Reference Architecture for Efficient Computer Integrated

Manufacturing

Abdelkarim Remli, Amal Khtira and Bouchra El Asri

IMS Team, ADMIR Laboratory, Rabat IT Center, ENSIAS, Mohammed V University, Rabat, Morocco

Keywords:

Manufacturing Systems, Smart Manufacturing, Computer Integrated Manufacturing, Systems Architecture.

Abstract:

The technological progress combined with the rapidly changing customer demands are pushing for continuous

changes in manufacturing environments. This led industrial companies into seeking the optimization of their

processes through Computer Integrated Manufacturing (CIM). The main purpose of the latter is to link the

shop floor systems to the high business layer ones. Based on a literature review that we have conducted earlier

on CIM architectures, we have identified the different aspects related to CIM and detected the limitations of

the existing approaches. With the aim of overcoming these limitations, we present in this paper a reference

architecture for CIM based on the ISA-95 standard. We also explain how the proposed architecture was applied

on a case study from the automotive industry.

1 INTRODUCTION

The exponential and never ending progress of cus-

tomer demands alongside fierce competition can only

be seen as instigators of continuous change within

manufacturing environments. That is why, indus-

trial companies found themselves compelled to ma-

nipulate the concurrent advancement of products ef-

ficiently, along with processes and production sys-

tems (Meziane et al., 2000). Accordingly, companies

began to merge information technologies related to

other fields with the manufacturing process. This ad-

justment is known under several names among which

we find: Smart Manufacturing (Li et al., 2019) and

Computer integrated manufacturing (Hedberg et al.,

2016).

There are two key elements to this tendency: Cy-

bernation of the industrial processes, and the facilita-

tion of the exchange of data. This is feasible through

integrating every system in the manufacturing pro-

cess in the same architecture. The purpose is the cre-

ation of an exhaustively connected plant, where ev-

ery retrieved data is reusable in order to optimize the

various business processes. This is what is called a

smart factory (Li et al., 2017). In an attempt to ful-

fill that, the connection between the different levels of

the plant must be ensured. It should stretch from the

shop floor level, containing the production machines,

all the way to the highest level of the plant where

the company’s strategies are elaborated. This con-

nection is defied by the innate difficulty of agglom-

erating and contextualizing data from heterogeneous

systems across the production life cycle (Tolio et al.,

2013). Consequently, researches have managed to put

forward numerous solutions. The aforementioned so-

lutions are able to encompass the totality of the com-

pany’s major IT systems into one architecture all the

while securing the interchangeability among them. In

this article, we are proposing a reference architecture

capable of connecting the production and information

systems of the company. This architecture is based on

six aspects that we identified as main ones: Data inte-

gration, Systems integration, Security, Monitoring &

Data analysis, Mobility and finally Cloud computing.

Thus, this paper is structured in the following way:

Section 2 explains the background that prompted us

to propose this architecture. In Section 3, we present

the proposed architecture and we try to project the

six predefined aspects on it. An application of our

approach on a case study is presented in Section 4.

Lastly, Section 5 winds up the paper.

2 BACKGROUND

In this day and age, it has become a must for industrial

companies to digitize and optimize their processes.

The goal behind it is to keep up with the concurrence.

This digitization is fulfilled trough connecting the real

328

Remli, A., Khtira, A. and El Asri, B.

Reference Architecture for Efficient Computer Integrated Manufacturing.

DOI: 10.5220/0010497903280334

In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021) - Volume 1, pages 328-334

ISBN: 978-989-758-509-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

world to the virtual one, using cyber physical systems,

data sensors and IT Systems. However, the usage of

several systems and technologies in the same environ-

ment is very challenging. This is due to the dissimi-

larities between them and particularities of each one

of them. Subsequently, researchers have been able to

propose architectures that are capable of encompass-

ing every system in the CIM context.

2.1 CIM Architectures

A systematic literature review (SLR) has been con-

ducted on this topic. Its main objectives were: to in-

vestigate the different approaches proposed to handle

computer integrated manufacturing architecture be-

tween 2015 and 2019, to identify the nature of con-

tributions in this area and to determine the different

aspects covered by them (Remli et al., 2020). At the

beginning, we identified 4073 papers retrieved from

four digital libraries. Based on a set of quality assess-

ment and exclusion criteria, 29 relevant papers were

selected.

