Predictive Maintenance Model based on Asset Administration Shell

Salvatore Cavalieri

a

and Marco Giuseppe Salafia

b

University of Catania, Department of Electrical Electronic and Computer Engineering (DIEEI),

Viale A. Doria, 6, 95125 Catania, Italy

Keywords: Industry 4.0, Asset Administration Shell, Rami 4.0, Predictive Maintenance, Interoperability.

Abstract: Maintenance is one of the most important aspects in industrial and production environment. The availability

of huge amount of data coming from sensors and embedded systems, enabled the realisation of Predictive

maintenance (PdM). It is an approach that aim to schedule maintenance tasks on the basis of historical data

before the occurrence of failures, avoiding machine block downs and reducing the costs due to unnecessary

maintenance actions. The adoption of vendor-specific solutions for predictive maintenance and the

heterogeneity of technologies adopted in the brownfield for the condition monitoring of machinery reduce the

flexibility and interoperability required by Industry 4.0. The paper presents a PdM model leveraging on the

Asset Administration Shell (AAS) introduced in Reference Architecture Model for Industrie 4.0 (RAMI 4.0)

as a means to enhance interoperability and enabling flexibility and re-configuration of the production against

a PdM solution.

1 INTRODUCTION

Industry 4.0 introduced the application of modern

Information & Communication Technologies (ICT)

concepts in industrial contexts to create more flexible

products and services leading to new business models

and added value (Liao, 2017; Xu, 2018). This fourth

industrial revolution features flexible and adaptable

manufacturing concept to satisfy a market requiring

an increasing demand of customisation (Panda,

2018).

Among the main ICT solutions introduced in the

Industry 4.0, Industrial Internet of Things (IIoT)

allows the availability of huge amount of data coming

from sensors and embedded systems installed in a

modern plant (Khana, 2019). The Big Data so

available may be used for several purposes in order to

improve the performances of the factory.

Maintenance is of paramount importance since

avoiding failures is a key requirement in a

challenging market asking for high efficiency and

availability. An efficient use of historical data

collected by IIoT systems consists of predictive

maintenance (PdM) where maintenance actions are

scheduled when either a deterioration or a

a

https://orcid.org/0000-0001-9077-3688

b

https://orcid.org/0000-0002-9381-3857

degradation in the performances of the machinery is

detected by a suitable analysis of historical data.

Literature presents several PdM solutions

involving different technologies and approaches,

from the gathering of data to the prognostics of

failures. Furthermore, in the context of the fourth

industrial revolution, lots of different technologies

and protocols are adopted from the brownfield area

(i.e. sensors, fieldbuses) to the IT area. The adoption

of vendor-specific solutions for PdM reduces the

flexibility and interoperability required by Industry

4.0. Therefore, the definition of PdM solutions that

can adapt itself to the variation in the configuration of

the original production is hard to realise, setting new

constraints to the flexibility in the smart factory. What

is required is horizontal integration to hide

implementation details between devices, regardless

of both their manufacturer and technologies adopted.

In this manner, a device can be easily replaced with

an equivalent one providing the same functionalities.

In order to satisfy the requirements of

interoperability and flexibility demanded by industry

4.0, an approach for the definition of a PdM program

must address two main objectives: 1) defining generic

functionalities for the description of a technology-

Cavalieri, S. and Salafia, M.

Predictive Maintenance Model based on Asset Administration Shell.

DOI: 10.5220/0010389306810688

In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021) - Volume 2, pages 681-688

ISBN: 978-989-758-509-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

681

independent PdM solution and 2) hiding the

heterogeneity and complexity of the Operational

Technology (OT) level. Both the objectives are often

addressed either separately or partially (Birtel, 2018;

Lang, 2019; Wollschlaeger, 2015) but, at the best of

our knowledge, there is no solution facing both

together. Such objectives are confirmed in Groba et

al. (Groba, 2007), which analysed the challenges in

implementing a PdM solution and proposed a PdM

framework integrating the diversity of different PdM

techniques. Their framework cope only with 1) but

they identified that one of the biggest challenges

consists in describing the shop floor equipment and

corresponding condition indicators in a uniform

manner, hence 2).

The requirements for 2) can be satisfied using the

concept of the Asset Administration Shell (AAS)

presented in the Reference Architecture Model for

Industrie 4.0 (RAMI4.0) (DIN, 2016), which is a

digital and active representation of an asset,

containing all its relevant information in a uniform

and digitalised manner. In particular, in the area of

production automation, the intention of using AAS

for future implementation of PdM solutions is

confirmed in (Platform Industrie 4.0, 2018) where an

infrastructure consisting of components with uniform

interfaces is of utmost importance for condition

monitoring and PdM.

