Toolchain Development for Automated Scene Reconstruction using

Artificial Neural Network Object Detection and Photogrammetry for the

Application in Driving Simulators

Maximilian Jarofka, Stephan Schweig, Niko Maas and Dieter Schramm

Chair of Mechatronics, University of Duisburg-Essen, Lotharstraße 1, 47057 Duisburg, Germany

Keywords:

Artificial Neural Network, COLMAP, Clustering, Driving Simulator, Metashape, Meshroom, Object

Classification, Object Detection, Photogrammetry, Process Chain, Unity, VisualSFM.

Abstract:

This paper presents an automated process chain for the reconstruction of characteristic 3D objects, which can

be used in a simulation environment. The process chain can distinguish between recurring objects such as trees

and cars and specific objects like buildings. To acquire this, it detects and classifies objects in images from a

previously recorded video. In contrast to the specific objects, which are reconstructed during the workflow of

the process chain, the recurrent objects are loaded from already existing models and are placed multiple times

into the simulation environment. In terms of quality a visual comparison between the two integrated programs

for the reconstruction (Metashape and Meshroom) is carried out. Furthermore the accuracy of the positioning

of standard objects in the Unity game engine is examined.

1 INTRODUCTION

Today driving simulators are used in a wide variety of

areas. In the industry they are used, for example, to

simulate ships or to simulate the driving behaviour of

road vehicles. Furthermore, they serve as training de-

vices for new drivers in uncommon or dangerous sit-

uations. One big advantage of using simulators is the

reproducibility of different test scenarios, as well as

the secure simulation of risky situations. This paper

describes the development of an automated process

chain for object reconstruction on the example of an

automotive driving simulator.

Simulators benefit from the rapid development of

the computing power of microchips. Therefore, the

demands on the developed scenarios, especially with

regard to graphical details, are growing to the same

extend. To make the test drive within a driving simu-

lator as realistic as possible, a detailed graphical sim-

ulation environment must be provided.

Those scenarios consist of different types of ob-

jects. On the one hand, there are recurring objects

such as trees, cars or street lights. By loading them

from an object database they can be placed in the en-

vironment. To ensure a variation in the build scenario,

their individual properties such as colour or shading

can be modified. On the other hand, there are specific

objects, which cannot be replaced by objects from a

database or loaded multiple times into the simulation

environment due to their uniqueness. Therefore these

objects have to be modelled individually. If a sim-

ulation should be based on a real environment (e.g.

streets of an existing city), concise objects, such as

buildings, have to be modelled. This process does not

only take much time but also requires considerable

know-how in 3D modelling.

This paper presents an automated procedure for

the reconstruction of 3D objects and their integration

into a scenario. The automation is intended to make

the design of scenarios for driving simulators more

efficient and therefore less time consuming. The au-

tomated process chain is based on recorded data from

a ZED stereoscopic camera, manufactured by Stere-

oLabs (Stereolabs Inc., 2020). From this dataset, the

process chain will reconstruct specific objects and im-

ports them into a Unity scene along with standard ob-

jects like cars and trees, loaded from previously exist-

ing models.

In the first step objects and their three-dimensional

positions have to be determined. Afterwards, by ap-

plying photogrammetric methods, the objects are re-

constructed. Purpose of the developed process chain

is the generation of a scenario which can directly be

used as a simulation environment.

Jarofka, M., Schweig, S., Maas, N. and Schramm, D.

Toolchain Development for Automated Scene Reconstruction using Artificial Neural Network Object Detection and Photogrammetry for the Application in Driving Simulators.

DOI: 10.5220/0009590500250034

In Proceedings of the 10th International Conference on Simulation and Modeling Methodologies, Technologies and Applications (SIMULTECH 2020), pages 25-34

ISBN: 978-989-758-444-2

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

25

2 STATE OF THE ART

In this section, the theoretical concepts of this paper

are explained. Objects within recorded images are de-

tected automatically and subsequently reconstructed

to 3D models. An object classifier based on an artifi-

cial neural network is used for the detection of these

objects.

Therefore the basics of the used object classifier

are explained in the first subsection. Furthermore

the basic principles of photogrammetric methods are

stated. Through the use of these methods, the recog-

nized objects are transformed into 3D models.

2.1 Object Detection and Classification

There are big improvements in the field of object

recognition and computer vision in general. One rea-

son for these improvements is the increase in comput-

ing power and thus the associated possibility to use

deeper artificial neural networks, (He et al., 2016)

