Synthesis of Crosslinked Cellulose/PVA Bioplastic Strengthened with

Chitosan as and Alternative to Conventional Plastics

Eka Yulli Kartika and Endang Saepudin

Department of Chemistry, Faculty of Mathematics and Natural Science, Universitas Indonesia, Indonesia

Keywords: Crosslinked cellulose, Chitosan, Conventional Plastics.

Abstract: Environment problem from plastic waste should be reduced and solved. The development of biodegradable

plastic from cellulose can be a solution to solve it. Cellulose was a natural biopolymer that can be used as

bioplastics. Biodegradable plastics made from cellulose can be used as an alternative to conventional plastics,

because they are environmentally friendly, easy to obtain and easily degraded. However, used of cellulose-

based bioplastic requires physical or chemical modification to improve its physical and mechanical properties.

In this study, improvement of physical and mechanical properties of cellulose-based bioplastics was carried

out by adding polyvinyl alcohol (PVA), glutaraldehyde crosslinker and chitosan filler. Optimization the

synthesis of cellulose / PVA layers was carried out by varying the concentrations of glutaraldehyde and

chitosan from 0-56% and 0-33%.The results of the bioplastic film synthesis were evaluated for thickness,

swelling and solubility, biodegradability and mechanical properties, the optimum concentration of each

variation of glutaraldehyde and chitosan was characterized by FT-IR. The results showed that modification

of the cellulose/PVA-crosslinked glutaraldehyde film and the addition of chitosan fillers improve the physical

and mechanical properties of bioplastics, with the optimum concentration of each varian being 56% (w/w)

and 24% (w/w).

1 INTRODUCTION

Plastic is a product that can function as packaging, so

that it can facilitate human work. The high use of

plastic packaging causes an accumulation of plastic

waste, which causes environmental pollution

(Selvamurugan & Sivakumar, 2019). Plastic

packaging, especially food packaging that is

produced non-biodegradable, leads to environmental

problems because it takes thousands of years to

degrade. Biodegradable means that these materials

can be completely consumed by microorganisms

without leaving harmful pollutants in the

environment. To solve this problem, one solution is

to replace the non-biodegradable plastic base material

into a easily degraded material, namely biodegradable

plastic (Pikon & Czop, 2014). The material used for

the manufacture of plastics plays an important role in

determining the quality of the films produced. In the

manufacture of films can mix natural polymer

materials and synthetic polymer materials (Isroi &

Cifriadi, 2017).

In recent years, the use of natural fibers as

reinforcements in polymers has attracted much

attention due to the environmental concern. Cellulose

fibers exhibit high mechanical properties. Besides,

they also offer a number of other advantages over

conventional reinforcing materials, such as low cost,

worldwide availability, and biodegradability.

Particular attraction is its low density which leads to

high specific mechanical properties (Niu, et al. 2015).

These unique properties have made cellulose an ideal

candidate for high performance biocomposites.

Various biodegradable polymers, suchas chitosan

(Angadi, et al. 2012), starch, polycaprolactone (PCL)

(H.Lonnberg, et al. 2011), poly (3-hydroxybutyrate-

co-3-hydroxyvalerate) (PHBV) (E. Ten, et al. 2010),

polylactic acid (PLA) (L. Suryanegara, et al. 2010),

poly (furfuryl alcohol)(PFA) (H. Dekaa, et al. 2013),

and polyvinyl alcohol (PVA) (Priya, et al. 2014) have

been explored as potential matrices for this kind of

composites. PVA is the most widely produced

watersoluble synthetic polymer in the world. Itis also

a versatile polymer with broad applications due to its

biodegradability, biocompatibility, high tensile

strength, excellent adhesive properties, chemical

resistance and gas barrier properties (Niu, et al.

2015).

Kartika, E. and Saepudin, E.

Synthesis of Crosslinked Cellulose/PVA Bioplastic Strengthened with Chitosan as and Alternative to Conventional Plastics.

DOI: 10.5220/0010786800003317

In Proceedings of the 2nd International Conference on Science, Technology, and Environment (ICoSTE 2020) - Green Technology and Science to Face a New Century, pages 17-24

ISBN: 978-989-758-545-6

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

17

Plasticizers play a role in increasing the flexibility

and permeability of cellulose to water and gas vapor.

Synthetic polymer which is biodegradable as a

mixture of cellulose for the manufacture of

biodegradable plastic films is PVA. PVA is one of

the largest water-soluble, non-toxic and

environmentally friendly polymers. PVA has a polar

hydroxyl group attached to the carbon which makes

it very hydrophilic. In addition, PVA is widely used

in the plastic packaging industry because of its

solubility (Abdhulkani, et al. 2013). Although both

cellulose and PVA have plenty of hydroxyl groups

along their molecular chains, direct incorporation of

pristine cellulose fibers into PVA matrix cannot

produce composites with good mechanical

properties. This is due to the fact that most hydroxyl

groups in cellulose and PVA molecules have already

formed either intra- or inter-molecular hydrogen

bonds. Therefore, it is difficult to form new hydrogen

bonds between the two components by simple mixing

(Niu, et al., 2015).

