Predicting the Tear Strength of Woven Fabrics Via Automated Machine

Learning: An Application of the CRISP-DM Methodology

Rui Ribeiro

1,2 a

, Andr

´

e Pilastri

1 b

, Carla Moura

3

, Filipe Rodrigues

4

, Rita Rocha

4

and Paulo Cortez

2 c

1

EPMQ - IT Engineering Maturity and Quality Lab, CCG ZGDV Institute, Guimar

˜

aes, Portugal

2

ALGORITMI Centre, Dep. Information Systems, University of Minho, Guimar

˜

aes, Portugal

3

Riopele, Pousada de Saramagos, Portugal

4

CITEVE - Centro Tecnol

´

ogico das Ind

´

ustrias T

ˆ

extil e do Vestu

´

ario de Portugal, Famalic

˜

ao, Portugal

Keywords:

Fabrics, Tear Strength, Industry 4.0, Regression, Automated Machine Learning.

Abstract:

Textile and clothing is an important industry that is currently being transformed by the adoption of the In-

dustry 4.0 concept. In this paper, we use the CRoss-Industry Standard Process for Data Mining (CRISP-DM)

methodology to model the textile testing process. Real-world data were collected from a Portuguese textile

company. Predicting the outcome of a given textile test is beneficial to the company because it can reduce

the number of physical samples that are needed to be produced when designing new fabrics. In particular, we

target two important textile regression tasks: the tear strength in warp and weft directions. To better focus on

feature engineering and data transformations, we adopt an Automated Machine Learning (AutoML) during the

modeling stage of the CRISP-DM. Several iterations of the CRISP-DM methodology were employed, using

different data preprocessing procedures (e.g., removal of outliers). The best predictive models were achieved

after 2 (for warp) and 3 (for weft) CRISP-DM iterations.

1 INTRODUCTION

The textile and clothing industry is one of the largest

industrial sectors in the world (Shishoo, 2012). How-

ever, the textile market is highly competitive and there

is a pressure to improve production processes and re-

duce costs. Under this context, this industry can be

enhanced by adopting the Industry 4.0 concept, which

assumes the digitalization of the productive processes

(e.g., digital sensors with connectivity capabilities)

and a stronger usage of Information Technology (Lasi

et al., 2014).

In order to create the final textile product, the raw

materials undergo a series of processes, where fibers

are combined into yarns and the combination of these

yarns creates a fabric, which receives a series of treat-

ments, creating the final product that is delivered to

costumers. During this procedure, a large amount of

data is created and stored, such as the properties of

each yarn (e.g., color, thickness), the configuration

a

https://orcid.org/0000-0001-8078-4148

b

https://orcid.org/0000-0002-4380-3220

c

https://orcid.org/0000-0002-7991-2090

of each machine used in the creation process (e.g.,

spinning) (Mozafary and Payvandy, 2014) and the re-

sults of the fabric quality tests. All these data can be

processed by Data Mining (DM) and Machine Learn-

ing (ML) methods, allowing the discovery of valuable

knowledge in order to improve the textile manufactur-

ing process (Yildirim et al., 2018).

This paper presents an implementation of the

CRoss-Industry Standard Process for DM (CRISP-

DM) methodology (Wirth and Hipp, 2000), based

on Automated ML (AutoML), to predict the results

of tear strength test (warp and weft directions) on

fabrics. The data were collected from a Portuguese

textile company, aiming to reduce the number of at-

tempts required to produce a fabric.

2 BACKGROUND

2.1 Fabric Testing

Every time a textile company creates a new woven

fabric, it will typically execute a series a tests. These

548

Ribeiro, R., Pilastri, A., Moura, C., Rodrigues, F., Rocha, R. and Cortez, P.

Predicting the Tear Strength of Woven Fabrics Via Automated Machine Learning: An Application of the CRISP-DM Methodology.

