. The services should be linked to an exist-

ing knowledge representation in form of a domain

ontology. Domain ontologies are important for

modeling production systems and for the trans-

formation towards Industry 4.0 (Puttonen et al.,

2013). Due to the connection of semantic web

services with an existing ontology, it is possible to

directly check the result of a web service that re-

turns sensor values for plausibility. Furthermore,

it is possible to identify services that are currently

not available due to an error of a physical manu-

facturing resource.

RQ 3 – Enable Ontology and Knowledge Base Up-

dates and Real-Time Verification. In the con-

text of Industry 4.0, it is necessary to use real-time

data to make proper decisions (Burns et al., 2019;

Lasi et al., 2014). Thus, it is necessary to keep the

instances in the knowledge base up to date (Lobov

et al., 2008).

RQ 4 – Abstract from Low-level Control Com-

mands. It is important to abstract the web

services from individual low-level control com-

mands to create a hardware abstraction layer for

CPSs. In order to use the web services in a busi-

ness process management context, each service

should additionally perform an atomic operation

(Puttonen et al., 2019). It is a necessary require-

ment to be able to break down end-to-end pro-

cesses (see Challenge 7 in Janiesch et al., 2020).

RQ 5 – Enrich Web Services with Semantic De-

scriptions. Due to the semantic enrichment of

web services in a SOA, it enables the use of AI-

IN4PL 2020 - International Conference on Innovative Intelligent Industrial Production and Logistics

36

uses

Design

Layer

Request

Enactment

Layer

Adaptation

Layer

ResponseCommand

WebServer

Web

Service

Cyber-PhysicalLayer

actuatesmeasuresactuates

configures configures

Response

Domain

Ontology

describes

presents

supports

Service

Service

Profile

Service

Model

describes

Service

Grounding

OWL-S

contains

describedby

uses

uses

CPS

interacts

ServiceLayer

Figure 4: Service Conceptualization for Flexible Production Control (Based on Marrella and Mecella 2018).

based technologies such as those presented in the

use cases for improving resource utilization and

for controlling the execution of the whole manu-

facturing processes, i. e., preconditions and effects

can be used to determine the impact of certain

activities (see Challenges 15 and 16 in Janiesch

et al., 2020 and also Hepp et al., 2005).

RQ 6 – Model Relationships between Web Ser-

vices. Relationships and interconnections be-

tween atomic as well as composed web services

should be modeled to determine dependencies be-

tween services of individual manufacturing re-

sources and to identify semantically similar ser-

vices (see Challenge 6 in Janiesch et al., 2020).

RQ 7 – Parameterization of Web Services. Re-

configurability of production systems is needed to

satisfy changing process goals. By parameteriz-

ing web services that represent the possible capa-

bility configuration settings of physical manufac-

turing devices, different production goals can be

achieved (Lobov et al., 2008).

RQ 8 – Resolve Mutual Exclusion. To prevent

multiple access to a single physical manufactur-

ing resource, the SOA should ensure that only

one service may have simultaneous access to this

resource to execute the corresponding operation

(Lobov et al., 2008). During this time, however,

further service requests should not be lost, but

saved.

RQ 9 – Orchestrate and Composite Web Services.

It should be possible to orchestrate or composite

the developed services to more complex processes

(Lobov et al., 2008) and in order to fulfill an over-

all process goal (Puttonen et al., 2013, 2019).

3.2 Architecture Overview

Our concept integrates a SOA composed of corre-

sponding semantic web services with a domain on-

tology in an architecture of a CPS, which is, in fact,

the foundation for research on AI-based control for

flexible manufacturing processes. More precisely, we

adopt the layered architecture for managing cyber-

physical workflows proposed by Marrella and Me-

cella (2018) depicted on the right side as a basis to

define a SOA as a service layer. Additionally, we

linked the SWSs of the service layer to an existing do-

main ontology of a manufacturing environment and

to OWL-S. An overview of the proposed architec-

ture is shown in Figure 4. Starting from the bot-

tom, the Cyber-Physical Layer represents the man-

ufacturing environment where several cyber-physical

production workflows are executed. We propose to

represent each resource (e. g., actuator, sensor etc.) as

well as their relationships in a domain ontology. On

top of this layer, the Service Layer is responsible for

transmitting and executing control commands to the

Cyber-Physical Layer and receiving responses (e. g.,

raw data from sensors). Therefore, this layer contains

semantic web services on different abstraction levels

for control commands as well as for sensor data re-

Semantic Web Services for AI-Research with Physical Factory Simulation Models in Industry 4.0