Chemical crosslinking in composites is an

efficient way to achieve desired compatibility [4].

Chabba et al. crosslinked soy flour/flax yarns

composites using glutaraldehyde (GA) as the

crosslinking agent to improve the tensile and thermal

properties (Chabba, et al., 2015). Li et al. also used

GA to prepare crosslinked chitosan/PVA blend beads

with high mechanical strength (Li, et al., 2007).

Glutaraldehyde is a crosslinking agent that has the

ability to bind hydroxyl groups to polymeric

materials. Glutaraldehyde is also one of the

crosslinking agents which can cause the matrix cross-

linking to be tighter and increase the tensile strength.

In addition, it can improve the mechanical properties

of the mixed film and can improve the characteristics

of water resistance and film thermal stability (Basuki

& Sanjaya, 2009).

To increase the strength and hardness of

bioplastic products, it can be increased by adding

fillers. Chitosan is a polysaccharide that is abundant

in nature after cellulose. The use of chitosan as an

additive in making plastic films serves to improve the

transparency of the plastic film produced. The more

chitosan is used, the better the mechanical properties

and air resistance of the bioplastic products. In

addition, chitosan is non-toxic, easily biodegradable

and is polyelectrolytic (Mollah, et al., 2016).

Therefore, this research will conduct the

development of bioplastic films that are innovative,

environmentally friendly and biodegradable. The

process of making the film was carried out by

preparing the bioplastic film Cellulose / PVA with

added glutaraldehyde as cross-linker with the

addition of chitosan filler as reinforcement.

2 RESEARCH METHODS

2.1 Materials

Commercial cellulose (99%-cellulose). PVA was

purchased from Merck Company (Germany).

glutaraldehyde, chitosan, dimethyl sulfoxide

(DMSO) was purchased from Merk

MERCKMILLIPORE (Germany), CH

3

COOH,

distilled water, filter paper from the Universitas

Indonesia Materials Technology Laboratory.

2.2 Celulose Activation

Cellulose (0.5 g) was immersed in solvent (water:

DMSO :: 1:3) for 24 hours to swell and to activate

reactive sites on the surface (Kohli, et al., 2017).

2.3 Bioplastic Film Synthesis

2.3.1 Cellulose / PVA Crosslinked

Glutaraldehyde Film

The synthesis process begins with the manufacture of

cellulose / PVA. A total of 2 g of PVA was dissolved

in 23 mL of distilled water, heated at 80

o

C for 1 hour

while stirring at high speed. Then add cellulose

which has been activated overnight and stirred again

for 30 minutes at high speed. Then added

glutaraldehyde (0-56%, w/w). Then the bioplastic is

molded and left at room temperature overnight. Then,

oven for 5 hours at a temperature of 60◦C.

2.3.2 Cellulose / PVA Filler Chitosan Film

Solution of 1% chitosan (w/w) was made using 2%

(w/w) acetic acid solution. The chitosan solution (0-

33% w/w) is added to the cellulose / PVA /

glutaraldehyde mixture by the process described in

2.3.1. The mixing is carried out right after the

crosslinking agent is added, before the mixture

thickens and becomes agar. Then the bioplastic is

molded and left at room temperature overnight. Then,

oven for 5 hours at a temperature of 60◦C.

ICoSTE 2020 - the International Conference on Science, Technology, and Environment (ICoSTE)

18

2.4 Film Characterization

2.4.1 Measurement of Film Thickness

The thickness of the samples was determined with a

couplers micrometer. This tool has an accuracy of up

to 0.01 mm. Measurements were repeated in ten

different regions of each sample. Average values

were calculated and used (Abdollahi, et al., 2012).

2.4.2 Swelling and Water Solubility

Measurements

The sample was cut into small pieces (2x2 cm) and

weighed to determine their dry mass. The weighed

samples were placed in closed beakers containing 30

mL of water and stored at temperature room. The

kinetic of swelling was evaluated by periodically

measuring the weight increment of the samples. The

film is taken, cleaned and shaken several times to

remove the liquid that is on the surface of the

bioplastic film and weighed. The weighing was

continued until equilibrium state. The procedure was

repeated three times for each sample to confirm its

repeatability. The water gain of each sample was

calculated as follows:

Swelling %

x 100%

where Ws is the weight of the film sampel after

immersion and W0 is the weight of the initial film

sampel (Abdollahi, et al., 2012).

After that, the film from the swelling test is dried

until the mass of the sample film is constant and the

solubility is calculated using the equation:

WS %

x 100%

Where Wk is weight of the dried layer after

swelling test (Sa’adah, 2020).

2.4.3 Biodegradability in Soil

In this method, samples films 20 mm × 20 mm × 1

mm small pieces were weighted and placed for 120

days into the agricultural soil in a pot. The pot was

covered with a plastic net and exposed to atmospheric

conditions for 120 days. Variations in film

morphology, the time of films disintegrated and

weight loss were recorded. To determine the weight

loss the specimen of each sample was quickly washed

with cold water and dried in an oven at 70 ◦C to

constant weight. The weights of the sample, before

and after washing were recorded (Priya, et al. 2014).