DOI: 10.5220/0009411205480555

In Proceedings of the 22nd International Conference on Enterprise Information Systems (ICEIS 2020) - Volume 1, pages 548-555

ISBN: 978-989-758-423-7

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

tests have a crucial role in evaluating the product qual-

ity (Hu, 2008). The International Organization for

Standardization (ISO) has launched several standards

related to fabric testing for a whole series of tests that

examine the physical, mechanical and chemical prop-

erties of fabrics. Some tests can be made to test two

different aspects, such as the tensile strength in warp

and weft direction (Dimitrovski et al., 2004) or one

aspect, such as pilling (Beltran et al., 2006).

Each time a new fabric is created, the tests are

made using a sample that the company must produce.

The sample is then analyzed and several results are

possible: the sample can pass all the tests and met

the requirements, thus the fabric is read for massive

production; the sample did not met the client require-

ments, so the developer must start again the fabric de-

sign and change some of the characteristics; or the

fabric did not pass the standard tests and it must be

verified if the flaw is in conception phase or in the pro-

duction phase. This process can be repeated several

times until all the requirements are made, resulting

in additional time and costs. It should be noted that

the loom that manufactures the fabric sample needs

to produce a minimum of several meters of a fabric in

each design attempt. Thus, the dematerialization of

this process, by means of a DM predictive modeling,

can potentially reduce the number of physical fabric

sample productions, saving time and costs.

2.2 CRISP-DM and AutoML

The CRISP-DM is a open analytic process stan-

dard for increasing the success of DM projects.

The methodology is based on a hierarchical process

model, described at four levels of abstraction: phase,

generic task, specialized task, and process instance

(Wirth and Hipp, 2000). Overall, CRISP-DM pro-

vides an overview to the life cycle of a data mining

project, with iterations of several phase sequences,

as shown in Figure 1. The iterative execution of the

methodology also assumes an interaction between the

business experts and the DM analysts.

During the Modeling phase of CRISP-DM, Ma-

chine Learning (ML) algorithms are often used to ex-

tract valuable knowledge from the data. Due to the

relevance of ML, several algorithms have been pro-

posed is the last decades, each one presenting its ad-

vantages. Examples of popular regression algorithms

include (Witten et al., 2016): Regression Trees, Lin-

ear Regression, Generalized Linear Models, Support

Vector Machines, Ensembles (including Boosting and

Random Forest) and Neural Networks.

In practice, the ML model creation process tends

to involve a highly iterative exploratory process. In

Figure 1: Phases of the CRISP-DM Model, Adapted from

(Wirth and Hipp, 2000).

this sense, an effective ML modeling process requires

solid knowledge and understanding of the different

types of ML algorithms and their hyperparameter ad-

justment (Maher and Sakr, 2019). In effect, the selec-

tion of the best ML algorithm is often performed us-

ing a trial-and-error procedure, which can be guided

by the analyst expert knowledge or heuristics (Gibert

et al., 2018). Such iterative and explorative nature of

the modeling process is commonly tedious and time-

consuming. Moreover, the quality of the ML results is

also dependent of data engineering aspects (e.g., fea-

ture selection, outlier detection) that are typically per-

formed on the Data Understanding and Data Prepara-

tion CRISP-DM stages (Gibert et al., 2016).

In this work, we use Automated Machine Learn-

ing (AutoML) (Feurer et al., 2015) during the Mod-

eling stage of CRISP-DM. AutoML systems were

specifically developed to automate this challenging

and time-consuming process (Le et al., 2019). There-

fore, AutoML allows the DM analysts to focus their

effort in applying their expertise in other important

components, such as feature and data engineering,

model validation and deployment.

2.3 Data Mining Applied to Fabrics

Textile fabric manufacturing generates large amounts

of data. DM techniques started being used in textile

engineering during recent years, aiming to solve the

difficulties of classical statistics in modeling complex

data relationships. Most DM applications to the tex-

tile industry involve classification tasks, such as qual-

ity control (e.g., textile image inspection) (Yildirim

et al., 2018). The application of DM to test areas is

more scarce, including the prediction of tear strength.

