Automatic Food Packaging System using Programmable Logic

Controller

Ahmad Sahru Romadhon, Vivi Tri Widyaningrum

Mechatronic Departement, Faculty of Engineering University of Truojoyo Madura, Raya Telang Street PO BOX 2 Kamal,

Bangkalan, East Java, Indonesia

Keywords: Food packaging, PLC and automatic packaging.

Abstract: Food packaging using conventional machine has undelighted results, so it automatic packaging would be the

solve that problem.it can more productive and quick. Basically, the working system of this automatic

packaging begins with installing plastic on the rollers and installing plastic on the edge of the feeding tube so,

the plastic will have a shape also like the tube. The next step is to put food into the container in the machine

and the engine is turned on. Next, for the packaging grooves, the plastic will be pulled by the motor, then the

bottom of the plastic is glued by the pressing process which later the plastic will form a container in

accordance with a tubular mold. Food that has filled the container in the machine is passed through a tube that

was previously covered by plastic, then the top plastic is glued by the pressing process. The results of PLC

application testing on mechanics by providing a 12 volt power supply to a DC motor in a mechanical system

show that the program loaded into the system provides the expected results.

1 INTRODUCTION

The development of technology in the modern

industrial era is increasingly rapidly. Especially in

control systems, the technology is developing rapidly

as well where the current process is in the control

system not only in the form of a circuit that using

electrically assembled equipment, but also has used a

computer program to control it. This situation

certainly requires a simple, practical and high-tech

supporting equipment (Nanda, 2014). For example, it

can be seen at the creation of equipment that can work

automatically, thereby reducing the role of humans to

do food packaging.

Packaging is a way to protect food products,

beverages or the consumable things from damage

caused by air. According to several studies showing

that packaging is one of the most important

considerations that can influence consumer for

purchasing products. The packaging of a product can

be attractive to consumers if the packaging is well

made and neat, so it requires a packaging machine

that is simple and easy to use (Simran, ,2019). Based

on this description, the idea to create a PLC

(programable logic controller) automatic food

packaging Machine that could be make easier to the

home industry community to packaging their

products.

PLC can be used as a fairly reliable control

equipment so it is widely used in industrial

equipment, for example in the process of selecting

materials, packaging, handling materials, automatic

assembly and others. Basically, almost all systems

that require control over electricity or electronics

require a PLC (Pralhad, 2018, Sasidhar, 2017). So in

this research, PLC can be more innovating to create

Automatic Food Monitoring System Using PLC

(Programmable Logic Controller).

Basically, the packaging system in this study

functions to laminate plastic parts that have been

filled with food, so that the food is in the form of a

vacuum bag. This automatic food packaging system

begins with mounting plastics on rollers and installing

plastics on the edge of the feeding tube so the plastic

will have a shape like the tube. The plastic will be

pulled by two motors, then the bottom of the plastic

is glued by the pressing process which later the plastic

will form a container in accordance with a tubular

mold. After the pressing process is finished, the next

process is filling in the plastic and the plastic will be

pressed once more at the top.

Romadhon, A. and Widyaningrum, V.

Automatic Food Packaging System using Programmable Logic Controller.

DOI: 10.5220/0010331202710277

In Proceedings of the International Conference on Health Informatics, Medical, Biological Engineering, and Pharmaceutical (HIMBEP 2020), pages 271-277

