Conveyor Belt Longitudinal Rip Detection Implementation with Edge AI

Emerson Klippel

1 a

, Ricardo Augusto Rabelo Oliveira

2 b

, Dmitry Maslov

3 c

,

Andrea Gomes Campos Bianchi

2 d

, Saul Emanuel Delabrida Silva

2 e

and Charles Tim Batista Garrocho

2 f

1

Vale Company, Parauapebas, Para, Brazil

2

Computing Department, Federal University of Ouro Preto, Ouro Preto, Minas Gerais, Brazil

3

TinkerGen, Seeed Studio, Shenzhen, China

Keywords:

Deep Neural Network, Device Edge, Rip Detection, Conveyor Belt.

Abstract:

Failures in the detection of longitudinal rips on conveyor belts are events considered catastrophic in mining

environments due to the financial losses caused and the exposure to safety risks of the maintenance teams. The

longitudinal rip detection technologies used today have limitations, being the most reliable systems expensive

and complex and the simplest and cheapest systems unreliable. In view of this scenario, we studied the

implementation of a longitudinal rip detection solution based on images of the conveyor belt. The images

will be collected in real time and inference, rip detection, will be carried out locally using a deep neural

network model executed on device edge. The results obtained with the prototype, in controlled field tests,

were satisfactory and showed the feasibility of using deep neural network algorithms executed on device edge.

These results encourage the development of a complete solution for the detection of defects in conveyor belts

considering all the operational conditions found in the mining environment.

1 INTRODUCTION

One of the main assets used in iron processing plants

are conveyors. Even in medium-sized plants there are

more than a dozen kilometers of this equipment in-

stalled and in continuous operation. The main compo-

nent of these conveyors is the vulcanized rubber belts

with an internal steel or canvas structure.

The sensitivity to damage by the conveyor belts by

piercing and cutting elements is notable, especially

in transfer houses where the material transported by

the belts is transferred between them. In these places

the material being carried and metal scraps can get

stuck, acting as blades, causing longitudinal cuts in

the conveyor (Hardyg

´

ora et al., 1999).

Situations in which longitudinal rips conveyors

cause large losses in belts are common, including total

losses with impacts related to risk exposure by main-

a

https://orcid.org/0000-0003-0312-3615

b

https://orcid.org/0000-0001-5167-1523

c

https://orcid.org/0000-0002-9888-6107

d

https://orcid.org/0000-0001-7949-1188

e

https://orcid.org/0000-0002-8961-5313

f

https://orcid.org/0000-0001-8245-306X

tenance teams and financial losses due to belt repair

and production losses. The Figure 1 shows a belt slot

with total loss of the asset.

The most common belt tear sensors found in the

iron ore mining environment are electromechanical

and electronic. Electromechanical devices are not

very reliable since they need a direct interaction be-

tween the tear or its effects and the sensor, on the

other hand they are inexpensive and easy to maintain.

Electronic sensors are more reliable but have a high

cost and require the installation of sensor elements in

the belt structure, not allowing the interchangeability

of belts in case of maintenance demands (Gruenhagen

and Parker, 2020).

Figure 1: Image of total loss on conveyor belt by rip.

496

Klippel, E., Oliveira, R., Maslov, D., Bianchi, A., Silva, S. and Garrocho, C.

Embedded Edge Artificial Intelligence for Longitudinal Rip Detection in Conveyor Belt Applied at the Industrial Mining Environment.

DOI: 10.5220/0010447204960505

In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021) - Volume 1, pages 496-505

ISBN: 978-989-758-509-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

The objective of our work is to detect longitudinal

rips in conveyor belts using images of its surface cap-

tured in real time and a model of deep neural network

(DNN). This model will make inferences locally us-

ing a device edge without the need for centralized pro-

cessing. This capture of images in real time and exe-

cution of the model locally are the main differences of

the work when compared to other detection solutions

based on image with centralized processing.

The local inference of the model, with all the pro-

cessing being carried out on the device edge is im-

portant taking into account the restrictions of connec-

tivity to the existing network in the case of conveyor

belts (Jurdziak et al., 2018).

In general, our work brings an approach based on

the AI on Edge paradigm for the solution of an impor-

tant problem in the iron ore processing industry. More

specifically, our solution proposal utilizes the poten-

tial of decentralized processing of DNN models run-

ning on device edge, eliminating restrictions on lack

of connectivity and communication latency, allowing

for real-time actions, necessary for the type of solu-

tion proposed here.

2 THEORETICAL REFERENCE

The evolution of artificial intelligence algorithms,

mainly after the development of deep learning algo-

rithms and the hardware optimizations for the exe-

cution of these models, has allowed everyday tasks,

previously considered feasible only by humans, to be

efficiently performed by machines. This work item

addresses, not exhaustively, the theoretical foundation

for deep learning and edge AI device.

2.1 Deep Neural Network

Modern artificial intelligence models have dozens of

layers, thousands of neurons and millions of trainable

parameters. This coupled with training techniques

using massive volumes of data and specialized hard-

ware for both training activities and model inference

led to deep learning algorithms or deep neural net-

work (DNN). These algorithms have become practi-

cally standard for systems that involve image classifi-

cation and detection (Koul et al., 2020).

Deep learning models with convolutional layers

are used to detect and classify images. These layers

work as filters, extracting characteristics from the im-

ages(Krizhevsky et al., 2017). In the implementation

of deep learning optimization techniques are used in

order to reduce the size of the model and its process-

ing demand, among them we have dropout, parame-

ter sharing and rectified linear units (ReLU) activation

functions (Krizhevsky et al., 2017).