The tear strength is usually a measure of the force

(tensile stress) required to propagate a tear and is of-

ten used to give a direct assessment of the service-

ability of the fabric (Teli et al., 2008). Tear strength

Predicting the Tear Strength of Woven Fabrics Via Automated Machine Learning: An Application of the CRISP-DM Methodology

549

can be tested in both warp and weft directions and it

is considered one of the most important performance

attributes of woven textiles (Malik et al., 2011). Most

of the tear strength prediction studies employ linear

models, which are rather rigid and thus fail when non-

linear relationships exist among the data attributes. In

(Kotb, 2009), linear regression models were used to

predict the fabric tearing force based on 9 identified

input features, concluding that tearing force is largely

affected by the type and number of weft yarns, weft

density, ground structure, and ground yarns, while the

shape of the pile and the change in pile designation

have minor effects. In another study, the linear regres-

sion was also used to predict the fabric tear strength in

warp and weft direction for woven wool fabrics, ob-

taining a Pearson correlation between the actual and

the predicted strength for warp and weft of 0.976 and

0.975, respectively (Malik et al., 2011). The same lin-

ear regression model was used in (Eltayib et al., 2016)

to predict the relationship between fabric tear strength

and other independent variables, such as yarn ten-

sile strength, yarn count and fabric linear density. In

(Zeydan, 2010), a flexible nonlinear model, based on

an Evolutionary Artificial Neural Network, was pro-

posed to predict the tensile strength in a woven fabric,

outperforming a linear regression model.

In this paper, we use recent data, collected by a

Portuguese textile company, aiming to predict the tear

strength test, at both warp and weft directions, of fab-

rics. Within our knowledge, this is the first textile

industry study that employed an AutoML procedure,

which automatically tested five families of flexible

regression algorithms during the Modeling stage of

CRISP-DM. Such an automatic selection of the best

ML method allowed us to perform more quickly dif-

ferent CRISP-DM iterations (described in Sections

3.2, 3.3 and 3.4), after obtaining feedback from the

textile company and aiming to explore different data

and feature engineering approaches.

3 MATERIALS AND METHODS

In this paper, we use recent data, collected by a Por-

tuguese textile company, aiming to predict the tear

strength test, at both warp and weft directions, of fab-

rics. This Portuguese textile company creates and

produces fabrics for fashion and clothing collections

from diverse customers. The current fabric design is

based on the designer experience and intuition and

several trial-and-error fabric sample production ex-

periments. When designing new fabrics, in order to

meet the requirements of the client, the company pro-

duces several small sample attempts. In each attempt,

several laboratory tests are used to verify if the fabric

complies with quality goals. If this sample is not ap-

proved, the design process must be repeated, which is

translated into more time and costs for the company.

The fabric design process generates data that is related

to the several components of the fabric, as well as the

quality test results.

Within our knowledge, this is the first textile in-

dustry study that employed an AutoML procedure,

which automatically tested five families of flexible

regression algorithms during the Modeling stage of

CRISP-DM. Such an automatic selection of the best

ML method allowed us to perform more quickly dif-

ferent CRISP-DM iterations (described in Sections

3.2, 3.3 and 3.4), after obtaining feedback from the

textile company and aiming to explore different data

and feature engineering approaches.

3.1 Computational Environment

All executed experiments were conducted in two dif-

ferent open source computational environments: the

R statistical tool and its rminer package, that facil-

itates the use of DM techniques ML result analysis

(Cortez, 2010); and H2O, which implements an easy

to use AutoML algorithm (Landry et al., 2018). The

AutoML was configured to automatically select the

regression model and its hyperparameters based on

the best Mean Absolute Error (MAE) over a valida-

tion set, using a 10-fold cross-validation that is ap-

plied over the whole training data. A total of five

different regression families were automatically com-

pared by the AutoML. These include three individ-

ual base learners, namely Generalized Linear Models

(GLM), Gradient Boosting Machines (GBM) and dis-

tributed Random Forests (XRF), and two stacking en-

sembles, one using all trained models (Stacking All)

and other using just the best model per ML base algo-

rithm (Stacking Best).

3.2 First CRISP-DM Iteration

In this iteration, we performed the first five phases of

the CRISP-DM, Business Understanding to Evalua-

tion, aiming to predict the two fabric tear strength tar-

gets (warp and weft).

