A Secure Network Scanner Architecture for Asset Management in

Strongly Segmented ICS Networks

Matthias Niedermaier

a

, Thomas Hanka, Florian Fischer

b

and Dominik Merli

HSA innos, Hochschule Augsburg University of Applied Sciences, Germany

Keywords:

Network, Security, Scanning, ICS, SCADA.

Abstract:

Industrial Control System (ICS) are essential for process automation and control in critical infrastructures,

like smart grids, water distribution and also food production, in our modern world. These industrial devices

will be even more connected, due to the trend of Industry 4.0 and Internet of Things (IoT), to provide addi-

tional functionality. An example for a use case is predictive maintenance, where sensor data is required, to

e.g. replace defective parts before outage. While connectivity enables easier and more efficient process man-

agement, it also increases the attack surface for cyber-attacks. To provide secure operation for interconnected

ICSs additional protection measures, like asset management should be applied, to observe and maintain assets

within a control network. One of the first steps to improve cyber-security with asset management is device

identification in ICS networks. A common method for device identification is active network scanning, which

adds additional network traffic to the ICS network. Because of the common segmentation with firewalls of ICS

networks, scanner nodes in each sub-network are necessary. The distribution of active scan nodes typically

adds additional cross connections within segmented ICS networks. In this paper, we introduce a secure scan-

ning architecture for fragile ICS networks. Our architecture is based on scanning nodes, which use the concept

of hardware-based data diodes to e.g. separate the critical control network from the office network. To ensure

a gentle scan on fragile ICS networks, the scan node provide a bandwidth limitation of the scan, to reduce risk

of influences within ICS networks. We implemented a Proof of Concept (PoC) system and evaluated it within

our industrial testbed, to show the feasibility of our architecture.

1 INTRODUCTION

Industrial Control Systems (ICSs) control our daily

life, unnoticed by the majority of the population. A

typical field of application for ICS devices is process

automation within building automation or production

lines in the area of chemistry and automotive. But

ICS devices are also applied to critical infrastructures,

such as electricity or water supply, to automate and

control critical tasks. In these environments, a distur-

bance of the regular execution may have severe con-

sequences and e.g. could lead to a blackout.

Historically, ICSs were operating in isolated net-

work and field-bus environments, due to lack of ne-

cessity for data exchange to the outside of the ICS.

In contrast to this, in recent years, the connectivity

of ICSs and distribution of information within indus-

trial networks is increasing and will further increase

a

https://orcid.org/0000-0003-4550-7422

b

https://orcid.org/0000-0002-4532-731X

in the future, due to the trend of Industry 4.0. A use

case, which relays on the networking ability and inter-

connection of ICS is predictive maintenance, where

outages can be foreseen, based on the continuous ob-

servation of certain parameters. This data exchange

between ICSs and data processing systems in modern

networks is often Internet Protocol (IP)-based, which

also allows an interaction with common Information

Technology (IT) systems.

But next to the advantages of interconnected de-

vices, this connectivity leads to an enlarging attack

surface of ICS devices. The main reason for this is,

that the network interfaces introduce the possibility of

remote attacks on the Operational Technology (OT)

environment. This leads to the point, that a proper

security strategy must be applied to reduce the new

possible attack vectors.

Important measures to increase the IT-Security are

proper update and vulnerability management, to react

on new vulnerabilities as fast as possible. In order

to identify which versions of hardware and software

Niedermaier, M., Hanka, T., Fischer, F. and Merli, D.

A Secure Network Scanner Architecture for Asset Management in Strongly Segmented ICS Networks.

DOI: 10.5220/0010191603470355

In Proceedings of the 7th Inter national Conference on Information Systems Security and Privacy (ICISSP 2021), pages 347-355

ISBN: 978-989-758-491-6

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

347

are currently in use, asset identification is essential to

perform a proper asset management (Vanier, 2001).

This information is required, to determine currently

existing vulnerabilities in the products in use, or if e.g.

security updates are available from the manufacturer.

There are various options for gathering the data

necessary for asset management. Next to manual

gathering with e.g. inventory lists, it is possible to ac-

cess necessary information technically via passive or

active network scanning. While with passive network

scanning the data traffic is used, that already exists in

the network, and with active scanning additional net-

work traffic is brought into the network. This is also

one of the main differences, which usually leads to

a poorer detection rate for passive network scanning.

One of the main reasons for the mostly lower scan

result quality of passive scanning is, that e.g. no in-

formation about the software version used by the de-

vices is transmitted in regular communication. Both

technologies have their right to exist and, depending

on the application, show their strengths. However, in

this work, the focus is on active network and vulnera-

bility scanning as a technology for asset management,

because of the mostly better detection rate.

Due to the strong segmentation in industrial net-

works, active scanning is usually implemented with

scanner nodes in each sub-network. These nodes of-

ten struggle the problem, that if they contain vulner-

abilities themselves, additional attack vectors are cre-

ated.

In this paper we present a secure scanning archi-

tecture for asset management within industrial net-

works with the following contributions:

• Safe and secure scanner architecture for ICSs,

which ensure a slow and therefore gentle device

scanning in fragile networks.

• ICS scanner node based on a bidirectional Intelli-

gent Data Diode (IDD) with strong segmentation.

• Evaluation of the concept with a low-cost pro-

totype, build with common off-the-shelf compo-

nents.

The paper is structured as follows. In Section 2

the current state and challenges of asset management

and industrial network scanning is explained. The

methodology behind the here presented network scan-

ner is introduced in Section 3. Afterwards, the im-

plementation is described and evaluated in Section 4.