For the detection and classification of objects the

artificial neural network with the name ”You Only

Look Once (YOLO)” is used in this work. This

network was originally developed in the year 2015

and is now published in the third version, (Redmon

et al., 2015; Redmon and Farhadi, 2016; Redmon and

Farhadi, 2018). The actual version of YOLO consists

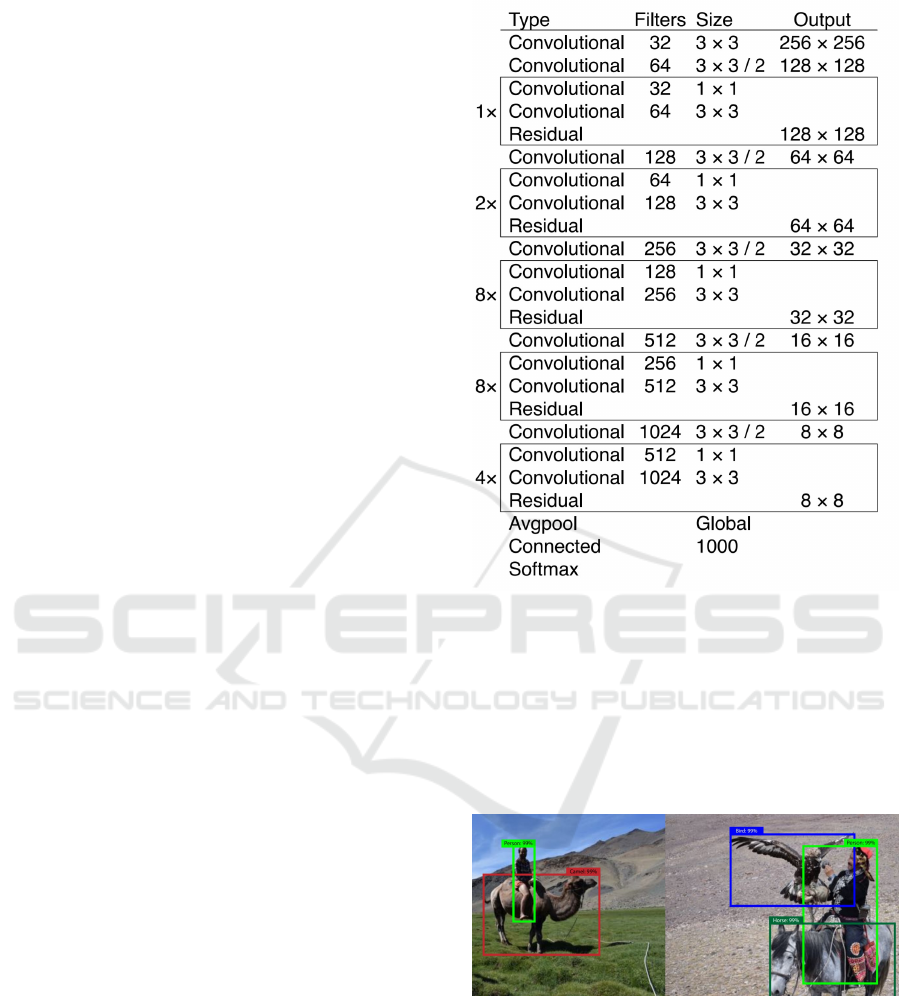

of a large number of hidden layers. Figure 1 shows

the detailed structure of the network.

This specific system has a number of features that

distinguish it from other object classifiers. Different

bounding boxes are predicted in a single evaluation

of the source image. A probability value is assigned

to each of them. This value represents the combined

probability of the object being correctly mapped and

the correct assignment of an object class.

In contrast to this procedure other systems run

a classifier over the input image at predefined in-

tervals to perform object detection at each of these

points. As a result, the detection process takes com-

paratively long. Also other systems often consist of a

sequence of different processes which form a process

chain. The resulting interdependencies between dif-

ferent process parts make it very difficult to improve

the overall performance in one step. The YOLO ob-

ject detection system however, consisting of a single

network, makes it easy to apply known strategies from

the field of artificial neural networks for improving

performance, (Redmon and Farhadi, 2018).

The results of the classification process with

YOLO are bounding boxes. Each box contains the

location in image coordinates (X,Y) and the width

and height of the box in pixels. In addition, a bound-

Figure 1: Layers of the artificial neural network YOLO ver-

sion 3 (Redmon and Farhadi, 2018).

ing box also contains an object class and a probabil-

ity information about the correct mapping of the ob-

ject. This probability considers (as already mentioned

above) the correct position and class of the object.

Figure 2 shows possible object detections and their

visualization in the original image.

Figure 2: Detected objects in original picture (Redmon and

Farhadi, 2018).

Which objects can be recognized by the system

depends on the training data used. Like the human

brain, the network must first ”learn” the detection of

specific objects. In this paper the artificial neural net-

work YOLOv3, pre-trained on the open-image dataset

is used. With this version it is possible to recognize

and classify 601 different objects (Kuznetsova et al.,

2018).

SIMULTECH 2020 - 10th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

26

2.2 Photogrammetry

Photogrammetry originally describes the measure-

ment of various properties of an object from images.

Today the term ”photogrammetry” is mostly used to

describe the determination of three dimensional co-

ordinates from different images of an object without

any physical contact. Thus it is possible to reconstruct

complete 3D models of these objects. Depending

on the camera used (standard digital camera or spe-

cial measuring camera) very high accuracies of these

models can be achieved, (Donath, 2009).

Since the first developments in the field of pho-

togrammetry, those methods have established them-

self as an important and widely used tool. A

special approach within photogrammetry is the so

called Structure-from-Motion method (SfM), (West-

oby et al., 2012).