3.2.1 Business Understanding

The textile company expressed the need to reduce the

number of attempts that were necessary to produce a

fabric sample. The two fabric tear strength numeric

attributes (warp and weft directions) were also iden-

tified as relevant prediction targets, thus setting two

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

550

regression tasks. We also selected the computational

tools (R and H2O), as detailed in Section 3.1.

3.2.2 Data Understanding

First, we analyzed the textile company two main fab-

ric data sources: the Enterprise Resource Planning

(ERP), which included the 88,653 fabric main data

records, and the laboratory testing database, which

contained the fabric quality tests performed between

February 2012 to March 2019. After merging the two

data sources, the resulting dataset had 12,088 exam-

ples for the warp test and 12,143 for weft. Table 1

summarizes the initial set of input attributes, as sug-

gested by the textile company. Most attributes are nu-

meric and the exceptions are the type of fabric and

yarn code. The last 5 rows are related with yarn at-

tributes. We note that the each fabric can include sev-

eral types of yarns, which is a relevant issue that is

handled in Section 3.2.3. Figure 2 shows the box plot

distribution of the fabric weft and warp tear strength.

Figure 2: Box Plot of the Test Targets Used in First CRISP-

DM Iteration.

3.2.3 Data Preparation

A Data Warehouse system was implemented, in

which an Extraction, Transform, Load (ETL) pro-

cess was used to merge the ERP and laboratory test

databases and preprocessing some data records. The

preprocessing included the removal of fabric records

with missing components (e.g., with not registered

yarns). Also, in some cases it was detected that the

same fabric had different quality test values, related

with repeated tests conducted at different fabric pro-

duction stages. In order to have a single test value

per fabric, the distinct test values for the same fabric

were averaged. The resulting preprocessed data in-

cluded 8,453 observations for the warp test and 8,423

examples for the weft tear strength.

Each fabric can include several types of yarns. In

this work, we propose a novel input combination of

features in which we include the sequence of all pos-

sible yarns (up to 9 in our dataset), for both warp

and weft. Since each yarn is represented by 5 fea-

tures (Table 1), the regression models are fed with

12+9×5×2 (warp and weft)=102 input variables. A

zero padding (i.e., addition of zero values to missing

elements) was performed on all fabrics that had less

than 18 yarn codes. Finally, before feeding the data to

the ML algorithms, the numeric input attributes were

standardized to a zero mean and one standard devi-

ation, while the nominal variables were transformed

using the one-hot binary encoding, which sets one bi-

nary variable per possible level.

3.2.4 Modeling

To evaluate the models, an external holdout split was

executed, in which the data was randomly divided into

training (75%) and test (25%) data. The quality of the

predictions was measured using (Cortez, 2010; Wit-

ten et al., 2016): the Mean Absolute Error (MAE),

Adjusted R2 (Adj. R2) and classification Tolerance.

For MAE, the lower the values, the better are the pre-

dictions. Regarding Adj. R2 and Tolerance, higher

values indicate better predictions. Adj. R2 is often

used in multiple linear regression and it ranges from

0 to 1. The Tolerance value is based on the REC anal-

ysis and it measures the percentage of correctly clas-

sified examples when assuming a fixed absolute er-

ror tolerance (Bi and Bennett, 2003). In this paper,

three tolerance values were set: 5%, 10% and 20%.

We note that the percentage of error tolerance is com-

puted by considering the range of the true values.