At the end, in Section 5, a conclusion and outlook is

given.

2 ASSET MANAGEMENT AND

NETWORK SCANNING IN ICS

NETWORKS

Asset management has various specifics and chal-

lenges in industrial networks. These are taken up and

explained in the following.

2.1 Network Segmentation in ICS

First and one of the most important measures within

a defense-in-depth strategy is the zoning or segmen-

tation of assets within sub-networks. This segmenta-

tion is mostly done according to their application sce-

nario or logical relationship to each other. This results

commonly in sub-networks for IT assets and one or

multiple sub-networks for OT assets. Between these

sub-networks, there are often firewalls (Nivethan and

Papa, 2016) placed between the IT, OT and other sub-

networks. These are used to actively protect against

attacks against the ICS network.

In addition to the obvious advantages of segmen-

tation, it is often implemented because of recom-

mendations or requirements in various guidelines and

standards. For instance “NIST SP800-82 – Guide to

ICS Security” (Stouffer et al., 2015) recommends the

segmentation of control networks and corporate net-

works. In addition to that, the IEC 62443-3-3 (IEC,

2020) in particular “SR 5.1 Network Segmentation”,

describes, that control system networks should be log-

ically segmented from non-control system networks.

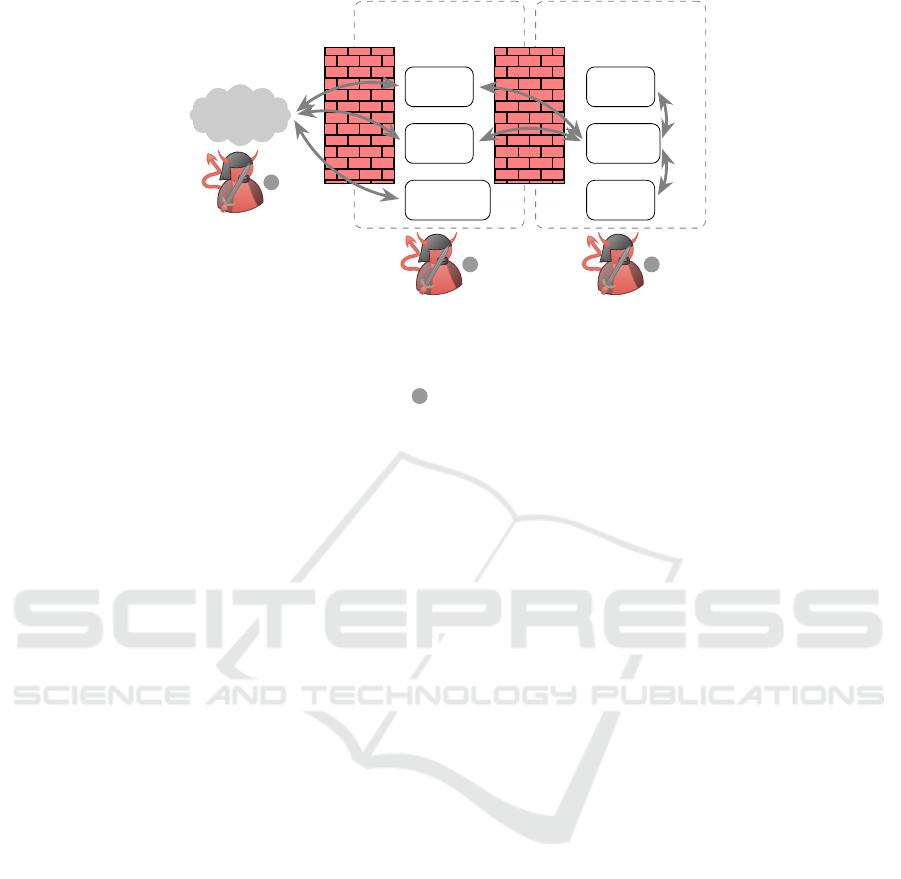

Figure 1 shows an example of a common net-

work structure with a defense-in-depth strategy, as

used in manufacturing industry (Kuipers and Fabro,

2006). In this example, the ICS network contains

Programmable Logic Controllers (PLCs), which in-

teracts with the physical world, a Supervisory Con-

trol and Data Acquisition (SCADA) system for mon-

itoring and controlling the process, as well as a Hu-

man Machine Interface (HMI) for user interactions.

In the corporate network, often Manufacturing Exe-

cution System (MES)/Enterprise Resource Planning

(ERP) systems are located, which allows planning of

the production. Furthermore, standard computer and

other standard components like printers are also lo-

cated in the corporate network. In this case, the corpo-

rate network is protected from the untrustworthy In-

ternet with a firewall. In addition, the ICS network is

furthermore protected by a firewall from the corporate

network. If an external attacker 1 wants to take over

the control network, two firewalls must be compro-

mised. An internal attacker or virus in the office net-

work 2 must also compromise the industrial firewall

in order to get access to the ICS network. Only an

ICISSP 2021 - 7th International Conference on Information Systems Security and Privacy

348

ICS networkCorporate network

Internet

External

1

Internal

2

Internal

3

PLC

HMI

SCADAERP

MES

Computer

FirewallFirewall

Figure 1: Example network architecture and data flow following the principal defense in the depth for segmented ICS infras-

tructures.

attacker who has already access to the ICS network 3

does not have to overcome perimeter protection.