An important concept used in DNN is that of

knowledge transfer. This technique allows the use of

previously trained models from specific datasets, sim-

plifying the final training process. In this case, it is

not necessary to carry out the training from scratch,

reducing the size of the datasets and consequently

the training time and complexity (Krizhevsky et al.,

2017).

The implementation of the deep learnig algo-

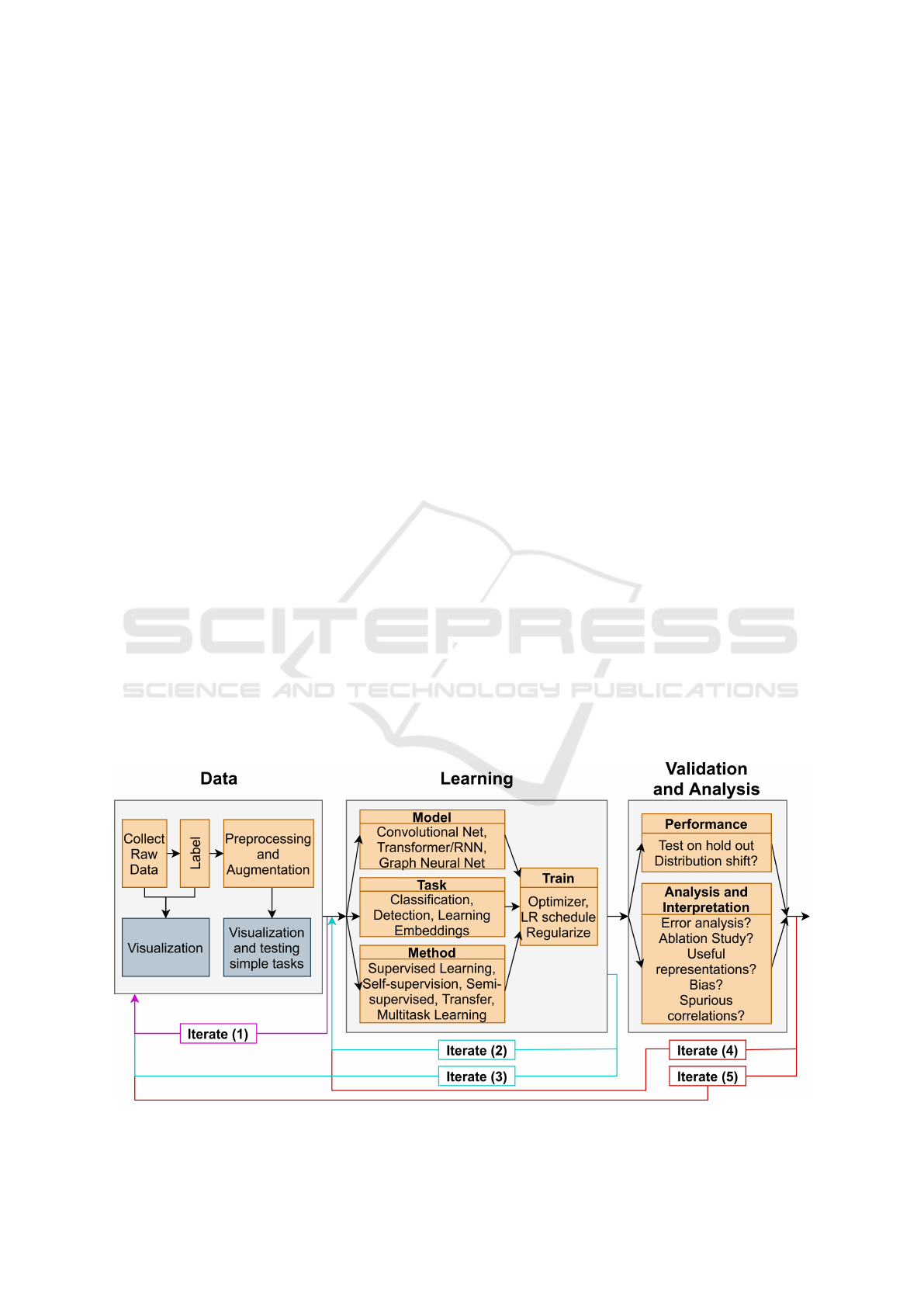

Figure 2: Stages of DNN implementation.

Embedded Edge Artificial Intelligence for Longitudinal Rip Detection in Conveyor Belt Applied at the Industrial Mining Environment

497

rithms can be divided into three stages as can be seen

in Figure 2. The first step consists of processing the

data to be used in the training process. In the second

stage, the models to be used are defined considering

the task to be performed, the training methods, its ex-

ecution and optimization. In the third stage, perfor-

mance tests are carried out in a set of analyzes that

aim to detect generalization capacity, bias and spuri-

ous correlations(Raghu and Schmidt, 2020).

