Internet of Things based Product-Service System

in the Maritime Industrial Sector

Islam Abusohyon and Flavio Tonelli

DIME - Department of Mechanical Engineering, Energetics, Management and Transportation, Polytechnic School,

University of Genoa, Italy

Keywords: Product-Service Systems, Internet of Things (IoT), Cyber Physical Systems (CPS), Value-added Data,

Smart Control Framework.

Abstract: The continuous progress of technology affects all aspects of life and business, dynamically. In order to take

the advantaging of technology development, business owners need to adapt themselves with the changes

stemming from it. Digitalization of production and service processes is one of the directions that alignment

with it will bring many privileges. Internet of Things, cyber-physical system, and artificial intelligence are

the popular components of digitalization that constantly undergo evolution. Utilizing these advanced

components enables business owners to transform the product-centric processes to smart control digital

service-oriented ones. The main motivation of current research work is analysis a theoretical thematic of

literature on IoT and CPS servitization topics to shed the light on the main areas that the researchers are

focusing on since 2009 and bridge the gap that exists in the literature regarding the implementation of these

technologies in the remote monitoring processes in the maritime sector. The result of the literature

examination revealed five dominant areas. Through utilizing these disclosed areas, a ten-step approach

block diagram for IoT-based ‘smart product servitization’ was designed. The proposed framework supports

companies to take the first steps toward remote monitoring servitization through the implementation of IoT

and CPS to produce a fully integrated smart monitor system to improve assets’ health and performance and

reduce costs and waiting time. Moreover, a case study of a smart injector for marine engine is analysed to

propose a working framework supporting the implementation of IoT and CPS to communicate the added-

value data within the smart system built on five modules: process control module, process diagnosis module,

healing module, storage module, and human interaction module.

1 INTRODUCTION

The industry 4.0 revolution has brought a substantial

paradigm shift in industrial practices by propelling

these practices toward automation and digitalization

of the industrial processes. The integration of the

digital, and physical worlds along with the

expanding utilization of modern technologies such

as artificial intelligence, cloud computing, and

Internet of Things (IoT), are the principal

characteristics of fourth industrial revolution which

enable organizations to achieve self-monitoring

capability and consequently reduce the number of

human interventions (Heiner L. et al. 2014).

Therefore, the implementation of these digital

technologies forces the transformation of traditional

manufacturing into digital manufacturing (Tonelli et

al. 2017; Kristen et al. 2018; Marco et al. 2018;

Tonelli F. et al. 2019 & Damiani L. et al. 2017) and

to deliver a more customized, smart and service-

based offerings (Shum et al. 2008). And in order to

do so, many infrastructures require a combination of

these new technologies to adapt themselves with

changes stemming from Industry 4.0 revolution

(Damiani L. et al. 2018) such technologies

originated from different disciplines. Among them,

IoT and Cyber Physical System (CPS) are gaining

vast attention from a wide range of industries (Li D.

et al. 2018).

The “CPS,” and “IoT,” mechanism emanate from

distinct origins, but some common features can be

found in their definition. As a matter of fact, the

main stimulus of both is integrating digital

capabilities, containing network connectivity and

computational capability, with physical devices and

systems for the purpose of data collection and

Abusohyon, I. and Tonelli, F.

Internet of Things based Product-Service System in the Maritime Industrial Sector.

DOI: 10.5220/0010423501770184

In Proceedings of the 6th International Conference on Internet of Things, Big Data and Security (IoTBDS 2021), pages 177-184

ISBN: 978-989-758-504-3

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

177

exchanging (Christopher G. et al. 2019; Sumayya M.

et al. 2015; Keyur K. Sunil M. 2016). And according

to the survey that was conducted by Yang L. in

2017, CPS and IoT technologies are the way toward

innovated and integrated smart systems.

With the implementation of artificial intelligence

and machine learning algorithms, IoT has

accelerated this evolution by using sensors to extract

data throughout the lifecycle of the product, in order

to create value and knowledge from the huge

amount of the collected data, such as the knowledge

of the product performance and conditions (Marco

C. et al. 2019), and this has enabled the

transformation in several industries to move toward

selling this data to get more revenue and higher

margins instead of selling their final product

(Suliman A. et al. 2018; Bianchi N. at al. 2009;

Taticchi P., et al. 2009 & Enrico S. 2019), and this

process of creating additional values by adding

services to products to achieve financial and

strategic benefits, is called servitization (Natalia K.

et al., 2014). One of the ways to achieve data

monetization could be by providing fee-based

structures for value-added data services (Baecker J.

et al., 2020).