2.2 Asset Management and Protection

Strategies in ICS

For the subject of asset and vulnerability management

there are similar techniques used, how the required in-

formation is gathered (Knapp and Langill, 2014). Be-

side manual gathering the information by hand, there

exist two common strategies for identifying assets and

related metadata for vulnerability detection within an

industrial network environment.

The first variant is the complete passive approach,

which analyzes the existing network traffic within an

OT network, e.g. by listening to a mirror port. This

approach causes no additional network traffic to the

observed devices and the network. On the downside

the detection potential is limited to the information,

which can be extracted from the existing network traf-

fic.

The second variant is based on actively scanning

the assets within the network, which generates ad-

ditional traffic within the OT network. The targeted

and active information gathering increases the quality

of results and therefore the detection accuracy. But

the additional network traffic also can cause distur-

bance to the targeted assets (Niedermaier et al., 2018).

Due to the fragility of common off-the-shelf industrial

components, active scanning must be executed with

caution and the amount of generated network traffic

must be chosen with care. Thus it is important, to

limit the scan rate and therefore the traffic generated

by the scanning process to a predefined and uncritical

threshold value.

Another security measure within the defense-in-

depth approach is the inclusion of devices and ser-

vices to recognize ongoing attacks on the assets with

the ability to react towards these attacks. To detect at-

tacks in progress, Intrusion Detection Systems (IDSs)

and network monitoring systems (Maynard et al.,

2018) are commonly used, while Intrusion Prevention

System (IPS) systems are used to prevent influences

of attack attempts and preempting the attacker.

In addition to find devices, network scanners (Cof-

fey et al., 2018) can also be used to uncover unneces-

sary open ports and services, as well as other miscon-

figurations. Furthermore, with network scanner it is

also possible or detect changes of the network config-

uration, e.g. according to an attack. The use case of

active network scanning for asset identification, vul-

nerability detection and asset management in general

in ICS is where the work of this paper focuses.

2.3 Current Challenges of Active

Network Scanning in ICS

The segmentation also means that active scanners that

can be used for asset management must be able to in-

teract with segmented sub-networks. There are there-

fore two common ways of realizing this for active

scanners: on the one hand, the firewall can be set up

so that it is open for scanners and, on the other hand,

scan nodes can be placed in every sub-network. The

use of scan nodes in the sub-networks is usually pre-

ferred, as this does not weaken the segmentation con-

cept through firewalls. However, it is important, that

the scan nodes itself does not bring in additional vul-

nerabilities.

One of the most known and used network scan-

ners is nmap (Lyon, 2009). An off-the-shelf network

scanner, which is extensible by scripts (Nmap Script-

ing Engine (NSE)) to use e.g. ICS specific protocols.

Nmap is limited by the point, that it is not able to make

A Secure Network Scanner Architecture for Asset Management in Strongly Segmented ICS Networks

349

distributed scans by itself. However, nmap is an excel-

lent and well-tested network scanner and is used as a

pure scanner for this work. The required architecture

for network segmentation around nmap in this work

is an in-house development to circumvent the weak-

nesses of nmap.

Another common scanner framework is the com-

mercial product Nessus from Tenable (Tenable,

2020). This vulnerability scanner supports some in-

dustrial protocols and is able to scan distributed with

agents. However, it is not open source and does

not offer any hardware segmentation in the scanner

nodes.

An open-source alternative to this framework is

Greenbone Vulnerability Management (GVM), for-

merly known as OpenVAS which was split off from

Nessus, when it switched to a proprietary license in

2005. However, the OT security feed is only available

in the professional Greenbone Security Feed (GSF),

but not in the Greenbone Community Feed (GCF).

Furthermore, no hardware segmentation in the scan-

ner nodes is currently implemented.

Powler (See et al., 2017) is an open-source dis-

tributed network vulnerability scanner, which uses

nmap as a scan engine. However, the scan node is not

segmented and also not designed for the usage within

ICSs.

For a distributed network scanner archi-

tecture (Bidaud, 2003) and hardware separa-

tion (Goldring, 2013; ?), there are already concepts

available on the market. Though, to the best of the

author’s knowledge, there are no concepts of dis-

tributed scanners with hardware separation, aiming

especially for fragile ICS networks.

(Niedermaier et al., 2019) introduced a network

scanning architecture on low-performance Microcon-

troller Units (MCUs). This scanner is based on a basic

port scan, without any service detection carried out by

e.g. sensors or actuators. However, this is not suitable

for use on proprietary devices and does not offer any

segmentation concept.

The problems within existing approaches show

that not all challenges are solved to implement a

secure and feasible asset management process in

ICSs (Wedgbury and Jones, 2015).

3 A SAFE AND SECURE

NETWORK SCANNING

ARCHITECTURE

For the use of an industrial network scanner, a number

of requirements were set up specifically for the ICS

environment as part of this work. These requirements

are extensions, that distinguish the here presented net-

work scanner from common of-the-shelf scanners.

• Safe and secure distributed scanning: The scan-

ning architecture must operate in a highly seg-

mented network.

• Secure without updates: The network scanner it-

self must not introduce new vulnerabilities to an

ICS in any way.

• No influences by the scan: The scan must not in-

fluence the ICS devices.

• No unintended access to scan jobs and results:

The scan jobs should only be given in order by

authorizes persons and the scan results must be

securely stored and also should only be accessible

by authorized persons.