Using only training data, the AutoML procedure

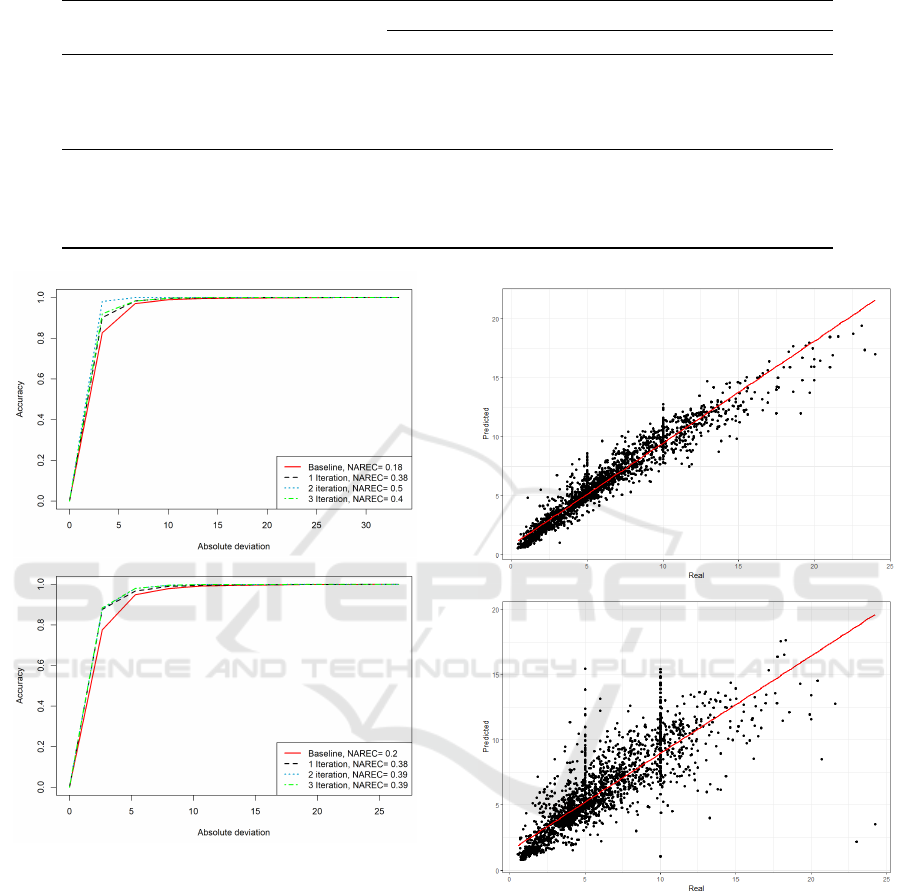

was applied, as described in Section 3.1. Figure 3

shows the REC curves and respective MAE values,

computed using validation data, for the best five ML

algorithms that were obtained when using the internal

10-fold procedure for the warp and weft tear strength

predictions. The REC curve shows the error tolerance

on the x-axis versus the percentage of correctly pre-

dicted points within the tolerance on the y-axis. In all

AutoML experiments conducted in this study, and for

both targets, the selected ML algorithm was a stacked

ensemble that used all trained models (Stacking All).

3.2.5 Evaluation

The obtained test set predictions are shown in Fig-

ure 4, in terms of the predicted (y-axis) versus real (x-

axis) values. The plots show an interesting initial fit,

with most points being close to the perfect prediction

(the red diagonal line), although there are high errors,

particularly when the real target values increase. This

behavior alerted the textile company experts for the

need to discard outliers, which was addressed in the

second CRISP-DM iteration.

Predicting the Tear Strength of Woven Fabrics Via Automated Machine Learning: An Application of the CRISP-DM Methodology

551

Table 1: List of Input Attributes Used for Regression.

Name Description (data type) Min. Max. Average

T cm Number of finished threads per centimeter (numeric) 18 1,321 115.60

P cm Number of finished picks per centimeter (numeric) 7 510 88.87

weight/m

2

Weight (in grams) per square meter (numeric) 22 1,690 241.70

finished width Width in centimeters (numeric) 90 168 140.00

weave design Weave pattern of the fabric (nominal with 21 levels) - - -

reed width Width of the reed in centimeters (numeric) 30 242 188.80

denting Number of the reed dents per centimeter (numeric) 0 252 126.80

ends/dent Number of yarns per dent (numeric) 0 88 2.30

n picks Number of picks on loom per centimeter (numeric) 0 81 16.50

weft code Identification code of the weft (nominal with 6,883 levels) - - -

warp code Identification code of the warp (nominal with 5,353 levels) - - -

warp total ends Total number of threads on the warp (numeric) 477 21,858 6,950.00

yarn code Identification code of the yarn (nominal with 11,020 levels) - - -

n folds Number of single yarns twisted (numeric) 1 12 1.60

yarn count Mass per unit length of the yarn 2 268 47.70

yarn usage If the yarn is used in warp or weft (binary) - - -

yarn repetitions Number of yarn repetitions in warp or weft 1 8 1.42

Figure 3: AutoML Validation REC Curves for the Warp

(Top) and Weft (Bottom) Tear Strengths.