Authors already adopted the concept of AAS to

abstract the complexity of plant configuration

(Cavalieri, 2020a). In this paper, an approach for the

representation of a PdM solution in terms of generic

and technology-independent functionalities is

presented, and the AAS issued mainly in brownfield

to achieve interoperability among devices.

2 PREDICTIVE MAINTENANCE

The approach of PdM consist in detecting the type of

failure on the basis of the current condition of the

machine, allowing the organisation of maintenance

operations to prevent catastrophic failures. PdM is

also referred in literature as Condition-based

Maintenance (CBM) since uses actual operating

condition of the equipment and a model defined using

historical data to predict the future state of the

machine (Motaghare, 2018). The foundation of

predictive maintenance is the Condition Monitoring

(CM) process (Birtel, 2018), where sensors are

applied in machinery to continuously monitor signals,

or other appropriate indicators, to assess the health of

the equipment (Ahmad, 2012).

Since there are lots of different techniques and

approaches involved for the realisation of PdM, in

this section the main parts composing a generic PdM

approach will be pointed out. A generic CBM

program can be divided in three main parts: data

acquisition, data processing, and maintenance

decision-making (Jardine, 2006).

2.1 Data Acquisition

Data acquisition is the first process of the PdM

program, and it consists of collecting data directly

from the physical assets that will be used to evaluate

the relevant health conditions. Sensors are the

primary source of information here and the kinds of

data collected vary case by case depending on the

machine to be maintained and hence on the sensor

used. Most of the time, old equipment requires the

additions of new sensors (Strauß, 2018).

2.2 Data Processing

Often data collected are subjected to a pre-process

step where their volume is reduced (i.e. aggregation)

to pass only the selected and extracted features (i.e.

feature extraction) (Strauß, 2018) to the forecasting

and/or decision-making algorithms. The techniques

adopted to process and analyse data mainly depend

on both the types of data collected and the algorithms

used to reveal the condition of the machine.

2.3 Maintenance Decision-making

The techniques adopted for maintenance decision-

making in CBM are classified in diagnostics and

prognostics. The former deals with finding the source

of a fault, whilst the latter deals with estimating when

a failure may occur in future. It follows that

prognostics is preferred than diagnostics because in

the first case the failure is tried to be prevented whilst

in the second case the failure already occurred. Since

prognostics cannot prevent all faults; diagnostics

techniques are often used as complementary support

for prognostics. Furthermore, diagnostics results can

be used as feedback to improve the accuracy of

prognostics solutions (Jardine, 2006).

3 ASSET ADMINISTRATION

SHELL

Industry 4.0 involves a massive digitalisation process

where assets in the physical world must be

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

682

represented in the information world by means of a

digital and uniquely identifiable counterpart (DIN,

2016). RAMI4.0 refers to such an entity with the

name of AAS. The AAS contains all the information

relevant to a specific asset, its lifecycle, technical

functionalities and it can also integrate procedures for

the integration of sensor data and condition

monitoring (Infosys, 2018).

The conjunction of an asset with its relevant AAS

defines the so-called I4.0-Component (DIN, 2016),

which refers the concept of Cyber-Physical System

(CPS) in the context of RAMI4.0 (Tantik, 2017). In

addition, it features an I4.0-compliant

communication with the other I4.0-Components in

the value-chain network.

The AAS is an abstraction means providing a

common structure for the information relevant to

different assets and a common way to exchange and

access such information (Cavalieri, 2020b), enabling

the cooperation of assets based on different

technologies and information models.

