Semi Quantitative Risk Analysis of Onshore Receiving Facility

Patria Wiratama, Yuliusman

Department of Chemical Engineering, Engineering Faculty, University of Indonesia, Depok, Indonesia

Keywords: Onshore receiving facility, risk analysis, monte carlo simulation.

Abstract: During the onshore receiving facility (ORF), a potential hazard that could cause an installation failure is found.

Onshore receiving facility installation operator needs to do a risk analysis to identify hazards, determine the

probability of Failure and consequence of Failure and conduct Semi-quantitative risk analysis due to knowing

the risk profile at the onshore receiving facility and the consequence for the environment, people,

assets/business, and company reputation. Based on the risk level, the ORF operator can determine a mitigation

plan and recommend reducing risks such as inspection frequency, maintenance, and repairs related to internal

corrosion and external corrosion. The result of risk analysis states that the overall risk of the ORF installation

is at low risk.

1 INTRODUCTION

1.1 Background

The oil and gas business involves several stages, such

as exploration, exploitation, and production. In

general, the oil and gas business is an industry with

high risks both from a business perspective and a

safety/accident perspective, especially risks caused

by fires and explosions.

Significant hazards in the oil and gas and chemical

industries are related to fires, explosions, and toxic

releases. Of the three hazards, the most common is

fire, but the explosion has the most significant effect

on mortality and loss of production. (Lees, 1994).

The Flixborough incident was the enormous

explosion that occurred in Great Britain, which

caused 28 fatalities and total damage to the vicinity of

the NYPRO plant. The explosion on the Bombay

High North Platform on 27 July 2005 was caused by

a support vessel hitting the gas export riser platform,

causing 22 fatalities and environmental damage, and

loss of production of 120,000 barrels of oil and 4.4

million cubic meters of gas per day. One of the most

significant accidents and the largest accident in the oil

and gas industry occurred on July 6, 1988, at the Piper

Alpha platform in the North Sea, which killed 167

people and totalled the US $ 3.4 billion business

losses. This type of risk is a category of catastrophic

events. Although these occurrences are rare, the

repercussions can be enormous. Not only events that

result in an unacceptable loss of life, large-scale

environmental problems, the economy, poor

community relations, civil litigation, and even

criminal prosecution. These events also often have a

major impact on the development of management

systems and regulations. (Sutton, 2015).

In the oil and gas industry, risks cannot be

avoided. However, these risks can be managed by

referring to the concept of risk management. Risk

management aims to increase opportunities and

minimize losses. The risk management process based

on ISO 31000: 2018 includes: Risk Identification,

Risk Analysis, Risk Evaluation, and Risk Treatment /

Control.

In the gas processing facility, there is a risk of fire

and explosion due to the content of natural gas, most

of which is mainly methane (around 70-90%) and is

highly flammable. These risks can potentially cause

harm to humans (serious injuries, minor injuries, and

death), environmental damage, equipment damage,

and company reputation. These losses can be

controlled by carrying out a risk analysis.

1.2 Facility Description

Onshore Receiving Facility receiving gas and crude

oil from Floating Production Unit (FPU). Gas and

condensate from FPU are separated in the separator.

The volume of the gas from the separator is measured

and sent to the customer. Part of the gas is used to

supply ORF fuel gas used to purge gas and pilot flare

Wiratama, P. and Yuliusman, .

Semi Quantitative Risk Analysis of Onshore Receiving Facility.

DOI: 10.5220/0010785600003317

In Proceedings of the 2nd International Conference on Science, Technology, and Environment (ICoSTE 2020) - Green Technology and Science to Face a New Century, pages 5-11

ISBN: 978-989-758-545-6

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

5

gas in the flare system. Meanwhile, condensate from

the separator is combined with the crude oil from the

FPU to be sent and stored in a storage tank.

2 METHODOLOGY

2.1 Hazard Identification

Hazard identification is carried out by understanding

the equipment damage mechanism in the Onshore

Receiving Facilities installation. It is crucial to make

a proper plan to reduce the failure rate of the

equipment and increase the safety of the plant

operation. Table 1 shows the identification of hazards

and damage that may occur during the operation of

the installation.

Table 1. Damage and Hazard Mechanism of Installation

E

quipment

Damage

Mechanism

Cause Hazard

Pressure

Vessel

Erosion

Corrosion

Failure is

characterized

by metal loss

or thinning of

the pressure

vessel caused

by the

abrasive

material. The

severity is

determined by

gas flow rate,

pressure, type,

and quantity.

