Solution of a Practical Pallet Building Problem with Visibility and

Contiguity Constraints

Manuel Iori

2

, Marco Locatelli

1

, Mayron C. O. Moreira

3

and Tiago Silveira

1

1

Department of Engineering and Architecture, University of Parma, Parma, Italy

2

Department of Engineering and Architecture, University of Modena and Reggio Emilia, Reggio Emilia, Italy

3

Department of Computer Science, Federal University of Lavras, Lavras, Brazil

Keywords:

3D Packing, Practical Constraints, Contiguity, Visibility, Constructive Heuristics, Real-world Instances.

Abstract:

We study a pallet building problem that originates from a case study at a company that produces pallet building

robotized systems. The problem takes into account well known constraints, such as rotation and stackability,

and we introduce two practical constraints named visibility and contiguity between items of the same type.

We formalize the problem and propose heuristic algorithms to solve it, using a strategy that first creates 2D

layers and, then, creates the final 3D pallets. The proposed heuristic is based mainly on the Extreme Points

heuristic, that is tailored to choose feasible positions to pack items during the construction of the solution.

Besides that, we adapt our proposed heuristic using other basic heuristics from the literature, considering

different constraints. The performance of the algorithms is assessed through extensive computational tests on

real-world instances, and the obtained results show the proposed heuristics are able to create compact packing

in a very short time.

1 INTRODUCTION

We study the problem of loading a given set of items

into one or more pallets, so as to minimize the num-

ber of pallets used. The problem originates from a

real-world robotized application and is thus subject to

some non-trivial operational constraints. Items should

be packed into layers, that must then be piled one over

the other while respecting given stackability rules. In

addition, items are grouped into families, and, to fa-

cilitate loading/unloading operations, items from the

same family packed into the same layer should be

contiguous one with the other.

The problem we face lies in the field of Cutting

and Packing (C&P), one of the most widely studied

areas of Operations Research (Scheithauer, 2018; Iori

et al., 2019; Bortfeldt and W

¨

ascher, 2013; Crainic

et al., 2012; Hopper and Turton, 1998). In cutting

problems, a set of stock units has to be cut to pro-

duce smaller items, while in packing problems, a set

of items has to be packed into one or more contain-

ers. These problems have attracted the attention of re-

searchers both for their practical and theoretical inter-

est. Some practical applications involve the produc-

tion of materials that come in panels (such as wood or

glass), the optimization of layouts (as in industry or

newspaper paging), and the loading and subsequent

transportation of items employing containers, to men-

tion a few. Most C&P problems are associated with

mass-production operations in a company. Therefore,

improvements in the time performance of the process

as well as reduction in the material wasted are directly

related to the application of efficient methods. Previ-

ously, C&P tasks were usually made by skilled ex-

perts, but this has been changing over the years by

automated-packing (robotized) systems, as is the case

for the problem we face in this work.

Several interesting surveys and books have been

published in recent years to try to review the fast-

growing C&P literature, see, e.g., (Crainic et al.,

2012), (Lodi et al., 2014), (Silva et al., 2016) and

(Scheithauer, 2018). A typology of C&P problems

has been proposed by (W

¨

ascher et al., 2007). Later,

(Bortfeldt and W

¨

ascher, 2013) extended the paper of

(W

¨

ascher et al., 2007), considering the area of con-

tainer loading and its main constraints. They noted

that “the space available for packing above a pallet

might be interpreted as a container, too”, so they dis-

cussed constraints that can arise either when loading

a container or a pallet. Indeed, apart from container-

related constraints (such as weight limit and distri-

bution), they also discussed item-related constraints

Iori, M., Locatelli, M., Moreira, M. and Silveira, T.

Solution of a Practical Pallet Building Problem with Visibility and Contiguity Constraints.

DOI: 10.5220/0009351703270338

In Proceedings of the 22nd International Conference on Enterprise Information Systems (ICEIS 2020) - Volume 1, pages 327-338

ISBN: 978-989-758-423-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

327

(as loading priorities, orientation, and stacking) that

can be useful for pallets. The authors also considered

cargo-related constraints, positioning constraints, and

other load-related constraints that may appear dur-

ing transportation, see also (Iori and Martello, 2010);

(Iori and Martello, 2013), such as vertical and hori-

zontal stability.

The problem we face includes many of such con-

straints (as outlined in detail next in Section 2). In

particular, we highlight the contiguity among items

that belong to the same family. The concept of conti-

guity has already been addressed in the C&P literature

(Terno et al., 2000; Scheithauer and Sommerweiβ,

1998), although we could not find a univocal and for-

mal description, probably because it was included in

heuristic algorithms.

The pallet building problem that we study in this

paper is NP-hard, because it is a specific case of the

Bin Packing Problem, which is known to be NP-hard

(Martello et al., 2000). In addition, it needs to be

solved fast because it is frequently encountered at the

operational level during the everyday working activ-

ity of a robotized packing system. For these reasons,

we found it necessary to adopt heuristic solution al-

gorithms. We derived these algorithms from the most

successful and recent C&P studies, by embedding in

them in a tailored way the additional operational con-

straints of the problem at hand.

Our main contributions can be sketched as fol-

lows: an interesting problem that derives from a real-

world industrial application is presented; a concise lit-

erature review is provided; the concept of contiguity

of items, that is very useful in practice during load-

ing/unloading operations but has never been formally

treated in the literature, is discussed in detail; exten-

sive computational tests on instances derived from the

real-world case study are given.

The remainder of the paper is organized in five fur-

ther sections. Section 2 provides a formal description

of the problem. Section 3 briefly reviews the related

literature. Section 4 presents the heuristic algorithms

that we implemented. Section 5 gives the outcome of

extensive computational tests. Conclusions and some

future research directions are given in Section 6.

2 PROBLEM DESCRIPTION

We are given an arbitrarily large set R = {1, 2,.. . , m}

of identical pallets. Each pallet has a two-dimensional

loading surface of width W ∈ Z

∗

+

and length L ∈

Z

∗

+

, which can be used to load items up to a max-

imum height H ∈ Z

∗

+

. We are also given a set I =

{1,2, . . ., n} of 3D rectangular item types, where each

item type i ∈ I contains b

i

identical items, each hav-

ing width w

i

∈ Z

∗

+

, length l

i

∈ Z

∗

+

, and height h

i

∈ Z

∗

+

,

such that w

i

≤ W , l

i

≤ L, and h

i

≤ H.

Item types are partitioned in input into a set F

of families as follows. Each item type i belongs to

a given family f

i

∈ F, which is defined as a set of

item types having similar height and weight. About

this concept, as we are interested just in the packing

problem, it is enough to take into account only the ge-

ometric characteristics of the items, since they have

the same final destination.