2.4.4 Mechanical Properties

Tensile strength (TS) and elongation at break (E%) of

the film samples were determined according to

ASTM standard method D882–02 with an Strograph

EII Testing Machine. The film samples were cut in

rectangular specimens (40x20 mm). The test is done

by clamping both ends of the sample to a tensile

testing machine. Then the start knob is turned on and

the tool will pull the sample until it breaks. Saved and

recorded the results of tensile strength and%

elongation that are on the tools.

2.4.5 Fourier Transform Infrared

Spectroscopy (FTIR) Analysis

FTIR spectra were studied with a Nicolet 560

spectrometer (Nicolet Co., USA). KBr solids are

smoothed and inserted into the holder for background

measurement. Bioplastic film samples on top of the

holder and measured in the wave number range 500-

4000 cm

-1

(Abdollahi, et al., 2012).

3 RESULTS AND DISCUSSION

3.1 Film Thickness

Bioplastic film thickness measured using a

micrometer. Thickness is one of the parameters used

to determine the quality of a bioplastic characteristic.

The results showed that the thickness of the bioplastic

did not increase significantly with an increase in the

glutaraldehyde crosslinker concentration. However,

at certain concentrations it will increase the thickness

of the printed plastic (Table 3.1). The results showed

that all variations of glutaraldehyde and chitosan had

the same film thickness. The same thickness value

caused because the dissolved material evaporates

when heated.

Table 1 Film Thickness

Treat

ment

Glutaral

dehyde

(%w/w)

Thick

ness

(mm)

Treat

ment

Chitosan

(%w/b)

Thickness

(mm)

PPP

0

0 0,12

PPP

0

0 0,12

PPP

30

30 0,20

PPP

12

12 0,20

PPP

46

46 0,20

PPP

24

24 0,20

PPP

56

56 0,20

PPP

33

33 0,20

Synthesis of Crosslinked Cellulose/PVA Bioplastic Strengthened with Chitosan as and Alternative to Conventional Plastics

19

Bioplastic thickness influenced by the area of the

mold, the volume of the solution and the total amount

of dissolved solids (Sa’adah, 2020). In this study, the

mold area was made the same, so the influencing

factor was the volume of solute glutaraldehyde and

chitosan. So, the addition of glutaraldehyde and

chitosan increases the thickness.

3.2 Swelling and Water Solubility

The swelling test was conducted to determine the

interaction between the bioplastic film and water.

Conventional plastics circulating in the community

are hydrophobic, making it difficult to dissolve in

water. Therefore, the development of bioplastic films

which are difficult to dissolve in water is carried out

(Sa’adah, 2020).