Out of the analyzed papers, twelve have proposed

architectures in relation to our research. For ex-

ample, Sprock and McGinnis proposed an architec-

ture for smart manufacturing to bridge the gap be-

tween system data and analysis models (Sprock and

McGinnis, 2015). Similarly, Tang et al. proposed

the Cloud-Assisted Self-Organized Architecture (CA-

SOA) to build a vertically enabled system for data

consolidation (Tang et al., 2018). Caggiano and his

colleagues’ Cloud Based Framework enables smart

monitoring of machining in order to offer real time di-

agnosis (Caggiano et al., 2016). In the same vein, Tao

et al. presented the Data-Driven Smart manufacturing

Framework, which enables the usage of the data col-

lected through the manufacturing process, in order to

increase its efficiency (Tao et al., 2018).

2.2 CIM-related Aspects

After the analysis of the selected papers, we identified

six aspects that we deemed essential to handle in a

contribution: Data integration, Systems integration,

Security, Monitoring & Data analysis, Mobility and

Cloud computing.

• Systems Integration. It is the capability of a so-

lution to ensure the integration and the coopera-

tion between different IT systems in the same ar-

chitecture (Thames and Schaefer, 2016).

• Data Integration. It consists of applying con-

text to data from heterogeneous systems across

the production life cycle (Leit

˜

ao et al., 2017).

• Security. It is the ability of the proposed solution

to provide secured connection for systems’ inte-

gration and data exchange (Lia et al., 2018).

• Monitoring and Data Analysis. It consists of

utilizing collected manufacturing data to improve

productivity. In this aspect, we can distinguish

two types of data. The first one is Real-time Data

used generally for monitoring and the second type

is Historic Data used for Data analysis (Bousdekis

et al., 2015).

• Mobility. It is the ability to integrate IT systems

on phones and tablets, generally for data monitor-

ing. (Menezes et al., 2018).

• Cloud Computing. This aspect concerns the ca-

pability of the solution to ensure the usage of

cloud computing for some or all the functionali-

ties (Weihraucha et al., 2018).

The common point between the chosen papers of the

literature review is that each and every one of them

encompasses the aspect of data integration. Right af-

ter it, comes Data analysis and monitoring as well as

Systems integration. We find it very logical that these

two aspects be the most covered ones. This is ow-

ing to the fact that computer integrated manufactur-

ing largely revolves around connected systems, data

interchangeability in addition to re-usability. The as-

pect that ranks third is the cloud computing. Regard-

ing Security, this facet in research draws little to no

attention. However, it stands as a pivotal requirement

in ensuring the sustainability of the business. Mobil-

ity was the least tackled one of the aspects. This came

as a surprise, considering that, in the era of industry

4.0, it has been an important feature. This qualifies it,

alongside with security, to be major features worthy

of being covered in a reference architecture.

3 ISA-95 BASED REFERENCE

ARCHITECTURE

In order to overcome the limitations of the existing ap-

proaches, we propose a new architecture based on the

hierarchy of the ISA-95 standard. In this section, we

first give an overview of the ISA-95 standard. Then,

we explain the concept of Open Platform Communi-

cation. Finally, we present the proposed architecture.

3.1 ANSI/ISA-95

Generally, modern industrial companies have at least

two information systems; an ERP (Enterprise re-

source planning) for managing the inner resources

Reference Architecture for Efficient Computer Integrated Manufacturing

329

(Human resources, stock, suppliers..) and a MES

to manage real time production. The two systems

have separate scopes. The communication between

the pair of systems is an important task. It is usu-

ally carried using different communication protocols.

To standardize the communication between the con-

trol systems, the MES and the ERP, there are sev-

eral standards. The most commonly used one is the

ANSI/ISA-95.

The ANSI/ISA-95 standard was jointly developed

by the International Society of Automation (ISA), and

the American National Standards Institute (ANSI)

with the objective of providing abstract models and

standard terminologies for the exchange of infor-

mation between the enterprise business systems and

manufacturing operations systems in an enterprise

(Brandl and Consulting, 2008).

Figure 1: The CIM pyramid.

The ISA-95 presents a reference model that defines

five levels, in which we can cover the whole layers

of a manufacturing company. These five levels are

schematized in Figure 1. This representation is called

the CIM Pyramid, the higher one climbs in this pyra-

mid, the stronger the level of decision gets.