In contrast to other photogrammetric methods,

such as stereoscopic photogrammetry, a process chain

containing SfM offers several advantages. By using

SfM methods, it is possible to reconstruct a 3D ob-

ject without prior knowledge of the position and ori-

entation of the images taken. This means, that ob-

jects can be captured with standard cameras (without

any further sensory setup such as GPS or gyroscope)

and then be reconstructed into a 3D model, (Westoby

et al., 2012; Shashi and Jain, 2007).

The term ”Structure-from-Motion” here denotes

that 3D structures are reconstructed from the move-

ment of the camera and the resulting different angles

of view in each image, (Szeliski, 2010).

The entire process, from reading the individual

images to the finished 3D model, often is denoted

as Structure from Motion. More precisely, however,

SfM is only an intermediate step in the entire process

chain. The camera position, as well as the position of

the feature coordinates in a uniform coordinate sys-

tem, are determined from a priori detected geometri-

cal features. Subsequently, a point cloud can be cre-

ated to link these to a 3D model and texturing can be

used to create a final 3D model.

The flowchart shown in Figure 3 describes a pos-

sible photogrammetric process chain using SfM algo-

rithms as used in the AliceVision-Framework (Alice-

Vision, 2020).

3 AUTOMATED PROCESS CHAIN

Within this section, the basic procedure of an auto-

mated scenario reconstruction is presented. A process

chain is developed by which individual objects can be

detected and reconstructed. Subsequently, these ob-

Feature Extraction

Feature Matching

Structure from Motion

Multi Vision Stereo

(MVS)

Meshing and Texturing

3D Model

Figure 3: Flowchart of a possible SfM process chain (Al-

iceVision, 2020).

jects are assembled to a scenario in the Unity game

engine.

The process chain consists of a higher-level pro-

gram that calls and controls various subprograms.

The objective is to make the sequential flow of all

programs as independent from user interaction as pos-

sible. For this purpose, all important parameters are

collected within a configuration file. This allows the

user to specify all parameters in advance and then run

the process chain unattended.

In addition to the high degree of automation, the

process chain should also have the highest possible

degree of modularity. It should be possible to start in-

dividual steps without the preceding ones. This mod-

ular structure is very useful for adapting the param-

eters in test runs. If some steps of the process chain

have already been completed successfully, only the

following module can be started with adapted param-

eters. Thus, already completed steps do not have to

be repeated and the processing time is reduced.

Furthermore, the modular structure enables an in-

terruption of the process chain at any point and the

continuation at another time. However, since the se-

quence cannot be changed due to the dependencies of

the individual steps, the modules must be processed

one after the other and cannot be executed in paral-

lel (except the object detection/clustering and the data

extraction as seen in Figure 4). To activate each mod-

ule individually, the configuration file contains the pa-

rameter run = true/false for each module. Only the

modules with the parameter run = true are executed

within the process chain.

Figure 4 shows the process chain as a flow chart.

The different labels within this diagram represent dif-

ferent types of subroutines. The hatched fields rep-

resent self developed scripts. They are used to con-

trol an already existing software - such as Unity,

Blender or Metashape (Agisoft LLC, 2020; Alice-

Vision, 2020). The script enables the transfer of re-

quired parameters to the respective program. A spe-

cific programming interface of the program is then

Toolchain Development for Automated Scene Reconstruction using Artificial Neural Network Object Detection and Photogrammetry for the

Application in Driving Simulators

27

Data Acquisition

Video Files

Image- and Data Extraction Object Detection

Object Clustering

Assignment of Im-

ages to Objects

3D Reconstruction

Cutting of

3D Object

User Input

Import Unity

Figure 4: Flowchart of the developed process chain.

used to run the intended sub tasks. Fields high-

lighted in grey represent own programs, which were

developed especially for the integration in the process

chain.

In addition to the programs listed here, there

is another program that controls the entire pro-

cess chain. This program runs the individual sub-

programs/subscripts with corresponding parameters

loaded from the configuration file.

Splitting the task in different sub tasks ensures the

above-mentioned flexibility of the process chain. An-

other important factor in the development of the pro-

cess chain is the independence from direct user input.

As seen in Figure 4, only the cutting of 3D model and

the start of the import process of the objects into the

Unity game engine require direct user interaction.

In the following subsection only the most impor-

tant parts of the process chain are explained in more

detail. Thus the object detection, object clustering and

3D reconstruction are discussed further on.

3.1 Object Detection

To start the object detection, the corresponding

Python script in the installation folder of YOLO is

started by the main program. This is a version that has

been specially modified for the purposes of the auto-

mated process chain. The original script for the inte-

gration of the used stereoscopic camera in the YOLO-

workflow can be downloaded from GitHub, (Alex-

eyAB, 2018).

For each detected object the artificial neural net-

work provides specific values. In addition to the clas-

sification (e.g. tree), size of the bounding box (in

pixels) and position (in pixels) of the object, a value

for the accuracy of the detection is available. This

is a percentage value that indicates the certainty of

a correct classification. By selecting an appropriate

Threshold parameter in the configuration file, the ob-

jects can be filtered according to these values. Only

detections of objects with a certainty above the value

of the Threshold parameter are considered as correct

and will be saved. Initial tests have shown that a

Threshold of roughly 0.3 seems to be well suited for

the detection of buildings on the roadside.