Leak

Rupture

Atmospheric

Corrosion

Atmospheric

corrosion is

caused by

moisture in the

air which can

form a thin

layer of liquid

on the surface

of the pressure

vessel. This

depends on the

different

atmospheric

conditions of

the particles

and gases.

Leak

Rupture

E

quipment

Damage

Mechanism

Cause Hazard

Piping Mechanical

Fatigue

Cyclic load

processes and

stress loss.

Mechanical

fatigue can

cause failures

that occur at

relatively low

stress levels.

Leak

Rupture

External

Corrosion

Corrosion

occurs due to

contact

between pipes

and water/soil.

There is a

microscopic

reaction

between

anodic and

cathodic,

triggered by

coating

records,

differences in

aeration,

resistivity, soil

acidity, and

heterogeneity

of soil acidity.

Leak

Rupture

Internal

Corrosion

Corrosion is

caused by gas

content

containing

water, CO2,

H2S, or a

percentage of

SRB.

Leak

Rupture

Erosion

Corrosion

Failure is

characterized

by metal loss

or thinning of

the pressure

vessel caused

by the

abrasive

material. The

severity is

determined by

gas flow rate,

pressure, type,

and quantity.

Leak

Rupture

ICoSTE 2020 - the International Conference on Science, Technology, and Environment (ICoSTE)

6

2.2 Determine of Probability of Failure

(PoF)

Determination of the probability of Failure

(Probability of Failure), is done by evaluating the

parameters of the damage by considering the

percentage of each possible hazard that occurs. The

scoring system is carried out following the

requirements of the installation system. Parameters

and percentages used in the determination of PoF

such as

2.2.1 Corrosion Factor (30%)

Corrosion factors can cause a reduction in thickness

or a possible hazard to the walls of the installation

equipment (pipes and pressure vessels). A reduction

in thickness can be caused by the interaction of pipe

walls and pressure vessels with the products/fluids

contained in pipes and pressure vessels. To determine

the value of the corrosion factor, there are several

variables as follows: Inspection frequency (20%),

equipment service life (20%), external protection

(15%), equipment material (15%), fluid impact

(15%), water impact (15%).

2.2.2 Operating Condition Factor (25%)

In operating conditions, some factors may allow the

installation facility to fail. Factors that can cause

Failure are leaks in the installation equipment. To

determine the operating factor value, there are several

variables as follows: Excess flow (25%), excess

pressure (30%), pressure shift (15%), level shift

(15%), and temperature shift (15%).

2.2.3 Electrical Failure (5%)

In addition to leading equipment such as pipes and

pressure vessels, the ORF installation also includes

electrical instruments. As for the possibility of

damage that can occur to the electrical system caused

by internal factors (electrical equipment inspection

frequency) (55%) and external factors (history of

being struck by lightning ) (45%).

2.2.4 Leakage Factor (10%)

ORF installations have the highest design pressure of

2300 PSIG and an operating pressure of up to 1200

PSIG. Under these operating conditions, it can cause

erosion-corrosion and lead to leakage failure. To

determine the leakage factor value, there are several

variables as follows: Leakage history (40%), flange

management (30%), and valve inspection interval

(30%).

2.2.5 Third-Party damage (10%)

On the third party, factors indicate the extent of

activity or distraction from the third party to the ORF

installation. Third-party interference, in this case, is

the history and possibility of sabotage of the ORF

installation operation

2.2.6 Equipment Design (10%)

In the equipment system design factor, an assessment

is carried out on the suitability of the equipment

design with applicable codes and standards both

nationally and internationally.

2.2.7 Construction Factor (10%)

In the construction factor of the equipment, an

assessment of the suitability of the equipment with

the as-built drawing is also carried out and its

supervision.

2.3 Determine of Consequence of

Failure (CoF)

The consequences of Failure are determined based on

the risk parameters applied by the company by

considering the weight of each consequence factor on

the possible events that occur during operational

activities. The calculated consequence parameters

described as below.

2.3.1 Safety Factor (30%)

The variable of the safety factor is the level of fatality

that can occur in the Onshore Receiving Facility

Installation in the event of an operation failure. The

safety level is rated the size of the leak diameter. The

safety variable weights 30% of the total consequences

of installation failure.