3.1.1 Enterprise Resource Planning (ERP)

Enterprise resource planning (ERP) is defined as an

integrated computer based system that manages in-

ternal and external organization resources. These re-

sources include tangible assets, financial resources,

materials and human resources (Radovilsky and Bid-

goli, 2004). ERP provides an integrated and continu-

ously updated view of core business processes using

common databases maintained by a database manage-

ment system.

3.1.2 Manufacturing Execution System (MES)

A MES is an information system whose main objec-

tives are tracking and gathering real time data about

the production life-cycle from all the factory or a part

of it (Zhao et al., 2018). A MES provides inputs for

decision makers to decide how current conditions on

the plant can be improved and optimized. The col-

lected data set is used to carry out a certain number of

analysis activities:

• Traceability.

• Quality control.

• Production monitoring.

• Scheduling.

• Preventive and curative maintenance.

The final goal of a MES is to ensure effective exe-

cution of the manufacturing operations and improve

production output.

3.2 Open Platform Communication

(OPC)

Formerly known as Object Linking and Embedding

for process control, or simply OLE for process con-

trol (OPC). It is an interoperability standard used to

secure the exchange of data in the industrial automa-

tion space and in other industries. It is a cross plat-

form technology to ensure the seamless flow of infor-

mation among devices from multiple vendors (OPC

Foundation, 2021). The OPC Foundation is responsi-

ble for the development and maintenance of this stan-

dard. The OPC is implemented in server/client pairs:

• OPC Server. It is a software that can read one

specific machine language or many and can col-

lect data from it and expose it in OPC United

Architecture (OPC UA). It converts the hardware

communication protocols used by Programmable

Logic Controllers (PLC) into one standardized

protocol.

• OPC Client. An OPC client is any information

system that needs to connect to the machines to

get the data, such as HMI or MES. The OPC client

uses the OPC server as a bridge to get data from

the machines or to send commands.

3.3 Proposed Architecture

The architecture we are proposing is based on the

ISA-95 standard. Consequently, the hierarchy of the

proposed systems is respected (the ERP on the top of

the Pyramid and the machines in the bottom). Also,

the architecture is based on the idea that the MES is

the core element of the CIM, for it binds the whole

production system to the enterprise resources.

We propose that the company’s production system

should be divided into two levels as shown in Figure

2:

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

330

Figure 2: The proposed architecture.

• Plant Level. It consists of the local part of the

production system that will be specific to each

plant. It contains all the physical manufacturing

systems and equipment, such as: the machines

and their PLCs, the printers and their server, the

workstations, and finally the MES. This level thus

represents the four first levels of the CIM Pyramid

(Level 0, 1, 2 and 3).

• Corporate Level. It is the Central part of the pro-

duction systems that will be shared between the

company’s plants. It contains only the ERP sys-

tem of the company (Level 4).

To prove the consistency of the architecture, we are

going to project it on the six aspects we retrieved from

the literature.

3.3.1 Systems Integration

The proposed architecture allows the company’s sys-

tems to communicate with each other, using common

communication protocols:

• OPC Server / PLCs-Measuring Tools. The OPC

Server has the ability to communicate using sev-

eral protocols depending on the machine. It can

use either OPC UA Protocol for machines that are

using it, or use the specific PLC Driver of the ma-

chine.

• MES / OPC Server. The MES is considered an

OPC Client. As a result, this communication is

carried out using OPC UA Protocol or in some

cases HTTPS. MES Editors nowadays are adapt-

ing their solutions to the needs by providing OPC-

UA interpreters in their systems.

• Workstations-GUIs / MES. The MES system

Data can be accessed using HTTP Protocol by

workstations or by any other type of GUI (AN-

DONs for example).

• Print Server / MES. The printing server is con-

nected to the MES using TCP/IP Protocol, and it

is connected to the Printers using The IPP proto-

col.

• ERP / MES: This communication is fulfilled gen-

erally by using HTTPS Protocol. But for some

ERP solutions, RFC protocol or even some spe-

cific communication canals are mandatory.

Reference Architecture for Efficient Computer Integrated Manufacturing

331

Figure 3: Security implementation.

3.3.2 Data Integration

Data integration in the architecture can be summa-

rized in two points :

• The OPC Server allows data coming from ma-

chines to be formatted and normalized so that it

can be integrated in the MES.

• The communication between MES and ERP al-

lows Data exchange between the two systems.