2.2 AI on Edge

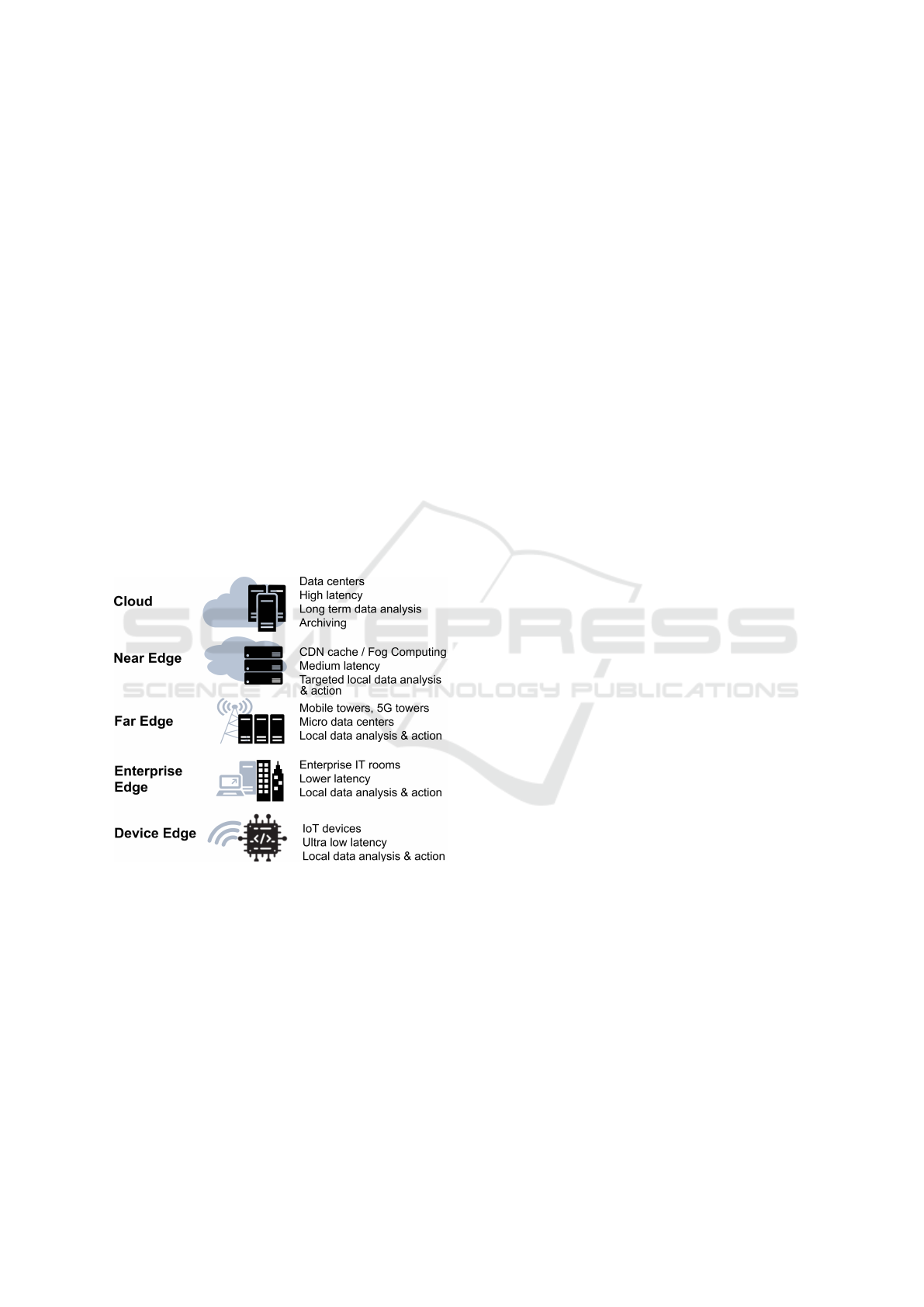

The edge computing paradigm was born from the

current demand for decentralized processing, mainly

considering the volume of data produced by the In-

ternet of Things (IoT) devices. At a high level, edge

computing can be divided into Device Edge, Enter-

prise Edge, Far Edge, and Near Edge. We can see

these levels in Figure 3. Devices Edges are closer to

the real physical world, collecting information from

the environment, processing these locally and taking

actions that interact directly there (Bertino and Baner-

jee, 2020).

Figure 3: Edge computing classification.

The convergence between AI and device edge cre-

ates a new field of studies and application develop-

ment, called AI on Edge. In these studies, efforts are

concentrated on the design of training and inference

frameworks, adapting the models and accelerating the

hardware for use with AI(Deng et al., 2020b).

The adaptation of models and training and infer-

ence frameworks are being carried out by device Edge

manufacturers for AI applications. In our studies, we

verified the existence of solutions such as the soft-

ware of the Google Coral platform (LLC, 2020), the

nncase compiler (Sunnycase, 2020), and the Open-

Vino toolkit from Intel (Corporation, 2020). The pur-

pose of these solutions is to adapt models trained in

the cloud or in hardware with a high processing power

for later use in Edge AI, devices with limitations in

processing capacity and memory.

Processors for AI on Edge applications are built

taking into account energy constraints, memory ca-

pacity and processing speed. The optimization of

these processors for the execution of AI algorithms

concerns the architecture of memory and the paral-

lelism of logical operations. (Deng et al., 2020a).

The generic architecture of a neural network ac-

celerator can be seen in Figure 4 being composed

of an array of processing elements (PE), each with

a small memory buffer, a global buffer for compen-

sating latency for accessing external memory. The PE

process the input and output activation functions, the

network weights, and the sum result function. The

joint execution of these functionalities by the PE al-

lows the implementation of the convolution, polling,

and feedforward processes of the deep neural net-

works (Deng et al., 2020a).

3 RELATED WORK

Techniques with the use of computer vision, computer

hearing and deep neural network to detect equipment

failures in an industrial environment are proposed by

several authors. In this topic we cover some of these

applications.

One of the proposals for the detection of longitudi-

nal rip in conveyor belts is the use of computer vision

combined with laser light to detect the failure. The

belt is illuminated by a laser on its surface opposite

the load region, a CMOS matrix captures the image

formed by the laser trace. This image goes through

filters and distortions in the design line by the laser

are extracted and detect the failure. In simulations, the

system showed the ability to detect with tears quickly

and with accuracy (Xianguo et al., 2018). In an-

other approach, the accuracy of 86.7% was obtained

in laboratory tests of the detection system based on

the combination of sounds and images. In this sys-

tem, real-time images obtained from the bottom of

the belt are processed with the application of filters,

binarization and bit counting, this counting is associ-

ated with the existence or not of tears in the image.

