A Holistic Approach for the Development of a Digital Twin Focused

on Commissioning and Control of Electromechanical Feed Axes

Manuel Norberger

1

, René Apitzsch

1

, André Sewohl

1

, Holger Schlegel

1

and Matthias Putz

1,2

1

Institute for Machine Tools and Production Processes, Chemnitz University of Technology, Reichenhainer Straße 70,

09126 Chemnitz, Germany

2

Fraunhofer-Institut forMachine Tools and Forming Technologies, Reichenhainer Straße 70, 09126 Chemnitz, Germany

Keywords: Industry 4.0, Automation Technologies, Virtual Commissioning, Digital Twin, Machine Tool, Drive Data.

Abstract: The conventional commissioning of a machine offers numerous starting points for the use of modern

methods and technologies. With virtual commissioning, the conventional sequential work tasks can be

parallelized, which represents an economic advantage. For the virtual commissioning of machines and

systems, an appropriate knowledge of automation technology and processes is necessary. This information

can be found in the abstracted image, the digital twin. The digital twin is an application-dependent complex

entity. Drive control is part of such an application. In the industrial environment, parameterization is usually

carried out once on the basis of empirical methods during commissioning. Knowledge and methods from

science and research for optimal adjustment are rarely used. In this publication a holistic approach to the

implementation of the digital twin including automation technology of a system with an electromechanical

feed axis as well as an approach for recording the information necessary for parameterizing the drive control

is shown. The focus is on the ability of the digital twin to process information about the dynamics of the

drive system.

1 INTRODUCTION

With the advancement of Industry 4.0 data-driven

innovations come to the fore. Within the scope of

the product lifecycle a detailed digital twin can open

new opportunities and therefore can bring many

advantages.

Referring to (Grieves and Vickers, 2016) the

origins of the digital twin date back to the year 2002

where it was described as a "Conceptual Ideal for

PLM". This concept already had all the features of

the digital twin as we know it today. There was the

real space, the virtual spaces and the bi-directional

links in-between showing the flow of information

throughout the whole product lifecycle. Over the

years the concept was expanded and the definition

was sharpened and in 2010 it was called "Digital

Twin" for the first time (Grieves, 2011). In the same

year, NASA defined the digital twin as "integrated

multi-physics, multi-scale, probabilistic simulation

of a vehicle or system that uses the best available

physical models, sensor updates, fleet history, etc.,

to mirror the life of its flying twin" (Shafto et al.,

2010). In 2011 this concept already plays a huge role

in the context of Industry 4.0 (Roth, 2016).