ISBN: 978-989-758-500-5

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

271

2 RESEARCH METHOD

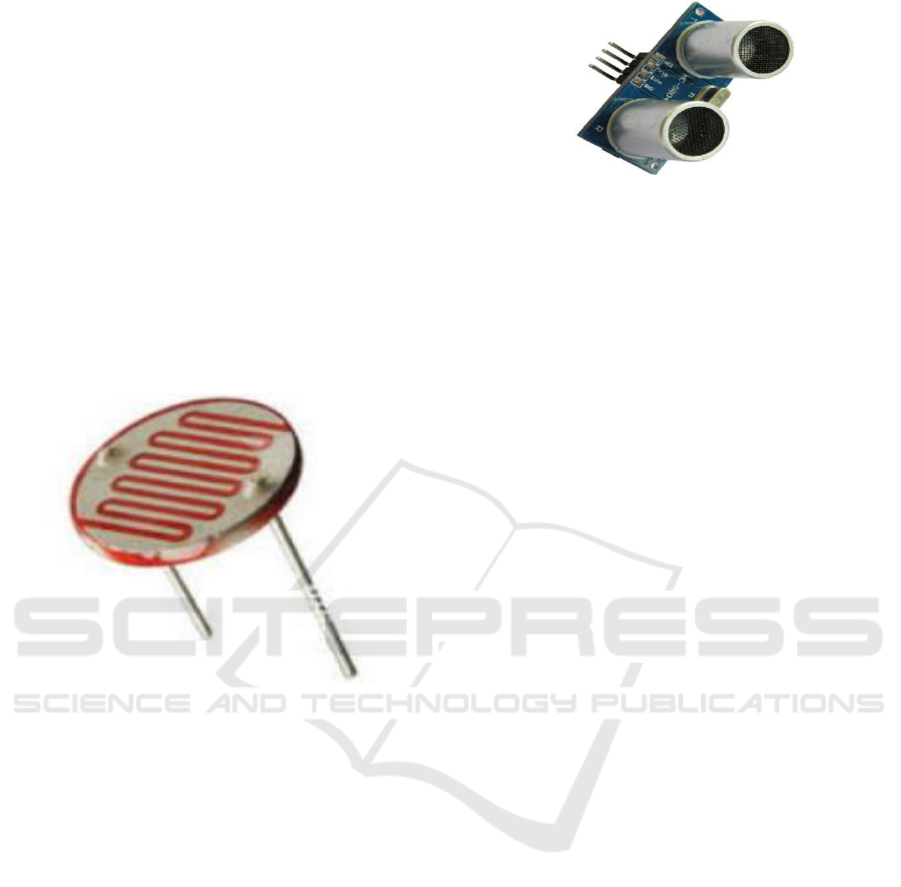

2.1 LDR (Light Dependent Resistor)

Sensor

LDR is one type of resistor whose resistance value is

affected by the light received. LDR was made from

cadmium sulfide which is sensitive to light. LDR is

made from cadmium sulfide which is sensitive to

light. Light has two different characteristic:

electromagnetic waves and energy particles (dualism

of light). The greater the intensity of the incoming

light, the more electrons are separated from the

bonds. So, LDR resistance will go down when the

light illuminates it (Romadhon, 2018). The symbol

and physical of the LDR can be seen in Figure 1.

Figure 1: LDR (Light Dependent Resistor) Sensor.

2.2 Ultrasonic Sensor First Section

The ultrasonic sensor is a tool for converting sound

quantities into electrical quantities and vice versa.

This sensor works using the principle of sound wave

reflection so that it can be used to predict the distance

of an object with a certain frequency. This sensor is

called an ultrasonic sensor because it uses ultrasonic

waves.

Ultrasonic sensors work by sending sound waves

at frequencies above human hearing. Transducer

sensor functions as a microphone for receiving and

sending ultrasonic sound. The way the ultrasonic

sensor works is by determining the reflected wave

from the target to be captured by the sensor, then the

sensor calculates the time difference between sending

the waves and the time the reflected waves are

received (Romadhon, 2018).

Figure 2: Ultrasonic Sensor.

2.3 PLC (Programmable Logic

Controller)

PLC is a programmable logic control which is an

electronic command that is designed to be able to

operate digitally by using memory as a storage

medium for internal instructions to perform logic

functions, such as counter / counter functions, process

sequence functions, timer functions , arithmetic

functions, and other functions by programming them.

PLC is the same as a microcontroller but here PLC

has got standardization as an industrial control

device.

Based on its name the PLC concept is as follows:

1. Programmable

It is the PLC's ability to store programs that

have been created so that they can be easily

changed or reprogrammed

2. Logic

It is the ability of PLC to process arithmetic and

logic data input (ALU), which is to perform

operations comparing, adding, multiplying,

dividing, dividing, subtracting, negation, AND,

OR, and so on.