Items belonging to the same family can be used

to form layers. Each layer is a 2D packing of items

whose total width does not exceed W , and whose total

length does not exceed L. In general, we consider

three types of layers:

• single-item type layers are formed by a unique

type of items;

• single-family layers are formed by different item

types, but all belonging to the same family;

• residual layers are formed by a combination of

items of different families or, alternatively, by

items belonging to the same family but with oc-

cupation lower than a pre-defined threshold.

Let us call a group a set of items having the same

item type and being loaded in the same layer. Pack-

ings of items in a layer should fulfill two operational

constraints that concern groups and are aimed at eas-

ing unloading operations when the pallet is delivered:

• the contiguity constraint imposes that all items

in a group are packed contiguously one with the

other, that is, each of them is ‘close enough’ to

one of the other items of the same group;

• the visibility constraint requires that at least one

item per group is packed with one of its edges

‘close enough’ to the border of the layer, so be-

ing visible by the outside;

Single-item type layers and family layers can be used

in a 3D packing to support other layers that are packed

on top of them. For this purpose, we establish two

additional conditions:

• a stackability constraint imposes that heavy items

can not be on top of fragile ones. Formally, each

family f ∈ F is assigned with a level of resistance

ρ

f

, with small values indicating fragile items and

large values indicating heavy ones. Items belong-

ing to family f cannot be put below items belong-

ing to family g if ρ

f

< ρ

g

;

• a layer can be used to support other layers only

if its total area loaded with items reaches a mini-

mum fraction of α of the total loading surface W L.

Parameter 0 < α < 1 is called fill-factor. A layer

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

328

with loaded area lower than αW L can still be used

to build a pallet, but can only be the topmost layer.

We call this the minimum supporting area con-

straint.

The aim of the pallet building problem (PBP) that we

face is to load all items into the minimum number of

pallets, by ensuring that the following constraints are

satisfied:

• all items should be packed in layers by satisfying

grouping and visibility constraints;

• single-item type and single-family layers can be

used to support other layers on top of them as long

as support and fill-factor constraints are satisfied;

• at most one residual layer can be used per pallet,

and, in such a case, it must be placed at the top of

the load;

• the total height of the layers in any pallet should

not exceed H.

Note that we use the term pallet building, instead of

pallet loading, to avoid confusion with the more fa-

mous pallet loading problem (PLP), which calls for

packing a set of two-dimensional rectangular items

without overlapping and by allowing a 90

◦

rotation

into a two-dimensional bin. We refer the reader in-

terested in the PLP to (Silva et al., 2016) for a recent

survey and to (Delorme et al., 2017) for a state-of-the-

art computational analysis.

3 BRIEF LITERATURE REVIEW

The PBP emerges as a variant of the Container

Loading Problem (CLP), which has received a good

amount of attention in the last years. (Bortfeldt and

W

¨

ascher, 2013) presented a comprehensive survey of

the main constraints used in the literature. They ver-

ified that heuristic approaches are more frequently

used than exact and approximation-guarantee algo-

rithms. (Silva et al., 2016) considered the PLP. They

proposed a broad analysis of the solution methods and

some aspects concerning computational complexity,

upper bounds, and data sets most used in numeri-

cal experiments. (Crainic et al., 2012) presented a

survey about 2D and 3D Orthogonal Packing Prob-

lems, focusing on data structures for the packing rep-

resentation and the item-positioning rules. Concern-

ing criteria to place items, they highlighted: (i) in-

terval graphs (Fekete and Schepers, 1997), to rep-

resent the overlap between items; (ii) corner points

(Martello et al., 2000), that describe feasible places to

pack an item in a partial solution; and (iii) extreme

points (Crainic et al., 2008), that increase the amount

of feasible regions on the partial packing of the corner

points. Recently, (Iori et al., 2019) proposed a sur-

vey on variants of 2D packing problems, considering

techniques to represent and handle items, relaxation

methods, as well as exact and heuristic approaches.

We also refer to (W

¨

ascher et al., 2007) for a catego-

rized typology of 2D packing problems.

The PBP can be separated into two subsequent de-

cisions: the first one consists in creating 2D layers,

while the second one involves staking layers to form

pallets and thus considers the 3D characteristics. In

the following, we discuss some relevant approaches

for 2D and 3D, respectively.

For what concerns heuristics for 2D problems,

(Chazelle, 1983) described an efficient way to imple-

ment the famous bottom-left heuristic, which packs

the items, one at a time in a given order, in the lowest-

most and left-most position. (Burke et al., 2004) pre-

sented a new placement heuristic, called best-fit, for

a 2D cutting problem, allowing non-guillotine pack-

ings and rotations of 90 degrees. This technique uses

a dynamic search based on the “niches”, which are

the available bottom-most gaps for an item in the par-

tial packing. In terms of metaheuristics, (Alvarez-

Valdes et al., 2008) developed a GRASP for the 2D

strip packing problem, which is the problem of pack-

ing items into a strip of a given width by minimizing

the used height. In the constructive phase, the items

are placed into rectangles following specific criteria.

A new rule attempts to foresee the future effect of the

tallest object in the final solution to avoid spikes. The

local search iteratively destroys and rebuilds portions

of the current solution. Extensive computational ex-

periments attested the effectiveness of the proposed

strategy. (Imahori and Yagiura, 2010) improved the

technique proposed by (Burke et al., 2004) by pre-

senting a quicker implementation based on a balanced

binary search tree and a priority heap with a doubly-

linked list. (Leung et al., 2011) presented a com-

plete set of techniques to deal with the 2D strip pack-

ing problem. They use the so-called “skyline” ap-

proach in conjunction with greedy local search, a sim-

ulated annealing metaheuristic, and a multi-start di-

versification strategy. We also mention the so-called

G4-Heuristic, developed by (Scheithauer and Terno,

1996) for the PLP.

For what concerns 3D problems, (Haessler and

Talbot, 1990) addressed a real CLP involving some

practical constraints. They proposed an integer pro-

gramming formulation and a heuristic algorithm.

(Bischoff and Ratcliff, 1995) presented two heuris-

tics for the CLP: the first one produces loading pat-

terns with a high degree of stability; the second one

considers a multi-drop situation in which a Last-In-

Solution of a Practical Pallet Building Problem with Visibility and Contiguity Constraints

329

First-Out constraint is imposed on the cargo. (Terno

et al., 2000) proposed the parallel generalized layer-

wise loading approach (PGL-approach) for the CLP.

