Tracking and Tracing of Global Supply Chain Network: Case Study

from a Finnish Company

Ahm Shamsuzzoha

1,3

, Michael Ehrs

2

, Richard Addo-Tengkorang

3

and Petri Helo

3

1

Department of Mechanical and Industrial Engineering, Sultan Qaboos University, PO Box 33, PC 123, Muscat, Oman

2

Department of Industrial Management, Novia-Vasa-Engineering, Wolffskavägen 65200, Vaasa, Finland

3

Department of Production, University of Vaasa, PO Box 700, Vaasa, Finland

Keywords: Tracking and Tracing Technologies, Supply and Logistics Network, Real-time Visibility, Finnish Case

Company.

Abstract: Supply chain and logistics network tracking and tracing is an essential need in global supply and logistics

network. Existing technologies are mostly suitable for single channel supply chain and are not suitable for

multi-channel supply network. The objective of this research study is therefore to outline technological

knowhow and possibilities related to tracking and tracking items within distributed supply chain and logistics

network. This research has focused to implement a novel tracking system applicable for total supply network

both inbound and outbound shipments. This study is validated within the boundary of how the available

tracking technologies can be useful for a Finnish case company to manage its global supply and delivery

network. Both hybrid and cloud enable online-based tracking systems are proposed in this research. The

application of the proposed tracking technologies provides the case company with real-time visibility on its

current logistics assets.

1 INTRODUCTION

There is growing interest of items tracking and

tracing in supply chain and logistics network for the

benefit of the end users. It is considered one of the

success factors in supply chain management and to

achieve competitive business advantage (Day, 1991).

Logistics companies are therefore investing

substantial amount of their resources in order to offer

better services to the potential customers (Toyryla,

1999). Such tracking and tracing service helps

customers to identify the location of their ordered

items, whether they are in-transit, or already to the

way towards the final destinations. This service

therefore helps customer to plan in case of delivery

delay of their ordered items.

In case of handling goods by one company,

contemporary tracking systems might be work well,

however, it may not suitable to track global logistics

network. In case of tracking and tracing of multi-

company supply networks, the tracking system is

done by using Internet, where customers can visualize

the status of their ordered items (Martinez-Sala et al.,

2009). In several situations, multi-company tracking

system can be interfaced with the customer company

for easier visibility (Giannopoulos, 2003; Kärkkäinen

et al. 2004; Benedikt et al., 2012). Although, such

interfacing might be challenging and costly too.

The objectives of this research study are too

divided into two steps. In the first step, fundamental

needs of tracking and tracing within supply and

logistics chain are identified along with checking-out

various available tracking principles used by the

companies for required tracking purpose. In the

second part, a real life case study is conducted, where

the multi-company tracking solutions are highlighted

that is based on World Wide Web.

The rest of the article is organized in the following

manner. In Section 2, a theoretical framework is

presented, where various aspects of tracking and

tracing in supply and logistics chains are elaborated.

The fundamental tracking requirements of supply

chain and logistics networks are highlighted in the

Section 3. In Section 4, various available tracking

principles are presented. In Section 5, an online

tracking system portal is highlighted, whereas in

Section 6 a case example is presented with the

objective to demonstrate a pilot project for tracking

phenomenon. This research is concluded with future

research directions in Section 7.

118

Shamsuzzoha, A., Ehrs, M., Addo-Tengkorang, R. and Helo, P.

Tracking and Tracing of Global Supply Chain Network: Case Study from a Finnish Company.

DOI: 10.5220/0010515401180125

In Proceedings of the 23rd International Conference on Enterprise Information Systems (ICEIS 2021) - Volume 1, pages 118-125

ISBN: 978-989-758-509-8

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 THEORETICAL FRAMEWORK

Although several researches have highlighted the

benefits of tracking system for supply and logistics

chain management over decades, companies are still

lacking behind to implement such technology

(Hinkka, 2012). Supply chain tracking or visibility is

nowadays getting much more attention from

companies in order to ensure security and minimizing

associated risks. According to Musa et al. (2014),

supply chain visibility can be defined to mean the

capacity of the supply chain to view a product’s

lifecycle from concept generation to product’s end-

of-life activities and processes. This tracking system

supports manufacturing companies to adopting just in

time operations (Hui, 2008).