2.3.2 Environmental Factor (25%)

The environmental impact variable is reviewed by the

level of pollution or damage caused by the installation

equipment if it experiences Failure or leakage. On the

consequences of environmental damage, an

assessment of the type of fluid service (40%),

flammability (30%), and population density (30%)

are carried out. The environmental damage variable

weighs 25% of the total consequences of installation

failure.

Semi Quantitative Risk Analysis of Onshore Receiving Facility

7

2.3.3 Assets Loss (35%)

The variable consequence of company asset loss is the

variable that states the company's infrastructure

damage caused by equipment damage to the ORF

installation. The asset damage variable weighs 35%.

2.3.4 Company Reputation (10%)

The company reputation variable shows the degree of

damage to the company's reputation that can be

caused by failure or damage to the ORF installation.

A company's reputation is determined by media

exposure of failure or damage; this variable weights

is 10%.

2.4 Risk Calculation

After all the parameters of the probability of Failure

(PoF) and Failure (CoF) have been determined, then

the risk calculation is carried out as follows

Total PoF = ∑ PoF

(i)

= 0,3 PoF

(1)

+ 0,25 PoF

(2)

+

0,05 PoF

(3)

+ 0,1 PoF

(4)

+ 0,1 PoF

(5)

+ 0,1 PoF

(6)

+ 0,1

PoF

(7)

………………………(1)

Total CoF = ∑ CoF

(i)

= 0,3 PoF

(1)

+ 0,25 PoF

(2)

+

0,35 PoF

(3)

+0,1PoF

(4)

……………...(2)

Risk = Total PoF x Total CoF…..(3)

From the total probability and consequence,

multiplication is then performed to obtain the ORF

installation risk value. The results of the risk value

calculation are then inputted into the risk matrix used.

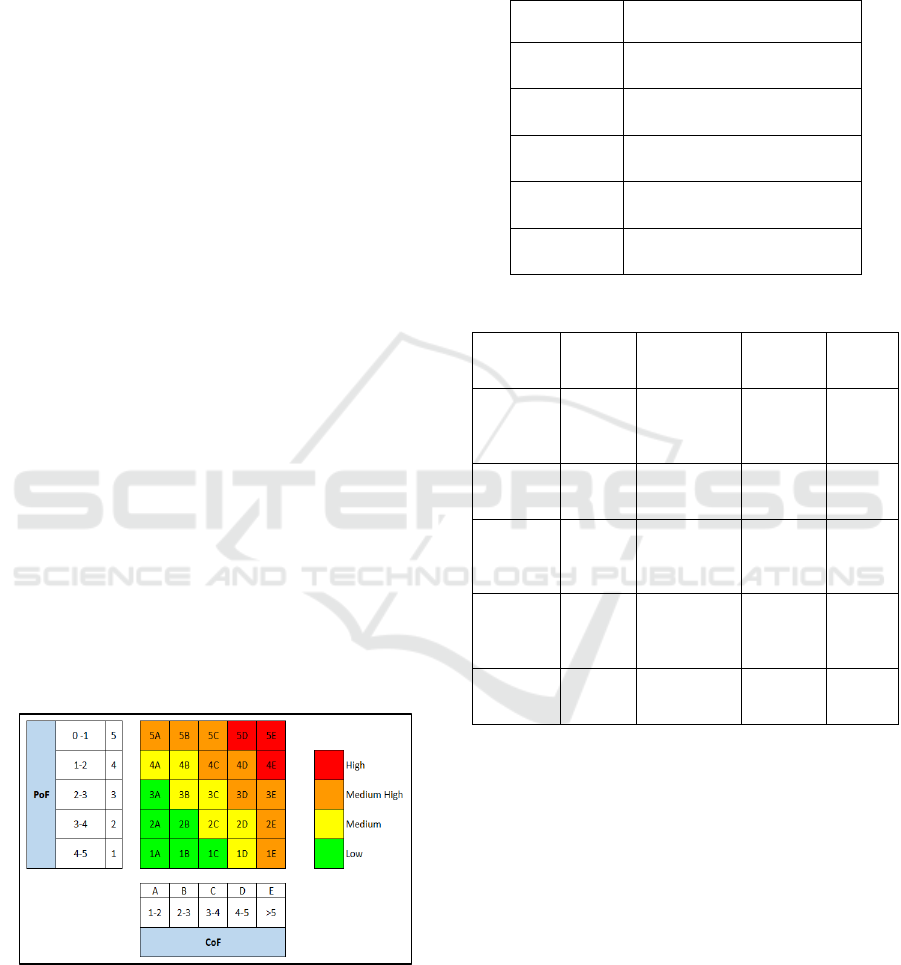

The risk matrix used is shown in Figure 1

Figure 1 Risk Matrix

In this study, the Monte Carlo equation is used.