To store the object information, a simple text doc-

ument is created for each processed video file. For

each recognized object within each image one line

with its information is stored. An example for such

entries is shown in Table 1. In addition to the number

of the image in which the object was detected, the

information about its mean position within the im-

age (X, Y, height, width) also its position in three-

dimensional space (Pos

X

, Pos

Y

, Pos

Z

in meters) is

stored. To calculate this 3D position of the object in

world coordinates, the point cloud of the respective

stereo image pair is used. The point cloud can be read

out directly via a software function provided with the

ZED camera.

The point cloud generated by the camera only con-

tains a certain distance range. All pixels whose calcu-

lated distance to the camera is too small or too large,

are not displayed in this point cloud. If a pixel is out-

side the point cloud, the value -1 is returned for its

position. In table 1, this is the case for the object in

the third line. The detected plant is too far away from

the camera and its position, as well as other calculated

parameters, are set to the error value of -1. In the fol-

lowing, such an object is considered as invalid and can

be excluded by the parameter includeInvalid=false in

the configuration file.

Furthermore the occlusion between two objects is

calculated. A percentage value for the overlapping

areas of both objects is determined if an object is oc-

cluded by another one in front of it. In further updates

of the process chain an automated selection of the ob-

jects which should be reconstructed could be imple-

mented based on this value.

3.2 Object Clustering

In the previous step, objects within individual images

were detected and their position in the world coordi-

nate system is calculated. Since the same object oc-

curs in different images, the object positions must be

clustered. As long as the positions of detected objects

are close enough to one another, they are assigned to

one object cluster. If a considered point lies within a

SIMULTECH 2020 - 10th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

28

Table 1: Object information saved by the YOLO script.

Nb. Class Accuracy X Y Width Height Pos

X

Pos

Y

Pos

Z

Distance Occlusion

1485 Building 38.0 861 131 411 533 -60.256 7.155 -28.700 11.285 0.307

1485 Building 36.0 0 137 587 510 -71.969 10.201 -41.555 20.350 0.107

1485 Plant 27.0 560 238 196 253 -1 -1 -1 -1 -1

1485 Car 26.0 490 522 186 110 -67.236 5.014 -29.367 7.535 0.0

1485 Plant 20.0 924 469 344 243 -63.875 4.727 -26.113 6.643 0.0

certain radius to any point in a cluster, it is also as-

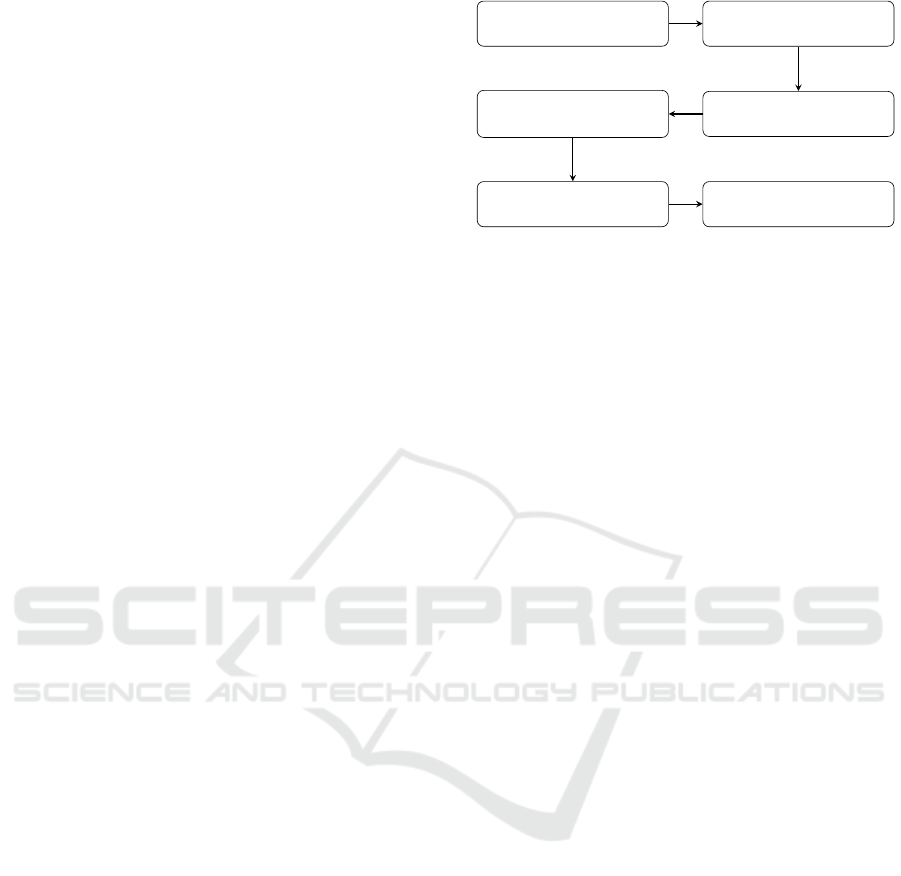

signed to it. Cloudlike object boundaries are created,

(compare Figure 5).

