High Uniformity Design of UV LED Illuminators for Exposure

Equipment

Chun-Han Chou

1,

*

a

, Yu-Hsuan Lin

1b

, Hsin-Yi Tsai

1c

, Ray-Ching Hong

1

and Yi-Yung Chen

2d

1

National Applied Research Laboratories, Taiwan Instrument Research Institute, 20 R&D Rd. VI, Hsinchu Science Park,

Hsinchu City 30076, Taiwan

2

Graduate Institute of Color & Illumination Technology, National Taiwan University of Science and Technology,

No.43, Keelung Rd., Sec.4, Da’an Dist., Taipei City 10607, Taiwan

Keywords: Lithography, Irradiance Measurement, Uniformity, REMA Lens System, UV LEDs.

Abstract: We have presented the optical system design of control uniformity illumination system for stepper lithography.

The illumination system acted a key factor in the lithography, because the output light source quality affected

the exposure resolution and yield rate of products. The illumination system was composed by seven lens,

imaging field was 12.6mm, chief ray angle was less than 0.4 degrees, distortion was less than 0.47% and

numerical aperture was 0.1644. the irradiance flux of target area average was about 20 mW/cm

2

. The system’s

uniformity deviation was less than ± 3 percentages. Each UV-LED of illumination system was individually

controlled. It could make the imaging plane always have high uniformity to overcome the problem of light

source attenuation.

1 INTRODUCTION

Currently, the integration circuit was rapidly

developing to high density and high productivity by

the lithography, pattern transfer and process

technology. While early integration circuits features

were 25mm, currently manufactured features were

less than 20 nm. The integration circuits of feature

size, separation of structures and layer-to-layer

registration were decreased by approximately 30%

linearly per generation and doubling of the density of

transistors each generation (Moore, 1998). It has

become what we know as "Moore's Law."

The exposure process was the most important

technology in the integration circuit fabrication. It

could directly affect the size of integrated circuits,

wafer utilization and productivity. Lithography

equipment usually composed by the illumination

system, projection lens system and movement

platform and it was used for exposure process

(Rueggeberg and Caughman et al., 1994). The

illumination system used to modify the light source

a

https://orcid.org/0000-0003-2460-5875

b

https://orcid.org/0000-0002-1981-0359

c

https://orcid.org/0000-0001-8275-6132

d

https://orcid.org/0000-0002-0966-5784

meted the request of numerical aperture, illumination

field and uniformity etc. The illumination system

output light source illuminated on the reticle and the

reticle pattern transfer to the wafer by projection lens

system. The illumination system acted a key factor in

the lithography, because the output light source

quality affected the exposure resolution and yield rate

of products. In the industry, the common lithography

equipment was proximity mask aligner. It had the

advantages of large area exposure and simple device

structure etc. In the 2010 years, Reinhard Voelkel

team created an illumination system which had two

microlens-based Köhler integrators. The Light source

output was telecentric and high uniformity. The

system resolution was 10um (Voelkel and Vogler et

al., 2010). In the 2010 years, S. Partel team created a

new illumination system for SUSS mask aligner using

two consequent optical integrators and an

exchangeable illumination filter plate. The filter plate

could reduce the interference effected to increase the

system resolution. The system resolution is 2um

(Partel and Zoppel et al., 2010). However, the

proximity mask aligner system resolution closed to

68

Chou, C., Lin, Y., Tsai, H., Hong, R. and Chen, Y.

High Uniformity Design of UV LED Illuminators for Exposure Equipment.

DOI: 10.5220/0010222300680072

In Proceedings of the 9th International Conference on Photonics, Optics and Laser Technology (PHOTOPTICS 2021), pages 68-72

ISBN: 978-989-758-492-3

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

the nanometer, this kind of lithography structure was

not valid for mass production and a single defect

already made a complete microchip unusable.