At the same time the noise produced by the belt is

captured close to the camera’s installation point, this

signal is processed using Mel-Frequency Cepstral Co-

efficients (MFCC) and Gaussian Mix Model - Univer-

sal Background Model (GMM-UBM) to identify pos-

sible signatures that can identify a tear. Video and au-

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

498

Figure 4: The typical digital architecture of neural accelerators.

Table 1: Device edge comparison.

Raspberry Pi 3 Jetson Nvidia Nano SiPEED MAiX BiT

Processor ARM Cortex A53 Quad-core a57 K210 RISC V

Clock (GHz) 1.2 1.43 0.40

RAM (GB) 1 4 0.008

AI resources NA GPU KPU

OS / Language Raspian / Python Ubuntu / SDK JetPack uPython

GPIO pins 40 40 48

Power rating (W) 15 10 5

Dimensions (mm) 85x56x17 100x80x29 52x39x10

Costs (US$) 75.00 194.00 21.00

dio processing information is combined to determine

the presence or absence of rip in conveyor belt(Hou

et al., 2019).

For the detection of dirt in the belt conveyor struc-

tures based on images, convolutional neural networks

were used with promising results (Santos et al., 2019).

ResNet18 and VGG16 architectures were used. These

models were trained from 73 photographs of clean

and dirty conveyor structures. Data augmentation

techniques were used to increase the generability of

trained models. Accuracy results of 95.5% were ob-

tained for the VGG16 mode and 81.8 % for ResNet.

study where YOLO (You Only Look Once) and

Faster R-CNN (Faster Region Convolutional Neu-

ral Network) models were used to detect damage on

paved roads and highways obtained satisfactory re-

sults with a precision of 93% and F1 (Overall Accu-

racy) and 84% for YOLO and precision of 75% and

F1 of 65% for Faster R-CNN (Majidifard et al., 2020).

For the construction of the training dataset, 7,237 im-

ages from the Google Street View were used. Each

of these images was classified by a human specialist

among 9 categories. This study is relevant to our work

due to the fact that the image of the damage to the as-

phalt of the street is similar, in aspect, to the damage

found in conveyor belts.

4 DEEP NEURAL NETWORK IN

EDGE AI

For the use of DNN at Edge, the platforms available

on the market at the time of the start of the work

were evaluated. The one with the best cost-benefit

ratio was the MAiX BiT board from the manufac-

turer SiPEED. The relevant characteristics evaluated

for choosing the board, considering the scope of the

work, are shown in the Table 1.

Below we discuss the main elements of SiPEED

architecture used in the implementation of our work.

4.1 SiPEED Architecture

The core of the SiPEED MAiX BiT board is the K210

Kendryte System on Chip (SoC) designed specifically

for computer vision and hearing applications, in addi-

tion to having an accelerator for convolutional neural

Embedded Edge Artificial Intelligence for Longitudinal Rip Detection in Conveyor Belt Applied at the Industrial Mining Environment

499

Figure 5: KPU block diagram.

networks. The K210 block diagram is shown in Fig-

ure 6.

Figure 6: Block diagram of K210.

SiPEED boards can be programmed using C or Mi-

cropython programming languages, C SDK and Mi-

cropython firmware both have a specific set of li-

braries for manipulation of convolutional neural net-

works, computer vision, and sound or voice. When

flashed with Micropython firmware, SiPEED boards

can be programmed using MaixPy IDE, an integrated

development environment derived from OpenMV,

that allows connection to the device, code execution,

and debugging with visual feedback.

The K210’s convolutional neural network accel-

erator is the Knowledge Processor Unit (KPU) be-

ing prepared to perform convolution, batch normal-

ization, activation and pooling operations. The KPU

can be interfaced directly with the Digital Video Port

(DVP) for real-time applications. Figure 5 shows the

K210 Kendryte KPU block diagram.

The KPU supports a wide range of tensor oper-

ations used in common network architectures, such

as Conv2D, DepthwiseConv2D, MaxPool2D, Relu6,

and others(20+ in total). Model compilation to K210

format(.kmodel) is performed using nncase software

developed by the K210 manufacturer. The manufac-

turer of the K210 is the Chinese company Cannan

Creative.

4.2 Training Framework

The aXeleRate framework was used in training the

deep learning model implemented in Edge AI. aXel-

eRate is based on Keras-TensorFlow and consists of

a set of scripts optimized to be executed in a jupyter

notebook running on the Google Collaboratory plat-

form (Maslov, 2020).

AXeleRate has a modular structure, allowing

users to combine different frontend architectures with

a variety of feature extractors, such as MobileNet,

NASNetMobile, ResNet, and others. Frontend de-

fines the format of data output by model - in aXel-

eRate users can choose between a classifier, YOLOv2

detector, and SegNet-basic semantic segmentation

network.

The data in front of the images are preprocessed

and fed into the feature extractor part of the network.

The resulting feature vectors are used by the network

frontend to classify the image, output the bounding

boxes or segmentation masks, depending on the type

of frontend.