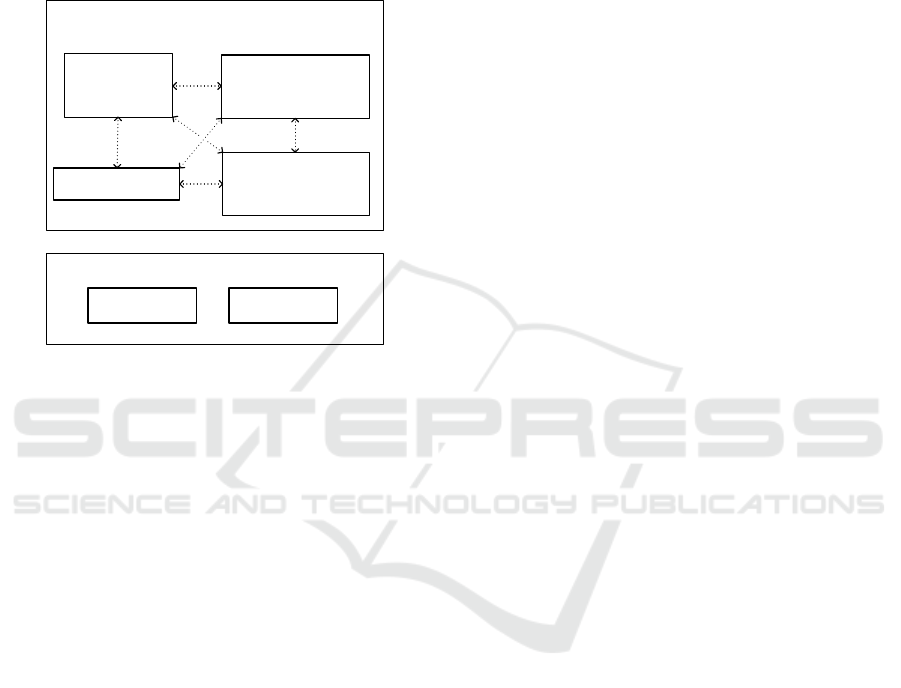

3.1 Structure of the AAS

From a high-level point of view, an AAS is structured

as depicted in Figure 1. It is composed by a header

containing all the information relevant to the

identification of both AAS and asset, and a Body

containing all the inherent information of the asset in

the form of properties and functions (also referred as

operations) (Platform Industrie 4.0, 2016).

Asset Identification

AAS Identification

...and others

Administration Shell

Header

Body

Submodel 1 e.g. energy efficiency

Property 1.1

Property 1.1.1

Property 1.1.2

Information

Function

Submodel 2 e.g. positioning mode

Property 2.1

Property 2.1.1

Property 2.1.1.1

Information

Function

Property 2.1.1.2

Function

Submodel 3 e.g. CAD model

Property 3.1

Property 3.1.1

Property 3.1.2

Information (CAD)

Information (CAD)

Figure 1: Structure of the AAS.

Properties are defined as classified and mutually

independent characteristics of systems that can be

associated with values (Kampert, 2012). Functions,

instead, are capabilities and actions that an asset

performs. Properties and functions are collected

under so-called sub models, each of which describe a

specific aspect relevant to an asset, like energy

efficiency, positioning, documentation, drilling,

maintenance, among others.

In November 2019, the initiative Platform

Industrie 4.0 released an AAS metamodel specifying

how structure the information inside the AAS. In

(Platform Industrie 4.0, 2019) the AAS metamodel is

presented as a UML class diagram, defining all the

“building blocks” that must be used to structure

internally the AASs of every possible asset.

Since the same entities of the metamodel may be

used to define elements representing different

concepts (e.g. modelling “height” or “rotation speed”

as properties), such entities must be semantically

annotated. Sub models, properties or functions

composing an AAS contains a special attribute,

named semanticId, pointing to a semantic definition

contained in an external semantic repository. The

term “semantic repository” identifies any sort of

database or catalogue where the semantic definitions

reside, like IEC Common Data Dictionary (CDD) or

eCl@ss.

AAS is important also to realise of one of the

main features that an I4.0 Component provides,

which is “nestability” as discussed in (Kagermann,

2013). In fact, the AAS of a composite component

reflects the composition relationship referencing the

ASSs of its components.

3.2 AAS Interface

The AAS is a software entity providing its internal

information to the external world by means of a

standardised API. Internal information is structured

according to the AAS metamodel, as discussed

previously. The API of an AAS provides a CRUD-

oriented interface, thus data are accessible by a

communication network so that an external client can

either retrieve or manage the data of interest making

simple requests to the relevant AAS.

In general, RAMI 4.0 do not put any constraints

about the location of an AAS: it may be embedded

directly on a smart device or deployed in a completely

different location, even though a connection with the

asset may be maintained.

4 PROPOSAL OF A PREDICTIVE

MAINTENANCE MODEL

The model presented in this paper realises a novel

approach for the definition of a PdM solution in the

context of the fourth industrial revolution. Such an

Predictive Maintenance Model based on Asset Administration Shell

683

approach is based on the concept of the so-called

Logical Block (LB). A LB is a modular element that

groups functionalities relevant to a specific aspect of

the PdM. The entire set of the functionalities of a LB

generalises specific operations for the PdM process,

regardless of how such operations are actually

implemented. LBs and their functionalities are meant

to be modular and cooperating elements in order to

describe a PdM solution (entirely or part of it) in a

generic manner without considering implementation

details. Describing a device in terms of its LB

functionalities permits the definition of a role for that

device. Such role identifies a sort of equivalence class

between all the devices implementing the same

functionalities. Therefore, this makes the replacement

of a device with an equivalent one seamless from the

point of view of the PdM program, without any

disruptive effect on it.