Therefore, in this paper we present an active scan-

ning architecture, which place individual scan nodes

into each sub-network and a central master node. One

of the most important aspects is the hardware-based

segregation of each scan node. This keeps the se-

curity measure of firewall segregated networks effec-

tive as is and limits the potential abuse of vulnerabil-

ities within the scanner itself. Furthermore, the active

scanner is optimized for use with fragile assets within

OT networks, with restricted scan traffic and a limited

scan rate. The configuration of the scanner is pro-

tected against manipulation, by the hardware-based

segregation. This avoids the creation of network traf-

fic, different from the pre-configured possibilities.

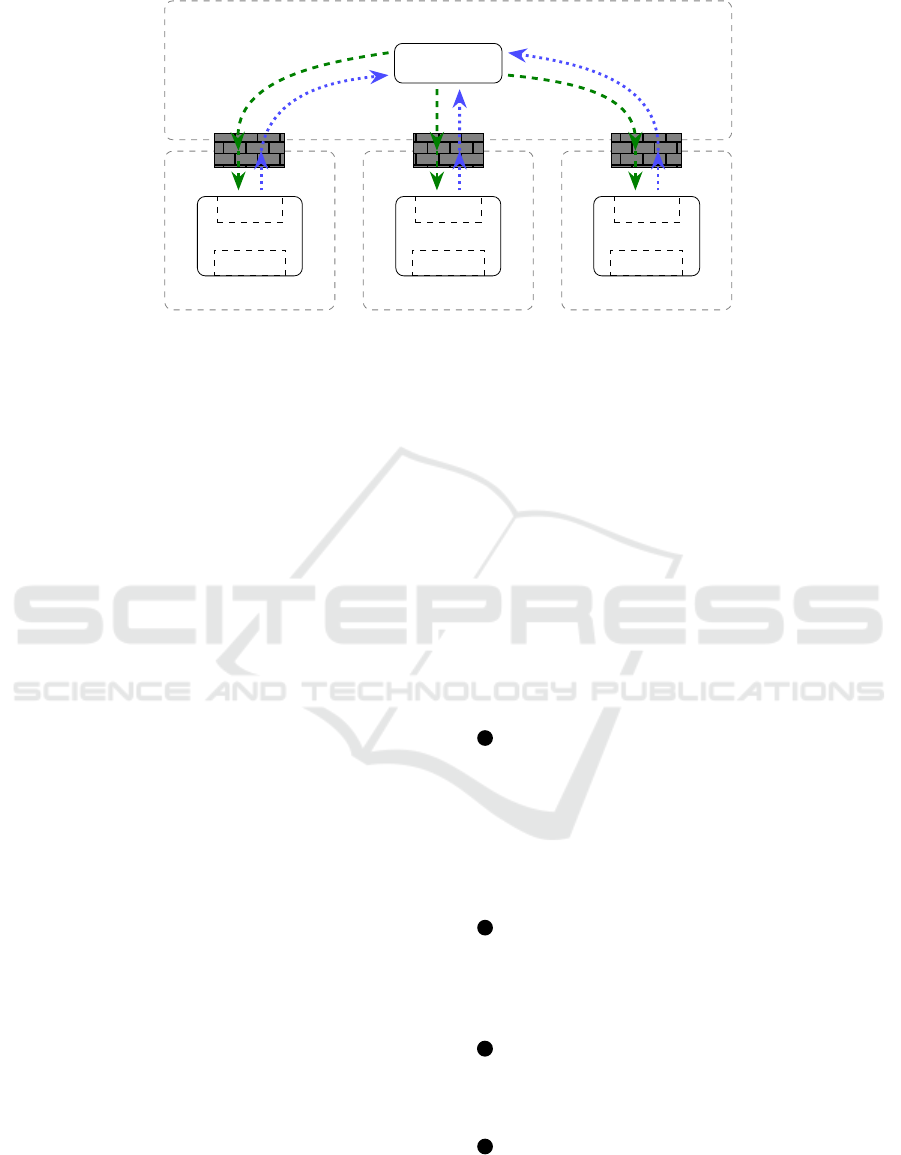

A common scanning architecture is shown in Fig-

ure 2, where a central server controls a number of

scanning nodes. This is often necessary, when ICS

networks are separated into different sub-networks,

which prevents scanning from a central scan node.

The architecture, presented in Figure 2, differs

from the central scan node approach and integrates

well in firewall segregated sub-network topologies.

First distinction of this approach is the point-to-point

connection between the scan master and the single

scan nodes (Network Interface Card (NIC) IT) as well

as the second network card (NIC OT). Only the net-

work card for the OT network has access to this net-

work. Next, the network card for the IT communica-

tion is physically not connected to the OT network.

The scan master is used to control the scan tasks

within the connected scan nodes and also gathers the

scan results for a centralized evaluation. A user,

which interfaces with the scan master, is able to con-

figure and create certain predefined scan jobs, which

are then propagated to the required scan node.

The communication between the scan master and

each scan node is protected against manipulation with

ICISSP 2021 - 7th International Conference on Information Systems Security and Privacy

350

Corporate network

ICS network 1 ICS network 2 ICS network n

Scan master

Scan node 1 Scan node 2 Scan node n

NIC IT

NIC OT

NIC IT

NIC OT

NIC IT

NIC OT

scan task

(signed)

scan results

(signed &

encrypted)

Figure 2: Distributed scanner architecture with a point-to-point connection trough the firewall from the scan master to the

scan nodes.

the use of signatures and the scan job messages can

also be encrypted on demand. This ensures, that scan

jobs on the scan nodes can only be executed from au-

thorized users. After a scan job has been received, the

scan node starts the network scan independently from

the master.