The main feature of aXeleRate is the automatic

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

500

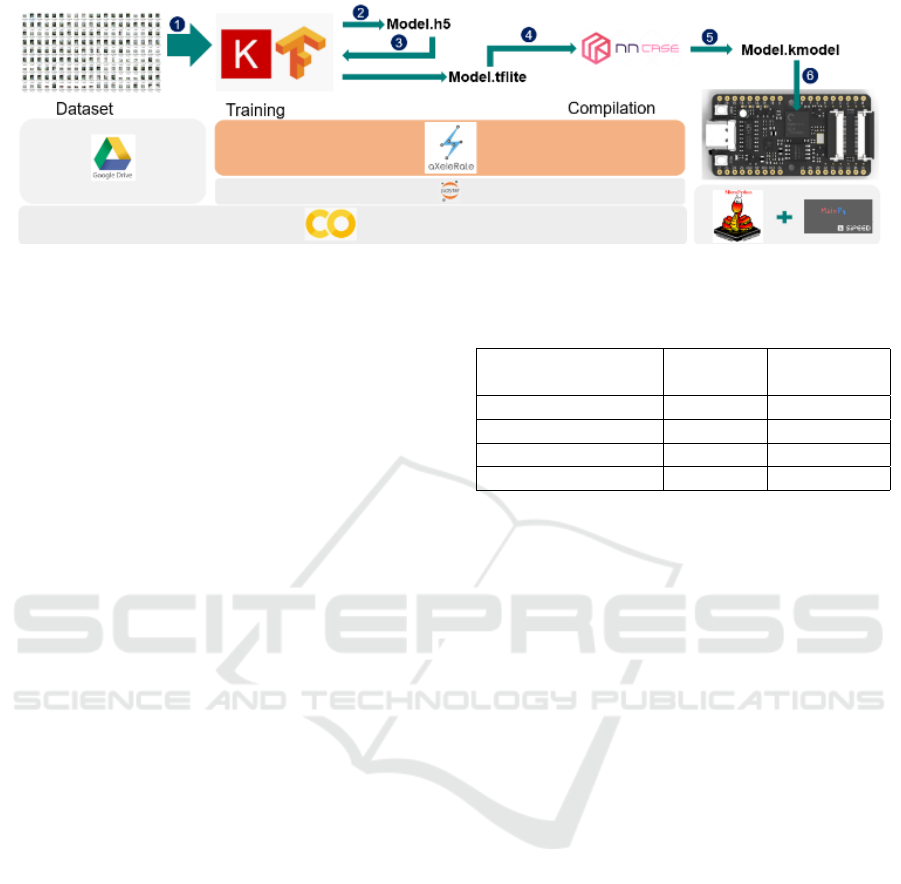

Figure 7: Training and compilation with aXeleRate.

conversion of trained models to the necessary format

for later use on Edge AI devices. The Edge AI de-

vices ecosystem is currently very fragmented, each

device requires the model to be converted into its own

format in order to accelerate inference. The conver-

sion is done using different tools that are often not

compatible with each other. For example, K210 uses

nncase converter, Nvidia Movidius chips use Open-

VINO toolkit and Google Edge TPU uses a propri-

etary model compiler. aXeleRate aims to make the

process of model training and conversion to different

formats for hardware-accelerated inference more con-

venient and less time-consuming for the end-user.

The process of using aXeleRate is shown in Figure

8 with the main steps indicated by the blue circum-

ferences The first step consists of loading the images

from the dataset stored in Google Drive for training

in the TensorFlow-Keras framework (indication 1).

After training, the model is delivered in .h5 format,

for classifiers (indication 2). Next, the .h5 model re-

turns to TensorFlow (indication 3), to be converted to

.tflite format (indication 4), and then to be compiled in

nncase. The nncase compiler performs the compres-

sion, parameterization, and compilation of the model

to the .kmodel format (indication 5). The .kmodel

model is executed by the KPU from the device’s SD

card (indication 6).

4.3 DNN Selection

In selecting the model, we take into account the mod-

els that can be compiled by nncase. Among these

models, we selected MobileNet due to its architec-

ture being efficient in terms of fine-grained recogni-

tion, accuracy, and low computational cost(Howard

et al., 2017). The comparison between the different

versions of MobileNet and the fine-grained recogni-

tion benchmark, in this case Inception v3, is shown in

Table ref tab: tab2. The Stanford Dogs dataset was

used to assess this capacity of the compared networks

Table 2: Model Comparison using Stanford Dogs, (Howard

et al., 2017).

Model

Top 1

Accuracy

Million

Parameters

Inception v3 84% 23.2

1.0 MobileNet-224 83.3% 3.3

0.75 MobileNet-224 81.9% 3.3

1.0 MobileNet-192 81.9% 1.9

5 METHODOLOGY

This section describes the training methodology for

the deep neural network, building the Edge AI proto-

type and field tests for the study.

5.1 Edge AI Prototype Construction

The prototype was built with the SiPEED board to

carry out field tests and capture images of the con-

veyor belt. A prototype was built from the SiPEED

board to obtain photos of the belt and field tests. In

the prototype, the SiPEED was protected from the ex-

isting dust and moisture near the conveyor belt. The

final structure of the prototype is shown in Figure 8.

The set thus built was installed on a tripod to allow

correct positioning and mobility between tests. In the

enclosure, fault indication LEDs were installed to fa-

cilitate the monitoring of the tests. The SiPEED elec-

trical supply was provided by a 5V and 10A power

bank installed inside the enclosure.

For the tests, three Python scripts were developed.

The first to capture photos in the field with 224x224

resolution and storage on the SD card. The second

for testing the model from the validation dataset pre-

viously stored on the SD card. The third for damage

classification tests in the field with storage of the clas-

sified photos with this situation on the SD card.

Embedded Edge Artificial Intelligence for Longitudinal Rip Detection in Conveyor Belt Applied at the Industrial Mining Environment

501

Figure 8: Edge AI prototype.

5.2 Training the DNN

The data set was developed to train the deep learning

model. For the dataset 396 photos of the damaged

belt (tear) and 396 photos of the normal belt were

taken. The damage simulations were carried out by

the maintenance team, Figure 9, and pictures of these

situations were taken with the belt stopped and in mo-

tion.

Figure 9: Edge AI prototype.

The photos were taken with SiPEED itself using the

224x224 resolution appropriate to the MobileNet in-

put format. Examples of these images are shown in

Figure 10. The images of each class were divided into

training images 360 and 36 verification images.