The tracking of supply network often used to

describe a product in the forward direction, whereas

tracing is used to infer the product’s path and history

from downstream to upstream of the supply chain

(Dabbene et al., 2014). It is therefore essential to

establish an efficient interface between the upstream

and downstream of the tracking system. In order to

make a tracking system it is required to establish a

real time information flow. Such real-time

information flow ensure to minimize potential risks

and events within the supply network. The supply

chain tracking enables companies to support

managers in choosing activities, methods and

technologies to increase supply chain security

without reducing its efficiency (Pero and Sudy,

2014).

The functionality of tracking system concerns

with three basic attributes, which can be explained as

to identify an item, to locate its current position and

current time. At the entry point usually the

consignment is tracked by automatic identification

technology that reads the code of the consignment

and updates its status (Kärkkäinen et al., 2010). In

continuous tracking system the assignment position

in any time is tracked by interrogating the tracking

database. In case of multi-company networks, there

need close cooperation and collaboration with each

other in order to fulfil the requirements for tracking

systems (Shamsuzzoha and Helo, 2012). The

information content can be varied between tracking

systems (Liwei et al., 2009).

Often a tracking system mainly records the

identity of an item, its position and both arrival and

departure time. However, there are many occasions

that also records other attributes like temperature,

humidity, vibration, etc., (Shamsuzzoha et al., 2013).

Such additional attributes protect tracked items from

unnoticed damage and ensure quality delivery. In

general, any company stores its tracking information

to its central database, which can be used further if

needed. In a network system, the information is stored

centrally and retrieves according to the tracking needs

(Helo and Szekely, 2005).

3 BASIC REQUIREMENTS OF

TRACKING WITHIN SUPPLY

CHAIN LOGISTICS

Nowadays different companies are choosing to

implement more advanced and intelligent tracking

systems. At the same time, there is a significant

amount of cost savings for the companies in terms of

better overview of flow of goods. However,

beforehand several critical questions are needed to be

answered by a company such as: what are the tracking

requirements, what are the relevant goods and flows,

what kind of information is available out there, and

what type of technology should be used? This

tracking requirement can be for specific product

centric and/or inbound outbound tracking.

3.1 Itemized Tracking: Perspectives

from Independent Transporters

In today’s business, it is nowadays a common trend

to outsource in order to meet up companies supply

and logistics requirements. From this strategic shift,

companies also expect real-time tracking solutions

from the logistics providers. However, several issues

create complicacy within the companies for both

inbound and outbound delivery of items. Both the

inbound and outbound transports companies usually

have for a relatively take long time and needs to track

their items. Some of these transport companies do

have sophisticated tracking systems that are used to

track their delivery items. None of these are able to

(automatically) track shipments once they are on

board a truck/vessel.

Furthermore, under logistical strategy choosing a

single transport company to monitor the entire supply

chain of a company would be complicated if not

impossible. In such a case, the monitoring will always

be reactive, not proactive - no transport company

knows enough about a company’s production and

business to be able to predict upcoming problems, and

correct accordingly.

In order to maintain a steady tracking of delivery

items, any companies need to formulate its own

tracking system rather than depending on the tracking

system provided by individual delivery companies. In

Tracking and Tracing of Global Supply Chain Network: Case Study from a Finnish Company

119

such perspective, the company needs to collect and

store necessary tracking data from various sources

3.2 Supply Chain Logistics: Inbound

and Outbound Tracking

In supply chain and logistics tracking both inbound

and outbound tracking of goods are essential. The

case of outbound logistics can be considered as the

shipments from consolidation warehouse to end

customer. This is seen as the most valuable part of the

flow of goods and a late delivery is the most costly at

this point with reduced customer satisfaction.

In case of inbound logistics tracking following

situations are considered as important for any

company: a) Lost goods, b) locating a specific

product/unit, c) warehouse problems, d) order

problems, e) time spent on customer inquiries etc.