A scan of a node within a sub-network results

in a scan report. The scan node encrypts and signs

these results, which include a timestamp, and trans-

mits them to the scan master. This means that attack-

ers cannot bring in historical or manipulated results

into the scan master and is also not able to read the

results.

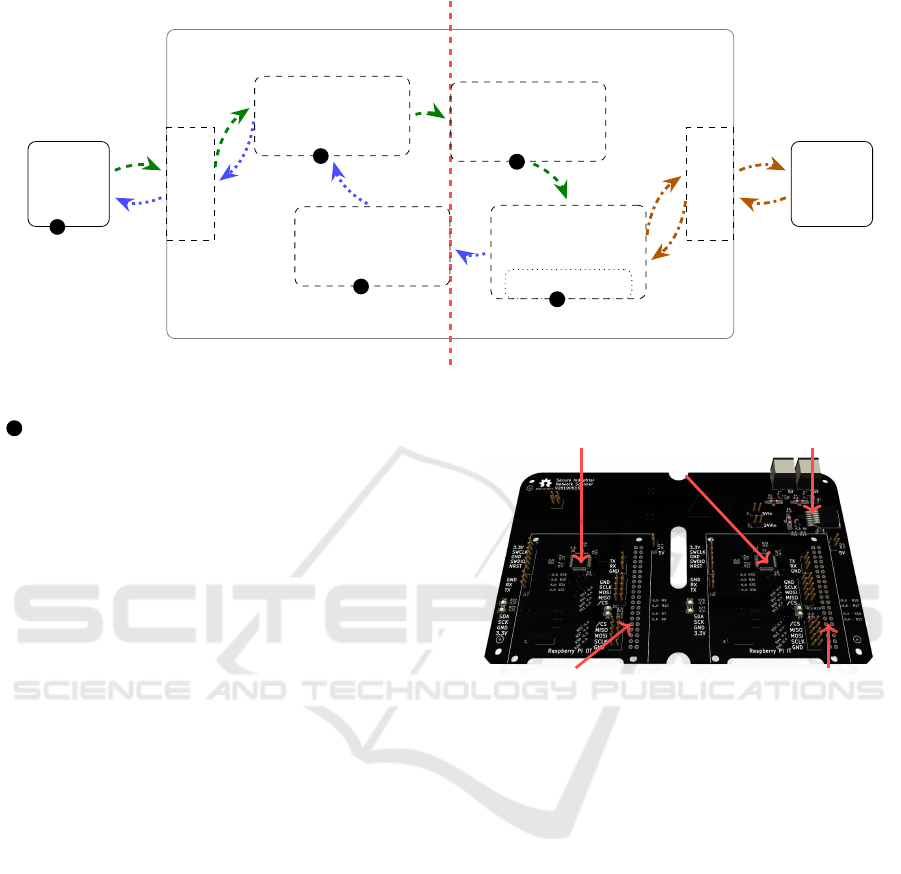

The concept of the hardware separation is shown

in Figure 3. On the left, the scan task comes from

the scan master, this scan job/task online contains the

start time of the scan. The rest of the configuration,

such as which IP address spaces are scanned and the

packet rate, are already stored on the OT scanner, im-

mutable over scan job messages. These configura-

tions could for example be saved on a SD card used

by the OT scanner. This is important, because if an at-

tacker succeeds, e.g. by taking over the scan master,

the attacker can only perform regular network scans,

but is not able to perform a Denial of Service (DoS)

attack. The IT controller, which must be able to han-

dle Ethernet, receives the scan task and forwards it to

the OT IDD, which serves as a Gateway (GW). The

IDD is capable of filtering and blocking traffic, which

passes through it. The level of detail with which the

IDD can do this depends on the implementation on

the IDD and the application, e.g. filter rules. After-

wards, the OT IDD interprets the message and checks

whether it is valid and thus serves as a packet filter

and data diode. If the scan task is valid, the message

is forwarded to the OT scanner, otherwise the mes-

sage is dropped. If the OT scanner receives a valid

signed scan job, it starts a network scan as config-

ured in the locally saved scan configuration file. After

completion of the scan, the scan results are encrypted

and signed and sent back to the IT IDD. If the data is

valid, it forwards the results to the IT controller. The

IT IDD serves as a packet filter and data diode in the

same way as the OT IDD. The IT controller sends

the results to the scan master, where the signature is

checked and the results gets decrypted.

The scan architecture is designed to limit the at-

tack surface for the ICS network to a minimum. The

following barriers are provided within the security

concept for the attack scenario, which does not di-

rectly impact the ICS network. In the following, it

is assumed that an attacker has already access to the

corporate network:

1 The scan master is compromised (1st layer barrier

compromised): If the scan master is taken over,

by worst it is possible to send regular scan jobs

which, cannot trigger a DoS, because the scan

configuration is already stored on the OT scanner.

Furthermore, if the attacker can manipulate or ac-

cess the cryptographic private keys, he can view

and manipulate scan results on the master.

2 The IT controller is compromised (1st layer bar-

rier compromised): Since the scan jobs are signed

and the scan results are signed/encrypted, an at-

tacker who has taken the IT controller can only

interrupt the connection.

3 The OT IDD is compromised (2nd layer barrier

compromised): If the first barrier level failed and

the OT IDD is overtaken by an attacker, scan jobs

can be intercepted, similar to the IT controller.

4 The IT IDD is compromised (2nd layer barrier

compromised): If the first barrier level failed and

the IT IDD is compromised by an attacker, scan

results can be intercepted, similar to the IT con-

troller.