Authors decided to use the concept of AAS and

I4.0 Component to cope with the problem of

heterogeneity of technologies present at OT level, as

discussed in the previous sections. The structure of

the AAS allows the realisation of LBs and their

functionalities as will be discussed further. The

common interfaces and the semantically enriched

information exposed by the AAS make this last the

foundation of the PdM model here presented. In fact,

AAS achieves interoperability creating a sort of

abstraction layer at the lowest level of the production

infrastructure and thus allows a PdM program to be

adapted to production reconfiguration.

The PdM model will be presented following a

bottom-up approach, starting with the description of

the most fine-grained elements and ending with the

high-level view of the model highlighting the

interactions between its components.

4.1 Logical Blocks for PdM

As said before, a Logical Block abstracts all the

functionalities required for the PdM process, thus

generalises and modularises the description of the

PdM solution. In this way, the implementation of

same functionalities and operations can be done using

different technologies and approaches but exposed

with a uniform interface. The LBs here presented

have been defined considering the common aspects of

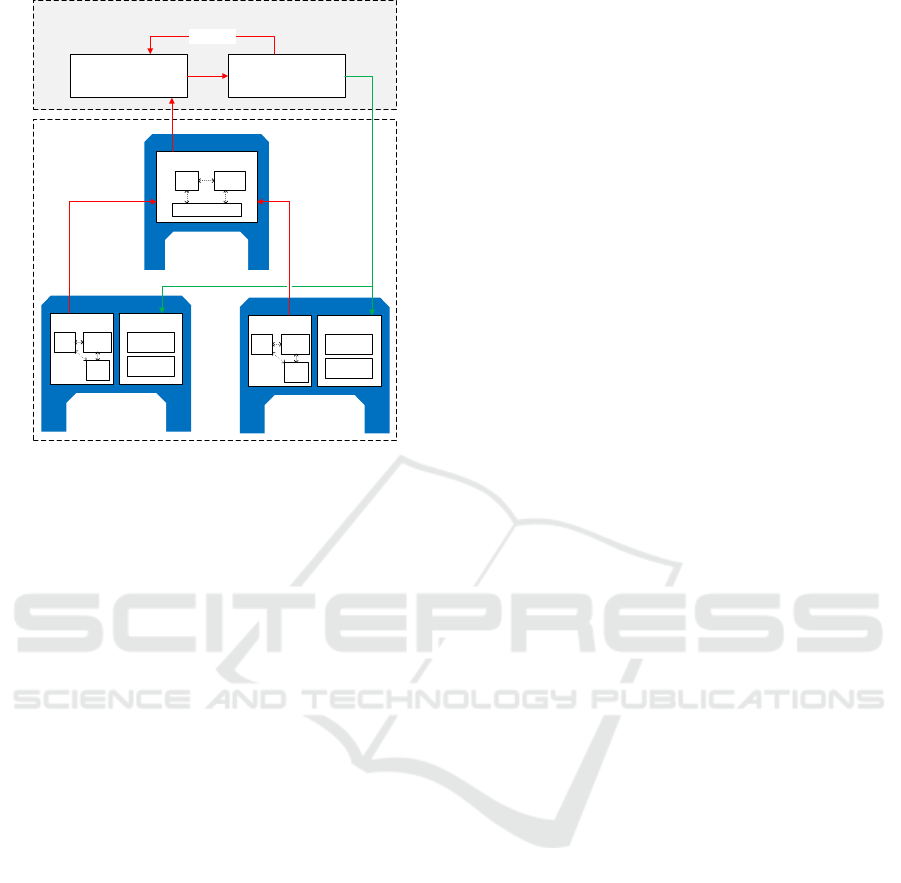

the state of the art of PdM. Figure 2 points out the LBs

described in the following subsections.

4.1.1 Data Acquisition

This LB provides all the functionalities required to

access data coming from sensors or devices. It

involves functions like the conversion of the output

of a transducer to a digital parameter representing the

physical quantity. Such digital values may be

enhanced with more quality parameters, like

calibration or timestamp.

Data Acquisition

- Get measured values

- Convert analog value

- Set measure unit

- Set sensitivity

- ...

Aggregation

- Calculate mean, rms, etc

- Interpolate values

- Set aggregation params

- ...

Data Manipulation

- Filter values

- Apply FFT

- Remove noise

- Transform values

- ...