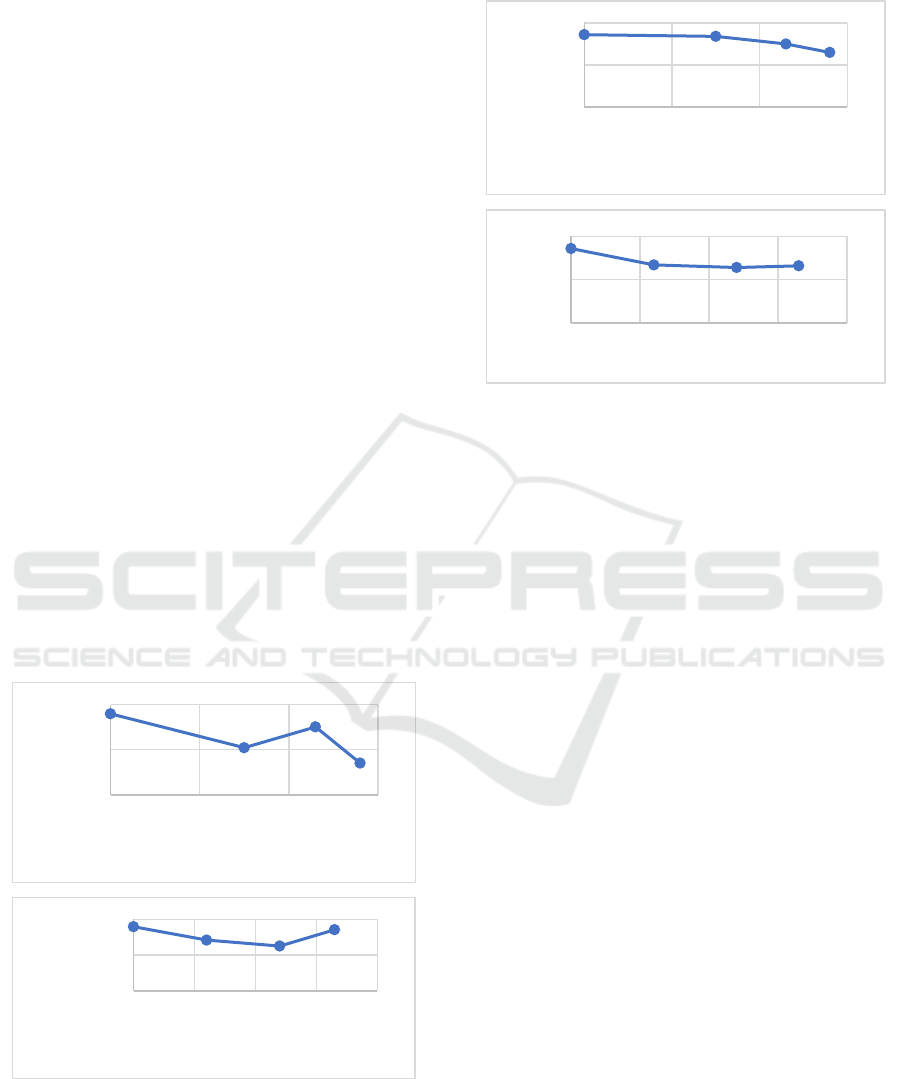

The results of the swelling and solubility test are

shown in Figures 1 & 2. Based on the results of the

study, the higher the concentration of glutaraldehyde

and chitosan added, the lower the% increase in mass

or swelling of bioplastics. This is due to the hydrogen

bonding that occurs between glutaraldehyde and

cellulose as well as chitosan and cellulose in the

bioplastic film, which prevents the formation of holes

that can be traversed by water. In general, the lower

the swelling ability of the bioplastic film, the lower

the film solubility. This is because the lower the

amount of water that enters the cavity, the less the

film component can dissolve (Niu, et al. 2015,

Abdhulkani, et al. 2013, Basuki & Sanjaya, 2009).

Figure. 1 Swelling

Figure 2. Water Solubility

The results showed that in general the swelling

ability of bioplastics decreased with increasing

concentrations of glutaraldehyde and chitosan

(Figure 1). The results showed that the% variation in

the development of glutaraldehyde and the lowest

chitosan in this study was 24% PPP56 and PPP24,

respectively, with a percentage of 141% and 251%.

Meanwhile, the highest% swelling was the PPP0

variation with the proportion of 359%.

Glutaraldehyde acts as a crosslinker and also acts as

a plasticizer. The PPP56 variation has higher

intermolecular interactions between molecules

compared to other variations, so that in other

variations the ability of glutaraldehyde to act as a

plasticizer. The results showed that the higher the

concentration of chitosan was added, the lower the

percentage increase in mass or swelling of

bioplastics. This is due to the hydrogen bonding that

occurs between chitosan and cellulose on the

bioplastic film, so that it prevents the formation of

cavities that can be passed by water (Sa’adah, 2020).

The solubility test results were obtained from the

dried swelling bioplastic film, then the final mass of

the sample was calculated. There is a correlation

between the results of the swelling test and the results

of the solubility test. The higher the swelling ability

of the bioplastic film, the more dissolved bioplastic

film mass will be shown (Figure 2). Addition of

glutaraldehyde and chitosan in Cellulose / PVA

matrix can reduce the solubility of films in water. The

highest yield of bioplastic film solubility at the PPP0

variation was 86%. For the glutaraldehyde variation,

the lowest solubility yield was 65% for PPP56. For

359

209

301

141

0

200

400

0% 20% 40% 60%

Water Uptake (%)

Variations Concentration of …

359

284

251

342

0

200

400

0% 10% 20% 30% 40%

Water Uptake

(%)

Variations Concentration of Chitosan

86 84

75

65

0

50

100

0% 20% 40% 60%

Weight Lost (%)

Variations Concentration of …

86

67

64

66

0

50

100

0% 10% 20% 30% 40%

Weight Lost

(%)

Variations Concentration of Chitosan

ICoSTE 2020 - the International Conference on Science, Technology, and Environment (ICoSTE)

20

chitosan variation, the lowest solubility yield was

64% for PPP24. The results obtained are linear with

the results of the swelling test. This will increase the

interaction between molecules and reduce sensitivity

to water (Basuki & Sanjaya, 2009).