The constraints they consider are: (i) weight capac-

ity; (ii) placement (some items cannot be inserted

over the others); (iii) splitting (items of the same type

should be loaded in a minimum number of contain-

ers); (iv) connectivity; and (v) stability. Using a com-

plex branch-and-bound algorithm, the authors show

a certain degree of competitiveness compared with

classical solutions reported in the literature. (Bort-

feldt and Gehring, 2001) proposed a hybrid genetic al-

gorithm to solve the CLP with a single container and a

strongly heterogeneous set of boxes, considering ori-

entation, stability, stacking, weight, and balance. The

results showed a better efficiency with more signif-

icant heterogeneity of the box sets. (Egeblad et al.,

2010) addressed the CLP for one container (in the

knapsack version), using irregular shaped items, and

taking a stability constraint into account. They per-

formed tests on randomly generated instances, and on

real-world instances deriving from a prominent Eu-

ropean furniture producer. (J

´

ozefowska et al., 2018)

study the CLP considering rotation, stackability, and

stability constraints. They considered a case study

arising from a household equipment factory. They

proposed a best fit heuristic based on the idea of wall-

building over available space.

The work that most resembles ours is the one by

(Alonso et al., 2016), who presented a real exam-

ple originating from a logistics company required to

load products into pallets (pallet building) and then

load the created pallets into trucks (truck loading),

by considering several practical constraints. For the

pallet building, they incorporated orientation, sup-

port, priority, and stackability constraints. Regard-

ing the truck loading, they adopted restrictions due

to priority among pallets, stability, and stackability.

They proposed a GRASP algorithm using a construc-

tive phase, a randomized strategy to diversify the so-

lutions, and an improvement phase. The efficiency

of their GRASP was analyzed by comparing it with

lower bounding procedures, showing good results.

The study was later extended by (Alonso et al., 2017)

and (Alonso et al., 2019), who focused on the devel-

opment of mathematical models for the case of mul-

tiple container loading, addressing a number of addi-

tional practical constraints such as vertical and hori-

zontal stability, multi-drop, and load balance.

4 SOLUTION ALGORITHMS

This section presents the 2-step heuristic that we de-

veloped to solve the PBP with visibility and contigu-

ity constraints, which we call Extreme Points Modi-

fied Heuristic (EPMH). EPMH produces feasible so-

lutions by dividing the problem into two parts. First,

we create layers to deal with individual items sepa-

rately. This phase forces the presence of packing, vis-

ibility, and contiguity constraints through a process

guided by an evaluation function. Second, the pal-

let generation step tries to minimize the quantity of

pallets using a greedy strategy. Next, we particularly

focus in the description of the first step (layers cre-

ation), as the second step (pallets creation) is based

on a quite standard algorithm.

4.1 Creating Layers

All 2D layers are created by taking into account only

the l

i

and w

i

dimensions of item i ∈ I. The following

concepts are related to the heuristic proposed.

Contiguity. Two items of the same type cannot be

placed far apart in a layer because of the contiguity

constraint. For this purpose, we establish the max-

imum euclidian distance that can separate the two

items without violating the constraint as follows.

Let ` be the smallest edge length among all items

in I. Let also G ⊆ I be a generic subset of items of

the same type packed into a layer. Then, two items

i, j ∈ G satisfy the contiguity constraint if the smallest

euclidian distance between the edges of i and the

edges of j is strictly lower than `. Roughly speaking,

in this way we guarantee that no other item can fit

between i and j. Therefore, the contiguity constraint

for a generic layer r is met if, for each group G

packed in r, any item in G meets the minimum

required euclidean distance from at least another item

in G, and there are no separated sub-groups of G (i.e.,

subgroups whose distance is ` or more).

Visibility. Similarly to what we stated for the conti-

guity, we say that a group is visible from the outside

if for at least one item in the group, the euclidean

distance between its edges and the borders of the

layer is strictly lower than `.

Item Positioning. To find the position of an item in

a layer, we use an adaptation of the Extreme Points

Heuristic (EPH) proposed by (Crainic et al., 2008).

Originally, EPH was described for 3D packings. As

we need to deal with just a 2D layer, we limit our de-

scription here to this simpler case. To this aim, let

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

330

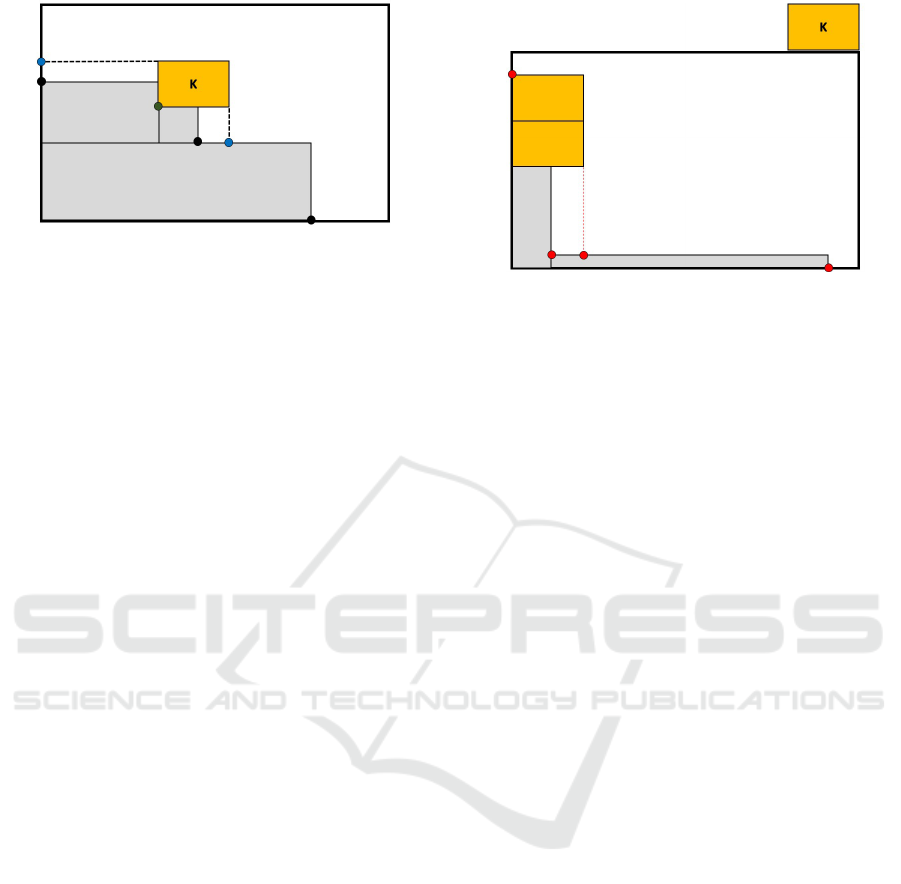

Figure 1: Extreme points: black and green points form the

current set E; the green point is chosen to pack item k (and

is then removed); blue points are the new extreme points

added to E after packing k.

us consider that the 2D layer under construction is

placed in the positive quadrant of the cartesian sys-

tem, with width parallel to the x-axis, length parallel

to the y-axis, and bottom-left corner located in the ori-

gin of the axes.