Calculations are used with the simulation program to

generate risk values according to the risk matrix. The

certainty level that used on this simulation is 80-85%.

The risk matrix is divided into four main areas,

namely the low-risk level, medium risk level, medium

high-risk level, and high-risk level.

Table 2 Probability Category

Probability

Level

Description

5

It happens several times per

year in the company

4

It happens several times per

year in the industry

3 Has occurred in the company

2 Has occurred in the industry

1 Never heard the industry

Table 3. Consequence Category

Conse

quence

Level

People Environment Property

Repu

tation

E Multiple

fatalities

Massive

effect

Extensive

damage

Internatio

nal

impact

D Fatality

Major effect

Major

damage

National

impact

C Major

injury

potential

Localized

effect

Localized

damage

C

onsidera

ble

impact

B Minor

injury

potential

Minor effect

Minor

damage

Limited

impact

A No health

effect

No effect

No

damage

No

impact

3 RESULTS AND DISCUSSION

3.1 Probability of Failure Calculation

3.1.1 Corrosion Factor

Based on the assessment, the corrosion factor score is

3.60. The result is obtained from the following

scoring results: Inspection frequency score 4.00,

equipment service life 2.00, external protection score

5.00, equipment material score 3.00, fluid impact

score 4.00, and water impact score 4.00. The

following figure is the simulation result of Crystal

Ball for the corrosion factor.

ICoSTE 2020 - the International Conference on Science, Technology, and Environment (ICoSTE)

8

Figure 2 Corrosion Factor Simulation

Based on Figure 2, the total PoF value of the corrosion

factor is 3.56, with a certainty level of 85%.

3.1.2 Operating Condition Factor

Based on the assessment, the operating condition

factor score is 4.10. The result is obtained from the

following scoring results: Excess flow score 5.00,

excess pressure score 3.00, pressure shift score 4.00,

level shift score 4,00, and temperature shift score

5.00. The following figure is the simulation result of

Crystal Ball for the operating condition factor

Figure 3 Operating Condition Factor Simulation

Based on Figure 3, the total PoF value of the

operational factor is 3.73 with a certainty level of 85%

3.1.3 Electrical Failure

Based on the assessment, the electrical failure score

is 3.35. The result is obtained from the following

scoring results: Electrical equipment inspection

frequency scores 2.00 and history of being struck by

lightning score 5.00 The following figure is the

simulation result of Crystal Ball for the electrical

failure.