37

trieval. To describe the services semantically, each

service contains a semantic description such as pro-

posed by OWL-S or the Web Service Modeling On-

tology (WSMO) (Roman et al., 2005) respectively. In

our concept, we re-model parts from both of them for

semantic enrichment of the web services. The result-

ing service ontology is merged with the domain ontol-

ogy FTOnto to relate physical resources to their cor-

responding services. Finally, these web services are

accessible via REST using a web server that can be

seen as an example of a Service Layer implementa-

tion. Thereby, each service has a Service Grounding

that describes the access to the actual service of the

Service Layer. In this regard, the Service Layer con-

stitutes the connection between the Enactment Layer

and Adaptation Layer with the Cyber-Physical Layer,

whereby the web server communicates with both up-

per layers and subsequently executes the desired web

services. The Enactment Layer is responsible for the

execution of modeled cyber-physical workflows by

using the corresponding underlying SWSs. If mod-

eled cyber-physical workflows can not be executed as

planned, adaptations may be necessary. For this rea-

son, the Adaptation Layer uses AI methods such as

presented in the use cases for intelligent production

control. Therefore, Enactment Layer and Adaptation

Layer need access to the Service Profile for discov-

ering services and to the Service Model for how the

service works. In addition, the Design Layer allows

users to exploit the knowledge modeled in the Service

Profile to find appropriate web services during work-

flow modeling.

ServiceLayer

Web

Service

Command

Response

actuates

measures

Controller

Request

Response

WebServer

Cyber-PhysicalLayer

Figure 5: Illustration of the Execution Sequence of a Web

Service Invocation.

Figure 5 shows how the invocation of a web ser-

vice results in a concrete action in the Cyber-Physical

Layer, where the functionality of the web service

is executed. The controller that manages the cor-

responding physical manufacturing resource receives

the request to execute a certain command, if neces-

sary with special capability parameter settings. The

controller actuates the managed device, measures the

corresponding value of a sensor or performs a basic

configuration of the device. Afterwards, the raw data

or generally the response is transferred back to the

web server, i. e., the sensor value or the message that

the command has been executed both with a start and

end time stamp.

3.3 Semantic Web Services for a

Physical Factory Model

Based on the presented architecture, a top-down ap-

proach has been applied to identify and develop 70

SWSs that allow to use independently all functions of

the physical devices of the complete shop floors pre-

sented in Section 2.2. The approach has been used for

the identification of services and selection according

to the level of abstraction corresponding to the use

cases (see RQ 4). All in all, 70 SWSs have been

derived in the refinement phase and due to the vari-

ety of possible parameter values, there exist 364 dif-

ferent configurations of the web services (see RQ 7).

During this phase, pre- and postconditions have been

modeled as web services, results with included ef-

fects have been added, and all web services have been

linked to the existing ontology (see RQ 2). For using

AI planning techniques, the modeled preconditions

and effects can be converted into a planning model.

The provided services are divided into services that

perform an activity in the physical factory and into

services that are offered for measuring sensor data or

for configuring device settings. Furthermore, the ser-

vices are hierarchically ordered into several more spe-

cific classes (see RQ 6). This is illustrated in Figure

6 with a class diagram of the physical resources from

our FT simulation factory (cf. Figure 1). The meth-

ods specified in the classes are encapsulated as web

services and we classified the web services into sens-

ing and configuration services as well as activity ser-

vices according to their purpose and separated by a

dashed line. Please consider that the General Con-

troller interface only provides generic sensing and

configuration services that are reused by the actual

controllers. For example, the method pickUpAnd-

Transport of the VGR has two capability parameters

(start and end) for specifying the start and end po-

sition of a workpiece transport. The method is sim-

ilarly implemented as a web service with the same

two parameters. Due to the variety of positions where

a workpiece can be picked up and dropped off, this

single web service results in 72 different configura-

tion possibilities; the superscript number above the

individual methods illustrates this. Each of these pos-

sibilities of different positions has specific precondi-

tions and effects depending on the given parameter

values for start and end. By encapsulating services of

different controllers of the cyber-physical layer, our

SOA contributes to achieving interconnectivity and

interoperability by providing RESTful web services

(see RQ 1). To describe the services semantically,

we have re-modeled the important concepts of OWL-

S and WSMO for our work and have especially tai-

IN4PL 2020 - International Conference on Innovative Intelligent Industrial Production and Logistics