Schedule

- Set maintenance task

- Get task information

- Get maintenance history

- ...

Status

- Set operating mode

- Set maintenance mode

- Get status log

- ...

Configuration

- Set LBs parameters

- Call LB's operations

- Save/load configurations

- ...

Prediction Model

- Manage model

- Train model (AI)

- Get forecasts

- Set model parameters

- ...

Maintenance

Decision-making

- Set decision algorithm

- Create maintenance task

- Commit technician

- Get decisions history

- ...

Figure 2: The LBs implementing generic functionalities

related to PdM aspects.

4.1.2 Data Manipulation

This LB defines all the operations that perform

analysis on signals and computes meaningful

descriptors from raw measures, which usually come

from the LB Data Acquisition (DA). It also performs

transformations on signals, like filtering or errors

correction, and applies algorithms for features

extraction.

4.1.3 Configuration

This LB provides an interface exposing parameters

and management functions for the configuration of

other data-processing LBs. For instance, some

configurations for the block DA may include the

relative position of transducers, monitoring polling

rates and calibration parameters, among others. Of

course, parameters and functionalities of LB

Configuration may be strictly dependant from the

implementation of the other LBs. For instance,

considering a block DA implemented using OPC UA

(IEC 62541) and the Subscription mechanism for data

retrieval, a LB Configuration may be used to

configure parameters relevant to the publishing

interval or sampling interval.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

684

4.1.4 Aggregation

This LB contains all the functionalities required for

data aggregation of all the different data coming from

monitored devices. Such a block may include

mechanisms of Sensor Data Fusion when, for

example, the data monitored from a complex device

come from sub-devices or sensors composing it. This

perfectly fits with the concept of AAS because it

allows the representation of complex devices by

means of composition of the AASs of their sub-

devices. In these terms, for instance, the Aggregation

block implemented in the AAS of a composite device

uses data coming from the DM or DA blocks

contained in the AASs of the component devices.

Furthermore, input data of an Aggregation LB may

come from other Aggregation blocks, hence realising

an aggregation hierarchy, which is required to

manage the large amounts of data coming from

sensors.

4.1.5 Prediction Model

All the functionalities and facilities needed for the

diagnostics and prognostics of the monitored

machinery are implemented in this LB. For instance,

this LB may consist of a neural network-based model

or decision tree-model. When it is possible, the

models here provided are trained using historical data

of both conditions and faults of machines, eventually

manipulated using the outputs of the other LBs

discussed previously. Furthermore, the models may

be constantly trained using data gathered in real time

from AASs or forecast errors may be used to improve

the accuracy of the model. It is worth noting that

technical personnel working on data analysis and the

tools they use are considered also entities

implementing functionalities of the block Prediction

Model.

4.1.6 Maintenance Decision-making

This LB involves all the functionalities required to

process the data coming from the block Prediction

Model to schedule appropriate maintenance actions

for the monitored machine. Therefore, this block

involves the facilities to schedule maintenance tasks,

to commit eventually the available technicians for the

maintenance, and to change the operational state of

the machine (i.e. changing the operational state from

“working” to “maintenance”). All these kinds of

operations change information in the proper AAS sub

model of the relevant devices.

In general, most of the functionality provided by

a Computer Maintenance Management System may

be considered part of the Maintenance Decision-

making block. It is worth noting that the output of this

LB may be used as a feedback for the Prediction

Model block to adjust the accuracy of the model

adopted or check its correctness.

4.1.7 Schedule

This LB collects all the facilities to manage the

information relevant to the maintenance tasks. For

instance, some information may include the date and

the duration of the maintenance task and the operator

assigned to it. This LB also includes the history of

maintenance operations as it can give an estimation

about the condition of the machine to consider or, in

the worst case, whether a replacement with a new one

occurred.

4.1.8 Status

This LB maintains the information about the status of

the machine. In particular, it explicitly shows when

the machine is in operating mode or in maintenance

mode. This information may be useful to check the

general status of the plant or to label eventual data still

being collected from the machine even during a

maintenance operation.

4.2 AAS Sub Model for PdM

LBs can be realised following different standards or

guidelines; for instance, functionalities for condition

monitoring of machines may be based on standard

like VDMA 24582 or ISO 17359.