From study it is identified that most internal

stakeholders said very clearly that the majority of

outbound problems are caused by inbound problems

- the incoming side of the supply chain would benefit

from proactive tracking as much as, if not more, than

the outbound side.

Having analysed the current state of the

order/delivery/shipment process in a company,

several future plans can be assessed to remedy the

problems. The best solution can be to form an online

tracking portal (based on cloud-ware), to which all

stakeholders could supply data for a smooth and

efficient delivery process. This portal would tie

together the different types of tracking data existing

in different databases and ERP's throughout

company’s supply chain, plus make use of special

online tracking services and the data from tracker

devices, making it an integrated solution for tracking

in the supply chain.

4 VARIOUS TRACKING

PRINCIPLES

4.1 Hybrid System (RFID and GPS

Tracker)

The hybrid system which is a combination of RFID

(Radio Frequency Identification) and GPS (Global

Positioning System) can be used to cover different

parts of the supply chain network. Rather than

focusing on one tracking technology only, it is better

to use a mix of two. It is studied that both inbound

and outbound transports have different needs. The

inbound deliveries are more diverse, come from many

places, are worth relatively less money (on an

individual basis) and it is not equally important to

know exactly (down to a meter), where a goods is. It

is more important to know which of a box is not being

delivered according to schedule. The outbound

shipments on the other hand, move together (most

often) are worth a lot of money (usually complete

product) and may need to be tracked very exactly.

The customer will need to know if a shipment is stuck

at a border crossing, very close to final destination,

etc.

From this situation, it is necessary to see what

technologies can be used to implement a suitable

solution for either inbound or outbound logistics. The

inbound flow of goods can be monitored well enough

by implementing a checkpoint system based on RFID

tags – scanned automatically whenever they move

past a certain stage or location, while the outbound

shipments are better monitored with more precise (but

also more expensive) GPS tracking devices attached

to especially expensive goods. An example of a

checkpoint system for inbound logistics is displayed

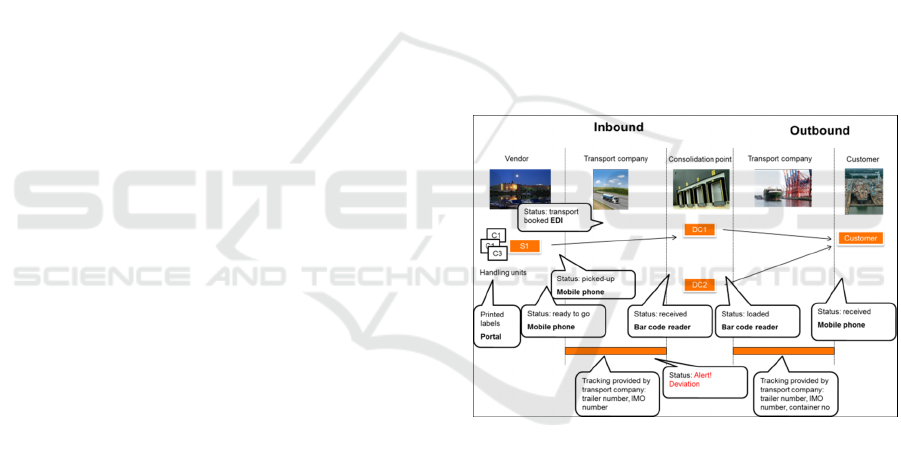

in Figure 1.

Figure 1: Checkpoint tracking system.

4.2 A Cloud Solution for Logistics

Tracking

The basic principle of Cloud solution for logistics

tracking uses an online program platform (Cloud-

ware) that supports both inbound and outbound

logistics easily. This solution generally interfaced

with a company’s current ERP (SAP) system in order

to integrate and store of all the company's data.

However, several factors talk against using ERP

(SAP) to integrate with the online platform for

tracking logistics chain (SAP, 2005).