For this reason, many people turned to research

step lithography systems. It had the advantage of the

higher resolution, low cost of reticle and easy to mass

production. In the 1986 years, Victor Pol team

presented a stepper lithography which light source

was KrF excimer laser (248nm). The lighting system

had the numerical aperture of 0.38 and the imaging

field greater than 14.5 mm. The system resolution

was 0.8um (Pol and Bennewitz et al., 1986). In the

2008, Rosanne M. Guijt team presented a low cost UV-

LED lithography which used a pinhole and a small

plastic tube and focused using a microscope objective

onto a substrate for direct lithographic patterning of the

photoresist. The system resolution was higher than 20

μm (Guijt and Breadmore, 2008). In the 2016 years,

Hans-Christoph Eckstein teams presented a UV LED

lithography which could be demagnified five to one

hundred times and position accuracy was higher than

100 nm (Eckstein and Zeitner et al., 2016). In the

prior art, people created lithography illumination

system by mercury lamp, LED or laser. When used

for long periods of time, these light sources attenuated

to affect output uniformity and flux. It declined the

yield rate of product.

Therefore, in the studying, we presented a control

uniformity illumination system for stepper

lithography. Each UV-LED of illumination system

was individually controlled. It could make the

imaging plane always have high uniformity to

overcome the problem of light source attenuation.

The illumination system composed by UV-LED,

reflector, REMA lens system and light source

controller. The UV-LED emission light intensity

distribution was changed by the reflector and coupled

to the projection lens system. The REMA lens system

organized the input ray to be user defined light

intensity distribution and illumination field size. The

controller was used to control each UV-LED output

efficiency made the imaging plane always has high

uniformity.

2 THE OPTICAL DESIGN OF

ILLUMINATION SYSTEM

Lithography is the key equipment in the integrated

circuit process and its’ Illumination quality was the

most important factor. It directly affected the size of

integrated circuit line per. There are three important

factors in the lithography illumination system

(Weichelt and Bourgin et al., 2017):

• NA: The illumination system NA should

correspond with the project lens system,

otherwise the resolution of the projection

system will decrease.

• Uniformity: It effects the exposure depth of the

lines. The uniformity deviation usually lower

than 10%.

• Efficiency: It effects the system conversion

efficiency.

The illumination system was designed by the

sequential optical simulation software(Zemax) and

non-sequential optical simulation software(FRED).

The sequential optical simulation software was used

to optimize the imaging plane uniformity and third

aberration. The non-sequential optical simulation

software used to eliminate the effects of stray ray. The

list of design goals was as follows:

1. Imaging plane numerical aperture 0.165

2. Imaging plane uniformity deviation < ± 4 %

3. Imaging plane irradiance > 15 mW/cm

2

4. Imaging plane size > 20 x 8 mm

2

5. Chief ray angle < 0.5 degrees

6. Distortion < 0.5 %

Figure 1: The UV-LED array arrangement.

The first step for design the illumination system

was to determine the light source parameters. When

the UV-LED(LTPL-C034UVH365) inputted 5V and

700mA, the UV-LED luminous flux was 720-

860mW. If the imaging plane irradiance should

higher than 15mW/ cm

2

, the UV-LED needed 5 x 5

chips array at least. In order to increase the utilization

rate of light source, the chips array coupled with a

reflector made the half of diverge angle of light

source less than 10 degrees, reference the Fig.1. The

REMA lens system was arranged behind the UV-

LED chips array. The REMA lens system was

designed by Köhler illumination (Köhler, 1893).

Köhler illumination proposed by August Köhler for

optical microscope illumination, allows to adjust the

size and the numerical aperture of the object

High Uniformity Design of UV LED Illuminators for Exposure Equipment

69

illumination in a microscope independent from each

other. Köhler illumination provides uniform

illumination of the object plane independent of shape,

extension and angular field of the light source.

2.1 Optical Design of REMA Lens

System

The lens system was designed by sequential and non-

sequential optical simulation software. The sequential

optical simulation software was used to design the

light path, optimize third aberrations and assemble

tolerance. The non-sequential optical simulation

software was used to analysis and eliminate stray ray

effects. Though these optical simulation, the

simulation results were more close to the fabrication

production.