3.3 Second CRISP-DM Iteration

In order to improve the previous results, a new itera-

tion of CRISP-DM was defined. During a new Busi-

Figure 4: Regression Scatter Plot for the First CRISP-DM

Iteration Warp (Top) and Weft (Bottom) Tear Strength Pre-

dictions.

ness Understanding phase execution, the textile com-

pany provided a list business normal ranges for the

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

552

tear strength values. Thus, all test values that were

inferior to 0.4 and superior to 25 were discarded in a

new Data Preprocessing stage, since these tests were

considered outliers (e.g., related with special uncom-

mon military fabrics). The resulting dataset included

8,431 observations for the warp shear strength target

and 8,399 examples for weft one. Figure 5 presents

the box plot values of the two analyzed targets. The

Modeling and Evaluation phases were then executed,

similarly to what is detailed in Section 3.2. When the

predictive results (presented in Section 4) were shown

to the textile company, they were considered more

satisfactory. However, the textile experts suggested

a new CRISP-DM iteration, which would test the im-

pact of using the overall composition of the fabric as

an useful and extra input element.

Figure 5: Box Plot of the Test Targets Used in Second

CRISP-DM Iteration.

3.4 Third CRISP-DM Iteration

In the third CRISP-DM iteration, we tested if the fi-

nal composition of the fabric (e.g., overall percent-

age of cotton and polyester), as an extra input feature,

could improve the predictions. During a new Data

Understanding stage, we collected the final compo-

sition attribute. The attribute, which contained 1,164

distinct levels, was treated as nominal, being thus pre-

processed using the one-hot transform. The remain-

ing CRISP-DM iteration was executed similarly to

the second CRISP-DM iteration (e.g., with outlier re-

moval), except that the predictive models used a total

of 103 input variables (and not 102).

4 RESULTS

Table 2 presents the overall predictive results for the

test data (25%) and the three CRISP-DM iterations.

For comparison purposes, we also tested a baseline

method that is equivalent to the first CRISP-DM it-

eration except that it uses the classical multiple lin-

ear regression model, as implemented in the rminer

R package (Cortez, 2010). In all three CRISP-DM

iterations, and as previously explained, the AutoML

selected model was the ensemble that included all

searched AutoML models (Stacking All).

The analysis of the tear strength warp results

shows an improvement from the first to second

CRISP-DM iteration but not from the second to the

third one. In effect, the best predictive results (for

all regression metrics) were achieved during the sec-

ond CRISP-DM iteration, showing that outlier re-

moval is beneficial when predicting the warp test, al-

though there is no gain in including the final fabric

composition as an input variable. Regarding the tear

strength weft, the results confirms the progress of the

CRISP-DM iterations, where each iteration resulted

in a lower MAE value. Also, the Adj. R

2

values im-

proved in a similar way. Thus, the best prediction re-

sults were obtained in the third iteration, which also

corresponds to the best classification Tolerance for all

5%, 10% and 20% values. This confirms that remov-

ing outliers and using the final fabric composition is

valuable for improving the weft quality predictions.

As for the baseline results, they are clearly worst

when compared to the AutoML method and for both

prediction goals, confirming that the regression tasks

are nonlinear. The MAE differences are higher when

comparing the linear method with the AutoML re-

sults for the first CRISP-DM iteration than when com-

paring different AutoML CRISP-DM iterations (e.g.,

the differences are 0.65, 0.08 and 0.02 for the weft

test), which clearly backs the AutoML as an interest-

ing modeling method.

To complement this analysis, Figure 6 plots the

REC curves for the predictive models from Table 2.