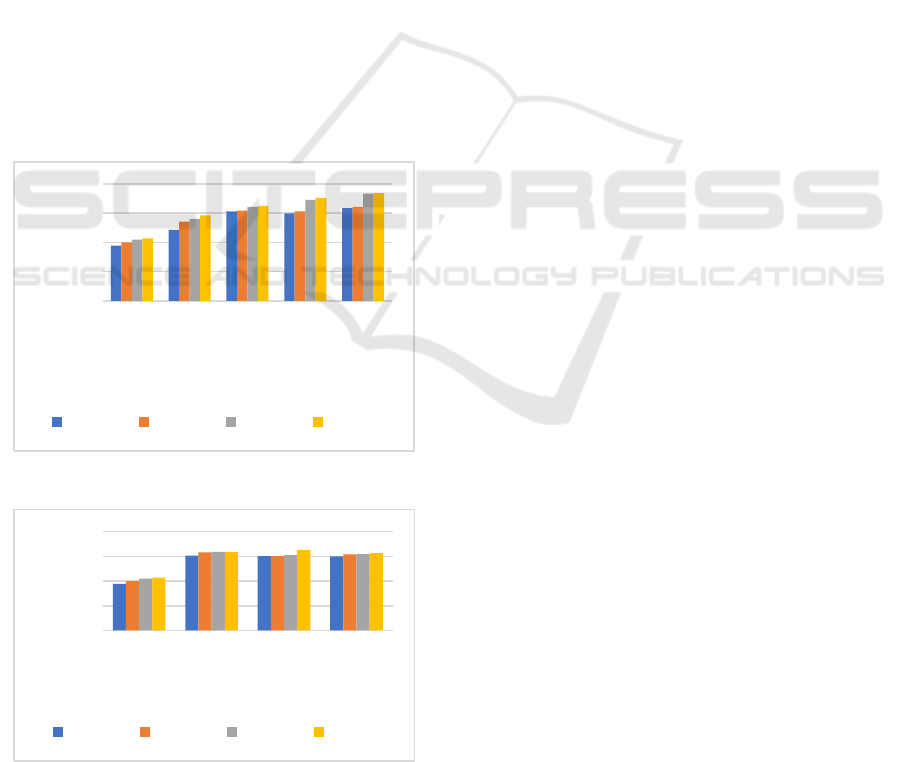

3.3 Biodegradability in Soil

Bioplastic film biodegradation testing was carried out

by means of the burial test method in the soil. The

biodegradation test aims to determine the level of

resistance of the bioplastic film in the soil for a

certain time. The results of the biodegradation

analysis showed that all variations experienced a

decrease in the mass of the bioplastic film, the mass

decrease for each variation did not experience any

difference significant (Figure 3 and 4). The decrease

in the mass of the bioplastic film is an indication that

the bioplastic film is biodegradable. The reduction in

the mass of the bioplastic film was caused by the

attack of microorganisms and the absorption of water

content (swelling) of the bioplastic film which is in

the soil, initiates a hydrolysis reaction so that the

bioplastic polymer can be decomposed into smaller

compounds (Sa’adah, 2020).

Figure. 3 Biodegradability Variation of Glutaraldeyde

Figure. 4 Biodegradability Variation of Chitosan

The results showed that the higher the

concentration of glutaraldehyde and chitosan was

added, the% biodegradability of bioplastics

increased. The results showed that the higher the

concentration of glutaraldehyde added, the%

biodegradability of bioplastics was increased.

Glutaraldehyde acts as a crosslinker and plasticizer,

where the increased glutaraldehyde concentration

will increase its ability as a plasticizer. This can

reduce the interaction between macromolecules, so

that the bonds between macromolecules are easier to

break, so that the bioplastic film will be more easily

degraded by microorganisms. In addition, the

hydrophilic groups present in glutaraldehyde will

make the degradation process easier, thus making

bioplastics more environmentally friendly (Basuki &

Sanjaya, 2009).

The increase in the amount of chitosan in

bioplastics causes the amount of carbon to also

increase. Carbon is one of the elements needed by

microorganisms as a food source, increasing the

amount of chitosan will increase the carbon source

that can be used as food for microorganisms in the

soil. The% increase in biodegradability is due to

increased hydrolysis of random chain cutting which

triggers a reduction in molecular weight. The

reduction in molecular weight will trigger these

molecules to become smaller molecules, so that they

will be easier to degrade by microorganisms

(Abdullah, et al., 2020). There are various kinds of

microorganisms that have been isolated from the soil

using bioplastics as a carbon source. Some of these

microorganisms include Actinobacteria species such

as Amycolatopsis, Thermomactimuces,

Actinomadura, Nanomuraea, Laceyella and

Streptomyces, of which the most common species are

Amycolatopsis and Streptomyces. In addition, there

are also species of Paenibacillus, Pseudomonas,

Bacillus and Bulkholderia. Several types of fungal

species that have been isolated and are responsible

for degrading bioplastics are Aspergilus, Fusarium

and Penicillium, Penicillium is the most common

species (Emadian, et al., 2017).