In this paper it has been assumed that I4.0-

Components implement all the functionalities of their

LBs inside specific sub models. Such functionalities

are implemented inside the sub models as properties

and operations, both semantically annotated. The

main idea in Industry 4.0 is having a standardised sub

model definition for every relevant aspect of an asset

but, up to now, no standardised sub model definition

has been released. The model here proposed involves

the definition of new AAS sub models containing

well-known LB functionalities, so that some of the

steps of the PdM process may implemented in a

common and standardised manner inside I4.0-

Components. Furthermore, since AAS allows for

composition, functionalities in sub model may be

represented as composition of functionalities of the

AASs of sub-devices or logically underlying devices.

For instance, configuration functionalities of a high-

level device may be represented as a composition of

several configuration functionalities of underlying

devices.

Predictive Maintenance Model based on Asset Administration Shell

685

The two sub models presented and discussed in

the following cover all the functionalities required for

the condition monitoring and for the scheduling of

maintenance operations of a device; they are named

“Condition Monitoring” and “Maintenance”,

respectively. Figure 3 shows the LBs implemented

internally by the two sub models highlighting the

relationships between them.

Submodel: Condition

Monitoring

Sub model: Mainten ance

Data

Acquisition

Configuration

Data

manipulation

Schedule Status

Aggregation

Figure 3: Sub model definition for Condition Monitoring

and Maintenance and the LBs they implement.

As shown in figure, the sub model Condition

Monitoring implements the LBs Data Acquisition

(DA), Data Manipulation (DM), Configuration and

Aggregation. The presence of the depicted LBs in the

sub model is not mandatory. Whether a LB is

implemented or not depends on the specific case in

examination. For instance, a smart sensor may not

implement the functionalities of the block

Aggregation inside its AAS, whereas for an industrial

gateway is quite common implementing aggregation

functionalities. All the LBs in the Condition

Monitoring sub model may interact to each other, as

depicted in figure by means of dotted arrows. Such

interactions represent data flows, events dispatching,

function calls or parameter settings.

The sub model Maintenance implements the

functionalities of the block Schedule and Status. In

general, the scope of this sub model involves

everything concerning the maintenance tasks and

operational condition of the device.

The blocks Prediction Model and Maintenance

Actions are not considered inside the sub models

definitions here provided because such high-level

functionalities with high-demanding computational

requirements may not be easily implemented in I4.0-

Components at OT level. It is worth noting that this

assumption is not a limitation, because an AAS of a

high-specialised tool may implement, if the solution

requires so, the Prediction Model functionalities

inside a well-known sub model.

4.3 Description of the PdM Model

From a high-level point of view, the PdM model is

divided in two main parts: Operational Infrastructure

(OI) and Prognostics & Maintenance Management

Infrastructure (PMMI). The former encompasses all

the elements of the plant which are part of the PdM

solution and involved in the data collection and data

manipulation processes required for prognostics.

Examples of such elements are the machines to be

maintained, industrial gateways, industrial PCs, but

even high-level tools like MES and ERP may be

considered being part of OI. The latter, instead,

encompasses all the elements of the PdM solution

using data coming from OI to forecast machine

failures and schedule maintenance actions. Examples

of such elements may be AI models (e.g. Recurrent

Neural Network), tools for data analysis and software

for the maintenance management.

The structure of the PdM model is depicted in

Figure 4 highlighting the relationship between

components and the data streams from low-level

devices to the PMMI elements for the decision-

making task, depicted by red arrows. Furthermore,

the figure shows how the topmost components

interact with the maintained devices to set their

operational status and commit maintenance tasks.

This procedure is depicted with green arrows.

As shown in figure, OI consists of I4.0-

Components providing both data for the condition

monitoring (e.g. production machinery that will

require maintenance, sensors) and operations for data

manipulation required from the first steps of the PdM

process (e.g. Smart Device, Industrial PC, Gateway).

In general, what belongs to Operational Technology

(OT) is considered part of the OI. Therefore, devices

like sensors, actuators, machinery, but also PLC,

SCADA, DCS, may be considered part of OI, but also

Information Technology (IT) elements like databases,

industrial PCs, or edge devices like gateways. The

presence of AAS is mandatory for the devices at the

lowest levels of the infrastructure because such

devices features a high degree of heterogeneity in the

technologies and data representation adopted.

Therefore, the AAS realises the abstraction layer

needed to achieve interoperability at that level. The

only requirement in the PdM model is that every PdM

component that need to interact with an I4.0-

Component need to communicate with the AAS API

and thus understand its semantics.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

686

Condition

Monitoring

Maintenance

DA

Config

DM

Schedule

Status

AAS Device

Maintenance

DA

Config

DM

Schedule

Status

AAS Device

Condition Monitoring

Config

DM

AAS Aggregator

Aggregation

Prognostics & Maintenance Management Infrastracture

Prediction

Model

Maintenance

Decision-making

Feedback

Operational

Infrastracture

Condition

Monitoring

Figure 4: AAS-based PdM model for predictive

maintenance.