EPH works with the concept of extreme points.

An extreme point e is a point in the 2D space, where

an item k ∈ I can be packed by taking into account a

partial packing solution built so far. For the sake of

clarity, packing an item k in an extreme point e means

packing the bottom-left corner of k in e.

In EPH, the items are packed one at a time in the

layer, by considering a set E of available extreme

points. The set is initialized with the origin point

(0,0). Then, each time a new item is packed, the set is

updated by removing the point used for the packing of

the item, and possibly inserting new extreme points.

These new extreme points are obtained by computing

the projection of k over the partial packing solution

under construction, considering the two axes.

For the x-axis, EPH horizontally projects the top

edge of item k to its left, until the projection touches a

previously packed item or the left border of the layer

(i.e., the y-axis). This is the first extreme point that

is possibly created. For the y-axis, instead, EPH con-

siders the right edge of item k and vertically projects

it towards the bottom until the projection reaches a

previously packed item or the bottom border of the

layer. This is the second extreme point possibly cre-

ated. These two points are added to E if they were

not already included in it. Figure 1 depicts an exam-

ple with a set E formed by green and black points.

The green point is selected for the packing of item k

and is thus removed from E. The blue points are the

new extreme points added to E after the packing of k.

An extreme point e can be either feasible or infeasible

for the packing of the next item k, depending on the

fact that such packing meets all required constraints.

In addition to what we described so far, please also

note that, besides the projections from k, it is manda-

Figure 2: A case where the EPH generates only extreme

points that are infeasible for the PBP with visibility and con-

tiguity constraints. Packing the next item k is impossible, so

the current layer is closed and a new one is opened.

tory to verify all projections from i ∈ I that lie on k.

This step, that we name past projections, is needed to

find new extreme points not yet available. We execute

it right after having computed the projections from k.

The original EPH solves pure 2D packing prob-

lems, so we need to include a set of changes to be

able to solve the more complex PBP with visibility

and contiguity constraints. The first modification we

apply consists in increasing the search space inside a

layer. The EPH creates only two new extreme points

at a time, whereas visibility and contiguity constraints

narrow the search space. As a consequence, a layer

could be closed even when its occupation is low, be-

cause set E does not contain any feasible extreme

point. Figure 2 shows an example where this situa-

tion occurs, since none of the current feasible extreme

points fulfills the contiguity constraints.

To overcome this limitation, we included some

new extreme points, considering two cases: contigu-

ity and visibility. In the first case, the extreme points

are included around item k (the last item packed), to

allow the contiguity with the next items of the same

type. Basically, four new points are added: the k top-

left and bottom-right corners allow the top and right

connections, respectively, and the points on the left

and below k enable the left and bottom connections,

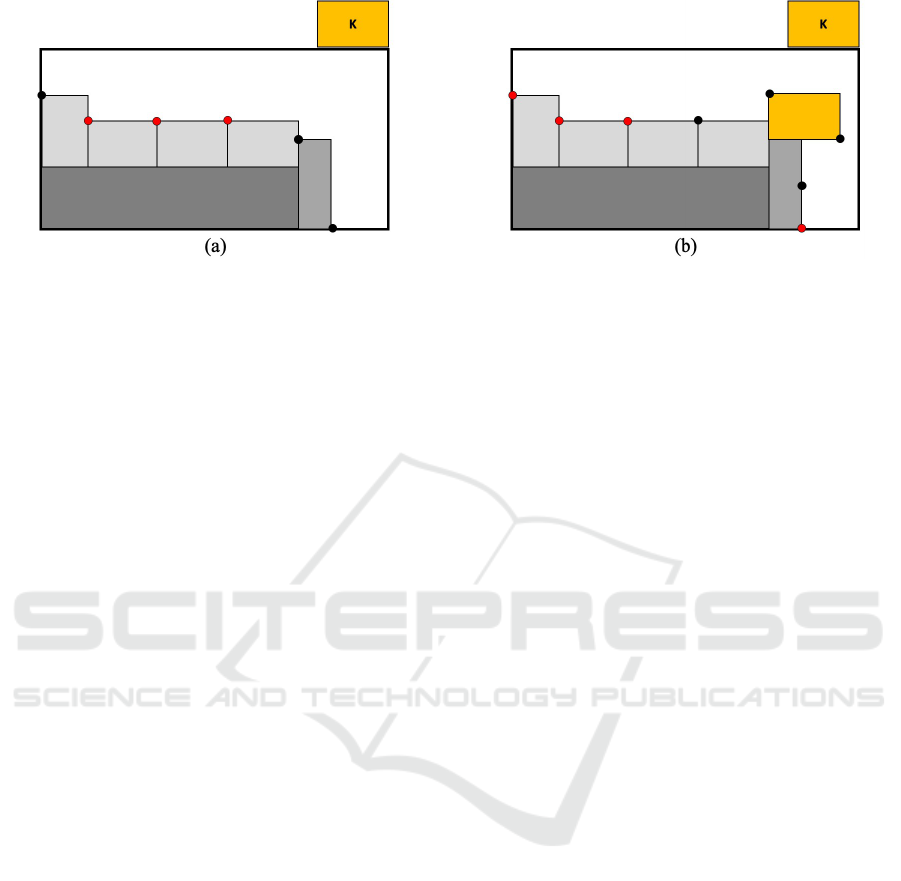

respectively. Figure 3 shows the new extreme points

for the contiguity case.

Extreme points regarding the visibility case are in-

cluded close to the top and right layer borders, when

item k has a different type from the previously packed

items, and there is no point in E that allows k to meet

the contiguity with the layer and the packing con-

straints. In this case, two new points are added: from

right to left relative to layer, we take the first feasible

point that meets the contiguity to the top layer border.

Also, from top to bottom relative to layer, we consider

the first feasible point that meets the contiguity to the

Solution of a Practical Pallet Building Problem with Visibility and Contiguity Constraints

331

Figure 3: New extreme points created for contiguity: after

packing k in the green point (which is then removed from

the current set E), four extreme points (represented in blue)

are added.

right layer border. Figure 4 shows the new extreme

points for this case.

The second modification is related to heuristic

efficiency. Current extreme points are directly linked

to the visibility and contiguity constraints. Note

that these points can be enabled according to item

k and its current item group in the partial solution.

Thus, we work with two extreme points sets: feasible

extreme points, E

f

, and infeasible extreme points,

E

i

, representing, respectively, points that meet or

do not meet the visibility and contiguity constraints

for item k. Therefore, before adding k to the partial

solution, we first update these two sets, and only after

this is done we check if k overlaps with previously

packed items. Note that these two sets are relative

to the current configuration and after the addition of

the new items infeasible points may become feasible

and viceversa. The benefit of using these sets is that

we avoid checking the overlapping constraint for all

extreme points, increasing the heuristic efficiency.