The plots include also the Normalized Regression Er-

ror Characteristic (NAREC) value for each curve (the

higher, the better). The REC curves confirm the best

performance of the third CRISP-DM iteration model

for tear weft and second CRISP-DM iteration model

for tear warp. The quality of the best model pre-

dictions can be visualized in Figure 7. The regres-

sion scatter plots show that the predictions are more

closer to the real values when compared with the scat-

ter plots of the first CRISP-DM iteration (Figure 4).

A high quality regression was achieved for the warp

tear strength prediction (top of Figure 7). These re-

gression results were shown to the textile company

experts, which provided a very positive feedback. In

effect, the best predictive models are already being

incorporated into a prototype tool, which includes a

friendly dashboard that will be soon integrated with

the textile production information system.

Predicting the Tear Strength of Woven Fabrics Via Automated Machine Learning: An Application of the CRISP-DM Methodology

553

Table 2: Overall Predictive Results for the Test Data (Best Values in Bold).

Target Regression Metrics

Test Iteration Interval MAE Tol. 5% Tol. 10% Tol. 20% Adj. R

2

Tear warp

Baseline [0.52,50.00] 2.06 2% 4% 7% 0.44

1

st

[0.52,50.00] 1.30 6% 12% 23% 0.68

2

nd

[0.44,24.00] 0.70 8% 16% 29% 0.92

3

rd

[0.44,24.00] 1.20 6% 14% 23% 0.75

Tear weft

Baseline [0.50,44.52] 1.92 2% 4% 8% 0.49

1

st

[0.50,44.52] 1.27 5% 12% 20% 0.69

2

nd

[0.56,24.25] 1.18 5% 11% 22% 0.71

3

rd

[0.56,24.25] 1.16 6% 12% 21% 0.72

Figure 6: REC Curves for the Warp (Top) and Weft (Bot-

tom) Tear Strength Prediction Models.

5 CONCLUSIONS

In this paper, a DM approach guided by the CRISP-

DM methodology was used to predict the results of

fabric tear strength tests in warp and weft directions.

A total of three CRISP-DM iterations were executed,

aiming to explore distinct data preprocessing oper-

ations (e.g., outlier removal, inclusion of additional

inputs) for the two regression tasks. The data were

collected from a Portuguese textile company and it

included an initial database of thousands of fabric

records from 2012 to 2019. A Data Warehouse was

Figure 7: Regression Scatter Plot of Best Models for the

Warp (Top) and Weft (Bottom) Tear Strength Predictions.

created, allowing to clean and merge these records

with the laboratory test data, resulting in a warp and

weft test datasets with around 8,400 examples. Dur-

ing the Modeling stage of CRISP-DM, an AutoML

was adopted, automatically tuning and selecting the

best ML model for a particular dataset. The Au-

toML tool always selected a stacking ensemble that

included all tested ML models and that obtained much

better regression results when compared with a linear

regression baseline model.

The best warp tear strength predictions were

ICEIS 2020 - 22nd International Conference on Enterprise Information Systems

554

achieved at the second CRISP-DM iteration, which

involved outlier removal, while the best weft test re-

sults were obtained at the third CRISP-DM iteration,

which included the final fabric composition as an ex-

tra input feature. The best predictive results were an-

alyzed as valuable by the textile company experts. In

future work, we intend to apply a similar approach

in the prediction of other fabric quality tests, such as

pilling. Moreover, we intend to apply the best predic-

tion models in a real textile environment, aiming to

reduce the number of fabric sample creation attempts.

ACKNOWLEDGMENTS

This work was carried out within the project “Tex-

Boost: less Commodities more Specialities” ref-

erence POCI-01-0247-FEDER-024523, co-funded

by Fundo Europeu de Desenvolvimento Regional

(FEDER), through Portugal 2020 (P2020).

REFERENCES

Beltran, R., Wang, L., and Wang, X. (2006). Predicting the

pilling tendency of wool knits. The Journal of The

Textile Institute, 97(2):129–136.

Bi, J. and Bennett, K. P. (2003). Regression error char-

acteristic curves. In Proceedings of the 20th inter-

national conference on machine learning (ICML-03),

pages 43–50.