The approach in this paper is based on the

definition of the Digital Twin in (Grieves and

Vickers, 2016) that's why it is briefly outlined

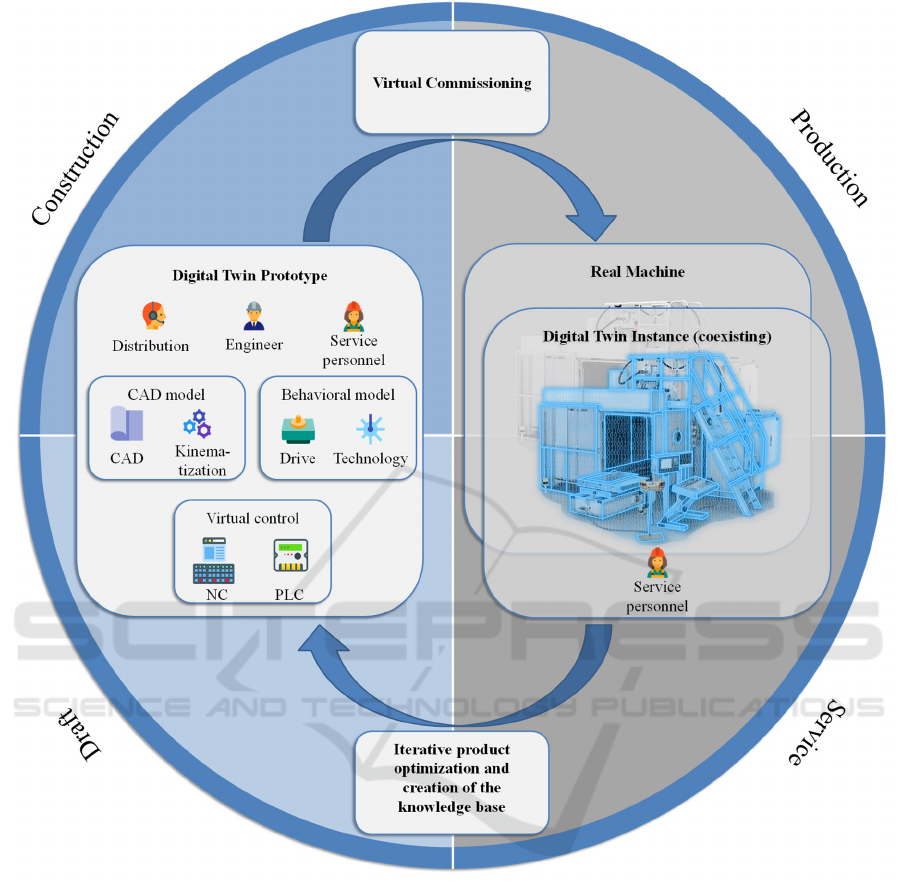

hereinafter. As shown in Figure 1, the Digital Twin

includes virtual information which describes a

potential or physical entity depending on the phase of

the lifecycle. An ideal Digital Twin would contain

every measurable information of its physical

counterpart. In the field of mechanical engineering a

Digital Twin can exist for a product, a machine (tool)

or an entire factory. In the scope of this work we are

referring to a Digital Twin for a machine tool.

Regarding the potential or physical entity from

above there are two types of Digital Twins: Digital

Twin Prototype (DTP) and Digital Twin Instance

(DTI). The Digital Twin Prototype (DTP) contains

all necessary information to create a potential

physical version including CAD models, control and

regulation logics etc. and is primarily used in the

development phase of the product. The Digital Twin

Instance (DTI) emerges out of the DTP and is

directly related to a specific physical entity and stays

connected throughout the whole lifecycle. This also

means the DTP and the DTI are in a parent-child

relationship.

Norberger, M., Apitzsch, R., Sewohl, A., Schlegel, H. and Putz, M.

A Holistic Approach for the Development of a Digital Twin Focused on Commissioning and Control of Electromechanical Feed Axes.

DOI: 10.5220/0009884707690774

In Proceedings of the 17th International Conference on Informatics in Control, Automation and Robotics (ICINCO 2020), pages 769-774

ISBN: 978-989-758-442-8

Copyright

c

2020 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

769

Figure 1: Influence of the digital twin for the product life cycle.

Throughout the lifecycle, many different user

groups interact with the machine tool and therefore

with its Digital Twin. They add as well as extract

information for a specific purpose, e.g. faulty parts

for maintenance, CAD models for assembly

simulation or requirement specification for

marketing. In (Winkler et al., 2020) it is described

which role the user and his or her acceptance play

during the development and usage of a Digital Twin.

It is of vital importance to know and overcome the

obstacles for the user in order to exploit the full

potential of the Digital Twin. This can be achieved

by technological and social solutions for example

through an intuitive user- or rather situation-specific

user interface and by answering to the question:

"What is the benefit for the user?" during the

instructions.

This paper particularly focuses on the virtual

commissioning of electromechanical feed axes of a

machine tool. Especially in the context of

commissioning tasks are performed sequentially.

Therefore, a process parallelization is proposed in

this paper as well as the usage of a consistent data

model, the Digital Twin, which offers the

opportunity to use the stored information as an input

for the parameterization of the electromechanical

feed axes.

ICINCO 2020 - 17th International Conference on Informatics in Control, Automation and Robotics