3.3.3 Monitoring & Data Analysis / Mobility

The MES gives us the possibility to expose produc-

tion data to be used by Client-side applications, using

web-services and Web-sockets. Moreover, MES So-

lutions nowadays provide development modules that

Allow us to develop and deploy cross-platform Web

Applications for Production monitoring, and for trac-

ing ability and Dash boarding such us ANDONS and

Cockpits. These applications can consume the ex-

posed data, which gives real-time visibility on the

production life-cycle, provides inputs for decision

makers, and represents Mobile-Friendly applications

for easy knowledge access.

3.3.4 Cloud Computing

As we already explained, there are two levels in the

proposed architecture: Corporate level that contains

the ERP and that is shared with all the company’s

plants, so it should be deployed on a Cloud server, and

the Plant level that contains all the remaining systems.

The IS systems for plant level are to be deployed on-

premise.

3.3.5 Security

Based on the best practices set up by the Escal Insti-

tute of Advanced Technologies also known as SANS

institute, we propose the architecture in Figure 3 to il-

lustrate the practices to secure the whole architecture

(Oxenhandler, 2003):

• For workstations, a separated network has to be

created with a specified address to each machine.

An ACL (Access-Control List) is to be imple-

mented to control authorizations. Also, the work-

stations operating systems must always be up-to

date.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

332

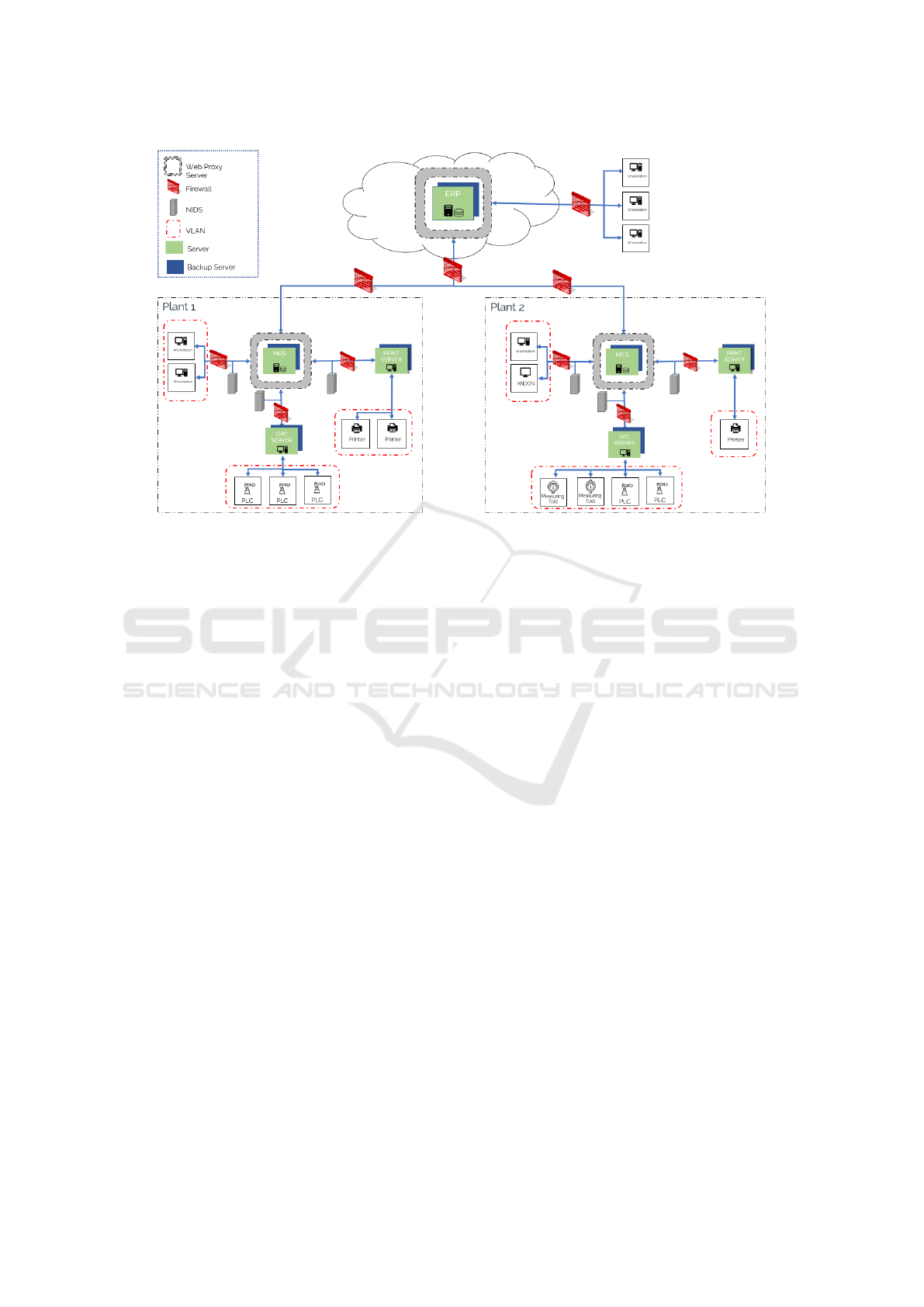

Figure 4: The Architecture of an Automotive Company.

• PLC and Measuring tools: The PLCs are con-

nected to OPC server only trough Ethernet in a

VLAN, so an ACL is mandatory to secure them.

We can install SSL certificates to secure data ac-

cess in PLC for more security.

• MES server: As the core element of the architec-

ture, it should be secured on a highly level. For

that, we propose a Firewall for all the Local con-

nections (Plant level), an ACL to control access

to the Data (Operators can have HTTPS Access

and Printers can access only through TCP/IP).

For more security, a Web Proxy Server should be

setup to secure the MES as a web application from

DDOS attacks, and finally, a NIDS (Network-

based Intrusion Detection Systems) is used to an-

alyze all traffic.

• For the printers, a separated network has to be cre-

ated with a specified address to each printer, an

ACL (Access-Control List) is to be implemented

to set the appropriate permissions on files and

folders (Xiaodong et al., 2012).

• The servers besides the VLANS have to be phys-

ically separated.

• To ensure the continuity of the production life Cy-

cle and the availability of all the functionalities

trough it, the MES, the ERP, the OPC server and

the printing server should have at least one back-

up server each.

4 CASE STUDY