A B

Figure 5: Visualization of the clustering process.

In addition to characteristic delimitations, two dif-

ferent cases of clustering can be seen in Figure 5. Sce-

nario A is a single smaller object that was recorded

from all camera perspectives. Due to inaccuracies in

the image recording or object recognition, deviations

of the object positions in the world coordinate system

(gray dots) occur. However, each of these positions

is within the threshold (radius) to a different point.

Therefore, all points are combined into a common

cluster (and thus into one object) with an averaged

centre position (black point).

Scenario B is a continuous object that is too big to

be captured in one image. YOLO detects the object

approximately over the entire width of the respective

image. This results in points shifted parallel to the

movement of the camera. Just like scenario A, how-

ever, these are within the selected threshold and are

thus assigned to one and the same object. This proce-

dure for clustering objects makes it possible to cluster

even larger objects correctly, which span over several

images.

In addition to the threshold value for the proximity

of all points to one another, a further threshold value

for the number of points is introduced. Individual

clusters are only considered as correct if the number

of points in them exceeds the threshold value. This

means that individual faulty detections are not con-

sidered as a separate cluster with a very small number

of individual points.

The program for creating the object clusters first

reads the files with the information about all detected

objects (compare section 3.1). A label for the clus-

tering can now be specified via the configuration file.

If an object does not have the appropriate label, it is

discarded and not assigned to a cluster. If all objects

have been distributed to the clusters or have been dis-

carded, the clusters with too few individual objects are

also discarded. The mean value of the position is now

calculated for all remaining clusters. The resulting av-

eraged objects are then saved in another text file. Si-

multaneously to the positions and other information,

all image numbers in which the respective object oc-

curs are saved. Using these numbers, the extracted

images can be split up and further be processed to re-

constructed objects using photogrammetry.

3.3 3D Reconstruction

In order to determine a suitable reconstruction pro-

gram for the use within this process chain, some pre-

liminary tests were carried out during its develop-

ment. At first, different software solutions for the

reconstruction of 3D models were tested. The used

camera already comes with software for 3D recon-

struction. It is integrated in the software development

package and already has a graphical user interface.

It uses the point clouds generated by the stereo cam-

era for the reconstruction of objects. However, it was

not able to provide usable models in initial tests and

was therefore not considered further for the use within

the process chain. In addition, the programs Visu-

alSFM (Wu, 2013; Wu et al., 2011) and COLMAP

(Schonberger and Frahm, 2016) were tested in ad-

vance. They were also unable to deliver satisfying

results in initial tests and were therefore also not con-

sidered for further use in the process chain.

All the above mentioned programs delivered 3D

models with many holes in the reconstructed surfaces

as well as faulty textures. The minimum requirements

for the generated models are a continuous surface and

correct texturing. Furthermore, the texture of the ob-

jects should not overlap with textures from objects

which are in front of them.

The first program to achieve acceptable results

under these aspects was Metashape (Agisoft LLC,

2018). For this reason, the process chain was initially

developed using this program. However, since it is a

software that requires a licence, the program Mesh-

Toolchain Development for Automated Scene Reconstruction using Artificial Neural Network Object Detection and Photogrammetry for the

Application in Driving Simulators

29

room was also tested and integrated into the process

chain. It is a free open-source software which uses the

AliceVision-Framework (AliceVision, 2020). Mesh-

room also allows the reconstruction of acceptable 3D

models.

4 EXPERIMENATAL RESULTS

After the explanation of the developed automated pro-

cess chain in the previous chapter, this chapter deals

with some selected experiments carried out with it.

As described in section 3.1 the two already inte-

grated programs in the process chain are Metashape

and Meshroom. In the first section of this chapter they

are compared in concerning the resulting 3D models.

Besides the reconstruction of objects by pho-

togrammetric methods, the developed process chain

also allows multiple imports of existing standard ob-

jects into the scene.

Therefore the second section of this chapter deals

with the accuracy of this import procedure.

4.1 Comparison between the Two

Integrated Reconstruction

Programs

A uniform test procedure was defined, so that the two

programs can be compared with each other. In the first

part of the test runs, the standard process chain was

applied several times to the same scenario. The num-

ber of images used and their resolution were varied.

Through this procedure the results can be evaluated

in terms of quality.

In order to guarantee constant conditions for the

reconstruction programs, the process chain was only

carried out up to the partial step of assigning the im-

ages to a specific object. Afterwards the test runs were

carried out for both programs with a varying number

of images. For this purpose the parameter SkipCount

in the section [Imagecopy] of the configuration file

was varied. This means that only every n

th

frame from

the video file is used for the reconstruction.

A street with three buildings on the side was cho-

sen as the test scenario. To minimize the time required

for all test runs, only the building in the middle was

reconstructed. For better illustration it was roughly

cut into shape in a manual step. The recorded screen-

shots of the respective building can be visually com-

pared with each other with regard to quality.