First of all, security issues of company’s internal

data. Allowing outside parties such as transport

companies and warehouses to automatically add and

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

120

store data directly in the ERP (SAP) databases should

require a certain amount of human supervision - a

certain degree of filtering and approval of edits. An

independent online platform adds a layer of

separation this interaction - nothing more than the

purely transport-connected data available in the

online tracking portal can ever be accessed by an

outsider, lost due to software error, outside attack, etc.

Secondly, cost. The Electronic Data Interface

(EDI) service as used by any company to

communicate automatically with its ERP's of certain

often-used suppliers, charges a certain cost for every

update and status message sent. With a tracking

system, the amount of such messages might quickly

rise to become a significant cost in the system.

Thirdly, ease of modification. With each new

module, each new modification, upgrading the ERP

(SAP) software site becomes a more expensive and

complicated affair. Furthermore, making changes to

the ERP (SAP) site requires an extensive approval

process by the computer management of any

company in order to maintain security. An easily

modified online platform could allow more flexibility

in making sudden changes and additions, when new

tracking solutions and services are added to the mix.

Eventually, an online platform (e.g.

Salesforce.com) can provide free online cloud-ware

creation and modification within their developer's

‘sandbox’; because of ease of programming within

this environment; and the way it can easily store and

receive data online through a set of standardized

interfaces.

4.3 RFID/Barcode Combination

System

In order to reduce cost a company often uses single

tracking solution such as RFID tags or barcode.

However, only using RFID tags or barcode cannot

often meet the tracking requirements for a company.

The best solution will of course be to use a mix of all

possibilities. The uses of barcodes are old and well-

known technology already and comparatively easy to

use. However, unlike barcodes the RFID tags are a bit

more complicated to integrate with the any tracking

system since they require a physical component - an

actual physical antenna tag that cannot be moved over

the Internet.

RFID systems are good because of their automatic

scanning capabilities, but if a warehouse worker

nevertheless has to manually scan half of the

inbound/outbound goods, the benefits are eroded.

Since RFID printers are relatively expensive (€2000-

€3000) it would be impossible to demand such an

investment from small or infrequently used suppliers.

Usually large size company uses the combination

system for its tracking where RFID tags and barcode

are used concurrently for better outcomes.

5 ON-LINE TRACKING SYSTEM

PORTAL ARCHITECTURE

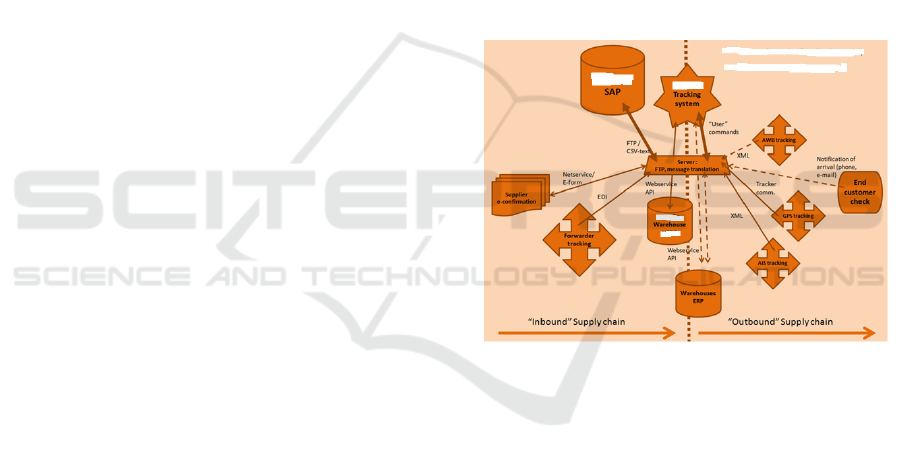

Figure 2 displays the overall architecture of an online

tracking system. From Figure 2 is seen that the

tracking system directly interact with the server

which is also interfaced with company’s SAP

database, supplier e-confirmation, forwarder

tracking, warehouse, AIS (Automatic Identification

System) tracking and GPS tracking The server that is

worked as FTP and message translation also

interfaced indirectly with warehouse ERP, AWB

tracking and end customer.