770

2 CONTROL OF MACHINE

TOOLS

In machine tools, the creation of a desired shape

requires a relative movement between the tool and

the workpiece. Movements are realized via feed

drives. In modern processing machines, electric feed

drives are used almost exclusively (Groß et al.,

2006). These are also known as electromechanical

axes (Hellmich, 2014). A control is necessary, so

that defined movements are observed as precisely as

possible. There are numerous strategies for

controlling machine-specific variables, such as the

position or speed of electromechanical axes,

whereby the concept of the cascade structure, also

known as servo control, has prevailed (Schröder,

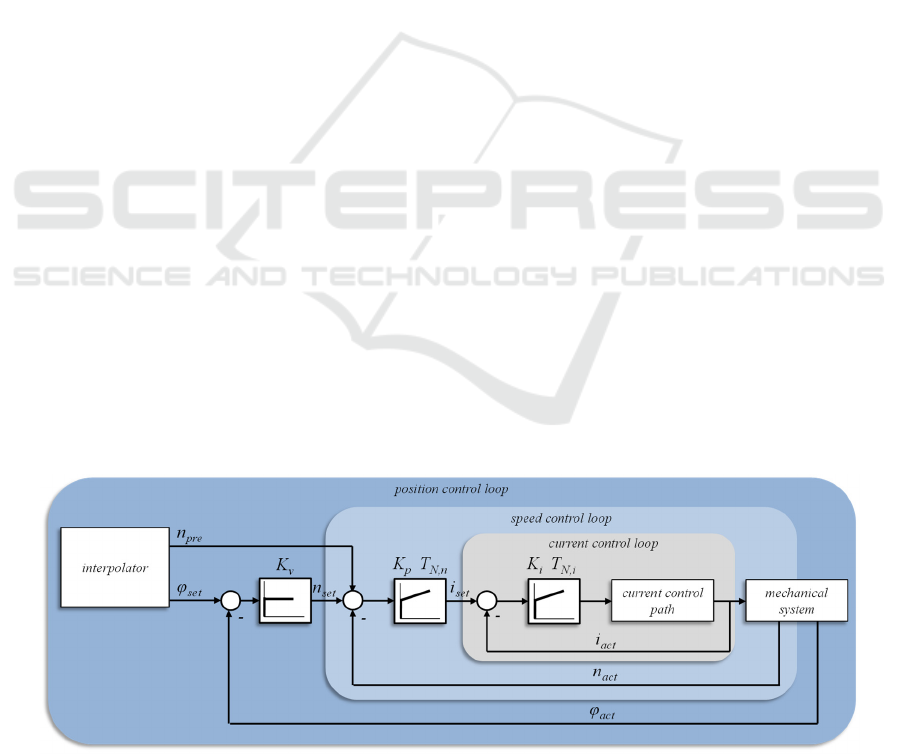

2009). The principle and the simplified structure of

the position control in a cascade structure are shown

in Figure 2. It is characteristic that the three control

loops are superimposed on one another. The current

control loop, which is part of the superimposed

speed control loop, is inside. At the very outside is

the position control loop, which is often

supplemented by a feed forward control. This can

reduce lag errors. In the industrial environment,

additional extensions are usually used, for example

filters, band-stops or additional feedback.

With the use of controlled electromechanical

drive systems, the increasing demands on machine

productivity and thus on dynamics can be met with

higher accuracy. Nevertheless, there are ongoing

efforts to improve manufacturing strategies and

processes in terms of stability, quality and

efficiency. The parameterizations of the control and

the control quality have a significant influence on

the process and the product quality. Accuracy and

productivity can be maximized by optimally

utilizing the control potential. However, studies have

shown that the control on machine tools are very

often not optimally designed (Schönherr, 2012).

Various methods are available for parameterizing

the controller. Very good results can be achieved

with a systematic design. However, this requires the

use of identification procedures, which are

associated with a significant additional expenditure

of time. For this reason, this procedure is rarely used

in industrial practice. Here, the control is usually

designed purely empirically based on the knowledge

of the commissioning engineer. At this point, the use

of the Digital Twin offers enormous potential for

improvement, especially in combination with virtual

commissioning.

3 VIRTUAL COMMISSIONING

Appropriate data and knowledge according the

handling of information are required for virtual

commissioning (VC). The real machine is built

based on the VC and the model data of the DTP. The

digital twin prototype also creates the DTI of this

specific machine. This DTI already exists during the

actual commissioning. The data obtained in this way

(e.g. frequency response, sensor data, etc.) are used

for the digital twin prototype and thus for the design

phase of the next machine. In this way, a knowledge

base for the products is created.

In addition, a large amount of data is generated

in the real operation of the producing machine. This

data enables direct or indirect conclusions to be

drawn about the machine status. Furthermore, the

coexisting DTI is used for process monitoring and

setting. For example, processing steps for new

workpieces can be virtually implemented and

optimized beforehand using the digital twin. This

leads to a minimization of the machine downtime.