Figure 4 Electrical Failure Simulation

Based on Figure 4, the total PoF value of the electrical

failure is 3.44, with a certainty level of 85%

3.1.4 Leakage Factor

Based on the assessment, the leakage factor score is

5.00. The result is obtained from the following

scoring results: Leakage history score 5.00, flange

management score 5.00, and valve inspection interval

score 5.00. The following figure is the simulation

result of Crystal Ball for the leakage factor

Figure 5 Leakage Factor Simulation

Based on Figure 5, the total PoF value of the electrical

failure is 4.96 with a certainty level of 85%

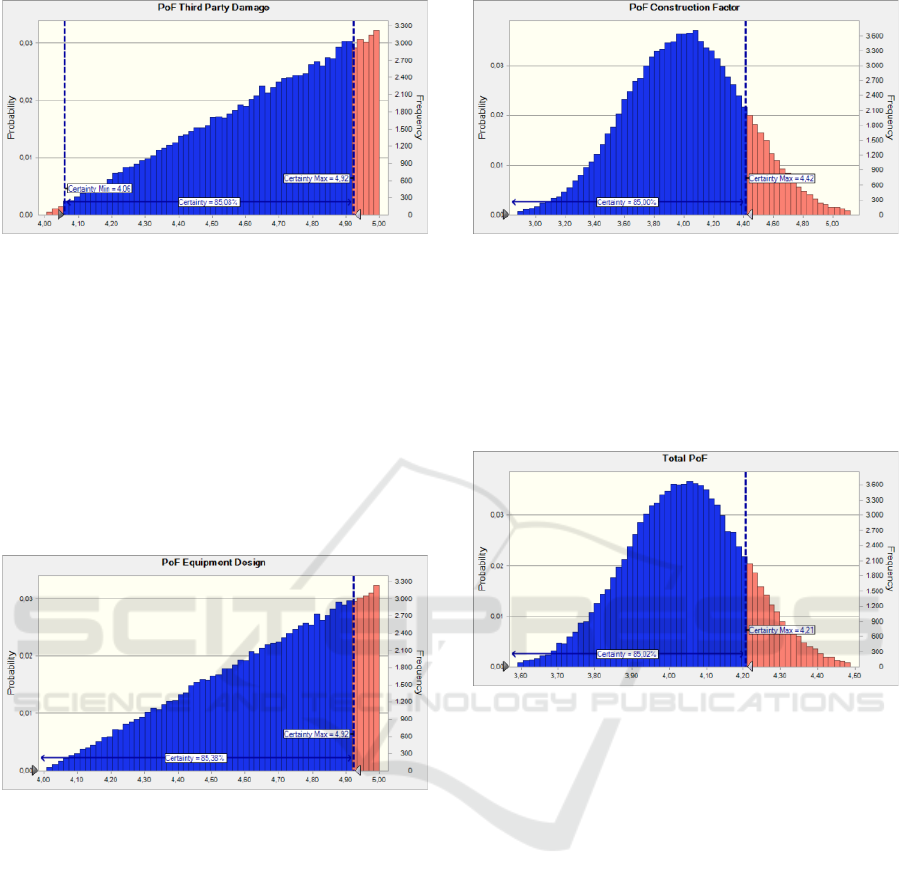

3.1.5 Third Party Damage

Based on the assessment, the third-party damage

score is 5.00. These results are based on the situation

surrounding the installation being stable, and there is

no history of sabotage. The following figure is the

simulation result of Crystal Ball for the Third Party

Damage.

Semi Quantitative Risk Analysis of Onshore Receiving Facility

9

Figure 6 Third-Party Damage Simulation

Based on Figure 6, the total PoF value of the third

party damage is 4.92, with a certainty level of 85%.

3.1.6 Equipment Design

Based on the assessment, the equipment design score

is 5.00. These results are based on the design is well

documented, and the design of the equipment meets

the international applicable codes & standards. The

following figure is the simulation result of Crystal

Ball for the Equipment Design.

Figure 7 Equipment Design Simulation

Based on Figure 7, the total value of the equipment

design is 4.92 with a certainty level of 85%.

3.1.7 Construction Factor

Based on the assessment, the equipment design score

is 4.00. These results are based on the equipment

constructed following (as-built drawing) and mainly

supervised (75%). The following figure is the

simulation result of Crystal Ball for the Construction

Factor.

Figure 8 Construction Factor Simulation

Based on Figure 8, the total value of the

equipment design is 4.42 of 85%

3.1.8 Probability of Failure Total Score

The following figure is the simulation result of

Crystal Ball for total Probability of Failure (PoF)

Figure 9 Total PoF

Based on Figure 9, the total PoF value of installation

is 4.21, with a certainty level of 85%. Referring to the

risk matrix, the probability level is at level 1

3.2 Consequence of Failure Calculation

3.2.1 Safety Consequence

Based on the assessment, the safety factor score is

1.00 of 5.00. These results are based on no leakage

history in the installation.

3.2.2 Environmental Consequence

Based on the assessment, the environmental score is

3.50 of 5.00. These results are based on the

installation fluid service score is crude oil & sweet

natural score 5.00 of 5.00 which are flammable

material, but there is no ignition source the score 2 of

5.00, and the density of population is ASME location

class 2 the score 2 of 5.00

ICoSTE 2020 - the International Conference on Science, Technology, and Environment (ICoSTE)

10

3.2.3 Assets Loss Consequence

Based on the assessment, the assets loss score is 1 of

5.00. These results are based on the 1 (one) day

production delay, which cost <US$ 1 million in

repair, but there is no record of shutdown history.

3.2.4 Company Reputation Consequence

Based on the assessment, the company reputation

consequence score is 4 of 5.00. These results are

based on the national media coverage in the event of

an installation failure.