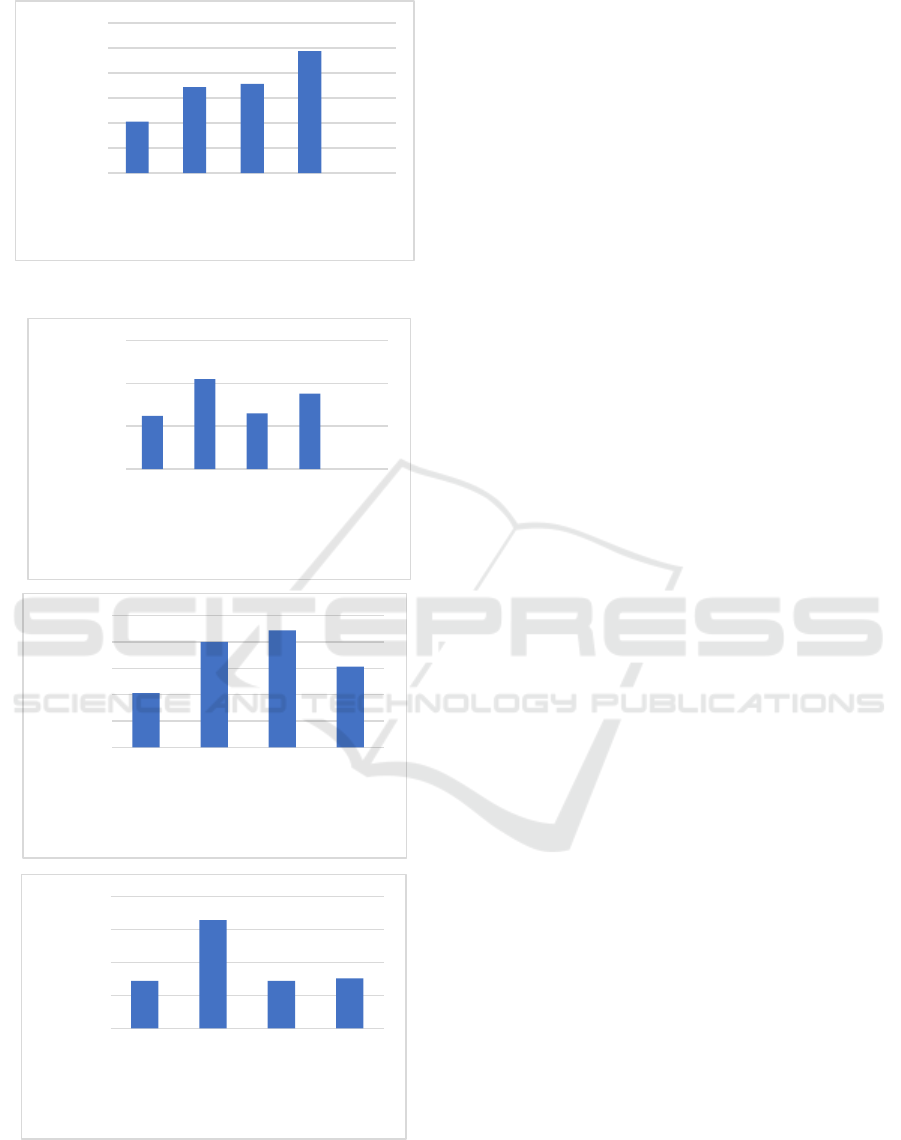

3.4 Mechanical Properties

The mechanical strength test of bioplastics is carried

out by measuring the tensile strength and strain (%

elongation). Tensile strength (tensile strength) is the

ability of a bioplastic film to withstand a given load

until the bioplastic breaks, while% elongation is the

optimum stretch extension or increase in bioplastic

when it is pulled to break. % elongation is used to

measure the elasticity of a polymer.

0

20

40

60

80

PPPS0 PPPS30 PPPS46 PPPS56 PPPS75

%Biodegradabilitas

Variations Concentration of

Glutaraldehyde

Week1 Week2 Week3 Week4

0

20

40

60

80

PPPS0 PPPS12 PPPS24 PPPS33

%Biodegradabilitas

Variations Concentration of Chitosan

Week1 Week2 Week3 Week4

Synthesis of Crosslinked Cellulose/PVA Bioplastic Strengthened with Chitosan as and Alternative to Conventional Plastics

21

Figure 5. Tensile Strength

Figure 6. Elongation

The presence of cross-linking will also increase

the molecular weight of the bioplastic, where the

tensile strength of the polymer increases with

increasing molecular weight and reaches a saturation

level at a certain molecular weight. At lower

molecular weights, the polymer chains are loosely

bound and the chains are easier to move so that the

strength of the polymer is low (even though it has a

higher crystallinity), whereas polymers with large

molecular weights have large chains and give strength

to the polymer. The results of the bioplastic tensile

strength test with variations in the concentration of

chitosan are shown in Figure 5. The results of the

tensile strength test showed that the higher the

concentration of chitosan added, the tensile strength

of the bioplastic was increased. This is due to the

presence of filler so that it can improve the

mechanical properties of the bioplastic film. The

improved mechanical properties of bioplastics can

also be attributed to the good interface adhesion,

which can form hydrogen bonds between cellulose

and filler chitosan (Sa’adah, 2020).

The effect of glutaraldehyde on% elongation is

shown in Figure 6. The parameter of% elongation is

used to determine the flexibility and tensile strength

of the bioplastic film. An increase in the

glutaraldehyde concentration will increase the%

elongation of the bioplastic film. This is because the

role of glutaraldehyde as a plasticizer can reduce the

interaction of the intermolecular bonds of the

bioplastic polymers and replace them with hydrogen

bonds formed between the plasticizer and the

polymer, thereby reducing stiffness and increasing

the flexibility of the film. The addition of chitosan to

bioplastics will reduce the% elongation (elongation)

of the bioplastic. This is because the addition of

chitosan will increase the stiffness of the bioplastic,

thus reducing the% elongation ability of a bioplastic

film. In addition, increasing the amount of chitosan

filler will increase the hydrogen bonding interaction

between the filler and the cellulose matrix, thereby

reducing the flexibility of the bioplastic film (Mollah,

et al., 2016).