PMMI consists of IT elements and software

components providing all the functionalities needed

for data analysis, failures prediction, and scheduling

of the maintenance tasks. The nature of such

components is not specified but they are described

only in terms of the functionalities they provide (i.e.,

their LBs). Such functionalities may be implemented

on devices of the Information Technology (IT)

infrastructure and/or in Cloud (in case of Cloud-based

PdM). For this reason, it makes no sense speaking of

“devices” because at this level what really matters are

functionalities, and their implementation strictly

depends on the solution adopted for PdM. For

instance, the prediction functionalities defined for

PMMI may be implemented either by a Recurrent

Neural Network (Artificial Intelligence-based

solution) or by a physical operator consulting a visual

tool for data analysis; even if the former is a software

component and the latter is a human being, both of

them are considered entities of the PMMI because

realises the same functionalities but in different ways.

Since entities implementing functionalities in PMMI

interact and use data coming from OI entities, it

follows that they must understand the AAS API and

data of the OI entities.

The differentiation between Device and

Aggregator depicted in figure is not formal and is

used just to clarify which role an entity plays in the

OI. The role an entity plays depends on the LB it

implements. For instance, AAS Device in Figure 4

identifies the role of a generic Device that provides

condition monitoring features to evaluate is health

condition and eventually schedule maintenance tasks.

AAS Aggregator, instead, identifies the role of a

device that is not a direct subject of the maintenance

process but required for it. In particular, the LBs it

implements suggest that the role of AAS Aggregator

is that of collecting data coming from different

underling devices with the role of “Devices” and do

some sort of manipulation (e.g. data aggregation,

sensor data fusion) before sending them to other

entities.

The role of an entity can be discriminated just

looking at the LBs and the relevant functionalities it

implements. This aspect of the proposed PdM model

allows the definition of a sort of equivalence classes

for PdM components because such roles are defined

in terms of collection of generic PdM functionalities.

The possibility of describing roles for components of

a PdM solution gives the great advantage of

seamlessly replace a device with another device of the

same role during a re-configuration in the production,

without affecting the PdM program.

5 CONCLUSIONS

PdM solutions can be adapted to production re-

configuration if satisfy two main requirements: a

model to describe the solution in terms of generic

functionalities not depending from the approach used

to realise PdM and an abstraction mechanism for all

the different technologies adopted for the PdM

implementation. This paper proposes a PdM model

defining a new approach to satisfy both, whose

advantages rely on both the concept of LB and AAS.

The former is a conceptual group of functionalities

related to the same aspect of a PdM solution and

allows the definition of roles for the components of

the maintenance program, which enable both easy

replacement and changings in the PdM solution in a

seamless manner. The latter, instead, provides an

abstraction layer for the heterogeneity of devices and

technologies adopted (especially in the brownfield)

improving the degree of integration between PdM

components and a common structure to the

information and operation featured by devices.

As discussed in the paper, the structure of the

AAS perfectly fits for the realisation of LB

functionalities using semantically annotated

properties and functions inside sub models. Both the

LBs and AASs adopted in the PdM model here

presented allow the definition of maintenance

programs in a way that improves the level of

flexibility in production. PdM solutions based on

different approaches to PdM may be represented

Predictive Maintenance Model based on Asset Administration Shell

687

according the proposed model: all the relevant part of

the solution may be described in terms of generic LB

functionalities, defining the roles that such PdM

components play in the whole PdM solution.

Generalisation dictated by the model allows easy

reconfiguration and extensibility of the production

systems, increasing the integration of all the different

parts of a PdM solution.

ACKNOWLEDGEMENTS

This paper belongs to a research path funded by

University of Catania (PIA.CE.RI. 2020-2022 Linea

2—GOSPEL Project—Principal investigator A.

Costa—Code 61722102132).

REFERENCES

Ahmad, R., & Kamaruddin, S., 2012. An overview of time-

based and condition-based maintenance in industrial

application. Computers & Industrial Engineering, pp.

135-149.

Birtel, M., Mohr, F., Hermann, J., Bertram, P., &

Ruskowski, M., 2018. Requirements for a Human-

Centered Condition Monitoring in Modular Production

Environments. IFAC-PapersOnLine, pp. 909-914.

Cavalieri, S., & Salafia, M. G., 2020 (2020a). Asset

Administration Shell for PLC Representation Based on

IEC 61131–3. IEEE Access, pp. 142606-142621.