Cortez, P. (2010). Data mining with neural networks and

support vector machines using the r/rminer tool. In In-

dustrial Conference on Data Mining, pages 572–583.

Springer.

Dimitrovski, K., Gabrijel

ˇ

ci

´

c, H., Kova

ˇ

cevi

´

c, S., and

Nikoli

´

c, M. (2004). The influence of weft yarn char-

acteristics on tensile strength of woven fabrics in warp

direction. In Magic World of Textiles.

Eltayib, H. E., Ali, A. H., and Ishag, I. A. (2016). The

prediction of tear strength of plain weave fabric us-

ing linear regression models. International Journal of

Advanced Engineering Research and Science, 3(11).

Feurer, M., Klein, A., Eggensperger, K., Springenberg, J.,

Blum, M., and Hutter, F. (2015). Efficient and robust

automated machine learning. In Advances in neural

information processing systems, pages 2962–2970.

Gibert, K., Izquierdo, J., S

`

anchez-Marr

`

e, M., Hamilton,

S. H., Rodr

´

ıguez-Roda, I., and Holmes, G. (2018).

Which method to use? an assessment of data mining

methods in environmental data science. Environmen-

tal modelling & software, 110:3–27.

Gibert, K., S

`

anchez-Marr

`

e, M., and Izquierdo, J. (2016). A

survey on pre-processing techniques: Relevant issues

in the context of environmental data mining. AI Com-

munications, 29(6):627–663.

Hu, J. (2008). Fabric testing. Elsevier.

Kotb, N. (2009). Engineering of tearing strength for pile

fabrics. Journal of Textile and Apparel, Technology

and Management, 6(1).

Landry, M., Bartz, A., Aiello, S., Eckstrand, E., Fu, A., and

Aboyoun, P. (2018). Machine Learning with R and

H2O: Seventh Edition. Technical Report September.

Lasi, H., Fettke, P., Kemper, H.-G., Feld, T., and Hoffmann,

M. (2014). Industry 4.0. Business & information sys-

tems engineering, 6(4):239–242.

Le, T. T., Fu, W., and Moore, J. H. (2019). Scaling

tree-based automated machine learning to biomedical

big data with a feature set selector. Bioinformatics.

btz470.

Maher, M. M. M. Z. A. and Sakr, S. (2019). SmartML:

A Meta Learning-Based Framework for Automated

Selection and Hyperparameter Tuning for Machine

Learning Algorithms. In EDBT: 22nd International

Conference on Extending Database Technology, Lis-

bon, Portugal.

Malik, Z. A., Malik, M. H., Hussain, T., and Arain, F. A.

(2011). Development of models to predict tensile

strength of cotton woven fabrics. Journal of engi-

neered fibers and fabrics, 6(4):155892501100600407.

Mozafary, V. and Payvandy, P. (2014). Application of

data mining technique in predicting worsted spun

yarn quality. The Journal of The Textile Institute,

105(1):100–108.

Shishoo, R. (2012). The global textile and clothing indus-

try: technological advances and future challenges. El-

sevier.

Teli, M., Khare, A., and Chakrabarti, R. (2008). Depen-

dence of yarn and fabric strength on the structural pa-

rameters. AUTEX Research Journal, 8(3):63–67.

Wirth, R. and Hipp, J. (2000). Crisp-dm: Towards a stan-

dard process model for data mining. In Proceedings of

the 4th international conference on the practical ap-

plications of knowledge discovery and data mining,

pages 29–39. Citeseer.

Witten, I. H., Frank, E., Hall, M. A., and Pal, C. J. (2016).

Data Mining: Practical machine learning tools and

techniques. Morgan Kaufmann.

Yildirim, P., Birant, D., and Alpyildiz, T. (2018). Data min-

ing and machine learning in textile industry. Wiley In-

terdisciplinary Reviews: Data Mining and Knowledge

Discovery, 8(1).

Zeydan, M. (2010). Prediction of fabric tensile strength by

modelling the woven fabric. Woven Fabric Engineer-

ing, page 155.

Predicting the Tear Strength of Woven Fabrics Via Automated Machine Learning: An Application of the CRISP-DM Methodology

555