A Secure Network Scanner Architecture for Asset Management in Strongly Segmented ICS Networks

351

Scan node

untrusted trusted

NIC

OT

OT scanner

(e.g. Linux-based)

OT IDD

(e.g. RTOS-based)

scanner config

ICS

devices

NIC

IT

IT controller

(e.g. Linux-based)

IT IDD

(e.g. RTOS-based)

Scan

master

scan task

(signed)

scan results

(signed &

encrypted)

scan

traffic

1

2

3

4

5

Figure 3: Methodology of the hardware concept.

5 Only if the 1st and 2nd barrier are hacked (3rd

layer compromised), the OT scanner could be at-

tacked. This of course allows DoS or other attacks

to be carried out on the OT network. This requires

several serious errors in various implementations

of the defense-in-depth architecture of our scan-

ner.

The multiple barrier security concept shown here

shows that an IT security risk for the OT network only

arises through multiple errors. However, the possibil-

ity for this to happen is quite low.

4 PROOF OF CONCEPT

IMPLEMENTATION

To show the feasibility of the secure network scan-

ner concept and its practicability, a Proof of Con-

cept (PoC) implementation was built.

4.1 Hardware

The hardware of our PoC is based on two Raspberry

Pis Model 3B (Raspberry Pi Foundation, 2015). One

is connected to the critical ICS network side and

the other on the untrustworthy office network side.

The two Raspberry Pis are electrically connected via

data diodes (STM32). For the data diodes, two

STM32F030CCT (STMicroelectronics, 2020) based

on Cortex

®

-M0 are used. Electrically the MCUs are

connected to the Raspberry Pis via Serial Peripheral

Interface (SPI). A Printed Circuit Board (PCB) (Fig-

ure 4) was designed for our PoC, which implements

this hardware segmentation.

MCU OT IDD

MCU IT IDD

24V power supply

Connector

Raspberry Pi OT

Connector

Raspberry Pi IT

Figure 4: Pictures of the PCB of the network scanner ren-

dered in KiCad (Charras, 2012). On the bottom, two Rasp-

berry Pis get mounted. On the top, two displays controlled

by the Raspberry Pis can be attached to prompt the current

status.

Figure 5 shows the complete network scanning de-

vice within a 3d printed case for IEC/EN 60715 rail

mount for appliance in industrial environment. On the

bottom of the custom PCB, there are the two Rasp-

berry Pis mounted. Furthermore, the two Organic

Light Emitting Diode (OLED) displays are installed,

which show the current status of the IT and OT side.

The PoC hardware part is implemented as described

in the concept and is about e 100 in component costs.

4.2 Software

The use of Linux-based (Torvalds, 1997) controllers

on the one hand and minimal Real-time Operat-

ing System (RTOS) systems on the other offers

various advantages from a security point of view.

The system was prototypically implemented with

ICISSP 2021 - 7th International Conference on Information Systems Security and Privacy

352

Ethernet

connector OT

OLED OT

Ethernet

connector IT

OLED IT

Figure 5: Picture of the complete device within a 3d printed

IEC/EN 60715 rail mountable case.

Python (Rossum, 1995) on the Linux devices and

the widely used and tested nmap network scanner

with OT NSE scripts is used. These scripts offer the

possibility to access information about ICS-specific

and proprietary protocols. Currently, the following

NSE scripts are in use s7-info, pcworx-info,

modbus-discover, knx-gateway-discover,

snmp-info, codesys-v2-discover, enip-info,

bacnet-info, dnp3-info, fox-info,

iec-identify, moxa-enum, omrontcp-info,

and omronudp-info. Using Linux provides the

advantage of an updateable and secure base system.

The prototypical Python implementation within the

PoC could be replaced in a real product by a secure

programming language such as Rust (Matsakis and

Klock, 2014). This could further increase the security

of the scanning architecture and prevent e.g. buffer

overflows.

Furthermore, the MCUs based on FreeRTOS are

a part of the security concept. The firmware of the

RTOS is written in C (Kernighan et al., 1988) and

the implementation of the data diodes differs from the

more powerful OT scanner and IT controller. These

MCUs only pass the data further if they have a cor-

rect format and thus serve as a data diode and packet

filter. E.g. the length and the message type are veri-

fied and if this does not meet the predefined structure,

the message is not forwarded.

The results can be displayed via a website or oth-

erwise e.g. further processed in a Security Informa-

tion and Event Management (SIEM).

4.3 Minimizing the Scan Impact

As previously mentioned, it is important that the gen-

erated scan traffic can be configured. This is done

through the configuration file on the OT scanner, so

that attackers cannot change it without physical ac-

cess. This prevents attackers from performing a DoS

attack on components in the OT network.

The scan duration depends on the selected packet

rate and could be reduced by a higher packet rate.

However, higher packet rates increase the risk that

scanned devices get influenced by the increased traf-

fic. As an example configuration, a slow packet rate

of maximum 20 packets per second was selected for

the test. This is configured on the one hand in nmap

and on the other hand in iptables (Andreasson et al.,

2001), so that the Linux operating system does not

cause additional packets. This limitation of the net-

work traffic leads to a high scan duration, which is,

however, safer for the industrial network.