An example of sets E

f

and E

i

is provided in Figure 5.

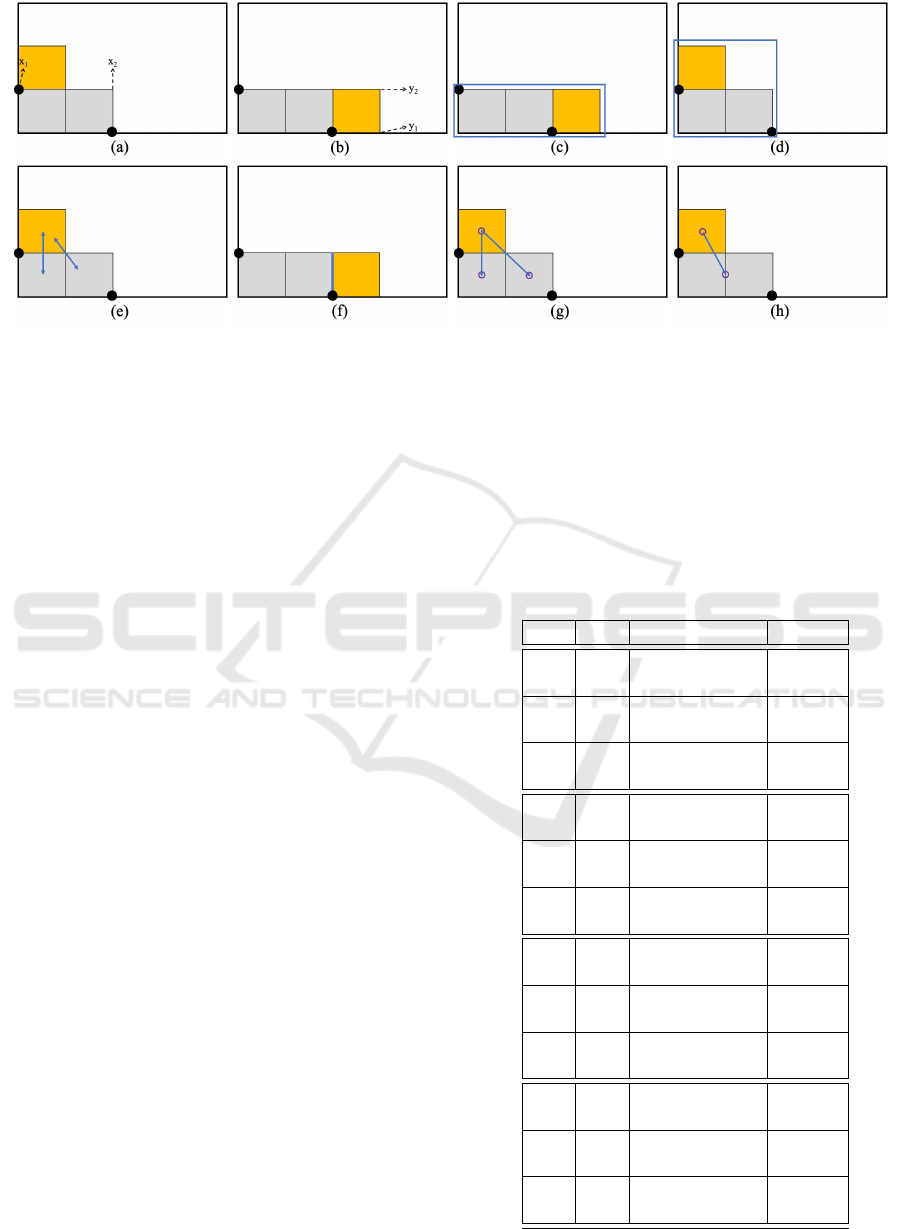

Evaluation Functions. Given a set E

f

for the next

item k that meets the packing constraints, we should

choose which point results in the best packing. To

this aim, we propose the following fitness evaluation

functions:

• LOWER X: finds the point that has the minimum

x value among all feasible points;

• LOWER Y: finds the point that has the minimum

y value among all feasible points;

• BOUNDING BOX: calculates the bounding box

area – minimum rectangle area that covers a set

of items – with k, and finds the point which mini-

mizes the area among all bounding boxes;

• BOUDING SQUARE: same as above but with

squares instead of boxes;

Figure 4: New extreme points created for visibility: pre-

vious extreme points that do not meet visibility and the

packing constraints are shown in red; new feasible extreme

points that meet these constraints are shown in blue.

• SIMPLE CONTACTS: calculates the number of

contacts – a contact between two items happens

when they meet the contiguity previously de-

scribed in this Section, i.e., when their distance

is lower than ` – with k, and finds the point which

maximizes this number;

• COMPLEX CONTACTS: similar to the previous

one, but the number of contacts is switched by

the contact length – the euclidian distance of edge

overlap between different items – among the items

that meet the contiguity with k. It finds the point

which maximizes this value;

• DISTANCE SUM: calculates the distance sum

among the center of gravity of each packed item

with the center of gravity of k, and finds the point

which minimizes this sum;

• CENTER OF GRAVITY: evaluates the distance

between the center of gravity of the partial pack-

ing and the center of gravity of k, and finds the

point that minimizes this distance.

Figure 6 shows a graphical example for each fitness

evaluation function proposed.

The fitness of a new item k is calculated from the

partial packing in the layer using a specific group of

items, formed by some or the whole set of their items.

To form these groups, we proposed the following

strategy: when k is the first item of a specific type in

the partial solution, the fitness is calculated consider-

ing the group formed by all items in the layer. When

there is at least one item of the same type of k, the

fitness is calculated by considering the group formed

by the items of this specific type.

Layer Creation and Classification. The main idea of

EPMH is to create as many single-item and single-

family layers as possible. This is because the residual

layers have to be inserted at the top of pallets, at most

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

332

Figure 5: Partial solutions and their feasible (black) and infeasible (red) extreme points for the next item k: representation of

the extreme points that meet the (a) boundary, and (b) contiguity constraints.

one residual layer per pallet, so their number should

be as small as possible. The layer generation that we

adopted follows this rationale as follows.

In the first step, we sort the family items by non-

increasing value of stackability. Within each fam-

ily, item types are sorted by non-increasing value of

height. Using this order, EPMH tries to generate

single-item layers by packing items one at a time ac-

cording to the concepts described before in this sec-

tion. If the packing obtained with a single item type

meets the fill-factor constraint but it is not enough to

fill up the layer yet, EPMH tries adding more items of

the same family to generate a single-family layer.