The scenario above was recorded in two different

resolutions. 720p as a medium resolution and 2.2K as

maximum resolution delivered by the camera. Table 2

shows the resulting matrix for all test runs carried out

with each reconstruction program.

Table 2: Example for one test matrix.

SkipCount

2 5 10 20

Nb of images (720p) 566 228 114 58

Nb of image (2.2K) 162 66 34 18

Figures 6 and 7 show exemplary reconstructed

3D models for the largest number of images at the

medium resolution of 720p.

Figure 6: Resulting 3D model from Metashape (resolution

720p).

A direct comparison of the two models reveals

differences in quality. The program Metashape (Fig-

ure 6) delivers better quality results than Meshroom

(Figure 7). The boundaries of the object are less

uneven. Also the actual flat surfaces of the build-

ing appear much smoother in the reconstruction of

Metashape. Besides the unevenness of the boundaries

and surfaces, the texture of the model in Figure 6 also

appears sharper and less blurred.

In the second part of the tests, all runs were per-

formed with the data recorded in the maximum reso-

lution of 2.2K. The results of the two reconstruction

programs will be compared with each other again for

the largest number of used images.

Figures 8 and 9 show the resulting 3D models with

the highest number of images used.

Overall, this comparison reveals similar differ-

ences. Again, the building facades from Metashape

were reconstructed less uneven. The boundaries and

edges of the building are also much clearer. This is

SIMULTECH 2020 - 10th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

30

Figure 7: Resulting 3D model from Meshroom (resolution

720p).

Figure 8: Resulting 3D model from Metashape (resolution

2.2K).

particularly noticeable in the transition between the

building and the sky. If all parts of the reconstructed

sky were removed, Metashape would have a relatively

straight edge. The reconstruction with Meshroom on

the other hand has a much more uneven and jagged

roof edge.

The tests with less images used for the reconstruc-

tion showed similar results. In general Metashape de-

livered better quality in all reconstructions. With a

very low number of images the overall quality was re-

Figure 9: Resulting 3D model from Meshroom (resolution

2.2K).

duced. Less than 66 images led to many holes and

artefacts in the resulting 3D models.

In general it can be stated, that contrary to expec-

tations, the quality is not improved by using the higher

camera resolution. By using the maximum resolution,

the quality of the reconstructed models is worse. Es-

pecially the frontal facade of the building shows con-

siderably more unevenness. Also the floor is more un-

even when using the higher resolution and is showing

single gaps that were not reconstructed correctly.

In all reconstructed models, artefacts arise be-

tween the object and its surroundings. With regard

to the reconstructed building, this is particularly no-

ticeable in the transition from the building to the sky.

In the immediate vicinity of the building, parts of the

sky are also reconstructed. In the course of quality as-

sessment these artefacts will not be considered. Since

the creation of these artefacts cannot be prevented in

both programs, they must be removed in the process

of manual cutting anyway. Thus they do not represent

an explicit characteristic of quality in a direct compar-

ison.

4.2 Positioning of Standard Objects into

the Game Engine Unity

With the developed automated process chain it is also

possible to import recurring objects. As already men-

tioned above, objects can be recognized with YOLO

and then be replaced by prefabricated 3D models at

the corresponding positions within the scene. Regard-

ing poly count and effective modelling, this allows the

Toolchain Development for Automated Scene Reconstruction using Artificial Neural Network Object Detection and Photogrammetry for the

Application in Driving Simulators

31

models to be optimized in advance.

In the following section, the detection of such

standard objects and their import are discussed. The

tests were performed for the detection of cars at the

roadside of the recorded scene. However, it is theo-

retically possible to use any of the object classes de-

tectable by YOLO, see (Kuznetsova et al., 2018).