Servitization has paved its way through

manufacturing industries by proving its capabilities

in being an effective strategy that provides not only

financial advantage (Andrea T. and Enrico S. 2019),

but competitive advantage as well, by providing

competitive offerings to manufacturing companies

(Natalia K. et al., 2014). In the shipping industry,

servitization has helped in decreasing the cost and

increasing the revenue (Pagoropoulos A. et. al.,

2017).

One of the industries that are witnessing the

servitization trend through the implementation of

IoT, CPS and intelligent data analytics is the

maritime industry, by improving the services

provided to their products such as maintenance,

repair and performance services (Moritz S. et al.,

2016). And what characterizes the maritime sector is

that systems in this sector are complex systems that

generate huge amount of data continuously which

needs to be analysed, used and stored in a very

effective manner based on the integrated

implementation of internet of things and CPS

technologies (Sullivana B. et. al., 2020)

Lokukaluge P. & Brage M. in 2019 highlighted

the importance of the modern internet of things in

facilitating the management and the control of ship

vessels through the smart aggregation and analysis

of real-time data from various ships in different

locations, to digitalize the shipping industry.

Moreover, asset owners in the maritime sector are

looking for reducing cost with smart maintenance,

which is the main reason why the maritime domain

is witnessing digital transformation especially in the

smart remote control and automation of processes

through the extraction of valuable knowledge of the

large stream of data collected from sensors and

actuators. Therefore, the ability to access data

remotely from hard-to-reach assets and handling

these huge datasets is so important in the maritime

domain because it helps in achieving a cost-effective

maintenance and higher performance for the assets.

However, the research and interest in the maritime

domain is still new while a lot of research is

focusing on the manufacturing domain in the past

few years (Taylor N. et al., 2020), without a clear

framework for the remote monitoring through the

implementation of these technologies.

The rest of the paper is structured as follows.

Section 2 presents the assumptions, hypotheses, and

research questions formulation; section 3 presents

the case study; section 4 discusses the framework

formulation and the results; and section 5 provides

some conclusions.

2 FROM LITERATURE REVIEW

TO ASSUMPTIONS,

HYPOTHESIS, AND

RESEARCH QUESTIONS

FORMULATION

For an in-depth investigation of the literature in

order to understand better the implementation of IoT

and CPS in servitization, a group of articles were

collected and analysed using Scopus database. After

deciding about the articles that are related to this

topic, a theoretical thematic approach was used to

extract the important data and finally categorizing

the final list of articles according to the important

extracted data (Vaismoradi M. et al., 2013).

The first step of the literature analysis started

with the search for papers’ titles, abstracts, and

keywords: “Internet of things” using the time frame

2008-2019. This search was done to get an idea

about the size of the existing literature that is related

to Internet of Things, the result shows 70.247 of

articles, which reflects the importance that this topic

is getting from the researchers. After that, to narrow

this literature and focus it on the articles that

discussed the implementation of this technology

within a specific device, another search was

conducted but this time with the key words “IoT”

IoTBDS 2021 - 6th International Conference on Internet of Things, Big Data and Security

178

and “physical device”, and this reduced the list to

12.119. Speaking specifically about the situation of

the IoT in the Maritime industry, “IoT”, “Physical

device”, and “Maritime” were used as keywords on

Scopus, and this time the result shows just 75

articles showing that the implementation of “IoT” is

still a new area of interest in maritime sector

deserving research effort.

A more focused research refinement was done to

understand the effect of implementing IoT, CPS, and

operational research (OR) algorithms and

servitization concept as the following:

The analysis was done, as mentioned above,

within a fixed time range (2008-2019), carrying the

following steps:

• Scopus searching for papers’ titles,

abstracts, and keywords: “cyber physical

system” and “operational research

techniques”;

• Filtering the results and make them limited

to “English” articles that were published in

“Journals” only in the field of “Engineering,

and Computer Science”, in the window

frame from 2008-2019; a list of 143 articles

was the result.

By analysing the corpus data, a list of 36 articles

were defined as the most related ones for this

research according to a proper research questions

and assumptions formulation process.

Table 1 is the result of the analysis of this list of

articles identifying five areas of interest and

development on which researchers focus the most.

Table 1: Main Research Priorities.