When the sum of all items of a specific family is

less than the required percentage to meet the fill factor

constraint, the remaining items are put in a residual

item list. A particular case occurs when the sum of

all items of some type has enough area to meet the fill

factor constraint, but the current solution found by the

packing heuristic creates a packing that does not meet

that constraint. In this case, the heuristic removes all

items of this layer, putting them in the residual item

list. At the end of the process, after all families have

been analyzed, the items of the residual list will be

packed in remaining layers, thus forming residual lay-

ers. The classification of a layer is made after it is

closed, analyzing its occupation, the families and the

item types that are included in it.

4.2 Creating Pallets

After all items have been packed into layers, we need

to put layers together into the minimum number of

pallets. To this aim, we propose a simple greedy

heuristic. The height of each layer is calculated as

the height of the highest item in the layer. Simi-

larly, the stackability of a layer is computed as the

maximum stackability value among the items in the

layer. Single-item, single-family and residual layers

are sorted according to non-increasing stackability,

breaking ties by non-increasing height, and this order

is used throughout the algorithm.

Since residual layers need to be packed in sepa-

rated pallets, the greedy heuristic starts by choosing

the first residual layer, if any, in the order, and using

it to initialize a pallet. Then, it fills the current pal-

let with single-item layers, one at a time in the order,

by respecting stackability and maximum height con-

straint. If the current pallet has still unused height but

no more single-item layer can enter it, the heuristic

attempts filling the pallet with single-family layers.

Also in this case, the layers are scanned according to

the above order. The process is repeated until no more

layer can enter the pallet. The process is repeated un-

til all layers are packed into pallets.

This greedy heuristic allows us to have a feasible

PBP solution in quick time. We used it as a basis for

evaluating our new EPMH under several fitness func-

tions as well as existing heuristic in the literature (that

do not consider contiguity and visibility constraints),

as shown in the next section.

5 COMPUTATIONAL RESULTS

In this section, we present the details of the instances

that we adopted for our tests and then show the com-

putational results that we achieved. All experiments

have been conducted on a PC Intel Core i5 Dual-Core

1.8GHz CPU, 8GB RAM, macOS Catalina Operat-

ing System. The algorithms have been implemented

in Java (Oracle

R

JDK 8). Due to its deterministic na-

ture, each heuristic was run only once. Because of

the high number of instances addressed, in the fol-

lowing we mostly report average results for groups of

instances.

Solution of a Practical Pallet Building Problem with Visibility and Contiguity Constraints

333

Figure 6: Fitness evaluation functions of feasible extreme points, considering a new yellow item: (a) Lower X; (b) Lower Y;

(c) Bounding Box; (d) Bounding Square; (e) Simple Contacts; (f) Complex Contacts; (g) Distance Sum; (h) Center of Gravity.

5.1 Instances

The results were obtained from a real-world database

provided by an Italian company. We randomly se-

lected 24 instances, that are separated into 4 groups,

each containing 6 instances, characterized by differ-

ent intervals in the number of distinct items: from 17

to 32; from 33 to 48; from 49 to 64; and from 65 to

80. The average number of items for each instance

is approximately 690. Table 1 summarizes the details

of the instances, reporting the instance id number, the

number of items, the number of families, and the max-

imum number of items per type. For all instances, the

fill factor was set to 75%, and the container dimen-

sions were set to 1500, 1250, and 1050 for height,

width, and length, respectively. We tested a number

of configuration, including rotation of 90 degrees of

the items allowed or not.

5.2 Evaluation

We solved the proposed instances with three algo-

rithms. The first one is the basic EPH described in

Section 4, and the second is the constructive heuris-

tic based on skylines and proposed by (Leung et al.,

2011), named SLH in the following. These two meth-

ods are taken from the literature and do not take into

account contiguity and visibility of the items. The

third method is the newly-proposed EPMH method,

attempted with the different evaluation functions dis-

cussed in the previous section. All such methods are

adopted to generate 2D layers, which are then put to-

gether into pallets by the greedy heuristic of Section

4.2. In this way, we can evaluate all methods in a

consistent way and understand which one is more ef-

fective for the layer generation.

The computational results that we obtained are

summarized in Table 2. Each row in the table pro-

vides average results for a given algorithm on the

24 attempted instances. We tested the two heuristics

from the literature, namely EPH and SLH, with (R)

and without (-) rotation. We then tested EPMH with 8

different evaluation functions, attempting 4 different

Table 1: Instances settings.

ID n N. of families Max b

i

01

20

4 208

02 12 122

03

23

4 70

04 13 35

05

29

6 60

06 15 390

07

34

7 142

08 17 158

09

37

6 63

10 17 95

11

48

9 123

12 18 182

13

59

10 53

14 19 87

15

64

11 57

16 19 64

17

61

10 26

18 19 166

19

75

16 62

20 20 79

21

79

17 79

22 21 128

23

66

13 70

24 19 98

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

334

Table 2: Computational results (average results on 24 instances on each line).

Algorithm Constraint

N. of

pallets

N. of

layers

2D fill

factor

Single-

item

layers

Single-

family

layers

Residual

layers

Max. percent.

of residual

layers

N. of

non-contiguous

items

N. of

non-contiguous

layers

N. of

non-visible

items

N. of

non-visible

layers

Time(secs)

.