Figure 2: Principle and structure of cascade control.

A Holistic Approach for the Development of a Digital Twin Focused on Commissioning and Control of Electromechanical Feed Axes

771

The VC is defined in detail in (VDI, 2016). It

describes the overall test of the automation system

without a real machine. The development stages

software in the loop (SIL) and hardware in the loop

(HIL) can also be used to describe the testing of

automation solutions.

The digital twin is intended to support the VC on

the one hand and to coexist with the real system on

the other. The new possibilities thus obtained should

be used in a value-adding manner based on (VDI,

2018). For example, business models in the area of

control and process control or via projects based on

simulation integration can be developed.

4 MECHATRONIC DESIGN

4.1 Modularity and Standardization

To improve the overall mechatronic design of a

corresponding product, the modularization of

products has become established in recent decades.

This modularization brings with it a standardization

of components. A modular design simplifies the

collaboration of knowledge carriers from different

areas over the entire product lifecycle. The overall

mechatronic system includes disciplines in

electrical, mechanical and computer science (van

Beek et al., 2010).

To improve the usability of the digital twin, a

modular approach of the machine or system under

consideration should be carried out or assumed. For

this purpose, for example, libraries can be used in

the area of CAD as well as for automation

technology. Those libraries often depend on the

specific framework. The libraries correspond to the

modules. Usually these are specific machine

components, such as devices, drive systems, gears,

etc.

If the environmental conditions resulting from

the location of the specific machine (e.g.

temperature fluctuations, vibrations, etc.) are

neglected, the modularity of the production system

enables the module-related data to be returned from

the digital twin instance to the digital twin prototype.

Different instances of a machine, information from

individual modules (e.g. drive system, gearbox, etc.)

and their effects should be almost identical and

reproducible.

4.2 Level of Detail

Every component can be modeled and every data

point can be called up, from the system through the

machine to the drive. Depending on the task,

different aspects are focused. Suitable data

management for the digital twin is discussed in

(Winkler et al., 2020). An application- and goal-

oriented selection of the data to be recorded is

therefore just as important as the definition of the

system boundaries when creating the digital twin.

The amount of data must be kept lean and the

system clearly defined.

4.3 Estimating the Dynamics of an

Electromechanical Feed Axis

In order to improve the information content of a

Digital Twin of a machine, data from the real

process and model knowledge should be embedded.

For example, moments of inertia and friction can be

determined based on knowledge of the used

geometries, materials and material pairs. In addition,

models of the electromechanical axis have to be

developed to reflect the actual behavior.

This data and real recorded frequency responses

are intended to enable the digital twin to access

information on estimated frequency responses of the

virtual machine. In addition, algorithms are available

to determine the parameters for the drive control

from this information.

The estimated frequency responses must be

validated and adjusted using real frequency

responses of the real machine. On this basis, an

improvement of the drive dynamics model is

expected. The digital twin prototype thus has the

ability to make a statement about the dynamic

properties of the drive system from CAD- and

metadata. This approach concerns the digital twin

prototype that is decoupled from the real machine.