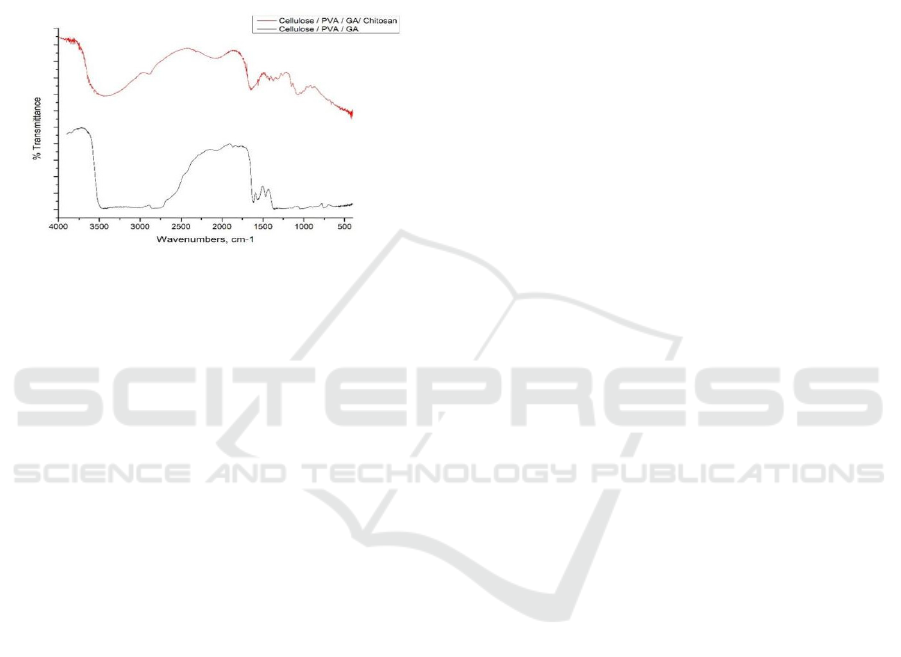

3.5 Fourier Transform Infrared

Spectroscopy (FTIR) Analysis

The analysis of functional groups on the effect of

adding glutaraldehyde and chitosan was carried out

by FTIR, which is shown in Figure 7. In the FTIR

spectra of cellulose / PVA / glutaraldehyde films

showed a widened peak at wave number 3200-3500

cm

-1

indicating the presence of an OH group. The

absorption band at the numbers 1700-1715 cm

-1

4,12

6,87

7,12

9,75

0

2

4

6

8

10

12

0% 30% 46% 56%

Tensile Strength (MPa)

Variations Concentration of …

0

50

100

150

0% 30% 46% 56%

% Elongation

Variations Concentration of

Glutaraldehyde

4,12

8

8,87

6,12

0

2

4

6

8

10

0% 12% 24% 33%

Tensile Strength (MPa)

Variations Concentration of

Chitosan

55

60

65

70

75

0% 12% 24% 33%

% Elongation

Variations Concentration of

Chitosan

ICoSTE 2020 - the International Conference on Science, Technology, and Environment (ICoSTE)

22

shows the peak area for the aldehyde group. The

FTIR spectra results of the cellulose / PVA /

glutaraldehyde / chitosan film showed absorption at

the wave number 3445.1 cm

-1

which is the –OH

region and water. The absorption band at wave

number 2928 cm

-1

shows the peak area for the C-H

group. The absorption at wave numbers 1659.7 and

1376.1 cm

-1

is the peak area for the N-H group of the

amine group and the C-H group on CH

3

(Basuki &

Sanjaya, 2009).

Figure 7: FTIR analysis

Figure 7. Results of the cellulose/PVA/glutaraldehyde/

chitosan

4 CONCLUSION

Based on the research that has been done, it can be

concluded that the variation in the concentration of

cross-linking agent glutaraldehyde and chitosan filler

has an effect on the physical and mechanical

properties of the bioplastic film layer, with each

optimum concentration to improve the physical and

mechanical properties of the bioplastic is 56% (w / w)

and 24% (w / w). Evidenced by the% swelling and the

lowest solubility and the highest tensile strength

values. Increasing the concentration of

glutaraldehyde and chitosan at a certain concentration

decreased the physical and mechanical properties of

the bioplastic film.

REFERENCES

Abdulkhani, A., Hojati, E., & Ashori, A, 2013, Preparation

of Cellulose / Polyvinyl Alcohol Biocomposite Films

Using 1-n-butyl-3-methylimidazolium Chloride,

International Journal of Biological Macromolecules,

Vol. 62, pp. 379–386.

Abdullah, A. H. D., Putri, O. D., Fikriyyah, A. K., Nissa, R.

C., Intadiana, S., 2020, Effect of Microcrystalline

Cellulose on Characteristics of Cassava Starch-based

Bioplastic, Polymer-Plastics Technology and

Materials, Vol. 59, pp. 1-9.