38

5

20

3

1

1

2

4

10

10

81

1

4

6

6

4

9

72

1

2

3

1

2

2

2

2

3

9

3

1

1

4

3

2

1

2

3

8

21

21

8

5

20

3

1

1

2

4

10

10

81

1

4

6

6

4

9

72

1

2

3

1

2

2

2

2

3

9

3

1

1

4

3

2

1

2

3

8

21

21

8

10

10

Figure 6: Class Diagram of the Physical Manufacturing Resources.

lored them to our simulation context. This means

that we only have one service class, corresponding

to the Service Profile in OWL-S, that describes the

functionality of the service w. r. t. its parameters, in-

puts, outputs, preconditions, and results. Addition-

ally, the description of postconditions is added and re-

modeled from WSMO. These semantic descriptions

can be used to determine what functionality the ser-

vice provides, what requirements have to be fulfilled

for execution, and how its successful execution can

be verified (see RQ 5). Whereas most previous work

updates the knowledge base continuously and verifies

the condition expressions based on the current real

world state, we link to other semantic web services

and use their response for our condition verification.

This means that conditions are evaluated in near real-

time based on sensor data that is accessed via a web

service invocation (see RQ 3). This functionality is

similar to what one would expect from a digital twin.

The web service used to check the conditions can in

turn require further web service invocations for condi-

tion verification (see RQ 6 and RQ 9). To handle mul-

tiple parallel requests to one physical resource, a pri-

ority queue according to the First-In-First-Out prin-

ciple is implemented and services are only executed

by the web server when all required resources are not

blocked by a previous request (see RQ 8). The goal

of the queue is to store incoming web service requests

to ensure that no conflicts between multiple requests

occur during execution of different resources. After

the service is carried out, we control the execution

with postconditions that have to be satisfied to deter-

mine whether a particular activity has been success-

fully performed. If all postconditions are fulfilled, the

successful response is given to the client, otherwise,

the client receives a message which postconditions are

not satisfied.

In the following, we present one of the modeled

semantic services in more detail. For this purpose, the

already mentioned pickUpAndTransport service of

Semantic Web Services for AI-Research with Physical Factory Simulation Models in Industry 4.0

39

1 PREFIX rdf: <http://www.w3.org/1999/02/22−rdf−syntax−ns#>

2 PREFIX owl: <http://www.w3.org/2002/07/owl#>

3 PREFIX rdfs: <http://www.w3.org/2000/01/rdf−schema#>

4 PREFIX xsd: <http://www.w3.org/2001/XMLSchema#>

5 PREFIX ftonto: <http://iot.uni−trier.de/FTOnto#>

7 SELECT ?service ?precondition ?preconditonCheckService ?

checkURL ?requiredKeyInServiceResponse ?

requiredValueInServiceResponse

8 {

9 ?service ftonto:hasURL "http://127.0.0.1:5000/vgr/

pick_up_and_transport?machine=vgr_1&start=sink_1

&end=oven"^^xsd:string .

10 ?service ftonto:hasPrecondition ?precondition .

11 ?precondition ftonto:isCheckedBy ?preconditonCheckService

.

12 ?preconditonCheckService ftonto:hasURL ?checkURL.

13 ?precondition ftonto:requiredKeyInServiceResponse ?

requiredKeyInServiceResponse .

14 ?precondition ftonto:requiredValueInServiceResponse ?

requiredValueInServiceResponse .

15 }

Listing 1: SPARQL Expression for Retrieving

Preconditions.

the VGR is selected since it contains most of the an-

notated semantic elements such as pre- and postcon-

ditions as well as results. Figure 7 illustrates the se-

mantic annotations and their relationships as a graph.

In this context, green rectangles with rounded corners

represent data properties, violet rectangles represent

instances of classes that are in turn represented by or-

ange ellipses. If invoked, this service fulfills the func-

tion of picking up a workpiece at sink one of the sort-

ing machine (start), transporting it to the oven, and

eventually dropping it off at the oven (end). Before

the execution starts, the request is scheduled in the

queue and as soon as no other request comes first, the

execution of the service starts. At this point, access to

the physical resource for other clients is blocked and

intermediate requests are stored in the queue. The first

part of the execution is the check of the preconditions.