4.4 Testbed

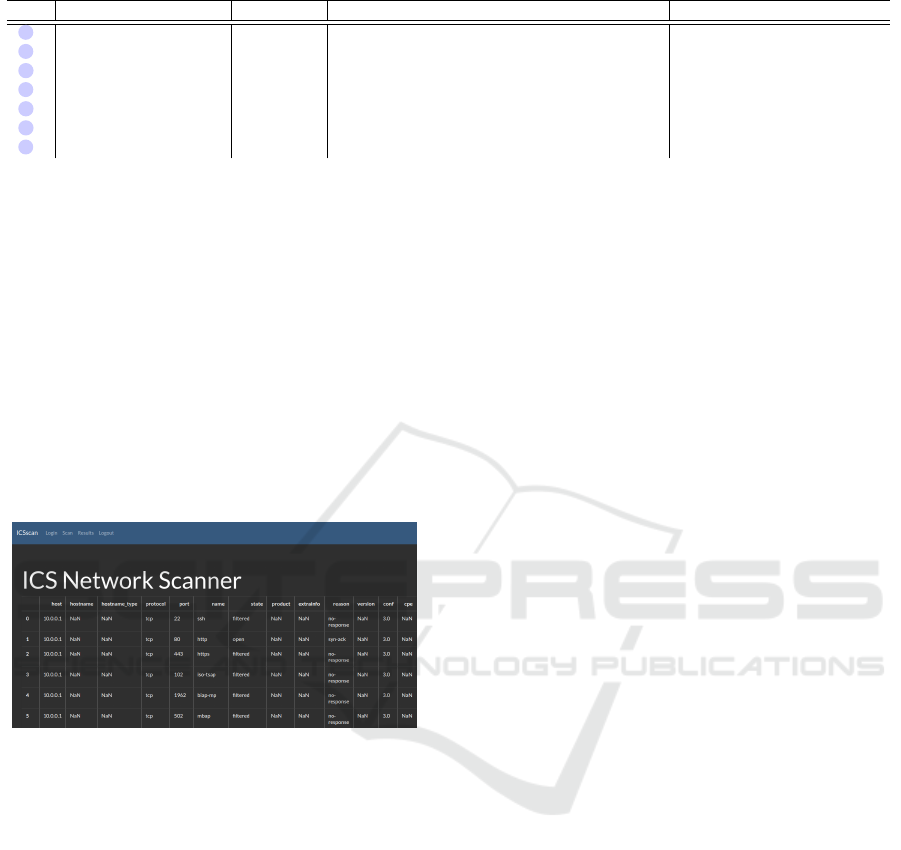

Table 1 lists the components that were used to evalu-

ate the network scanner. This testbed provide a solid

basis for checking whether the pipeline from sending

a scan task to receiving the scan results is working.

Figure 6 shows the laboratory setup on a stand,

with the various PLC solutions and one scanner

node 7 . Here the OT test network is completely in-

dependent and the scan jobs can be received over the

second wired interface (IT NIC) or over Wi-Fi. The

results are also sent back this way.

1

2

3

4

65

7

Figure 6: Picture of the testbed used for the evaluation, with

the scanner node on the top left and five ICS test devices.

A Secure Network Scanner Architecture for Asset Management in Strongly Segmented ICS Networks

353

Table 1: Overview of the devices in the testbed.

No. Device IP Software Open pots

1 TL-SG1016DE 10.0.0.1 1.0.1 Build 20180629 Rel.58355 80

2 Wago 750-842 10.0.0.2 05.05.02(19) 80, 502, 2455

3 Siemens S7-1212 10.0.0.3 V 3.0.2 80, 102

4 Siemens IoT 2020 10.0.0.4 CODESYS Control for IOT2000 SL 3.5.16.10 22, 1217, 1534, 4840, 11740

5 STM32MP157C-DK2 10.0.0.5 OpenPLC v3 (Alves et al., 2014) 22, 502, 8080, 20000, 44818

6 Raspbery Pi 3B 10.0.0.6 OpenPLC v3 (Alves et al., 2014) 22, 502, 8080, 20000, 44818

7 Scannerbox 10.0.0.100 Raspberry Pi OS –

4.5 Illustration of Results

Figure 7 shows the scan results of the PoC network

scanner for the testbed in the web browser. All

devices and open ports were found. Furthermore,

through the use of NSE scripts, the industrial proto-

cols could read out the versions of the components.

On the mirror port of the switch in the testbed, a

packet capture was generated over several scans over

the complete subnet (10.0.0.1/24). None of the cap-

tures shows more than the previously set maximum

packet rate. A section from a scan can be seen in Fig-

ure 8.

Figure 7: Results of the network scanner within the web-

based dashboard.

In the plot, the traffic caused is divided into Ad-

dress Resolution Protocol (ARP) and Transmission

Control Protocol (TCP) traffic. Since the scanner does

not have a fixed ARP table and the ARP cache is

empty at the beginning of the scan, ARP requests are

used to find out whether the scan target is available

and responding. Only when this request has been an-

swered, the TCP scan can be executed. In total, scan-

ning the subnet took about 4 hours with this configu-

ration. This mainly depends on the slow packet rate

of 20 packets per second and the scan of a full /24 net

with up to 254 hosts. Since the scan is carried out se-

quentially and each IP is tried to reach, the number of

active hosts plays a minor role. In contrast, the num-

ber of open ports per IP have an impact on the scan

duration.

5 CONCLUSION AND OUTLOOK

In this paper, we introduced a secure architecture for

network scanning in ICS networks. Special about this

concept is the strict hardware segmentation, which

does not break up segmented networks. Furthermore,

the scanner can be configured in such a way that unde-

sired high packet rates cannot occur and DoS attacks

are unlikely. Supplemental, the MCUs act as an IDD

and can filter the communication.