Figure 2: Tracking system program architecture.

This server worked as like as webpage from

where customers can visualize the updated

information of their logistics items after secured

logged in. Both the inbound and outbound supply

chain information can be visualized separately. The

information is displayed through various formats

such as XML, EDI, e-form and web-service API.

6 USE CASE SCENARIO: PILOT

PROJECT

In order to demonstrate the overall tracking system

this research uses a case company in Finland to track

its product from Vaasa (Finland) to Singapore port

(Singapore). The tracking route can be seen as in

Figure 3. The product started its journey from Vaasa

to Mäntyluoto harbour (Finland) by truck I order to

Tracking and Tracing of Global Supply Chain Network: Case Study from a Finnish Company

121

store it, which is then transported to Turku harbour

(Finland) by truck and eventually towards its final

destination to Singapore by vessel.

Figure 3: Snap shot of the tracking route map of the use case

company’s pilot project (Finland to Singapore).

In this pilot project, different available trackers in

the market were analysed with respect to their

qualities and most importantly battery life times and

TINO (Extended battery life) trackers, GPS trackers

and AIS system were selected and used. Both the GPS

tracker and the AIS system were interfaced with each

other with the objective to get tracking data from both

land and sea respectively. The tracking data from the

land was received from the GPS tracker, while AIS

tracking system receives data from online portal

(http://www.marinetraffic.com/; or

http://www.vesselfinder.com/). In this pilot study, an

option to switch tracking data from one source to

another was created. For instance, in case of a

location where a delivery item is within a geo-

location that is close to a harbour and a radius of 10

km around it, the tracking system will switch from the

GPS tracking device to the AIS tracking system to

collect any tracking data. However, if the delivery

item is at the pre-specified harbour, it will then get its

tracking data from the GPS tracker.

In this study, the battery life of the trackers were

extended to one month by a customized process

which were used considering the travel time from

Finland to Singapore. This shows that the extended

battery-life TINO trackers are viable options for the

international tracking of the case company’s goods.

The basic difference of using our proposed system is

that AIS only be used to find the location of the

shipment, but not the condition of the shipment’s

contents. Our proposed system would enable not only

to track the shipment accurately through the existing

AIS system but also send the conditional data

(humidity, temperature, dew point temperature,

vibration, etc.) of the goods in the shipment, which is

often considered as very important criteria of product

quality and customer satisfaction.

When a GPS-tracker is trapped inside a cargo, it

cannot transmit its tracking data. In that situation, the

AIS ship-tracking system is used to receive tracking

information. Of course, as can be seen from the route

map, certain areas of coastline are less actively

monitored by AIS hub-connected stations than others

- just before the coast of Portugal, the tracking system

did not pick up any transmissions for a few days.

The range of a normal AIS antenna is estimated

to about 70 kilometres, and if the data-sharing stations

on the coast are too far away and no data-sharing

vessels are nearby, the tracking system will not show

up-to-date tracking data. Certain areas are not

monitored at all (by law); such as the coast of Somalia

- the recent pirate activity there means that it would

be unwise for the tracking hubs to provide data for

anyone to access. Other areas are simply not being

monitored and/or shared with the tracking system.

More and more stations are joining every day, though.

In general, the swap of tracking data is

automatically conducted between the GPS tracking

device and AIS system. However, in case of AIS

tracking system, it is necessary to enter the IMO-

number (identification) of the ship manually in order

to work properly. In the future, the transport

managers of the case company will be able to monitor

and correct such cases in the online tracking system

directly.

6.1 Integration of Tracking

Data/Information over the Online

Portal

With more integrated data communication between

parties and better tracking coverage, finding logistics

items should become easier. The tracking system will

use the transport company and consolidation

warehouses (and possibly the suppliers) as sources of

checkpoint data and the system is notified whenever

an item is loaded / offloaded. If a delivery is missing

because of several reasons such as inappropriate

markings, error during transportation, warehouse

relocation, etc., then the search of the item is focused

to a specific certain area, at least. In the future, better

RFID tag systems may even allow the warehouse

personnel to go “hunting” for a lost item, with a

strong, directional RFID scanner.