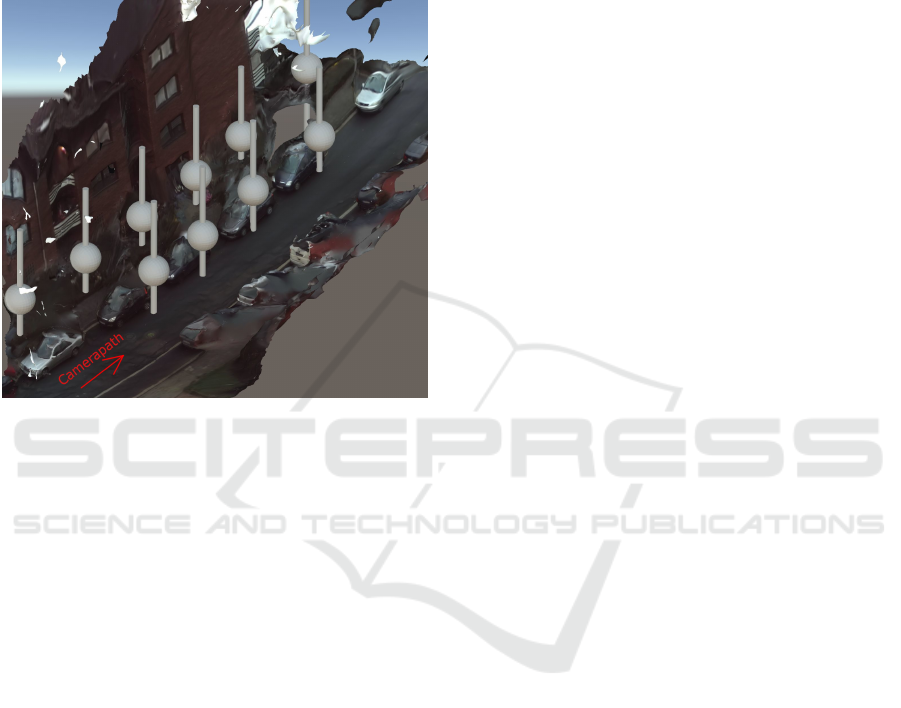

Figure 10: Imported standard objects at the detected posi-

tions of cars along a street.

Example objects are imported into the recon-

structed scenario to visualize the detected positions.

They consist of a long cylinder and a sphere. In Fig-

ure 10 it is clearly visible that the detected positions

do not match the actual positions of the objects in the

scene. They are shifted by a constant factor (here

4 m) along the x-axis. If the shift is corrected the

calculated positions match the positions of the recon-

structed model. A possible reason for the necessary

correction is the general positioning of the 3D model.

On the one hand, the reconstructed model has a spe-

cific coordinate system given by the reconstruction

program. On the other hand, the objects are refer-

enced to the coordinate system of the camera. There-

fore, it is necessary to convert between the two coor-

dinate systems.

In the current version of the process chain this is

done by taking the positional information of only one

image. If this is inaccurately aligned by the recon-

struction program or the information itself is inaccu-

rate, the whole model can easily be shifted.

In a second test scenario the positions of cars are

examined again. This time using a straight building

facade. Figure 11 shows the resulting point cloud for

the selected scenario. The positions of the cars, which

have to be detected, were marked manually by a red

circle and the automatically calculated positions were

marked by loading the sample objects. When compar-

ing the respective positions, differences are noticeable

depending on the camera path covered. At the be-

ginning of the recording (right part of Figure 11), the

automatically determined positions almost match the

manually marked positions. With increasing distance

covered by the camera, however, the positions deviate

more and more from each other. The automatically

calculated position of the last car deviates about 10

meters from the manually marked position.

The actual course of the recorded facade is com-

pletely straight and without curves. In the point cloud

shown, however, a bend to the right is clearly visible.

5 CONCLUSION

In the course of this paper a process chain for the

automated reconstruction of 3D models and integra-

tion into a simulation environment is presented. The

process chain uses data recorded from a stereoscopic

camera. By using the YOLO artificial neural network,

the process chain recognizes individual objects within

the video frames and clusters them. Specific objects -

such as buildings - getting converted into a 3D model

by a 3D reconstruction program using photogrammet-

ric methods. In addition to the object itself, its three-

dimensional position is calculated and saved. For this

purpose, the positional tracking of the stereoscopic

camera is used. Based on this position, the object can

be imported into a Unity scene. With the exception of

cutting the raw mesh and starting the import process,

the process chain is fully automated and does not re-

quire any user input.

To allow a certain modularity besides the automa-

tion, independent programs and scripts were devel-

oped. They were combined into a process chain by

developing a supervising control program. The used

parameters of all programs were combined in two

configuration files for easy handling. The flow of

the process chain already can be changed by adjust-

ing various parameters. This also makes it possible to

reconstruct scenarios coherently. Connected building

facades can thus be reconstructed by adjusting only

one parameter in a coherent model. It is also possible

to reconstruct a scene from different camera angles.

With the current design of the process chain, it is al-

ready possible to use a large number of cameras.

For the actual reconstruction of the 3D models,

existing programs within the process chain are used.

Two different reconstruction programs have already

been integrated into the workflow. On one hand, the

proprietary program Metashape from Agisoft can be

SIMULTECH 2020 - 10th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

32

Figure 11: Imported standard objects at the detected positions of cars along a facade.

used. A corresponding license with access to the

Python API must be available to use it. On the other

hand, the free open-source program Meshroom can be

used for reconstruction.

The differences between the two used programs

were examined in detail. For all examples used in this

work, the proprietary program Metashape generally

gave better results.

By calculating the occlusion of individual objects,

it is already possible to roughly divide the various ob-

jects within a scene according to the ability of being

reconstructed. It can already be estimated if an object

is suitable for reconstruction or whether it is too much

hidden by other objects in front of it.

Furthermore, with the scripts created in this work,

it is possible to cut the resulting 3D models and

import them into the game engine Unity via a cre-

ated graphical user interface. Not only newly recon-

structed models can be imported during the process

chain. It is also possible to import detected, recurring

objects in the form of standard objects.

It was shown that the calculation of the object po-

sitions within certain scenarios already matches the

recorded data with sufficient accuracy. Standard ob-

jects can thus be included in newly reconstructed sce-

narios but they require some manual corrections by

the user to compensate the shift. For the placement of

the reconstructed 3D objects, however, only a single

position specification is used so far. Depending on the

accuracy of the image arrangement within the recon-

struction program, this can lead to a general inaccu-

racy in positioning, especially in the case of longer,

connected objects.