Research Area Percentage of

papers

IoT real-time data analysis 38%

Product control and management 22%

Cyber security 19%

Integrated design and manufacturing

processes

11%

Human and CPS interaction in

problem-solving

8%

After analysing these categories, the following

five assumptions (A) were formulated:

A1: Cyber physical environment can integrate

digital product design and manufacturing processes

for higher quality and lower cost operations.

A2: Transforming product-centric processes to

service-oriented ones can be done with the support

of digital technologies.

A3: The digital transformation can be achieved

by the integration and the development of IoT, CPS,

with other physical devices.

A4: Operational research technologies “AI and

ML” can be used to support data intelligence

development and analytics into this application area.

A5: Improved field service, maintenance and

decision making is possible because of more

information about when and how their product is

being used.

According to the first assumption A1 and the

fifth one A5, the approved advantages of

servitization, companies in the maritime sector are

moving toward the implementation of this strategy.

And this has pathed the way to the formulation of

the first hypothesis:

H1: There is an increasing interest of the

maritime sector in servitization.

Moreover, based on the second A2 and the third

A3 assumptions, the secure implementation of

digital technologies facilitates the transformation of

the traditional companies to digital service-oriented

ones. Therefore, the following two hypotheses were

formulated:

H2: Engines and related systems (subsystems)

will benefit from the integration of IoT, CPS, and

OR techniques.

H3: Cyber security issues will increase in

importance.

Finally, since services, maintenance and

decisions can be improved by the right use of data

A5, the following hypothesis has been formulated:

H4: The success of servitization depends highly

on data understanding.

These assumptions and hypothesis lead to the

formulation of the following research questions

(RQ):

High level question:

RQ1: How IoT-enhanced CPS and servitization can

add value to a manufacturer or a components

provider in the maritime sector?

First level questions (Product level):

RQ1.1: How to use the collected real-time data RTD

from IoT sensors?

RQ1.2: What is the effect of the tardiness in

aggregating IoT-data?

Internet of Things based Product-Service System in the Maritime Industrial Sector

179

RQ1.3: Who are the beneficiaries of the aggregated

RTD?

Second level question (Manufacturing process

level):

RQ2: How to improve product manufacturing

process by using operational collected data?

In order to test and validate results obtained in

section 2, a 10-step approach for the development of

IoT-based product design for servitization was

proposed accordingly by detailing the previously

identified five areas represented in Table 1 and the

results of the analysis of the articles found in the

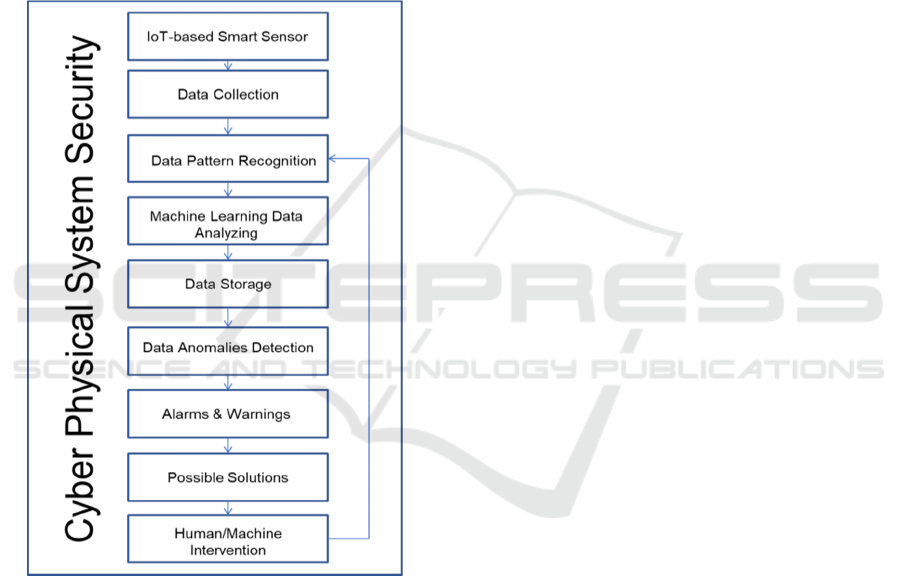

literature. Figure 1 shows the 10 main blocks in this

approach.

Figure 1: IoT-Based Smart Product for effective

servitization block diagram.