In this case, the SPARQL query as shown in Listing

1 is executed and returns five preconditions that must

be fulfilled (see Figure 7). For instance, the oven must

be available and ready and the light barrier that moni-

tors the end position of the transport must not be inter-

rupted, because that indicates an empty storage space.

In particular, these preconditions refer to other seman-

tic web services and their responses can be evaluated

outside of the knowledge base but using the verifica-

tion rules modeled in the knowledge base. This proce-

dure enables to perform the verification in near real-

time without importing large amounts of raw sensor

data produced with high frequency required for com-

plex reasoning within the knowledge base for precon-

dition verification. This could otherwise lead to con-

siderable overhead for reasoning and possibly wrong,

not real-time information for decision making. For

providing real-time data, web services to retrieve the

status of a sensor (e. g., a light barrier) are handled

by a separate queue as the web services that initi-

ate manufacturing operations. This division enables

an immediate result even if the corresponding ma-

chine is still performing a manufacturing operation.

The described principle is also applied to postcondi-

tions that are semantic web services, too. The exem-

plary service contains one postcondition that checks

whether the service has been executed successfully.

The postcondition checks whether the light barrier,

which was not interrupted for the corresponding pre-

condition, has now been interrupted, i. e., it is verified

that the workpiece has been transported from the first

sink of the sorting machine to the oven and thus the

execution was successful. For each service, regard-

less of whether it is used as a pre- or postcondition

or neither, the respective URL to invoke the service is

represented as instance (see Figure 7).

4 FEASIBILITY TEST

In this section, we demonstrate the usage of our devel-

oped SOA as part of the Evaluation phase of the on-

tology development methodology for usefulness for

the described use cases in Section 2.3. Therefore, we

have prototypically implemented the third use case by

using the workflow management system Camunda

3

.

Camunda is able to invoke web services by using

Business Process Model and Notation (BPMN) con-

form Service Tasks. We implement a small cyber-

physical production workflow that transports a work-

piece from the first sink of the sorting machine to the

oven, burns it, and after a quality inspection by an

employee, it is transported and stored in the high-bay

warehouse. Figure 8 illustrates the described man-

ufacturing process as a BPMN diagram. The corre-

sponding web server receives the web service invoca-

tions from Camunda and forwards the execution com-

mand to the controller of the specified physical de-

vice. Before execution, an implemented Python class

checks if the preconditions and after execution, the

corresponding postconditions, of the service are satis-

fied by using OWLReady

4

(Lamy, 2017). Moreover,

we also evaluated a failure scenario where the work-

piece is lost during the transport to the oven. In this

3

https://camunda.com/

4

https://pypi.org/project/Owlready2/

IN4PL 2020 - International Conference on Innovative Intelligent Industrial Production and Logistics

40

hasPostcondition

Service

isServiceOf

hasPrecondition

hasURL

Service_VGR_Pick_

Up_And_Transport

Cond_SM_1_Status_Of_

Light_Barrier_6_

Interrupted_True

Cond_VGR_1_State_Of_

Machine_Ready

contains

hasService

isLocatedIn

currentState

VGR

isCheckedBy

Cond_OV_1_

Status_Of_Light_Barrier_

5_Interrupted_False

Cond_OV_1_State_Of_

Machine_Ready

Cond_OV_1_

Status_Of_Light_Barrier_

5_Interrupted_True

Condition

hasPrecondition

hasPrecondition

hasPrecondition

hasPrecondition

FT_Factory_Shop_Floor_1

ShopFloor

http://127.0.0.1:5000/vgr/pick_up_and_transport?

machine=vgr_1&start=sink_1&end=oven

ready

Service_OV1_Status_Of_

Light_Barrier_5

isCheckedBy

hasTimestamp

locatedat

FT_Workpiece_X_

Result_1

FT_Workpiece_X Workpiece

Result

hasResult

Oven

isResultOf

2020-03-24T17:12:27

Machine

Cond_WT_1_Check_

Position_Oven_False

Figure 7: Semantic Annotations of the Pick Up and Transport Service from Vacuum Gripper Robot as a Graph.