2.1.1 Sequential Optical Simulation

In the optical simulation, the light source size was

30*30mm and half of divergence angle was 10

degrees. In order to reduce production price and error,

the lens radius and diameter should not exceed

500mm and 90mm, and the front and back radius of

each lens should differ by more than 10%. After the

design, the lens system was composed by seven lens,

imaging field was 15.6mm, chief ray angle was less

than 0.4 degrees, distortion was less than 0.47% and

numerical aperture was 0.1644. The data referred to

the Fig.2. and Table. 1.

Figure 2: Optical light path diagram.

Table 1: The Lens data of the REMA lens system.

The simulation results of REMA lens system meted

the goal, the next step was doing tolerance analysis.

The tolerance analysis had two parts that were lens

manufacturing tolerance analysis and lens system

assemble tolerance analysis. The tolerance analysis

data referred to the Table. 2. After the tolerance

analysis, the simulation results still comply with the

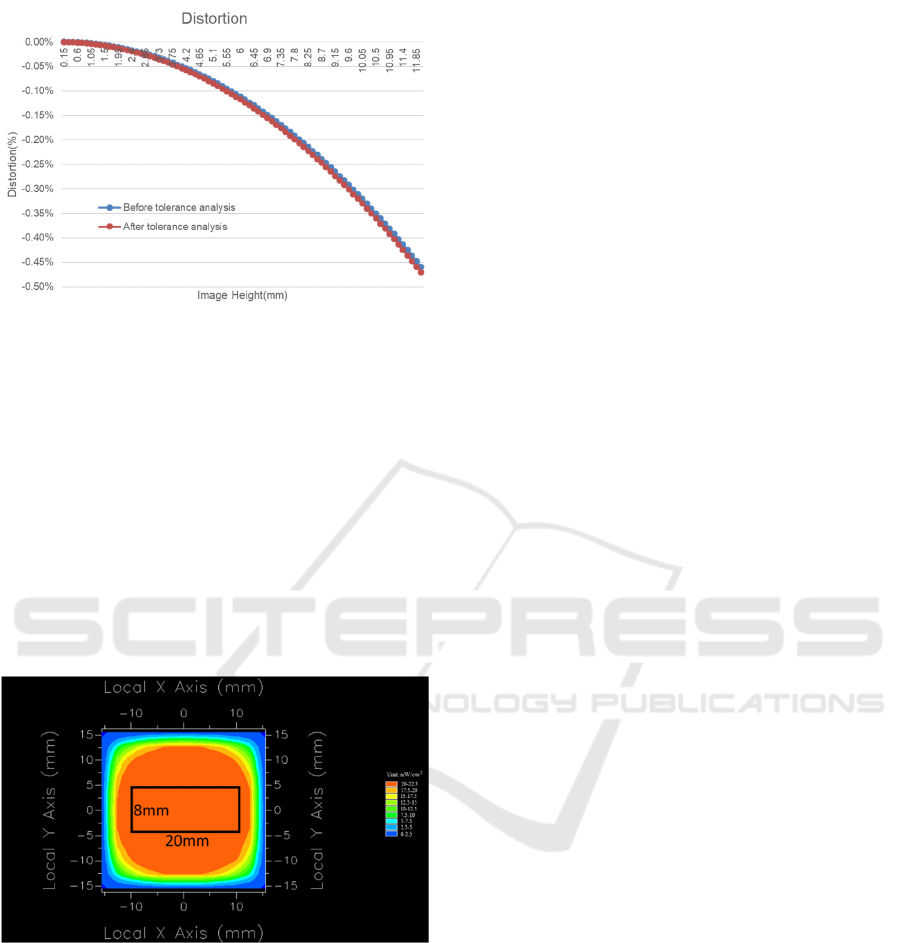

target, referred the Fig. 3.

Table 2: Tolerance analysis data.

(a)

Itesms surface Tolerances Element Tolerances

Radius 0.00% non

Thickness 0.1mm non

DecenterX 0.3mm 0.1mm

DecenterY 0.3mm 0.1mm

Tilt X 0.3 degrees 0.1degrees

Tilt Y 0.3degress 0.1degress

Tolerance Parameters(wavelength: 365nm)

PHOTOPTICS 2021 - 9th International Conference on Photonics, Optics and Laser Technology

70

(b)

Figure 3: Third aberration data. (a).Chief ray angle

diagram. (b). Distortion diagram.