EPH

R 24.75 43.46 0.82 14.46 9.13 19.88 76.36% 12.17 10.13 4.17 3.25 0.023

- 25.58 43.04 0.82 12.83 8.50 21.71 74.07% 4.75 3.88 5.42 4.33 0.026

SLH

R 22.83 42.17 0.84 16.75 7.17 18.25 73.08% 4.38 3.58 4.75 3.58 0.009

- 27.58 45.25 0.78 14.79 6.00 24.46 77.19% 5.67 4.54 7.00 5.17 0.011

EPMH –

LOWER X

R/B 22.83 42.00 0.84 14.42 9.38 18.21 73.08% 0 0 0 0 0.161

R/- 22.79 42.04 0.84 14.38 9.46 18.21 71.70% 0 0 2.92 2.42 0.068

-/B 25.88 43.29 0.81 12.83 8.46 22.00 74.07% 0 0 0 0 0.102

-/- 25.58 43.17 0.82 12.83 8.67 21.67 72.22% 0 0 3.71 2.67 0.068

EPMH –

LOWER Y

R/B 23.00 41.88 0.85 14.33 8.88 18.67 73.08% 0 0 0 0 0.137

R/- 22.83 41.75 0.85 14.33 9.00 18.42 73.08% 0 0 4.42 3.33 0.079

-/B 26.17 43.25 0.81 12.83 7.96 22.46 75.93% 0 0 0 0 0.108

-/- 25.96 43.13 0.82 12.83 8.21 22.08 74.07% 0 0 4.67 3.46 0.077

EPMH –

BOUNDING

BOX

R/B 14.46 41.00 0.86 21.79 11.58 7.63 66.67% 0 0 0 0 0.104

R/- 14.00 40.83 0.86 21.79 12.00 7.04 66.67% 0 0 6.08 3.96 0.070

-/B 26.17 43.25 0.81 12.83 7.79 22.63 75.47% 0 0 0 0 0.112

-/- 25.67 42.92 0.82 12.83 8.04 22.04 75.93% 0 0 5.38 3.79 0.068

EPMH –

BOUNDING

SQUARE

R/B 23.00 42.38 0.83 14.00 10.29 18.08 70.00% 0 0 0 0 0.110

R/- 23.50 42.42 0.83 14.04 9.63 18.75 72.55% 0 0 5.13 3.83 0.081

-/B 25.88 43.17 0.81 12.83 8.17 22.17 77.78% 0 0 0 0 0.106

-/- 25.96 43.08 0.82 12.83 7.92 22.33 74.07% 0 0 5.08 3.54 0.067

EPMH –

SIMPLE

CONTACTS

R/B 23.13 42.21 0.84 14.21 9.46 18.54 73.08% 0 0 0 0 0.110

R/- 23.33 42.29 0.84 14.21 9.29 18.79 74.51% 0 0 5.54 4.04 0.077

-/B 26.13 43.38 0.81 12.83 8.13 22.42 75.93% 0 0 0 0 0.119

-/- 26.04 43.38 0.81 12.83 8.38 22.17 75.93% 0 0 4.67 3.38 0.126

EPMH –

COMPLEX

CONTACTS

R/B 19.75 42.08 0.84 16.58 11.13 14.38 61.46% 0 0 0 0 0.110

R/- 20.50 41.88 0.84 16.58 9.96 15.33 62.50% 0 0 6.58 4.54 0.086

-/B 26.33 43.29 0.82 12.83 7.83 22.63 78.18% 0 0 0 0 0.116

-/- 26.21 43.29 0.82 12.83 8.08 22.38 75.93% 0 0 6.04 4.21 0.076

EPMH –

CENTER OF

GRAVITY

R/B 23.08 42.46 0.83 14.00 10.21 18.25 64.71% 0 0 0 0 0.129

R/- 23.88 42.29 0.83 14.00 8.88 19.42 71.15% 0 0 6.75 4.67 0.080

-/B 26.38 43.33 0.81 12.88 7.63 22.83 75.93% 0 0 0 0 0.100

-/- 26.67 43.17 0.82 12.88 7.33 22.96 75.93% 0 0 6.63 4.67 0.068

EPMH –

DISTANCE

SUM

R/B 23.17 42.38 0.83 14.04 10.04 18.29 66.67% 0 0 0 0 0.122

R/- 23.71 42.25 0.84 14.04 9.29 18.92 71.15% 0 0 6.88 4.67 0.080

-/B 26.42 43.42 0.81 12.88 7.79 22.75 76.36% 0 0 0 0 0.125

-/- 26.50 43.25 0.81 12.88 7.25 23.13 75.93% 0 0 6.79 4.46 0.070

Solution of a Practical Pallet Building Problem with Visibility and Contiguity Constraints

335

configurations: R/B stands for 90 degrees rotation al-

lowed and visibility constraint imposed; R/- stands

for rotation allowed and no visibility constraint im-

posed; -/B stands for no rotation allowed and visibil-

ity constraint imposed; and -/- stands for no rotation-

allowed but also no visibility constraint imposed. In

all cases, the EPMH meets the contiguity constraint

among items in the same group. In this way, we pro-

vide information on 240 solutions obtained, 10 for

each of the 24 instances.

The information on algorithm and constraint con-

figuration is contained in the first two columns. In the

six successive columns, we report, respectively, the

total number of pallets and layers created in the solu-

tion, the average fill factor considering the 2D space

of all layers, as well as the average number of single-

item, single-family and residual layers. Then we re-

port, in five additional columns, the maximum per-

centage of residual layers found among the instances

(worst case result), the average number of items not

satisfying the contiguity or the visibility constraint,

the average number of layers for which at least an

item does not meet the contiguity or the visibility con-

straint. The last column reports the computational

time in seconds. To facilitate the analysis of the re-

sults, we highlight in bold the best average values for

each column and constraint configuration.

Let us focus first on the performance of EPH and

SLH. From Table 2, we can notice that disregarding

rotation of the items has a considerable effect in the

solution cost, with an important increase in the num-

ber of single-family and single-item layers, as well as

a decrease in the number of residual layers. Between

these two algorithms, SLH has a slightly better per-

formance. This happens because the skyline structure

is an efficient structure that allows one to analyze only

a small part of the search space. However, this heuris-

tic has also the disadvantage of forming empty holes

depending on the sequence of the input items. We can

also notice that the average 2D fill factor achieved is

quite stable around 80%.

Now, let us consider the results obtained by the 8

attempted EPMH configurations. Also in this case,

rotation has a relevant impact on the solution cost. As

regards to the visibility constraint, we can notice a

slight difference in the number of layers, considering

both meeting rotation constraint and not. Concerning

the runtime, the visibility constraint has a more signif-

icant influence than the rotation constraint. Compar-

ing the results obtained by the proposed fitness eval-

uation functions, the Bounding Box function found

the best average results, at least for the configurations

R/B and R/-. The best average results for the con-

figurations -/B and -/- were instead achieved by the

Figure 7: Layers for the PBP instance 2, formed by 9 single-

item layers (layer border in blue), 1 single-family layer

(layer border in gray), and 6 residual layers (layer border

in red). Solution obtained by using the Bounding Box fit-

ness evaluation function.

Lower X function. For what concerns the number of

residual layers, the values found by the EPMH with

Bounding Box were considerably smaller than those

obtained with other functions. All computational ef-

forts were very low, always requiring less than 0.2

second on average. This is a very important detail for

future research as we can expect to create more com-

plex algorithms, maybe based on iterated executions

of the proposed heuristics, without incurring in large

computational efforts.

An example of a solution obtained for instance 2 is

provided in Figure 7. We can notice 9 single-item lay-

ers, 1 single-family layer and 6 residual layers. The

layers sum up to a total of 9 pallets.

6 CONCLUSIONS

In this paper, we studied a pallet building problem

with item rotations and practical constraints involving

visibility and contiguity. We proposed a 2-step con-

structive heuristic that enlarges the well-known ex-

treme points heuristic from the literature. In a first

step, we generate 2D layers by considering a larger

set of extreme points (candidate locations for pack-

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

336

ing) that are useful to model contiguity and visibility

requirements. In the second step, we used the cre-

ated 2D layers to build 3D pallets by using a sim-

ple greedy strategy. Extensive computational exper-

iments on real-world instances proved the effective-

ness of the proposed heuristic.