(a) Without tear. (b) With tear.

Figure 10: Images of conveyor belt.

The 0.75 MobileNet architecture was configured as a

classifier, with 224 inputs, 1 standard convolutional

layer, 26 depthwise layers followed by batch nor-

malization and ReLU activation function and 2 fully-

connected layers with 100 and 50 neurons, and a

dropout of 0.5. The training was carried out using

aXeleRate / Keras-TensorFlow in Google Colabora-

tory. The training was carried out in 10 epochs and the

learning rate adopted was 0.001. The initial weights

of the model are loaded considering previous training

with the ImageNet dataset.

5.3 Experiments

For the analysis of results, it used confusion matrices

with that of Figure 11 at the same time that they used

the parameters precision (1), recall (2), and overall

accuracy F1 (3). Where TP is truly positive, FP is

false positive, TN is true negative and FN is a false

negative.

precision =

T P

T P + FP

(1)

recall =

T P

T P + FN

(2)

F1 =

2 ∗ precision ∗ recall

precision + recall

(3)

Figure 11: Confusion matrix definition.

For DNN performance tests on the Edge device the

same images used in the validation of the training

performed by aXelerate are stored on the SD card of

the SiPEED board. From these images the inference

is made by the model compiled and executed in the

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

502

KPU. The classification results are stored in a txt file

for further analysis.

In the field tests we used the third script, the tests

were conducted on the conveyor belt of a bucket re-

claimer in the process of demobilization, in Figure 12

shows the equipment in question.

Figure 12: Bucket reclaimer used for field tests.

A single prototype (one sensor) was positioned close

to the belt so that the left side of the belt and half of

its center were in the SiPEED’s field of view, Figure

13. The maintenance team simulated cuts in the belt

and it was activated so that cuts would pass in front of

the prototype. It was defined that each simulated cut

would pass in front of the prototype 10 times. For

each detection, correct or not, the image would be

stored. Timed photos every 10s were also taken by

the prototype for future use.

During the positioning of the prototype, care was

taken to minimize environmental influences such as

shadows and glare, both by natural and artificial light.

Figure 13: Instalation position of prototype.

6 RESULTS

This section presents the results of the field tests with

the prototype and the general performance of the deep

neural network model. Validation of the model com-

pilation process is also addressed.

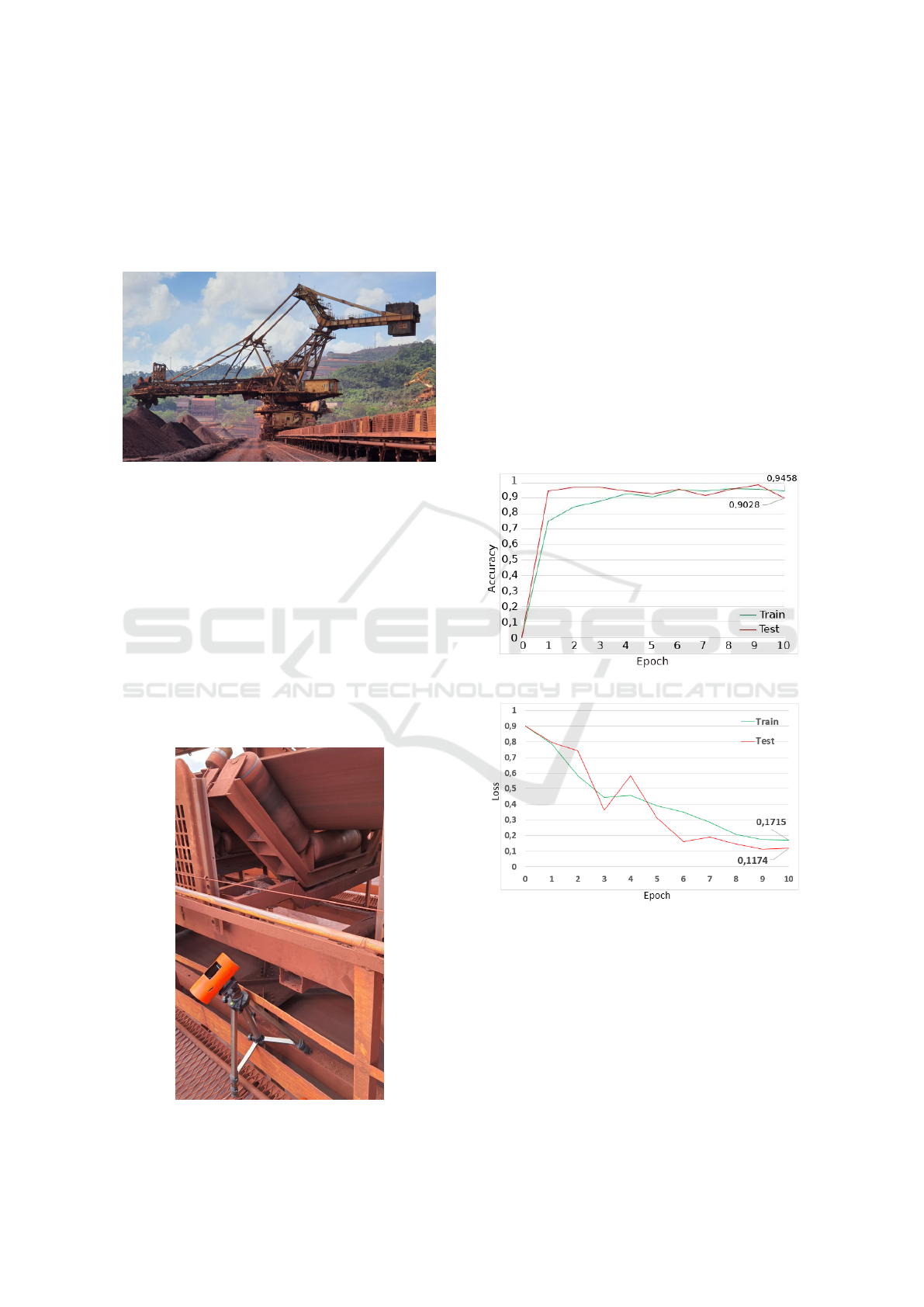

6.1 Trained Model Results

The entire training process for the MobileNet-224

model was carried out on the aXeleRate platform us-

ing the previously prepared belt tear image dataset.