2.1.2 Non-sequential Optical Simulation

The targets of uniformity and irradiance was

simulated by non-sequential optical simulation

software. From the simulation results, the irradiance

flux of target area average was about 20 mW/cm

2

.

The system’s uniformity deviation was less than ± 3

percentages. It proves that the stray ray effect was

very low, the irradiance distribution referred Fig. 4.

Figure 4: The REMA lens output irradiance map.

3 DISCUSSION

In the studying, we presented a control uniformity

illumination system for stepper lithography. The

system had the 25 UV-LED. Each UV-LED could

individually control the output flux and the light

source switching frequency was less than 20 ms to

avoid flicker effect. The REMA lens system was

design by sequential and non-sequential optical

simulation software. After the tolerance analysis, the

simulation results still meted the targets.

4 CONCLUSION

We have presented the optical system design of

control uniformity illumination system for stepper

lithography. The lens system was composed by seven

lens, imaging field was 15.6mm, chief ray angle was

less than 0.4 degrees, distortion was less than 0.47%

and numerical aperture was 0.1644. The irradiance

flux of target area average was about 20 mW/cm2.

The system’s uniformity deviation was less than ± 3

percentages. In the future, we could add an intelligent

uniformity control algorithm and auto irradiance

measurement system. The irradiance measurement

system used to capture each point irradiance on the

imaging plane, and the data transferred to controller.

The controller controlled UV-LED flux by the

algorithm that make the imaging plane always have

high uniformity.

ACKNOWLEDGEMENTS

The authors would like to express their appreciation

for financial aid from the Ministry of Science and

Technology, R.O.C under grant numbers MOST 109-

2221-E-492-004. The authors would also like to

express their gratitude to the Taiwan Instrument

Research Institute of National Applied Research

Laboratories for the support.

REFERENCES

Moore, G. E. (1998). Cramming more components onto

integrated circuits. Proceedings of the IEEE, 86(1), 82-

85.

Rueggeberg, F. A., Caughman, W. F., & Curtis, J. W.

(1994). Effect of light intensity and exposure duration

on cure of resin composite. Operative dentistry, 19(1),

26-32.

Voelkel, R., Vogler, U., Bich, A., Pernet, P., Weible, K. J.,

Hornung, M., ... & Zeitner, U. D. (2010). Advanced

mask aligner lithography: new illumination system.

Optics express, 18(20), 20968-20978.

Partel, S., Zoppel, S., Hudek, P., Bich, A., Vogler, U.,

Hornung, M., & Voelkel, R. (2010). Contact and

proximity lithography using 193 nm excimer laser in

mask aligner. Microelectronic Engineering, 87(5-8),

936-939.

Pol, V., Bennewitz, J. H., Escher, G. C., Feldman, M.,

Firtion, V. A., Jewell, T. E., ... & Clemens, J. T. (1986,

August). Excimer laser-based lithography: a deep

High Uniformity Design of UV LED Illuminators for Exposure Equipment

71

ultraviolet wafer stepper. In Optical Microlithography

V (Vol. 633, pp. 6-16). International Society for Optics

and Photonics.

Guijt, R. M., & Breadmore, M. C. (2008). Maskless

photolithography using UV LEDs. Lab on a Chip, 8(8),

1402-1404.

Eckstein, H. C., Zeitner, U. D., Leitel, R., Stumpf, M.,

Schleicher, P., Bräuer, A., & Tünnermann, A. (2016,

March). High dynamic grayscale lithography with an

LED-based micro-image stepper. In Optical

Microlithography XXIX (Vol. 9780, p. 97800T).

International Society for Optics and Photonics.

Weichelt, T., Bourgin, Y., & Zeitner, U. D. (2017). Mask

aligner lithography using laser illumination for versatile

pattern generation. Optics express, 25(18), 20983-

20992.

Köhler, A. (1893). Zeitschrift für wissenschaftliche.

Mikroskopie X, 433-440.

PHOTOPTICS 2021 - 9th International Conference on Photonics, Optics and Laser Technology

72