3. Controller

Is the ability to control and regulate the process

so that it can produce the desired output.

2.4 The Working Principle of PLC

In principle, a PLC through the input module works

to receive data in the form of signals from external

input devices. The external input equipment includes

switches, sensor buttons. Input data which is still in

the form of analogue signal will be converted by an A

/ D (analogue to digital module) input module into a

digital signal. Furthermore, by the central processor

(CPU) that is inside the PC the digital signal is

processed according to the program that has been

created and stored in memory. The CPU will then

make decisions and give commands via the D / A

output module (digital to analogue module) of the

controlled system such as in the form of a relay and

HIMBEP 2020 - International Conference on Health Informatics, Medical, Biological Engineering, and Pharmaceutical

272

motor which will be able to automatically operate the

controlled work system (Sasidhar, 2017). The

working principle of PLC can be seen in Figure 3.

Figure 3: PLC Working Principle.

2.5 Mechanical Design

The following is the design of an automatic

packaging machine as shown in Figure 4.

Figure 4: Design of an automatic packaging machine.

Index:

1. Food container

2. Pres plastic backside

3. Pres plastic top and bottom

4. Plastic roller holder

Figure 2.4 describes the working system of an

automatic packaging machine:

1. Before the machine is turned on, put the plastic

on the edge of the feeding tube, which is on the

plastic roller holder.

2. put food in the container, then the machine is

turned on.

Press the plastic on the back and the press plastic

on the bottom, then the plastic will be filled with

food after that, the top press.

2.6 Electronic System Design

In this section explains the overall function of the

automatic food packaging system using a PLC which

is divided into several grooves which are describes in

the following block (Sharma, 2017) diagram as

shown in Figure 5.

Figure 5: Function block of automatic food packaging

system.

The functions of each of the previous blocks are

as follows:

1. ON / OFF, to turn on or turn off the system

2. Ultrasonic, as a sensor to determine the existence

of plastic

3. LDR, as a sensor to find out whether or not the

food will be packaged

4. PLC, to control the system

5. Relay 4 Chanel, to provide voltage for output

6. Servo, as open and close food containers to

enters the plastic

7. Buzzer, to provide information if food and plastic

are used up

8. Motor, to pull plastic and move the press

3 RESULTS AND ANALYSIS

3.1 The Working System of Packing

Device

In Figure 6 described the working system on an

automatic packaging machine:

1. The first step is put food in the container, then

machine starts.

2. The second step is initialize the LDR sensor

which is used to detect food in the container. If

the LDR sensor gets light because food not

blocked the container, the buzzer will be active

which is to notify the operator that the food in the

container is finished.

3. The third step is the initialization of the

ultrasonic sensor, functions to measure the height

of the food (in this case is sugar) in the container.

If the sugar is less than 5 cm, the buzzer will be

active which is to notify the operator that the

container is empty.

Automatic Food Packaging System using Programmable Logic Controller

273

4. The fourth step is the plastic press that is on the

back of the feeding tube.

5. The fifth step, motor 1 will move which

functions to pull the plastic down.

6. The sixth step is the plastic press at the bottom

that serves as a plastic container for food.

7. The seventh step is the servo will be active with

a delay of 3 seconds to open and close the door

under the food container to regulate the contents

of the food in a plastic container.

8. The eighth step is the plastic press at the top is to

close the plastic container, and the plastic is cut

by the knife at the end of the pressing machine.

So food can be packed neatly and tightly.

Figure 6: Flowchart System.

3.2 The Physical of an Automatic

Packaging Device

After building all the hardware and software

components, then in this study testing and analysing

the machine that have been made, whether the

machine can work in accordance with the functions

and planning of tests that were assembly and then

combined in a control system that has been designed.