The feasibility of the concept was shown with a

PoC implementation. This includes a PoC implemen-

tation of the hardware and software, as well as the

possibility of sending scan tasks and receiving the re-

sults. In addition, a testbed with industrial devices

and software was set-up to test the PoC implementa-

tion. Moreover, the concept of the scanner architec-

ture and especially the scanner hardware was tested

and evaluated. As shown in this paper, the concept

presented here is ideal for segmented and fragile ICS

networks. However, this concept is clearly not lim-

ited to ICS applications and can also be used for other

highly segmented or fragile systems.

In the future, this concept needs to be further de-

veloped and tested in a real world ICS. Besides, an

additional feature, which could be provided by the

scanner nodes, would be the checking of the net-

work segmentation. This could e.g. be verified by at-

tempting to establish a connection between the scan-

ner nodes. If this connection is possible between

two scanner nodes in different network segments, this

could be an indication of a faulty segmentation.

AVAILABILITY

Additional material like software and net-

work captures are available on GitHub –

https://github.com/hsainnos/ICSscannerDiode.

ICISSP 2021 - 7th International Conference on Information Systems Security and Privacy

354

0 200 400 600 800 1000

Time in s

0

5

10

15

Number of packets

per second

ARP

TCP

Figure 8: Packets per second caused by the PoC implementation with a rate set to a maximum of 20 packets per second.

REFERENCES

Alves, T. R., Buratto, M., De Souza, F. M., and Rodrigues,

T. V. (2014). Openplc: An open source alternative to

automation. In IEEE Global Humanitarian Technol-

ogy Conference (GHTC 2014), pages 585–589. IEEE.

Andreasson, O. et al. (2001). Iptables Tutorial 1.2. 2. Copy-

right© 2001–2006 Oskar Andreasson, GNU Free

Documentation License.

Bidaud, O. (2003). Distributed Network Architecture Secu-

rity System. US Patent App. 10/118,632.

Charras, J.-P. (2012). KiCad: GPL PCB Suite.

Coffey, K., Smith, R., Maglaras, L., and Janicke, H.

(2018). Vulnerability Analysis of Network Scanning

on SCADA Systems. Security and Communication

Networks, 2018.

Goldring, B. A. (2013). Data diode. US Patent 8,380,913.

IEC, D. (2020). Industrial Communication Networks - Net-

work and System Security - Part 3-3: System Secu-

rity Requirements and Security Levels (DIN EN IEC

62443-3-3:2020).

Kernighan, B. W., Ritchie, D. M., et al. (1988). The C Pro-

gramming Language, volume 2. prentice-Hall Engle-

wood Cliffs, NJ.

Knapp, E. D. and Langill, J. T. (2014). Industrial Network

Security: Securing critical infrastructure networks for

smart grid, SCADA, and other Industrial Control Sys-

tems. Syngress.

Kuipers, D. and Fabro, M. (2006). Control Systems Cyber

Security: Defense in Depth Strategies.

Lyon, G. (2009). Nmap–Free Security Scanner for Network

Exploration & Security Audits.

Matsakis, N. D. and Klock, F. S. (2014). The Rust Lan-

guage. ACM SIGAda Ada Letters, 34(3):103–104.

Maynard, P., McLaughlin, K., and Sezer, S. (2018). Us-

ing Application Layer Metrics to Detect Advanced

SCADA Attacks. In ICISSP, pages 418–425.

Niedermaier, M., Fischer, F., Merli, D., and Sigl, G. (2019).

Network scanning and mapping for iiot edge node de-

vice security. In 2019 International Conference on

Applied Electronics (AE).

Niedermaier, M., Malchow, J.-O., Fischer, F., Marzin, D.,

Merli, D., Roth, V., and von Bodisco, A. (2018). You

Snooze, You Lose: Measuring PLC Cycle Times un-

der Attacks. In 12th USENIX Workshop on Offensive

Technologies (WOOT 18).

Nivethan, J. and Papa, M. (2016). On the use of Open-

source Firewalls in ICS/SCADA Systems. Informa-

tion Security Journal: A Global Perspective, 25(1-

3):83–93.

Peichl, T., Ehrenberg, T., and Schriefer, J. (2015). Serial

peripheral interface having a reduced number of con-

necting lines. US Patent 9,042,274.

Raspberry Pi Foundation (2015). Raspberry PI 3 Model B.

Rossum, G. (1995). Python Reference Manual.

See, F., Seng, W. C., and Liu, T. (2017). Prowler - Dis-

tributed Network Vulnerability Scanner.

STMicroelectronics (2020). STM32F0x0 Value Line.

Stouffer, K., Falco, J., and Scarfone, K. (2015). Guide to

Inustrial Control Systems Security. NIST SP 800-82

Rev. 2.

Tenable, N. (2020). Nessus Vulnerability Scanner.

Torvalds, L. (1997). Linux: A Portable Operating System.

Master’s thesis, University of Helsinki, dept. of Com-

puting Science.

Vanier, D. D. (2001). Why Industry Needs Asset Manage-

ment Tools. Journal of computing in civil engineering,

15(1):35–43.

Wedgbury, A. and Jones, K. (2015). Automated Asset Dis-

covery in Industrial Control Systems - Exploring the

Problem. In 3rd International Symposium for ICS

& SCADA Cyber Security Research 2015 (ICS-CSR

2015) 3, pages 73–83.

A Secure Network Scanner Architecture for Asset Management in Strongly Segmented ICS Networks

355