In this research work an online portal was

developed using the salesforce

(www.salesforce.com) platform. Figure 4 displays

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

122

the online portal with overall information display that

is needed to track an item. This portal consists of

various tabs such as customers, purchase orders,

projects, shipments, handling units etc., that are

required for specific tracking information.

Figure 4: Tracking portal interface.

If the delivery/project manager wishes to know

the status of any missing item, he/she could go to the

handling unit tab of the portal and insert the handling

unit number if known, otherwise can use the search

button to find the item. In the portal, usually all the

relevant tracking data of an item is stored. In addition,

delivery/project manager could also be able to know

the travel route of an item by using Google map as

interfaced with the tracking portal.

In case of absence of the handling unit number of

a missing item, it is also possible to know its status by

using the search tab of the tracking portal, where all

the items handling units are stored. From that tracking

portal, all the relevant information of an item such as

shipment/delivery date, its status, supplier’s name,

etc., are possible to retrieve. By this way, a

delivery/project manager would be able to know the

status of a delayed item too.

A customer demand to update frequently can be

easily met by using this online-based tracking portal.

If a tracker device is on board the shipment, or the

AIS number of the shipment vessel is known, a

delivery/project manager can see (down to the meter)

where the shipment is. They can see whether a

shipment is stuck at a border crossing or waiting off

the coast because of difficult harbour conditions. The

manager can easily take a screenshot of the route map

and show this to the customer. In the future, it is even

be possible to make this a feature of the portal -

automatically generating and sending an info mail or

a one-time-link to the customer's mail, at the press of

a button. This should provide a good amount of

customer good-will and reduce the human search time

considerably.

6.2 Combining Data from Sources

The function of the portal is to act as an integrator of

data. The HU screen shows (Figure 4) this principle:

the main data is taken from case company’s ERP

(SAP) and transport company’s but case data could

also be added by suppliers. Literature shows that a

higher degree of data integration in a supply chain

also leads to better data reliability because of fewer

manual data entries into different systems.

During the pilot project, two the most simple

forms of data communication have been used to

establish contact with warehouse and transport: text

files communicated via FTP server (in the UN

EDIFACT standard) and communication directly via

Salesforce’s own web interface/application interface.

6.3 Connecting Trackers to the Correct

Handling Unit of the Logistics Item

One important feature of the prototype tracking portal

is providing a simple system for “electronically”

attaching a tracker to a certain handing unit number

of an item needs to be tracked. While it is very easy

to physically attach a tracker device to an item, the

coupling of a tracker’s identification number (its

IMEI number, much like a mobile phone) and a

handling unit would require logging in into the portal

and manually writing in numbers.

In an attempt to simplify this process for factory

and warehouse personnel, an easy-to-use smartphone

application was created. By scanning the tracker’s

identification number bar code (already present on the

trackers) and the handling unit's bar code, the mobile

app will provide the portal with the information that

these two units have now been coupled. Using this

mobile app elaborate the tracking facility outside the

warehouse, which is often needed by the manager

remotely to track the status of delivery items within

the warehouse. Even knowing the handling unit

number of a shipment, managers would be able to

track the items already loaded on a vessel which is

integrated with mobile SIM card. This SIM card

transfers the necessary information of the items to the

mobile phones of the managers remotely through the

assistance of AIS portal system.

Figure 6 displays the snap shot of coupling

tracker/handling unit function with mobile app, while

Figure 7 visualizes the handling unit update function

with mobile app for tracking system of logistics

items.

Tracking and Tracing of Global Supply Chain Network: Case Study from a Finnish Company

123

Figure 6: Tracking system mobile app – coupling

tracker/HU function.

Figure 7: Tracking system mobile app – HU status update

function.

7 CONCLUSIONS AND FUTURE

RESEARCH

The importance of shipment tracking is getting more

and more attraction within supply and delivery

network. At the same time, delivery companies are

concern in today’s supply chain risk management and

like to minimize it by implementing appropriate and

cost effective tracking devices or tools. In order to

develop the predominant tracking systems,

companies are often forced to invest deploying

various available tracking devices for their tracking

needs.