Abdollahi, M., Rezaei, M., & Farzi, G., 2012, A Novel

Active Bionanocomposite Film Incorporating

Rosemary Essential Oil and Nanoclay into Chitosan,

Journal of Food Engineering, Vol. 111, No. 2, pp.

343–350.

Angadi, S.C., L.S. Manjeshwar., T.M. Aminabhavi, 2012,

Novel Composite Blend Microbeads of Sodium

Alginate Coated with Chitosan for Controlled Release

of Amoxicillin, International Journal of Biological

Macromolecules, pp. 45–55.

Basuki, B. R., Sanjaya, I. G. M., 2009, Sintesis Ikat Silang

Kitosan dengan Glutaraldehid serta Identifikasi

Gugus Fungsi dan Derajat Deasetilasinya Cross-

linked Chitosan Synthesis Using Glutaraldehyde and

Functional Group Identification as well as Its

Deacetylation Degree, Jurnal Ilmu Dasar, Vol. 10,

No.1, pp. 93–101.

Chabba, S., G.F. Matthews., A.N. Netravali, 2005, Green

Composites Using Cross-linked Soy Flour and Flax

Yarns, Green Chemistry, pp. 576–581.

Emadian, S. M., Onay, T. T., Demirel, B, 2017,

Biodegradation of Bioplastics in Natural

Environments, Waste Management, Vol. 59, pp. 526–

536.

Elena Ten, J. Turtle, D. Bahr, L. Jiang, M. Wolcott, 2010,

Thrmal and Mechanical Properties of Poly (3-

Hydroxybutyrate-co-3-hydroxyvalerate) / Cellulose

Nanowhiskers Composites, Polymer, Vol. 51, pp.

2652–2660.

H. Dekaa, M. Misraa, A. Mohanty, 2013, Renewable

Resource Based “All Green Composites” from Kenaf

Biofiber and Poly (Furfuryl Alcohol) Bioresin,

Industrial Crops and Products, Vol. 41, pp. 94–101.

Isroi, I., Cifriadi, A., 2017, Bioplastic Production from

Cellulose of Oil Palm Empty Fruit Bunch, IOP

Conference Series: Earth and Environmental Science

Vol. 65 International Conference on Biomass:

Technology, Application and Sustainable

Development.

Kohli, D., Garg, S., Jana, A. K., Maiti, M., 2017, Synthesis

of Graft Copolymers for Green Composite Films and

Optimization of Reaction Parameters using Taguchi

(L16) Orthogonal Array, Indian Chemical Engineer,

Vol. 59, No. 2, pp. 136–158.

L. Suryanegara, A.N. Nakagaito, H. Yano, 2010, The

Synergetic Effect of Phenylphosponic Acid Zinc and

Microfibrillated Cellulose on the Injection Molding

Cycle Time of PLA Composites, Cellulose, Vol. 17,

pp. 771–778.

Li, M., S. Cheng., H. Yan, 2007, Preparation of

Crosslinked Chitosan/Poly(Vinyl Alcohol) Blend

Beads with High Mechanical Strength, Green

Chemistry, Issue 8, pp. 894–898.

Mollah, M. Z. I., Akter, N., Quader, F. B., Sultana, S., &

Khan, R. A., 2016, Biodegradable Colour Polymeric

Film (Starch-Chitosan) Development :

Characterization for Packaging Materials, Open

Synthesis of Crosslinked Cellulose/PVA Bioplastic Strengthened with Chitosan as and Alternative to Conventional Plastics

23

Journal of Organic Polymer Materials, Vol. 06, No.

01, pp. 10–24.

Niu, Y., Xiaofang, Z., Xu, H., Jiangqi, Z., Wei, Z., &

Canhui, L., 2015, Effective Dispersion and

Crosslinking in PVA/Cellulose Fiber Biocomposites

Via Solid-State Mechanochemistry, International

Journal of Bilogical Macromolecules, pp. 855-861.

Pikoń, K., & Czop, M. (2014). Environmental Impact of

Biodegradable Packaging Waste Utilization, Polish

Journal of Environmental Studies, Vol. 23, No. 3, pp.

969-973.

Priya, B., Gupta, V. K., Pathania, D., Singha, A. S., 2014,

Synthesis, Characterization and Antibacterial Activity

of Biodegradable Starch/PVA Composite Films

Reinforced with Cellulosic Fibre, Carbohydrate

Polymers, Vol. 109, pp. 171–179.

Sa’adah, S.M., 2020, Sintesis Bioplastik Pati-g-PLA/PVA

Termodifikasi Ikat Silang dan Pengisian Selulosa

yang diperkaya dengan Aditif Antioksidan dan

Antimikroba, Tesis, FMIPA Kimia, Universitas

Indonesia.

Selvamurugan. M, P. Sivakumar, 2019, Bioplastics – An

Eco-Friendly Alternative to Petrochemical Plastics,

Current World Enivronment, Vol. 14, No. 1, pp. 49-

59.

ICoSTE 2020 - the International Conference on Science, Technology, and Environment (ICoSTE)

24