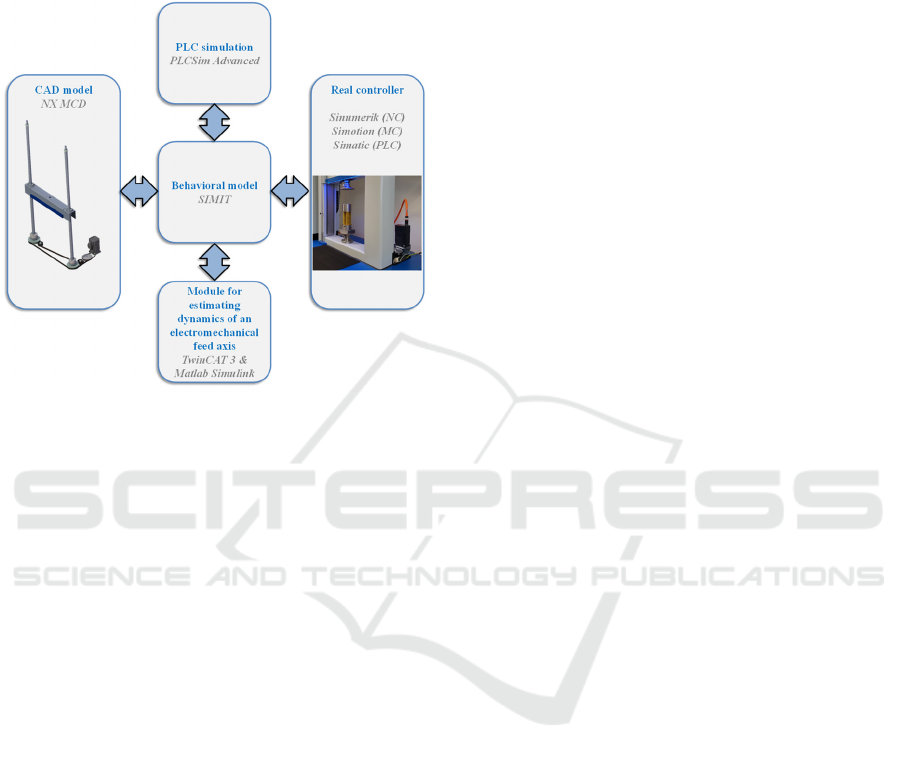

To estimate further machine states, a module is

to be developed that coexists with the real machine

and accesses drive and sensor data. Figure 3 shows

possible software solutions for this. Using the

example of the vertical electromechanical feed axis

shown in Figure 3, data from the CAD model such

as masses and moments of inertia are transferred to

the behavior model. With the SIMIT software from

Siemens, this data can be transferred to TwinCAT

via OPC UA. The advantage of TwinCAT is the

open structure and the possibility to use Matlab

Simulink models. SIMIT offers a separate interface

to the CAD software NX and the corresponding

kinematics tool Mechatronics Concept Designer

(MCD). The tool chain of an automated machine is

completed by PLCSimAdvanced. This enables the

simulative functioning of the PLC applications. The

final step in completing the digital twin approach is

ICINCO 2020 - 17th International Conference on Informatics in Control, Automation and Robotics

772

to build coexistence between the digital and physical

twin. This is also done via the SIMIT core element.

This offers corresponding interfaces to physical

controls. The approach thus includes both SIL and

HIL.

Figure 3: Exemplary structure of a testbed for an

integration of an estimation of machine conditions in the

digital twin.

The estimating module in TwinCAT receives

targeted data for example in order to make estimates

for the drive control from real drive data.

(Schöberlein, 2020) describes the disturbance

variable monitoring of speed-controlled mechatronic

drive systems by implementing corresponding

estimation algorithms. The information obtained in

this way is also fed back into the digital twin

prototype in order to make runtime information

available.

Thanks to the already mentioned modularization

of the machine, information for the virtual

commissioning of the drive can be generated

automatically. For example, libraries can be used for

the overall mechatronic design of a machine, which

feed data to algorithms and models running in the

background. When the draft is completed, they

already provide information and recommendations

for the parameterization of the drive. Knowledge

from research and science can thus be used

intuitively for technical staff and service personnel.

5 USAGE AND CONCLUSION

As part of the development of production plants, the

implementation of a holistic approach across the

entire product life cycle (as shown in Figure 2)

offers enormous potential for improvement and

savings. The focus is essentially on the

electromechanical feed drives. The use of the digital

twin is of great benefit for all areas of the product

life cycle.

As already described in the previous chapter,

important information can be stored and linked to

one another in the design phase of the machine. In

this way, effects on the drive control can be assessed

at an early stage. Constructive adjustments can be

made retrospectively, for example to influence

resonance frequencies. In this way, an overall

mechatronic design can be implemented.

The digital twin is of particular interest for the

commissioning phase. As part of virtual

commissioning, complex identification procedures

can already be used and automated. In this way, all

the information required for commissioning can be

stored and made available in advance. This

drastically reduces the effort during commissioning.

In addition, the non-reproducible empirical

procedure is substituted by scientific methods. A

significant improvement in controller performance

can therefore be expected. The prerequisite for this

is of course a sufficiently precise database.

Mechanical parameters such as masses, moments of

inertia, stiffness, damping and friction values are

particularly relevant for the controller parameters.