The weights backend used in the training was based

on the ImageNet dataset. The training was carried out

in 10 times taking 3 minutes in the process and reach-

ing the 94.6% accuracy shown in the Figure 14 and

the loss during the training is shown in the Figure 15.

Figure 14: Training graph.

Figure 15: Loss graph.

The model was evaluated using the set of verification

images separate from the original dataset. Altogether

there were 36 images with tears and 36 without tears.

The confusion matrix is shown in Figure 16. The per-

formance indicators can be seen in Table 3.

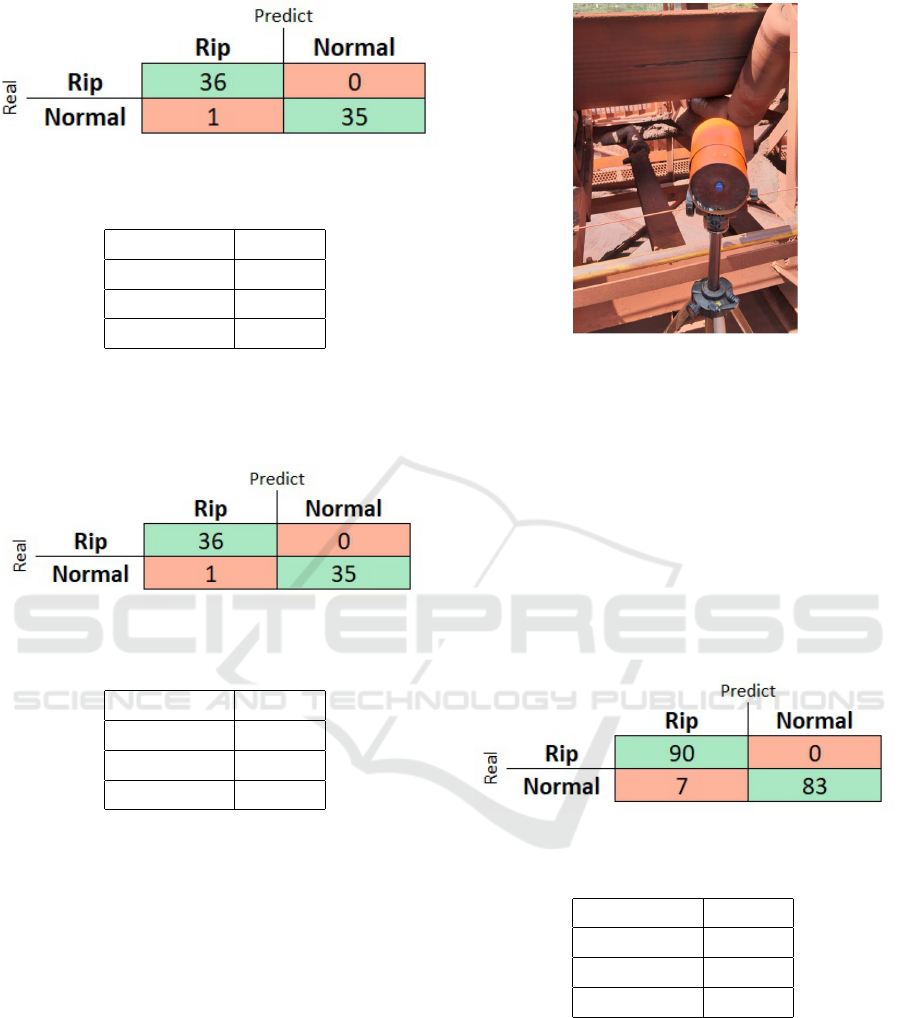

6.2 Performance of AI ond Edge

The same set of images used in the training validation

of the MobileNet 0.75 neural network model was an-

Embedded Edge Artificial Intelligence for Longitudinal Rip Detection in Conveyor Belt Applied at the Industrial Mining Environment

503

Figure 16: Validation confusion matrix - Google Colab.

Table 3: Model Results in Google Colab.

Indicator Value

Precision 100%

Recall 97%

F1 99%

alyzed by the SiPEED MAiX BiT board, loaded with

that optimized model. The results obtained are shown

in Figure17 and Table 4.

Figure 17: Matrix confusion model execution in SiPEED.

Table 4: Model Results in SiPEED.

Indicator Value

Precision 100%

Recall 97%

F1 99%

When we compare the results obtained in the valida-

tion of the aXeleRate training process, Table 3, with

the results of the model validation in SiPEED, Table

4, they are the same indicating that the compaction

process performed by nncase in compiling the model

for use by KPU did not cause losses in its indicators.

6.3 Performance of Field Tests

The field experiments were carried out in 9 campaigns

where the prototype was installed close to the belt so

that the simulated tears in the belt were in the sensor’s

field of view. The installation location of the belt is

shown in Figure18.