During the recording of connected building fa-

cades, general position deviations were also detected.

The position calculated by the camera deviates more

and more from reality during the recording of house

facades. Due to the rearrangement of the images dur-

ing the reconstruction of the 3D objects, the posi-

tions subsequently deviate more with increasing cam-

era movement. The objects can therefore only be ap-

proximately positioned.

6 OUTLOOK

Autonomous inland shipping is currently being re-

searched in the ongoing project ”Autonomes Binnen-

schiff – Simulation und Demonstration von automa-

tisiertem Fahren in der Binnenschifffahrt”. Sensors

from a real prototype ship are simulated to validate

and improve the control algorithms. Afterwards these

algorithms are tested in the simulation and on the

ship. Especially for the cameras, the simulation envi-

ronment has to be as realistic as possible with photo-

realistic textures and objects. In this research project,

the presented process chain will be adapted to the

changed environment and used to simplify the gen-

eration of it.

Further development of the entire process chain

will be carried out besides these specific adaptations.

By implementing the automatic evaluation of the suit-

ability for reconstruction and the resulting models

themself, the degree of automation will be further in-

creased. Next to this evaluation, using the already cal-

culated occlusion value, all used images will be eval-

uated in terms of quality. Bad images, such as blurry

ones, will be discarded in further updates of the pro-

cess chain.

Through the use of additional sensors, such as dif-

ferential GPS, gyroscope and accelerometer, the po-

sitioning of the reconstructed objects will be further

improved. Furthermore multiple images and their cor-

responding positions in real world coordinates will be

regarded for the reconstruction process.

Toolchain Development for Automated Scene Reconstruction using Artificial Neural Network Object Detection and Photogrammetry for the

Application in Driving Simulators

33

ACKNOWLEDGEMENTS

The ongoing research in the project ”Autonomes Bin-

nenschiff – Simulation und Demonstration von au-

tomatisiertem Fahren in der Binnenschifffahrt”, in

which the presented process chain will be used and

improved, is funded by the European Regional De-

velopment Fund (ERDF).

REFERENCES

Agisoft LLC (2018). Agisoft Metashape User Manual, Pro-

fessional Edition, 1.5 edition.

Agisoft LLC (2020). Agisoft metashape.

https://www.agisoft.com/; Last visited 06.03.2020.

AlexeyAB (2018). Github zed-yolo.

https://github.com/stereolabs/zed-yolo; Last vis-

ited 31.01.2020.

AliceVision (2020). Alicevision, meshroom.

https://alicevision.org; Last visited 06.03.2020.

Donath, D. (2009). Photogrammetrie. Vieweg+Teubner,

Wiesbaden.

He, K., Zhang, X., Ren, S., and Sun, J. (2016). Deep resid-

ual learning for image recognition. In Proceedings of

the IEEE conference on computer vision and pattern

recognition, pages 770–778.

Kuznetsova, A., Rom, H., Alldrin, N., Uijlings, J. R. R.,

Krasin, I., Pont-Tuset, J., Kamali, S., Popov, S., Mal-

loci, M., Duerig, T., and Ferrari, V. (2018). The open

images dataset V4: unified image classification, object

detection, and visual relationship detection at scale.

CoRR, abs/1811.00982.

Redmon, J., Divvala, S. K., Girshick, R. B., and Farhadi, A.

(2015). You only look once: Unified, real-time object

detection. CoRR, abs/1506.02640.

Redmon, J. and Farhadi, A. (2016). YOLO9000: better,

faster, stronger. CoRR, abs/1612.08242.

Redmon, J. and Farhadi, A. (2018). Yolov3: An incremental

improvement. arXiv preprint arXiv:1804.02767.

Schonberger, J. L. and Frahm, J.-M. (2016). Structure-

from-motion revisited. In Proceedings of the IEEE

Conference on Computer Vision and Pattern Recogni-

tion, pages 4104–4113.

Shashi, M. and Jain, K. (2007). Use of amateur cameras in

architectural photogrammetry. In Map World Forum,

Hyderabad, India.

Stereolabs Inc. (2020). Stereolabs zed 2k stereo camera.

https://www.stereolabs.com/; Last visited 07.02.2020.

Szeliski, R. (2010). Computer Vision: Algorithms and Ap-

plications. Springer-Verlag, Berlin, Heidelberg, 1st

edition.

Westoby, M. J., Brasington, J., Glasser, N. F., Hambrey,

M. J., and Reynolds, J. (2012). Structure-from-motion

photogrammetry: A low-cost, effective tool for geo-

science applications. Geomorphology, 179:300–314.

Wu, C. (2013). Towards linear-time incremental structure

from motion. In 2013 International Conference on

3D Vision-3DV 2013, pages 127–134. IEEE.

Wu, C., Agarwal, S., Curless, B., and Seitz, S. M. (2011).

Multicore bundle adjustment. In CVPR 2011, pages

3057–3064. IEEE.

SIMULTECH 2020 - 10th International Conference on Simulation and Modeling Methodologies, Technologies and Applications

34