In this section, we apply our architecture on a con-

crete example from the automotive industry. This ex-

ample consists of a company that has two main plants,

one plant in Tangiers, the second plant in Angers. The

company’s main business is assembling cars spare

parts. Figure 4 presents the projection of our archi-

tecture on the case study.

The Local level of Plant 1 contains three produc-

tion machines with a PLC for each, two printers and

two workstations. In the local level of Plant 2, we

have three machines; two of them have their own PLC

and one with two sensors. We have also two printers,

one workstation and finally an ANDON.

The security in the local level is insured by using

separated systems for the two plants, in other means,

nothing relates the two plants except for the Corporate

level. The elements of each plant are secured using

the best practices we listed in the section above.

To guarantee the data integration, the MES secu-

rity should be taken to a highly level, because of its

role as the corporate messenger in the plant, and with-

out which data will no longer be integrated in the ERP.

The MES we used allows us to customize several

dashboards that will provide information to the oper-

ators, which covers the Dash-boarding aspect. The

input that will be used is going to be the collected

manufacturing data. It also allows us to develop web

applications using cross-platform frameworks. These

ones can be accessed from the operator’s workstation

Reference Architecture for Efficient Computer Integrated Manufacturing

333

or from mobile terminals. The central level of the

company’s architecture contains the ERP. It orches-

trates the production on corporate level and commu-

nicates the company’s strategies to plants to be trans-

lated by the MES as orders to the Shopfloor.

5 CONCLUSION AND FUTURE

WORK

At the present time, digitization of processes has be-

come a must for companies that feel the need to op-

timize their costs, to keep up with the customers’ de-

mands and to lead over their competitors. This digiti-

zation is done by connecting the virtual world to the

real one using several technologies such us, data sen-

sors, IT Systems and cyber-physical systems. How-

ever, the usage of many systems and technologies in

the same environment can be really challenging, due

to the differences between them and particularities of

each one of them.

For that, we proposed in this paper a reference

architecture for computer integrated manufacturing,

which is able to encompass every system in the CIM

context. This architecture is based on the ISA-95

standard and takes into consideration six major as-

pects: Data integration, Systems integration, Secu-

rity, Monitoring & Data analysis, Mobility and finally

Cloud computing. However, much work remains to

be done in order to identify other aspects that can be

interesting in the CIM context and can also be handled

by our architecture.