In the tests 10 regions with tears and 10 regions

without tears were presented for the prototype. Both

for tear detection situations and for normal belt sit-

uations, the prototype took pictures of the belt. The

Figure 18: Field installation.

tests were conducted under lighting conditions rang-

ing from 800 to 10000 lux. The SiPEED imaging rate

was 6 fps during the tests. The 9 experiments totaled

180 exposures with the results presented in the confu-

sion matrix of Figure 19 and the performance of Table

5. Images of the prototype classifying the belt situa-

tion are shown in Figure 20. The results obtained in

the field tests were satisfactory when compared to the

works consulted and in the same line of study indicat-

ing the feasibility of using AI on Edge as a solution

for detecting longitudinal rip of conveyor belts in in-

dustrial environment.

Figure 19: Field test confusion matrix.

Table 5: Field Test Results.

Indicator Value

Precision 100%

Recall 93%

F1 96%

7 CONCLUSION

The training process of the deep neural network for

the detection of longiudinal rip in conveyor belts, its

conversion and compilation for later use in Edge AI

device showed satisfactory results. For the same set

of validation images, the results of the model classifi-

cation were the same both when executed in Google

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

504

(a) Tear detected. (b) Normal condition.

Figure 20: Images of SiPEED prototype in operation.

Collaboratory and executed by SiPEED’s KPU.

The results of precision (100%), recall (93%) and

total overall accuracy (96%) obtained during the 9

field tests performed were satisfactory and indicate

the feasibility of using edge AI with the MobileNet

deep learning model for the detection longitudinal rip

on belt. With these positive results we understand that

other failure modes, with distinct visual characteris-

tics such as misalignment, contamination of the belt

return and seam failures can be investigated.

As the objectives of the work were achieved, the

process of building 5 more prototypes for definitive

installation on 2 conveyor belts and continuous moni-

toring of their performance was initiated, considering

the normal operational conditions of the iron ore ben-

eficiation plant environment.

Continuing the development of the belt failure de-

tection system, new functionalities will be developed,

such as automatic verification of the cleaning condi-

tion of the optical system lens, detection of the correct

positioning of the sensor and detection of failures in

the lighting conditions. These improvements are nec-

essary to guarantee the reliability of the solution in

the operational conditions verified in the area.

ACKNOWLEDGMENT

This study was financed in part by the Coordenac¸

˜

ao

de Aperfeic¸oamento de Pessoal de N

´

ıvel Superior

- Brasil (CAPES) - Finance Code 001, the Con-

selho Nacional de Desenvolvimento Cient

´

ıfico e Tec-

nol

´

ogico (CNPQ), the Instituto Tecnol

´

ogico Vale

(ITV) and the Universidade Federal de Ouro Preto

(UFOP).

REFERENCES

Bertino, E. and Banerjee, S. (2020). Artificial intelligence

at the edge. arXiv preprint arXiv:2012.05410.

Corporation, I. (2020). Openvino toolkit.

Deng, L., Li, G., Han, S., Shi, L., and Xie, Y. (2020a).

Model compression and hardware acceleration for

neural networks: A comprehensive survey. Proceed-

ings of the IEEE, 108(4):485–532.

Deng, S., Zhao, H., Fang, W., Yin, J., Dustdar, S., and

Zomaya, A. Y. (2020b). Edge intelligence: the con-

fluence of edge computing and artificial intelligence.

IEEE Internet of Things Journal.

Gruenhagen, J. H. and Parker, R. (2020). Factors driving

or impeding the diffusion and adoption of innovation

in mining: A systematic review of the literature. Re-

sources Policy, 65:101540.

Hardyg

´

ora, M., Wachowicz, J., Czaplicka-Kolarz, K.,

and Markusik, S. (1999). Conveyor belts. WNT

Warszawa.

Hou, C., Qiao, T., Qiao, M., Xiong, X., Yang, Y., and

Zhang, H. (2019). Research on audio-visual detec-

tion method for conveyor belt longitudinal tear. IEEE

Access, 7:120202–120213.

Howard, A. G., Zhu, M., Chen, B., Kalenichenko, D.,

Wang, W., Weyand, T., Andreetto, M., and Adam,

H. (2017). Mobilenets: Efficient convolutional neu-

ral networks for mobile vision applications. arXiv

preprint arXiv:1704.04861.

Jurdziak, L., Blazej, R., and Bajda, M. (2018). Conveyor

belt 4.0. In International Conference on Intelligent

Systems in Production Engineering and Maintenance,

pages 645–654. Springer.

Koul, A., Ganju, S., and Kasan, M. (2020). Pratical deep

learning for cloud, mobile, and edge: Real world ai &

computer vision projects using pyhton, keras & ten-

sorflow.

Krizhevsky, A., Sutskever, I., and Hinton, G. E. (2017). Im-

agenet classification with deep convolutional neural

networks. Communications of the ACM, 60(6):84–90.

LLC, G. (2020). Coral ai.

Majidifard, H., Jin, P., Adu-Gyamfi, Y., and Buttlar, W. G.

(2020). Pavement image datasets: A new benchmark

dataset to classify and densify pavement distresses.

Transportation Research Record, 2674(2):328–339.

Maslov, D. (2020). Image recognition with k210 boards and

arduino ide/micropython.

Raghu, M. and Schmidt, E. (2020). A survey of deep

learning for scientific discovery. arXiv preprint

arXiv:2003.11755.

Santos, A. A., Rocha, F. A. S., Azp

´

urua, H., Reis, A. J. R.,

and G., G. F. (2019). Automatic system for visual

inspection of belt conveyors. Intelligent Automation

Symposium, pages 1192–1197.

Sunnycase (2020). Kendrite nncase.

Xianguo, L., Lifang, S., Zixu, M., Can, Z., and Hangqi, J.

(2018). Laser-based on-line machine vision detection

for longitudinal rip of conveyor belt. Optik, 168:360–

369.

Embedded Edge Artificial Intelligence for Longitudinal Rip Detection in Conveyor Belt Applied at the Industrial Mining Environment

505