However, communication, computing, cycle and

dead times that result from the control components

must also be included.

These parameters are of interest for ongoing

operation even after commissioning. A change in the

mechanical system over the running time of the

machine is conventionally hardly detected. The

digital twin can be used to feedback real sensor and

drive data from the machine. These are to be made

available for disturbance variable monitoring with

appropriate estimation algorithms. This enables

permanent monitoring and automatic adjustment of

the parameterization in perspective.

In addition, the inclusion of the processing task

in the sense of forward-looking process planning

offers additional potential for improvement. If

information regarding the workpiece masses and

disruptive process forces is stored in the digital twin,

this can also be included in the controller

parameterization. This enables a design that is

optimized for different machining tasks.

Furthermore, the digital twin serves to generate a

knowledge base and iterative process and product

optimization.

A Holistic Approach for the Development of a Digital Twin Focused on Commissioning and Control of Electromechanical Feed Axes

773

In the course of future research work, the

creation of a digital twin of an electromechanical

feed axis is initially being considered. The focus is

on demonstrating the functionality of the structure

illustrated in Figure 3. Basis is the test setup shown

in Figure 3. The corresponding CAD model and the

data from control components are already available.

With the implementation of the software

infrastructure, the data can be transferred to

parametric models in Matlab Simulink via the

interfaces. These models are used to carry out

systematic identification procedures. This enables

the calculation of controller parameters and the

assessment of the controller performance, too. In

addition, this data is in turn made available for

virtual commissioning. After validation, the

successive expansion with the additional modules

for monitoring and automatic adjustment of the

parameterization during operation is planned.

ACKNOWLEDGEMENTS

Funded by the European Union (European Social

Fund) and the Free State of Saxony.

REFERENCES

van Beek, T. J., Erdent, M. S. and Tomiyama, T., 2010.

Modular design of mechatronic systems with function

modeling. In Mechatronics, 20(8), 850-863.

Grieves, M., 2011. Virtually perfect: Driving innovative

and lean products through product lifecycle

management. Space Coast Press.

Grieves, M. and Vickers, J., 2016. Transdisciplinary

Perspectives on Complex Systems - Digital Twin:

Mitigating Unpredictable, Undesirable Emergent

Behavior in Complex Systems, Springer Cham.

Groß, H., Hamann, J. and Wiegärtner, G., 2006.

Elektrische Vorschubantriebe in der

Automatisierungstechnik: Grundlagen, Berechnung,

Bemessung. Publicis Corporate Publishing Erlangen.

Hellmich, A., 2014. Nichtinvasive Identifikation von

Regelstreckenparametern für elektromechanische

Achsen: Dissertation Arvid Hellmich, In Berichte aus

dem IWU, 85.

Schröder, D., 2009. Elektrische Antriebe - Regelung von

Antriebssystemen. Springer-Verlag Berlin Heidelberg,

4

th

edition.

Schönherr, R., 2012. Regelkreisüberwachung

mechatronischer Antriebssysteme: Dissertation Ruben

Schönherr, In Berichte aus dem IWU, 64.

Schöberlein, C., Norberger, M., Schlegel, H. and Putz, M.,

2020. Simulation and disturbance estimation of speed-

controlled mechatronic drive systems. In MATEC Web

of Conferences, 306.

Shafto, M., Conroy, M., Doyle, R., Glaessgen, E., Kemp,

C., LeMoigne, J. and Wang, L., 2010. Draft modeling,

simulation, information technology & processing

roadmap. In Technology Area, 11.

Roth, A., 2016. Einführung und Umsetzung von Industrie

4.0. Springer-Verlag Berlin Heidelberg.

VDI-Richtlinie 3693 Blatt 1, 2016. Virtual commissioning

- Model types and glossary.

VDI-Richtlinie 3693 Blatt 2, 2018. Virtual commissioning

- Introduction of virtual commissioning in companies.

Winkler, S., Schumann, M., Apitzsch, R., Klimant, F. and

Klimant, Ph., 2020. Der Digitale Zwilling – Probleme

und Lösungsansätze. In ZWF, 115.

ICINCO 2020 - 17th International Conference on Informatics in Control, Automation and Robotics

774