Cavalieri, S., & Salafia, M. G., 2020 (2020b). Insights into

Mapping Solutions Based on OPC UA Information

Model Applied to the Industry 4.0 Asset Administration

Shell. Computers, 9(2), 28.

DIN, 2016. DIN SPEC 91345:2016-04, Reference

Architecture Model Industrie 4.0 (RAMI4.0). Berlin:

Beuth Verlag GmbH.

Groba, C., Cech, S., Rosenthal, F., & Gossling, A., 2007.

Architecture of a Predictive Maintenance Framework.

6th International Conference on Computer Information

Systems and Industrial Management Applications

(CISIM'07). Minneapolis, MN, USA.

Infosys, 2018. Interoperability between IIC architecture &

Industry 4.0 Reference Architecture for Industrial

Assets. Retrieved 07 13, 2020, from

https://www.infosys.com/engineering-services/white-

papers/documents/industrial-internet-consortium-

architecture.pdf

Jardine, A. K., Lin, D., & Banjevic, D. (2006). A review on

machinery diagnostics and prognostics implementing

condition-based maintenance. Mechanical Systems and

Signal Processing, pp. 1483-1510.

Kagermann, H., Wahlster, W., & Helbig, J., 2013.

Recommendations for implementing the strategic

initiative INDUSTRIE 4.0. Final report of the Industrie

4.0 Working Group. Acatech, Frankfurt am Main.

Kampert, D., & Epple, U., 2012. Modeling asset

information for interoperable software systems. IEEE

10th International Conference on Industrial

Informatics. Beijing, China.

Khana W. Z., Rehmanb M. H., Zangotic H. M., Afzald, N.

Armia M. K., Salah K, 2019. Industrial Internet of

Things: Recent Advances, Enabling Technologies, and

Open Challenges. Computers & Electrical Engineering

81. DOI: 10.1016/j.compeleceng.2019.106522.

Lang, D., Grunau, S., Wisniewski, L., & Jasperneite, J.,

2019. Utilization of the Asset Administration Shell to

Support Humans During the Maintenance Process.

IEEE 17th International Conference on Industrial

Informatics (INDIN). Helsinki.

Liao, Y., Deschamps, F., Loures, E. de F. R., & Ramos, L.

F. P., 2017. Past, present and future of Industry 4.0—A

systematic literature review and research agenda

proposal. International Journal of Production

Research, pp. 3609–3629.

Motaghare, O., Pillai, A. S., & Ramachandran, K., 2018.

Predictive Maintenance Architecture. IEEE

International Conference on Computational Intelligence

and Computing Research (ICCIC). Madurai, India.

Moyne, J., Qamsane, Y., Balta, E. C., Kovalenko, I., Faris,

J., Barton, K., & Tilbury, D. M., 2020. A Requirements

Driven Digital Twin Framework: Specification and

Opportunities. IEEE Access,

pp. 107781-107801.

Panda, S. K., Schröder, T., Wisniewski, L., & Diedrich, C.

(2018). Plug Produce Integration of Components into

OPC UA based data-space. IEEE 23rd International

Conference on Emerging Technologies and Factory

Automation (ETFA). Turin, Italy.

Platform Industrie 4.0, 2016. Structure of the

Administration Shell - Continuation of the

Development of the Reference Model for the Industrie

4.0 Component. Berlin: Federal Ministry for Economic

Affairs and Energy (BMWi).

Platform Industrie 4.0, 2018. The Standardisation Roadmap

of Predictive Maintenance for Sino-German Industrie 4.

Federal Ministry of Economic Affairs and Energy.

Platform Industrie 4.0, ZVEI, 2019. Details of the Asset

Administration Shell.

Tantik, E., & Anderl, R., 2017. Potentials of the Asset

Administration Shell of Industrie 4.0 for Service-

Oriented Business Models. Procedia CIRP, pp. 363–

368.

Strauß, P., Schmitz, M., Wöstmann, R., & Deuse, J., 2018.

Enabling of Predictive Maintenance in the Brownfield

through Low-Cost Sensors, an IIoT-Architecture and

Machine Learning. IEEE International Conference on

Big Data (Big Data). Seattle, WA, USA.

Xu, L. D., Xu, E. L., & Li, L., 2018. Industry 4.0: State of

the art and future trends. International Journal of

Production Research, pp. 2941–2962.

Wollschlaeger, M., Theurich, S., Winter, A., Lubnau, F., &

Paulitsch, C., 2015. A reference architecture for

condition monitoring. IEEE World Conference on

Factory Communication Systems (WFCS). Palma de

Mallorca, Spain.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

688