Transport to

Oven

Review Quality

Transport to

High-Bay

Warehouse

Burn

Get Empty

Bucket

Figure 8: A BPMN Diagram of a Manufacturing Process.

case, the precondition that the workpiece is located

at the working platform on the oven to execute the

burn activity is not met and thus not executed. Af-

ter locating the workpiece at the required place, the

burning procedure is executed immediately. With this

example, we aim to demonstrate the feasibility of our

approach. In the same way, we have also evaluated

the functionality for all other services as well as for

more complex cyber-physical production workflows.

In summary, the example application demonstrates

the feasibility that our SOA is appropriate to exe-

cute SWSs with a state-of-the-art workflow manage-

ment system. Additionally, the re-modeled pre- and

postconditions from OWL-S and WSMO and the un-

derlying concept to determine their verification with

other SWSs is suitable for the presented use cases and

works as designed in near real-time. The developed

SWSs were checked for conformity and correctness

by using the OntOlogy Pitfall Scanner! (OOPS!)

5

. In

this process, no errors or inconsistencies have been

detected.

5 CONCLUSION AND FUTURE

WORK

In this work, we present a Service-Oriented Architec-

ture (SOA) with semantic web services for AI-based

research with physical factory simulation models in

Industry 4.0. First, we described use cases in which

service-oriented architectures with semantic web ser-

vices are valuable. Based on the described use cases,

requirements have been derived that should be met.

As a result, we modeled 70 semantic web services

5

http://oops.linkeddata.es/

Semantic Web Services for AI-Research with Physical Factory Simulation Models in Industry 4.0

41

based on standards such as OWL-S and WSMO. The

semantic services are enriched with inputs, outputs,

preconditions, and results with postconditions. Addi-

tionally, we have integrated our approach in a cyber-

physical business process management architectural

model. In our feasibility test, we have exemplary

demonstrated that the developed SOA is suitable to

be used in state-of-the-art workflow management sys-

tems to build valid cyber-physical production work-

flows. By using semantic web services as pre- and

postconditions of other semantic services, a near real-

time verification for executing cyber-physical work-

flows is ensured. Additionally, the developed services

provide the foundation to support low-code applica-

tions (Sanchis et al., 2020).

In future work, we investigate the described

use cases further to enhance workflow flexibility in

cyber-physical production systems. We assume that

Process-Oriented Case-Based Reasoning (POCBR),

for example, could be used for this purpose because it

has already shown great potential in various other do-

mains. Additionally, automated planning techniques

can be used to further increase workflow flexibility in

Industry 4.0. Therefore, the pre- and postconditions

of the semantic web services can be transferred into a

planning model and directly used during planning. In

this context, we plan to conduct an comprehensive ex-

perimental evaluation that assess the appropriateness

of the presented approach in more detail. With the fu-

ture application, the semantic web services are contin-

uously improved according to their environment and

requirements (see Application & Evolution phase).

ACKNOWLEDGEMENTS

This work is funded by the German Research Founda-

tion (DFG) under grant No. BE 1373/3-3. The basic

components of the semantic web services were devel-

oped in a student research project by Felix Reither and

Julian Sawatzki and revised by Marcel Mischo.

REFERENCES

Abele, E., Chryssolouris, G., Sihn, W., Metternich, J., El-

Maraghy, H., Seliger, G., Sivard, G., ElMaraghy, W.,

Hummel, V., Tisch, M., and Seifermann, S. (2017).

Learning factories for future oriented research and ed-

ucation in manufacturing. CIRP Ann., 66(2):803–826.

Bordel Sánchez, B., Alcarria, R., Sánchez de Rivera, D.,

and Robles, T. (2018). Process execution in Cyber-

Physical Systems using cloud and Cyber-Physical In-

ternet services. J. Supercomput., 74(8):4127–4169.

Boschert, S. and Rosen, R. (2016). Digital Twin—The Sim-

ulation Aspect. In Mechatron. Futur., pages 59–74.

Springer.

Broy, M., Cengarle, M. V., and Geisberger, E. (2012).

Cyber-Physical Systems: Imminent Challenges. In

Large-Scale Complex IT Syst. Dev., Operat. and

Manag. - 17th Monterey Workshop, volume 7539 of

LNCS, pages 1–28. Springer.

Burns, T., Cosgrove, J., and Doyle, F. (2019). A Review of

Interoperability Standards for Industry 4.0. Procedia

Manuf., 38:646–653.

Calà, A., Ryashentseva, D., and Lüder, A. (2016). Modeling

approach for a flexible manufacturing control system.