Moreover, the framework delivered by Yoval C. &

Gonen S. in 2020, was validated by implementing it

in OMT-Digital Smart fuel Injection System. OMT

has created the start-up company OMT Digital to

quickly evolve its offer to also include services

based on its products. To achieve this goal, the two

companies have worked together to create an

intelligent injector able to communicate its operative

characteristics to a local processing unit for

performing fast data analytics and providing

immediate feedback to the engine control unit and to

the engine room crew, as well as transmitting the

processed data to a cloud-based storage for further

analysis and knowledge generation (Marco C. &

Marco F., 2019). As a result, a smart process control

framework was elaborated.

3 THE DEVELOPED SMART

SYSTEM

The aim of OMT Digital is to be able to transform

traditional mechanical injectors into smart injectors

to be able to share, process, and store data for further

analysis to improve injectors’ performance and

increase its lifetime. Their smart system is made of

different layers, so there is a fully digital layer where

the injectors are connected in IoT system to the Hub.

In this layer the digitization of the analogue signal

takes place. After that comes the processing of the

signal, which is done in the fog node, and here is

where the algorithms run, and the reduction of data

occurs -process raw data to extract value added data-

and present directly to users’ interface the status of

the health of the system. And then the same data

further reduced is sent to the cloud when the

connection allows.

The IoT intelligence-related services/data

provided to the user are divided into three categories

(C):

• C1: drift compensation and product

development “automation system”. OMT has

GUI so they can see how all the injectors “in the

world” are operating and get important data to

help them develop the product further. This is

one of the benefits that the “injector

manufacturer” can get from this automation

system (i.e. getting numerous data from all the

operating injectors).

• C2: on-board maintenance so if there is a

problem in the injector; it needs to be fixed

quickly. The smart system here discovers the

abnormality and advises about the possible

actions “on the user interface” that need to be

taken in order to solve the problem. This leads

to an easier and faster maintenance for the

components

• C3: condition-based maintenance which means

the ability to measure the status of the injector

over time to predict failure before it occurs and

calculate its remaining life to decide what

maintenance needs to be done and when.

IoTBDS 2021 - 6th International Conference on Internet of Things, Big Data and Security

180

4 DISCUSSION & RESULTS

By taking into account the analysis of the literature

and OMT-Digital case and pursuing improvements

to the process control framework proposed by Yoval

C. & Gonen S. in 2019, a smart controller

framework for the fuel injection system “FIS” of

OMT-Digital is presented. Figure 2 describes its

main five modules and information flows in which

the model operates.

Figure 2: Smart controller framework for fuel injection

systems.

4.1 Process Control Module

This module is responsible on collecting the data

“mainly the temperature and the solenoid current”

and sending it to the “process diagnosis” control.

The injectors are connected to the system, and

whenever the injector is activated by the control unit

of the engine then this triggers data generation and

acquisition. Moreover, there is an analogue sensor in

the injector, and there is an analogue to digital

convertor, and then this data is sent to the Hub and

then sent via internet to this compute (fog node). So,

there isn’t any particular algorithm in this phase, it’s

just data coming into the sensor and then delivered

to the fog node.

4.2 Process Diagnosis Module

The processing of the collected data is done in this

module. The collected data is sent to the fog node,

then the fog node will machine learning algorithms”

or classical digital signal processing algorithms, in

order to process the data and transform it into a more

value-added data. The other level of data processing

is done in the cloud.

In the ship, the real-time analysis is taking place,

which means that if there is something changing

significantly, then this will immediately be

transferred with an alarm to people who are in

charge on the ship will be informed, so they can

perform immediate actions to the resulted changes.

On the other hand, the development of the

algorithms to estimate the components’ lifetime is

done on the cloud.

4.3 Healing Module

Based on the required type of intervention, the

corrective actions can either be performed

automatically as part of the smart control or through

manual intervention of a human expert. For

example, if there is a delay in the performance of the

injectors, the system can compensate for this defect

automatically by itself. However, in the case of more

complex faults, the intervention of human is

required

4.4 Storage Module

Here is where the data get stored, and it can be

stored in two ways, in the fog node for up to a month

of a capacity for local analytics on the ship, and once

there is internet connection, the data get

automatically stored in a data lake in the cloud. It’s

used to give lifetime prediction and to give access to

the data by different stakeholders

4.5 Human Interaction Module

This platform is used as one direction information

flow to provide the user with the valuable data. The

stakeholders can get access to the cloud with the

graphical user interface of OMT “OMT GUI”, and

the health of a specific engine with some KPIs can

be reviewed to the crew on the ship through alarms

on the platform which reflects if there is something

wrong, and the ways to solve this issue is provided

to the operator through the platform as well. And

this is done locally without the cloud connection

The main discussion areas in this research are the

importance of internet of things technology in

manufacturing comes from its ability to collect real

time data and extract valuable knowledge from this

huge amount of data which can be supported

through the implementation of smart IoT-based

servitization framework which was presented in this

research together with a 10-steps approach diagram.