Tests was done separately by ultrasonic testing,

LDR, servo motors and DC motors all worked well

with what was expected. After implementing and

testing software on Ultrasonic, servo motors, and dc

motors, an automatic packaging device can be run can

carry out plastic packaging automatically. Figure 7.

Shows the physical appearance of an automatic

packaging device.

Figure 7: The physical of an automatic packaging device.

3.3 Testing on Food Containers

The LDR sensor is placed in the container, so the

LDR sensor will not get light when the food is filled

in the container. LDR sensors is good condition if the

LDR can detection food in the container.

When the LDR sensor does not get light because

it is blocked by food, the system will run. Conversely,

when the LDR sensor is exposed to light, the system

will stop and the buzzer will activate to notify the

operator that the container is empty. Figure 8. Shows

that the position of the LDR sensor was located in a

food container.

Figure 8: LDR Sensor Position in food container.

HIMBEP 2020 - International Conference on Health Informatics, Medical, Biological Engineering, and Pharmaceutical

274

3.3 Testing on Ultrasonic Sensors

The ultrasonic sensor is placed in front of the plastic

so that it can measure distance between plastic and

sensor. This ultrasonic circuit is good condition if

ultrasonic sensor can detection a plastic is being used.

The testing will be success if ultrasonic sensor

can detect plastic with a distance of 36 cm to 5 6cm,

if ultrasonic sensor can detect more than 56 cm, the

buzzer will be active and notify the operator that the

plastic is used up. Figure 9. Shows that the position

of the Ultrasonic sensor was located in automatic

packaging device

Figure 9: Position of the Ultrasonic sensor.

3.4 Testing on Servo Motors

The initial position of the servo motor is at 0º, this

was done so that the servo motor can rotate to close

passage of food in the plastic container. Figure 10.

shows that the servo motor at condition 0º.

Figure 10: Servo Motor at condition 0º.

The next test is the position of the servo motor 90.

This was done so that the servo motor can rotate

automatically to the 90° position and open the

passage of food so that it can fill plastic containers.

The implementation results are as in Figure 11.

Figure 11: Servo Motor at condition 90º.

3.5 Testing on Pres Plastic Backside

The DC motor moves using a relay module with a

voltage of 24 V. There are two switches that function

as buttons on the back of the plastic press and the

indicator light functions as a marker if the press is

tightly closed, the indicator light will light up. The

implementation results are as in Figure 12.

Figure 12: Plastic press is open.

Press will close when touching switch 1 and the

indicator light is on which indicates that the heating

wire is active with 1.5 seconds. Then the press will

return in an open state and touch switch 2. The

implementation results are as in Figure 13.

Figure 13: Plastic press is closed.

Automatic Food Packaging System using Programmable Logic Controller

275

3.6 Testing on Pres plastic top and

bottom

The moving dc motor uses 2 relay modules. There are

two switches that function as buttons on the top

plastic press and indicator lights.

The test will be carried out if the top press touches

switch 3 then the press is open. As shown in Figure

14.

Figure 14: The bottom plastic press is open.

Press will close when touching switch 4 and the

indicator light is on which indicates that the heating

wire is active with 1.5 seconds. Then the press will

return in an open state and touch switch 2. The

implementation results are as in Figure 15.

Figure 15: The bottom plastic press is closed.

Table 1: Sensor experiment results.

No

Sensor

Distance to

object

Buzze

r ON

Buzze

r OFF

1

LDR

Sensor

LDR>150

-

2

Ultrasonic

Sensor

US>=36 cm

and US<=56

cm

-

3

LDR

Sensor

LDR<150

-

4

Ultrasonic

Sensor

US<=35 cm

andUS>=7 cm

-

In Table 1, it is explained that the sensors used

in this tool are the LDR Sensor and Ultrasonic Sensor.

When the LDR sensor is not blocked by food or

receives more than 150 light, the buzzer will activate

and when the LDR sensor is blocked by food or does

not receive light less than 150, the buzzer will turn

off. If the distance between the Ultrasonic Sensor and

the object is more than 36 cm and less than 56 cm, the

buzzer will be active, while the distance between the

Ultrasonic Sensor and food is less than 35 cm and

more than 7 cm, the buzzer will turn off.