In 21st Int. Conf. on Emerg. Technol. and Factory Au-

tomat., pages 1–4. IEEE.

Chen, L. and Yang, X. (2005). Applying AI Planning to Se-

mantic Web Services for Workflow Generation. In Int.

Conf. on Semant., Knowl. and Grid, page 65. IEEE.

Cheng, H., Xue, L., Wang, P., Zeng, P., and Yu, H. (2017).

Ontology-based web service integration for flexible

manufacturing systems. In 15th Int. Conf. on Ind. Inf.,

pages 351–356. IEEE.

Ciortea, A., Mayer, S., and Michahelles, F. (2018). Repur-

posing Manufacturing Lines on the Fly with Multi-

agent Systems for the Web of Things. In Proc. of

the 17th Int. Conf. on Autonomous Agents and Multi-

Agent Systems, pages 813–822. Int. Found. for Au-

tonomous Agents and Multiagent Systems / ACM.

Hepp, M., Leymann, F., Domingue, J., Wahler, A., and

Fensel, D. (2005). Semantic business process man-

agement: a vision towards using semantic Web ser-

vices for business process management. In Int. Conf.

on e-Business Eng., pages 535–540. IEEE.

Humm, B., Bense, H., Bock, J., Classen, M., Halvani, O.,

Herta, C., Hoppe, T., Juwig, O., and Siegel, M. (2020).

Applying machine intelligence in practice. Informatik

Spektrum.

Jammes, F. and Smit, H. (2005). Service-Oriented

Paradigms in Industrial Automation. IEEE Trans. Ind.

Inf., 1(1):62–70.

Janiesch, C., Koschmider, A., Mecella, M., Weber, B., Bu-

rattin, A., Ciccio, C. D., Fortino, G., Gal, A., Kan-

nengiesser, U., Leotta, F., Mannhardt, F., Marrella, A.,

Mendling, J., Oberweis, A., Reichert, M., Rinderle-

Ma, S., Serral, E., Song, W., Su, J., Torres, V., Wei-

dlich, M., Weske, M., and Zhang, L. (2020). The

Internet-of-Things Meets Business Process Manage-

ment. A Manifesto. IEEE Syst. Man Cybern. Mag.

Janowicz, K., Haller, A., Cox, S. J., Le Phuoc, D., and

Lefrançois, M. (2019). SOSA: A lightweight ontol-

ogy for sensors, observations, samples, and actuators.

J. Web Semant., 56:1–10.

Järvenpää, E., Siltala, N., Hylli, O., and Lanz, M. (2019).

The development of an ontology for describing the

capabilities of manufacturing resources. J. Intell.

Manuf., 30(2):959–978.

Klein, P. and Bergmann, R. (2019). Generation of Complex

Data for AI-Based Predictive Maintenance Research

With a Physical Factory Model. In 16th Int. Conf. on

Inform. in Control Automat. and Rob., pages 40–50.

SciTePress.

IN4PL 2020 - International Conference on Innovative Intelligent Industrial Production and Logistics

42

Klein, P., Malburg, L., and Bergmann, R. (2019). FTOnto:

A Domain Ontology for a Fischertechnik Simulation

Production Factory by Reusing Existing Ontologies.

In Proc. of the Conf. LWDA, volume 2454, pages 253–

264. CEUR-WS.org.

Lamy, J.-B. (2017). Owlready: Ontology-oriented pro-

gramming in Python with automatic classification and

high level constructs for biomedical ontologies. Artif.

Intell. Med., 80:11–28.

Lasi, H., Fettke, P., Kemper, H.-G., Feld, T., and Hoffmann,

M. (2014). Industry 4.0. BISE, 6(4):239–242.

Lastra, J. L. M. and Delamer, I. M. (2006). Semantic

Web Services in Factory Automation: Fundamental

Insights and Research Roadmap. IEEE Trans. Ind.

Inf., 2(1):1–11.

Lee, J., Kao, H.-A., and Yang, S. (2014). Service Inno-

vation and Smart Analytics for Industry 4.0 and Big

Data Environment. Procedia CIRP, 16:3–8.

Lemaignan, S., Siadat, A., Dantan, J.-Y., and Semenenko,

A. (2006). MASON: A Proposal For An Ontology

Of Manufacturing Domain. In Workshop on Distrib.