To evaluate the extreme points, we proposed sev-

eral fitness evaluation functions, and found that the

one based on the concept of Bounding Box gave bet-

ter results than the other ones on average. We also

analyzed the influence of some constraints (e.g., rota-

tion and visibility) when tailoring our heuristic to ba-

sic 2D packing heuristics from the literature, gaining

interesting insights in the difficulty of the real-world

instances that we tested.

As future work, we intend to develop metaheuris-

tic algorithms to try to enhance the quality of the solu-

tions that we generated so far. We also intend to pro-

pose formal mathematical models to express the con-

cept of contiguity and visibility of items, thus filling a

gap in the existing literature. We are also interested in

studying a more complex problem that joins together

the pallet building problem with the vehicle routing

problem, so as to consider the location of pallets into

trucks and their delivery to the clients that required

them. In this case, we should extend the concept of

family, not only relying on the geometric characteris-

tics of the items, but adding new criteria of separation,

in order to help both problems (packing and delivery)

to increase the quality of the final optimization.

ACKNOWLEDGEMENTS

We thank the University of Parma and the University

of Modena and Reggio Emilia (Italy) for the financial

support to this work.

REFERENCES

Alonso, M., Alvarez-Valdes, R., Iori, M., and Parre

˜

no,

F. (2019). Mathematical models for multi container

loading problems with practical constraints. Comput-

ers & Industrial Engineering, pages 722–733.

Alonso, M., Alvarez-Valdes, R., Iori, M., Parre

˜

no, F., and

Tamarit, J. (2017). Mathematical models for multi

container loading problems. OMEGA 66, pages 106–

117.

Alonso, M., Alvarez-Valdes, R., Parre

˜

no, F., and Tamarit, J.

(2016). Algorithms for pallet building and truck load-

ing in an interdepot transportation problem. Mathe-

matical Problems in Engineering, page 11.

Alvarez-Valdes, R., Parre

˜

no, F., and Tamarit, J. (2008). Re-

active GRASP for the strip-packing problem. Com-

puters & Operations Research, 35:1065–1083.

Bischoff, E. and Ratcliff, M. (1995). Issues in the devel-

opment of approaches to container loading. Omega,

23:377–390.

Bortfeldt, A. and Gehring, H. (2001). A hybrid genetic al-

gorithm for the container loading problem. European

Journal of Operational Research, 131:143–161.

Bortfeldt, A. and W

¨

ascher, G. (2013). Constraints in con-

tainer loading – a state-of-the-art review. European

Journal of Operational Research, 229:1–20.

Burke, E., Kendall, G., and Whitwell, G. (2004). A New

Placement Heuristic for the Orthogonal Stock-Cutting

Problem. Operations Research, 52:655–671.

Chazelle, B. (1983). The Bottomn-Left Bin-Packing

Heuristic: An Efficient Implementation. IEEE Trans-

actions on Computers, C-32:697–707.

Crainic, T., Perboli, G., and Tadei, R. (2008). Extreme

point-based heuristics for three-dimensional bin pack-

ing. INFORMS J. on Computing, 20:368–384.

Crainic, T., Perboli, G., and Tadei, R. (2012). Recent Ad-

vances in Multi-Dimensional Packing Problems. In

Volosencu, C., editor, New Technologies – Trends, In-

novations and Research. IntechOpen, Rijeka.

Delorme, M., Iori, M., and Martello, S. (2017). Logic

based benders’ decomposition for orthogonal stock

cutting problems. Computers & Operations Research,

78:290–298.

Egeblad, J., Garavelli, C., Lisi, S., and Pisinger, D. (2010).

Heuristics for container loading of furniture. Euro-

pean Journal of Operational Research, 200:881–892.

Fekete, S. and Schepers, J. (1997). A new exact algorithm

for general orthogonal d-dimensional knapsack prob-

lems. In Algorithms — ESA ’97, pages 144–156.

Haessler, R. and Talbot, F. (1990). Load planning for ship-

ments of low density products. European Journal of

Operational Research, 44:289–299.

Hopper, E. and Turton, B. (1998). Application of Genetic

Algorithms to Packing Problems – A Review. In Soft

Computing in Engineering Design and Manufactur-

ing, pages 279–288.

Imahori, S. and Yagiura, M. (2010). The best-fit heuristic

for the rectangular strip packing problem: An efficient

implementation and the worst-case approximation ra-

tio. Computers & Operations Research, 37:325–333.

Iori, M., Lima, V., Martello, S., Miyazawa, F., and Monaci,

M. (2019). Two-dimensional cutting and packing:

Problems and solution techniques. Technical report,

University of Bologna.

Iori, M. and Martello, S. (2010). Routing problems with

loading constraints. TOP, 18:4–27.

Iori, M. and Martello, S. (2013). An annotated bibliography

of combined routing and loading problems. Yugoslav

Journal of Operations Research, 23:311–326.

J

´

ozefowska, J., Pawlak, G., Pesch, E., Morze, M., and

Kowalski, D. (2018). Fast truck-packing of 3d boxes.

Engineering Management in Production and Services,

10:29–40.

Leung, S., Zhang, D., and Sim, K. (2011). A two-stage

intelligent search algorithm for the two-dimensional

strip packing problem. European Journal of Opera-

tional Research, 215:57–69.

Solution of a Practical Pallet Building Problem with Visibility and Contiguity Constraints

337

Lodi, A., Martello, S., Monaci, M., and Vigo, D. (2014).

Two-Dimensional Bin Packing Problems, pages 107–

129. John Wiley & Sons, Ltd.

Martello, S., Pisinger, D., and Vigo, D. (2000). The three-

dimensional bin packing problem. Operations Re-

search, 48:256–267.

Scheithauer, G. (2018). Introduction to Cutting and Packing

Optimization. Springer International Publishing.

Scheithauer, G. and Sommerweiβ, U. (1998). 4-block

heuristic for the rectangle packing problem. European

Journal of Operational Research, 108(3):509–526.

Scheithauer, G. and Terno, J. (1996). The G4-Heuristic for

the Pallet Loading Problem. The Journal of the Oper-

ational Research Society, 47:511–522.

Silva, E., Oliveira, J., and W

¨

ascher, G. (2016). The pallet

loading problem: a review of solution methods and

computational experiments. International Transac-

tions in Operational Research, 23:147–172.

Terno, J., Scheithauer, G., Sommerweiβ, U., and Riehme,

J. (2000). An efficient approach for the multi-pallet

loading problem. European Journal of Operational

Research, 123:372–381.

W

¨

ascher, G., Hauβner, H., and Schumann, H. (2007).

An improved typology of cutting and packing prob-

lems. European Journal of Operational Research,

183:1109–1130.

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

338