These are highly connected to the assumptions and

hypothesis that were mentioned before, so were used

to answer the research questions formulated earlier

in this research.

Internet of Things based Product-Service System in the Maritime Industrial Sector

181

Speaking about the first hypothesis “H1: There

is an increasing interest of the maritime sector in

servitization” which is directly linked to the first and

fifth assumptions “A1: Cyber physical environment

for integrating digital product design and

manufacturing processes for higher quality and

lower cost operations, A5: Improved field service,

maintenance and decision making is possible

because of more information about when and how

their product is being used”, these were tested

positive through the outcomes achieved by the

company under investigation in this study after

implementing the smart control fuel injection system

proposed earlier. OMT is a company in the maritime

sector which is achieving important benefits from

implementing this IoT-based servitization

framework within their operations. They start to

build a good reputation in the market for having this

technology “the smart control system”, and seen as a

technologically advanced injection system

developer, and this attracts a lot of new costumers

for the company “indirect revenue”, as well as the

financial revenue from selling the service provided

by the smart monitor FIS “direct revenue”. Also,

having the technology of IoT-based servitization

smart monitor system gives OMT the possibility to

gain more projects of this kind and to be able to

digitalize other products and not only the injector.

These benefits also provide an answer to the higher-

level question formulated earlier in this research:

RQ1: How IoT-enhanced CPS and servitization

can add value to a manufacturer or a components

provider in the maritime sector?

The second hypotheses “H2: Engines and related

systems (subsystems) will benefit from the

integration of IoT, CPS, and OR techniques”, which

was extracted from the second and third assumptions

“A2: Transforming product-centric processes

service-oriented ones through the help of digital

technologies implementation, A3: The digital

transformation can be achieved by the integration

and the development of IoT, CPS, with other

physical devices”, also found support since the IoT-

based framework that was implemented in a CPS

environment to support the smart fuel injection

system produced by the OMT-Digital, showed that

all the data were fed to machine learning and

artificial intelligence algorithms to enable the

prediction of the injector lifetime depending on the

actual conditions of use; this also answers the

second research question:

RQ2: How to improve product manufacturing

process by using operational collected data?

Regarding the third hypotheses “H3: Cyber

security issues will increase in importance”, this is

tested positive since the high amount of collected

and shared data needs to be processed in a secured

way otherwise the risk of cyber-attacks will increase

dramatically to the point where the implementation

of these new technologies will affect negatively on

the company. On the other side, if these real-time

data were treated securely, this will expose any

abnormalities that might occur. In the case study in

this research, the collected real-time data “RTD”

helped OMT in the detection of injector operation

anomalies such as delayed start of injection, which is

linked to higher fuel consumption, and their

compensation by the control unit to keep the engine

operating optimally. So, the RTD is used to detect

the performance and the lifetime of the injector, and

this data can support decision makers who are either

the ship stakeholders or the engineers in the crew of

the ship and guide them toward better understanding

of the performance of the injectors and therefore,

better maintenance. This answers the following

questions:

RQ1.1: How to use the collected real-time data

RTD from IoT sensors?

RQ1.3: Who are the beneficiaries of the

aggregated RTD?

However, since the proposed framework in this

research doesn’t cover the effect of the tardiness in

the detection of the real-time data, this leaves the

following question without an answer:

RQ1.2: What is the effect of the tardiness in

aggregating IoT-data?

Therefore, for being able to answer this question,

a further development to the proposed framework

can be suggested and then validated in other real-

case scenarios.