Intell. Syst.: Collect. Intell. and Its Appl., pages 195–

200. IEEE.

Lobov, A., Lopez, F. U., Herrera, V. V., Puttonen, J., and

Lastra, J. L. M. (2008). Semantic Web Services frame-

work for manufacturing industries. In Int. Conf. on

Rob. and Biomim., pages 2104–2108. IEEE.

Lu, Y. and Ju, F. (2017). Smart Manufacturing Sys-

tems based on Cyber-physical Manufacturing Ser-

vices (CPMS). IFAC-PapersOnLine, 50(1):15883–

15889.

Marrella, A. (2018). Automated Planning for Business Pro-

cess Management. J. Data Semant.

Marrella, A. and Mecella, M. (2018). Cognitive Business

Process Management for Adaptive Cyber-Physical

Processes. In Bus. Process Manag. Workshops,

LNBIP, pages 429–439. Springer.

Martin, D. L., Burstein, M. H., McDermott, D. V., McIl-

raith, S. A., Paolucci, M., Sycara, K. P., McGuinness,

D. L., Sirin, E., and Srinivasan, N. (2007). Bringing

Semantics to Web Services with OWL-S. World Wide

Web, 10(3):243–277.

McDermott, D. V., Ghallab, M., Howe, A., Knoblock, C.,

Ram, A., Veloso, M., Weld, D., and Wilkins, D.

(1998). PDDL - The Planning Domain Definition

Language: Technical Report CVC TR-98-003/DCS

TR-1165.

Minor, M., Montani, S., and Recio-García, J. A. (2014).

Process-oriented Case-based Reasoning. Inf. Syst.,

40:103–105.

Müller, G. (2018). Workflow Modeling Assistance by Case-

based Reasoning. Springer Fachmedien, Wiesbaden.

Monostori, L. (2014). Cyber-physical Production Systems:

Roots, Expectations and R&D Challenges. Procedia

CIRP, 17:9–13.

Ocker, F., Kovalenko, I., Barton, K., Tilbury, D., and Vogel-

Heuser, B. (2019). A Framework for Automatic Ini-

tialization of Multi-Agent Production Systems Using

Semantic Web Technologies. IEEE Rob. Autom. Lett.,

4(4):4330–4337.

Puttonen, J., Lobov, A., and Lastra, J. L. M. (2013).

Semantics-Based Composition of Factory Automation

Processes Encapsulated by Web Services. IEEE TII,

9(4):2349–2359.

Puttonen, J., Lobov, A., Soto, M. A. C., and Lastra, J. L. M.

(2010). A Semantic Web Services-based approach for

production systems control. Adv. Eng. Inf., 24(3):285–

299.

Puttonen, J., Lobov, A., Soto, M. A. C., and Lastra, J.

L. M. (2019). Cloud computing as a facilitator for

web service composition in factory automation. J. In-

tell. Manuf., 30(2):687–700.

Roman, D., Keller, U., Lausen, H., de Bruijn, J., Lara, R.,

Stollberg, M., Polleres, A., Feier, C., Bussler, C., and

Fensel, D. (2005). Web Service Modeling Ontology.

Appl. Ontol., 1(1):77–106.

Sanchis, R., García-Perales, Ó., Fraile, F., and Poler, R.

(2020). Low-Code as Enabler of Digital Transforma-

tion in Manufacturing Industry. Appl. Sci., 10(1):12.

Schnicke, F., Kuhn, T., and Antonino, P. O. (2020).

Enabling Industry 4.0 Service-Oriented Architecture

Through Digital Twins. In Softw. Archit., volume

1269 of Commun. Comput. Inf. Sci., pages 490–503.

Springer.

Seiger, R., Huber, S., and Schlegel, T. (2018). Toward an

execution system for self-healing workflows in cyber-

physical systems. Softw. Syst. Model., 17(2):551–572.

Sure, Y., Staab, S., and Studer, R. (2009). Ontology Engi-

neering Methodology. In Handb. on Ontologies, Int.

Handb. on Inf. Syst., pages 135–152. Springer.

Zeyen, C., Malburg, L., and Bergmann, R. (2019). Adap-

tation of Scientific Workflows by Means of Process-

Oriented Case-Based Reasoning. In Case-Based Rea-

son. Res. and Dev. - 27th Int. Conf., volume 11680 of

LNCS, pages 388–403. Springer.

Semantic Web Services for AI-Research with Physical Factory Simulation Models in Industry 4.0

43