REFERENCES

Bousdekis, A., Papageorgiou, N., Magoutas, B., Apostolou,

D., and Mentzas, G. (2015). A real-time architecture

for proactive decision making in manufacturing enter-

prises. In OTM Confederated International Confer-

ences On the Move to Meaningful Internet Systems.

SpringerLink.

Brandl, D. and Consulting, B. (2008). What is isa-95? in-

dustrial best practices of manufacturing information.

Caggiano, A., Segreto, T., and Teti, R. (2016). Cloud manu-

facturing framework for smart monitoring of machin-

ing. In CIRP Global Web Conference Research and

innovation for future Production. ScienceDirect.

Hedberg, T., Feeney, J. A. B., and Helun, M. (2016). To-

ward a lifecycle information framework and technol-

ogy in manufacturing. In Journal of Computing and

Information Science in Engineering.

Leit

˜

ao, P., Barbosa, J., Foehr, M., Cal

`

a, A., Perlo, P.,

Iuzzolino, G., Petrali, P., J.Vallhagen, and Colombo,

A. W. (2017). Instantiating the perform system ar-

chitecture for industrial case studies. In Interna-

tional Workshop on Service Orientation in Holonic

and Multi-Agent Manufacturing. SpringerLink.

Li, Q., Jiang, H., Tang, Q., Chen, Y., Li, J., and Zhou, J.

(2017). Smart manufacturing standardization model

and standards framework. In OTM Confederated In-

ternational Conferences On the Move to Meaningful

Internet Systems. SpringerLink.

Li, Q., Pu, Y., Xu, Z., Wei, H., Tang, Q., Chan, I., Jiang, H.,

Li, J., and Zhou, J. (2019). Architecture of integra-

tion of industrialization and informatization. In OTM

Confederated International Conferences On the Move

to Meaningful Internet Systems. SpringerLink.

Lia, Q., Tanga, Q., Chana, I., Weia, H., Pua, Y., Jiangb,

H., Lib, J., and Zhou, J. (2018). Smart manufactur-

ing standardization: Architectures, reference models

and standards framework. In Computers in Industry.

ScienceDirect.

Menezes, S., Creado, S., and Zhong, R. Y. (2018).

Smart manufacturing execution systems for small and

medium-sized enterprises. In CIRP Conference on

Manufacturing Systems. ScienceDirect.

Meziane, F., Vadera, S., and Proudlove, N. (2000). In-

telligent systems in manufacturing: Current develop-

ments and future, article in integrated manufacturing

systems.

OPC Foundation (2021). What is opc. https://

opcfoundation.org/about/what-is-opc/.

Oxenhandler, D. (2003). Designing a secure local area net-

work. SANS Institute.

Radovilsky, Z. and Bidgoli, H. (2004). The Internet Ency-

clopedia, Volume 1. John wiley & sons, inc edition.

Remli, A., Khtira, A., and Elasri, B. (2020). Computer in-

tegrated manufacturing architecture: A literature re-

view.

Sprock, T. and McGinnis, L. F. (2015). A conceptual model

for operational control in smart manufacturing sys-

tems. In International Federation of Automatic Con-

trol. Sciencedirect.

Tang, H., Li, D., Wang, S., and Dong, Z. (2018). Casoa: An

architecture for agent-based manufacturing system in

the context of industry 4.0. In IEEE Access. IEEE.

Tao, F., Qi, Q., Liu, A., and Kusiak, A. (2018). Data-driven

smart manufacturing. In Journal of Manufacturing

Systems. ScienceDirect.

Thames, L. and Schaefer, D. (2016). Software-defined

cloud manufacturing for industry 4.0. In Procedia

CIRP. ScienceDirect.

Tolio, T., Saccob, M., Terkajb, W., and Urgo, M. (2013).

Virtual factory: an integrated framework for manufac-

turing systems design and analysis.

Weihraucha, D., Schindlera, P. A., and Sihna, W. (2018). A

conceptual model for developing a smart process con-

trol system. In CIRP Conference on Intelligent Com-

putation in Manufacturing Engineering. ScienceDi-

rect.

Xiaodong, D., Quan, W., Pengfei, Y., Haijing, Z., Yuyan,

H., Haitao, W., and Zhongbin, P. (2012). Security sys-

tem for internal network printing. CPS.

Zhao, W., Shi, G., and Cui, Y. (2018). The planning, design

and application of mes. In ICITEE 18: International

Congress of Information Technology & Electrical En-

gineering -2018. ACM digital library.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

334