Finally, understanding the value of the collected

data and being able to extract knowledge out of it

and transform this huge amount of data into valuable

services, is the heart of servitization, and this

supports the final hypotheses “

H4: The success of

servitization depends highly on data understanding”

and its related assumption “A4: Operational research

technologies “AI and ML” are used to support data

intelligence development and analytics”

Moreover, the 10-steps approach diagram and

the smart control framework for the case under

investigation developed by this research can be

considered as the first steps toward implementing

IoT-based servitization concept in a CPS

environment to collect and analyse data for further

development and improvement in product

performance and maintenance. However, the smart

IoTBDS 2021 - 6th International Conference on Internet of Things, Big Data and Security

182

controller FIS framework proposed by this research

differs from the one described by Yoval C. & Gonen

S. in 2020, since it’s considering the storage process

of the collected value-added data, which is a new

module that was not covered in their framework.

Also, the healing module is mainly responsible on

performing the automatic intervention but can’t send

any updates or modifications to the machine learning

weights in the process control module. Moreover,

the human interaction platform in the framework

presented here is used just like a tool to provide

information to the operator, so the operator can’t

send any data to the other modules within the

framework. Finally, their framework assumes that

the sensors practice self-awareness and maintain

their own reliability, while it’s not the case of the

sensor developed by OMT-Digital.

5 CONCLUSION

With the evolution in the requirements of more

integrated and connected world, companies are

moving toward servitization and smart monitoring of

their assets to satisfy their customer’s needs.

However, smart monitoring and servitization

through the implementation of IoT and CPS

technologies in the marine sector, has remained

under-researched in literature.

In this research, we aimed to propose a

framework and approach to support companies in

remote mentoring and improving hard-to-reach

assets health and performance.

This paper introduces a ten-steps approach and a

framework to support the smart implementation of

IoT and CPS in the manufacturing companies in

order to be able to catch and communicate the

added-value data within the system in real time, and

this helps in servitization and the digital

manufacturing. It also shows that the majority of the

articles are focusing on the role of IoT real-time data

in supporting decisions. And this is exactly the main

idea behind the use of IoT data in service-oriented

manufacturing. Detailing these five areas resulted in

the formulation of a IoT-based servitization block

diagram that was implemented within OMT-Digital

boundaries, and one of its main features is the

“storage module” since this feature was neglected by

the researchers in the literature who produced

similar process control frameworks. The proposed

framework supports manufacturing companies who

want to take the first steps toward smart monitoring

through digitalization and servitization by the smart

implementation of IoT and CPS in the

manufacturing companies to produce a fully

integrated smart control system starting from the

aggregation of information to the storage of value-

added data in real time. Moreover, a case study of a

smart injector for marine engine is analysed to

propose a working framework supporting the

implementation of IoT and CPS to communicate the

added-value data within the smart monitoring

system built on five modules: process control

module, process diagnosis module, healing module,

storage module, and human interaction module.

Three important constraints limit the

generalizability of the framework presented in this

research. Firstly, the aggregation of data was mainly

focused on the first stages of the digitalization

process, because the smart system investigated in

this research was not yet acquired by so many

customers in the maritime sector, which made it

difficult to follow the complete servitization strategy

till the end of the product’s lifecycle. Future work

could include a longitudinal study for the complete

investigation of the servitization process by the

implementation of IoT and CPS. Secondly, the focus

of this research is on the maritime industry, future

research could include pursuing improvements to the

framework and validating it in other industries.

REFERENCES

Heiner L., Peter F., Thomas F., Michael H. (2014).

Industry 4.0. Business and information systems

engineering.

Demartini M., Tonelli F., Orlandi I., Anguitta D. (2017).

A manufacturing value modeling methodology

(MVMM): A value mapping and assessment

framework for sustainable manufacturing. 4th

International Conference on Sustainable Design and

Manufacturing.

Kristen L., Sven P., Kristin V. (2018). Drivers of digital

transformation in manufacturing. Hawaii international

conference on system sciences.

Marco S., Carlo A., Fabrizio D. (2018). How digital

transformation is reshaping the manufacturing industry

value chain: The new digital manufacturing ecosystem

applied to a casy study from the food industry.

Springer International Publishing AG.

Tonelli F., Galluccio F., Mattis P., Abusohyon I., Lepratti

R., Demartini M. (2019). Closed-Loop Manufacturing

for Aerospace Industry: An Integrated PLM-MOM

Solution to Support the Wing Box Assembly Process.

Advances in Production Management Systems.

Towards Smart Production Management Systems pp

423-430.

Damiani L., Demartini M., Cassettari L., G., Revetria R.,

Tonelli F. (2017). Digitalization of manufacturing

Internet of Things based Product-Service System in the Maritime Industrial Sector

183

execution systems: The core technology for realizing

future smart factories. Proceedings of the Summer

School Francesco Turco.