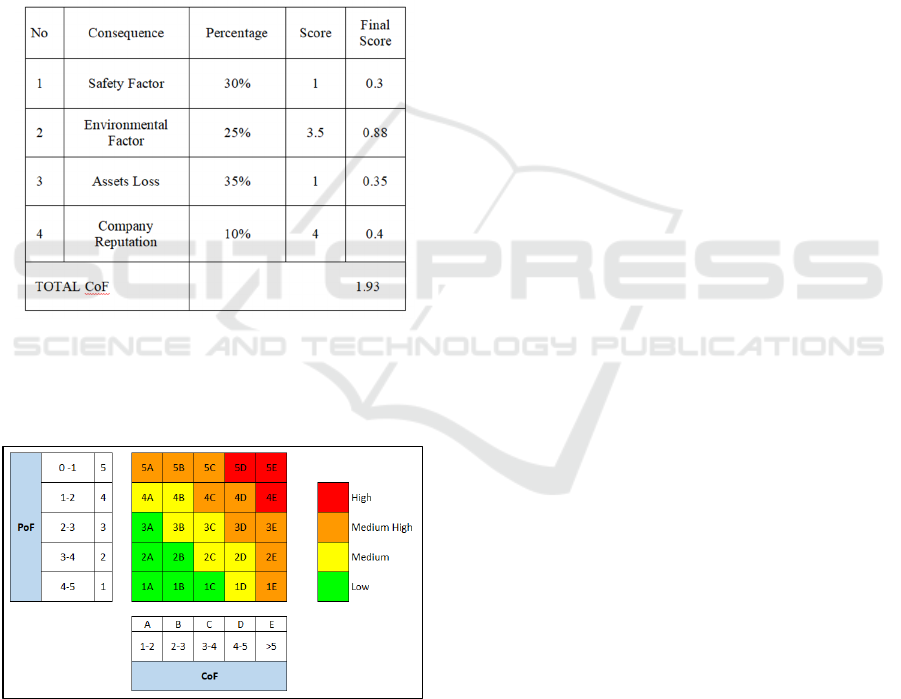

Table 4. CoF Calculation Result

3.2.5 Final Risk

Based on Total PoF x Total CoF, the result of ORF

Installation shown in the figure below.

Figure 10. Final Risk

4 CONCLUSIONS

Based on the risk analysis assessment results, the

probability level is 1 (one), and consequence A so

refer to the risk matrix that the risk level of the

Onshore Receiving Facility Installation is in the

"Low" zoning, which indicates an insignificant and

acceptable risk profileg.

REFERENCES

Arnur Ramdani, 2014, Analisis Semi-Kuantitatif Risiko

Kebakaran dan Ledakan Pada Fasilitas Pengolahan

Gas, Universitas Indonesia, Jakarta.

AS/NZS 4360. 2004. Risk Management Guidelines.

Canadian Society for Chemical Engineering, 2012, Process

Safety Management Guide, Ontario.

Crowl Daniel A, Joseph F. Louvar, 2001, Chemical Process

Safety Fundamentals with Applications: 2

nd

Edition,

Pearson College.

Crowl Daniel A, Joseph F. Louvar, Chemical Process

Safety Fundamentals with Applications: 3

rd

Edition,

Pearson College.

Khan, A. A, 1993, Risk Analysis of an LPG Storage Facility

in India, Indian Institute of Chemical Technology.

Lees Frank P, Loss Prevention in the Process Industries 2

nd

Edition, Vol. 1, Department of Chemical Engineering,

Loughborough University, United Kingdom.

Mannan, Sam, 2014, Lees’ Process Safety Essentials,

Elsevier Inc.

Martins M.R, Pestana, Quantitative Risk Analysis of

Loading and Offloading Liquified Natural Gas (LNG)

on Floating Storage and Regasification Unit (FSRU),

Journal of Loss Prevention in the Process Industries.

Sutton Ian, Process Risk and Reliability Management 2

nd

Edition, 2015, Oxford.

Tsan Ming Choi, Chun Hung Chiu, 2012, Risk Analysis in

Stochastic Supply Chains A Mean- Risk Approach, Vol.

178. Hongkong.

The US Department of Labor Occupational Safety and

Health Administration, 2002, Process Safety

Management.

Yakub Maulana, Sisca Mayang Puspa, 2019, Manajemen

Risiko Kebakaran Pada PT Pertamina EP Asset 4 Field

Sukowati, Journal of Industrial Hygiene and

Occupational Health, Vol. 3.

Semi Quantitative Risk Analysis of Onshore Receiving Facility

11