3.7 The Experiment an Automatic

Packaging Device

From the experiments that had been tried on the

automatic packaging system, it produces food

wrapped in plastic neatly, and the contents doesn’t

take into account the weight of the product in each

package and only depend on of servo motors that use

delay (time) which is functions as a regulator of

content on each package. as seen in Figure 16.

Figure 16: The experiment an automatic packaging device.

4 CONCLUSIONS

After some explanation, trial, and analyze we can

conclude that:

1. The ultrasonic sensor can detect the presence of

plastic when the distance between the plastic

and the ultrasonic sensor reaches less than 36

cm and more than 56 cm, the buzzer will turn

on, the ultrasonic sensor will read and send a

HIMBEP 2020 - International Conference on Health Informatics, Medical, Biological Engineering, and Pharmaceutical

276

signal to the buzzer, so the buzzer is active to

inform the operator that the plastic empty.

2. The LDR sensor can detect the presence of

food in the container, when the LDR sensor

receives more than 150 light, the buzzer will be

active, and if the LDR sensor receives less than

150 light, the buzzer will turn off.

ACKNOWLEDGEMENTS

We are thankful to GOD, our parents, teacher, and all

friends who helped and supported us at every

moment.

REFERENCES

Simran, Kamboj DS, Diwan A. 2019, Development Of

Automatic Sorting Conveyor Belt Using PLC.

International Journal of Mechanical Engineering and

Technology (IJMET). Volume 10, Issue 08, pp. 109-

118.

Nanda B. 2014, Automatic Sorting Machine Using Delta

PLC. International Journal of Innovative Research in

Advanced Engineering (IJIRAE). . Volume 1 Issue 7.

Rautu SV, Shinde AP, Darda NR. 2017, Sorting of Objects

Based on Colour, Weight and Type on A Conveyor

Line Using PLC. IOSR Journal of Mechanical and Civil

Engineering (IOSR-JMCE).

Sasidhar K, Hussain SF, Syed Ali Safdar SA, Uddin MA.

2017. Design and Development of a PLC Based

Automatic Object Sorting. International Journal of

Research and Scientific Innovation (IJRSI). Volume

IV, Issue XII.

Pralhad GD, Rajaram NP, Machindra PS. 2018. Lift

Automation and Material Sorting Using PLC.

International Journal of Engineering and Techniques.

Volume 4 Issue 3.

Zulfiqar R, Mehdi B, Iftikhar R. 2019. PLC Based

Automated Object Sorting System. 4th International

Electrical Engineering Conference (IEEC). IEP Centre,

Karachi, Pakistan.

Romadhon AS. 2018. System Security and Monitoring On

Smart Home Using Android. IOP Conf. Series: Journal

of Physics: Conf. Series 953.

Charles UN, Samuel NJ, Oladimeji O. 2017. Improving

Data Transmission Efficiency over Power Line

Communication (PLC) System Using OFDM.

International Journal of Applied Engineering Research.

Volume 12, Number 5. India.

Kim H, Lee J. 2016. PLC Control System For Vacuum and

20 KW RF Amplifier. Proceedings of Cyclotrons..

Zurich, Switzerland.

Sharma R, Navtake S, and Chaudhari HP. 2017.. Automatic

Material Storage and Retrieval System using PLC and

SCADA. International Journal of Computational

Intelligence Research. Volume 13. India.

Khakhi MF, Salman M, Shabir MF. 2017. Drugstore

Control System Design and Realization Based on

Programmable Logic Controller (PLC). Journal of

Electrotechnology, Electrical Engineering and

Management. Vol. 1, Number 1. Canada.

Hiray A, Chinchkar O, Butte P, Pyla V. 2017. PLC and

SCADA Based Sewage Water Treatment Plant.

International Journal of Innovative Research in

Electrical, Electronics, Instrumentation and Control

Engineering. Vol. 5, Issue 5.

Automatic Food Packaging System using Programmable Logic Controller

277