Shum, Kwok L., Watanabe, Chihiro (2008). The effects of

technological trajectory in product centric firms upon

the transition to smart service provision. The case of

smart solar photovoltaic. Journal of services research.

Damiani L., Demartini M., Guizzi G., Revetria R., Tonelli

F. (2018). Augmented and virtual reality applications

in industrial systems: A qualitative review towards the

industry 4.0 era. IFAC-Papers OnLine p.624-630.

Li D., Eric L., Ling L. (2018). Industry 4.0: state of the art

and future trend. International journal of production

research.

Christopher G., Martin B., David W., Edward G. (2019).

Cyber physical systems and internet of things.

National Institute of Standards and Technology

Special Publication

Somayya M, R. Ramaswamy, Siddharth T. (2015).

Internet of Things (IoT): A Literature Review. Journal

of Computer and Communications.

Keyur K. & Sunil M. (2016). A New Approach to

Integrate Internet-of-Things and Software-as-a-Service

Model for Logistic Systems: A Case Study.

International Journal of Engineering Science and

Computing.

Yang L. (2017). Cyber Physical System (CPS)-Based

Industry 4.0: A Survey. Journal of Industrial

Integration and Management

Marco C., Francesco C., Marco F., Marco L. (2019). Fuel

Injection 4.0: The Intelligent Injector and Data

Analytics by OMT Enable Performance Drift

Compensation and Condition-Based Maintenance. The

29th CIMAC World Congress 2019 in Vancouver,

Canada.

Suliman A., Husain Z., Abououf M., Alblooshi M., &

Salah K. (2018). Monetization of IoT data using smart

contracts. IET Digital Library.

Bianchi N. P., Evans S., Revetria R., Tonelli F. (2009).

Influencing factors of successful transitions towards

product-service systems: A simulation approach.

International Journal of Mathmetics and Computers in

Simulation.

Taticchi P., Tonelli f., Starnini E. (2009). A Framework

for Evaluating Product-Service Systems Strategies.

Proceedings of the 10th WSEAS Int. Conference on

mathematics and computers in business and

economics,

Natalia k., Sebastian k., Michal G. (2014). Servitization

Strategies and Product-Service-Systems. IEEE 10

th

world congress on services.

Baecker J., Engret M., Krcmar H. (2020). Business

Strategies for Data Monetization: Deriving Insights

from Practice. In book: WI2020 Zentrale Tracks

Andrea T. & Enrico S. (2019). Exploring the relationship

between the product-service system and profitability.

Journal of management and governance.

Sullivana B., Desaib S., Solec J., Rossia M., Ramundoa

L., Terzi S. (2020). Maritime 4.0 – Opportunities in

Digitalization and Advanced Manufacturing for Vessel

Development. Procedia Manufacturing

Volume 42, Pages 246-253

Pagoropoulos A., Kjær L., Bejbro J., Andersen1 and

McAloone T. (2017). The influence of costs and

benefits’ analysis on service strategy formulation:

Learnings from the shipping industry. Cogent

Engineering..

Moritz S., Carl R., Bjornar H., Klaus-Dieter T. (2016).

Utilising the Internet of Things for the Management of

Through-life Engineering Services on Marine

Auxiliaries. The 5th International Conference on

Through-life Engineering Services.

Lokukaluge P. & Brage M. (2020). Ship performance and

navigation information under high dimensional digital

models. Journal of Marine Science and Technology.

Taylor N., Human C., Kruger K., Bekker A. Basson A.

(2020). Comparison of Digital Twin Development in

Manufacturing and Maritime Domains. In book:

Service Oriented, Holonic and Multi-agent

Manufacturing Systems for Industry of the Future

Vaismoradi M., Taurunen H. & Bondas T. (2013). Content

analysis and thematic analysis: Implications for

conducting a qualitative descriptive study. Nursing

and Health Sciences, 15, 398–405

Yoval C., & Gonen S. (2020). Framework for smart

process controller implementation in an industry 4.0

setting.

Marco C. & Marco F. (2019). Towards the digital engine:

the OMT smart injector enables performance

monitoring and condition-based maintenance. 29

TH

CIMAC World Congress.

IoTBDS 2021 - 6th International Conference on Internet of Things, Big Data and Security

184