The objective of this study was to investigate and

analyze various available tracking technologies with

their functionalities or principles as we all as the

requirements of supply chain and logistics networks

tracking. In order to fulfill such aim, this study

presented a theoretical framework after critically

investigate and analyze past and present literature on

supply chain tracking and tracing systems. In

addition, this study also piloted a real-life multi-

company tracking system that might supports

companies to deploy their supply chain tracking

solutions successfully. The presented case example as

highlighted within this research scope will encourage

supply chain and logistics providers to implement an

effective and efficient tracking system of their

delivery networks.

In future research more case examples will be

conducted based on online tracking system in order to

generalize the presented approach. More available

technologies and tools on supply chain tracking and

tracing can be investigated to get optimum

performance. Additionally, an in-house tracking

device will be designed; developed and tested that can

be used for goods tracking purpose.

ACKNOWLEDGEMENTS

The authors would like to acknowledge the funding

from TEKES (The Finnish Funding Agency for

Innovation).

REFERENCES

Benedikt, M., Fiedler, M., Hille, A. and Björn, A. 2012.

How AutoID Processes Shape the Internet of Things:

The OpenID-Center Development Process.

Communications in Computer and Information

Science, Vol. 282, Part 5, pp. 134-147.

Dabbene, F., Gay, P. and Tortia, C. 2014. Traceability

issues in food supply chain management: a review.

Biosystems Engineering, Vol. 120, pp. 65-80.

Day, A. 1991. Who cares about international freight?.

International Journal of Physical Distribution &

Logistics Management, Vol. 21, No. 4, pp. 29-31.

Giannopoulos, G.A., 2003. The application of information

and communication technologies in transport.

ICEIS 2021 - 23rd International Conference on Enterprise Information Systems

124

European Journal of Operational Research, Vol. 152,

No. 2, pp. 302-320.

Helo, P. and Szekely, B. 2005. Logistics information

systems: an analysis of software solutions for supply

chain co-ordination. Industrial Management & Data

Systems, Vol. 105, No. 1, pp. 5-18.

Hinkka, V. 2012. Challenges for building RFID tracking

systems across the whole supply chain. International

Journal of RF technologies: research and applications,

Vol. 3, No. 3, pp. 201-218.

Hui, T. 2008. Application research of RFID in supply chain

logistics management. IEEE International Conference

on Service Operations and Logistics, and Informatics,

IEEE/SOLI 2008.

Kärkkäinen, M., AlaRisku, T. and Främling, K. 2004.

Efficient tracking for shortterm multicompany

networks. International Journal of Physical

Distribution & Logistics Management, Vol. 34, No. 7,

pp. 545-564.

Kärkkäinen, M., Ala-Risku, T., Främling, K., Collin, J. and

Holmström, J. 2010. Implementing inventory

transparency to temporary storage locations: A solution

design experiment in project business. International

Journal of Managing Projects in Business, Vol. 3, No.

2, pp.292 – 306.

Liwei, B., Huang, Y., Song, J. and Yang, Y. 2009. A Case

Study on the Supply-chain Reengineering Based on

Information Integration of Logistics. IEEE Second

International Symposium on Electronic Commerce and

Security, ISECS '09.

Martinez-Sala, A.S., Egea-Lopez, E., Garcia-Sanchez, F.

and Garcia-Haro, J., 2009. Tarcking of returnable

packaging and transport units with active RFID in the

grocery supply chain. Computers in Industry, Vol. 60,

No. 3, pp. 161-171.

Musa, A., Gunasekaran, A. and Yusuf, Y. 2014. Supply

chain product visibility: methods, systems and impacts.

Expert Systems with Applications, Vol. 41, No. 1, pp.

176-194.

Pero, M. and Sudy, I. 2014. Increasing security and

efficiency in supply chains: a five-step approach.

International Journal of Shipping and Transport

Logistics, Vol. 6, No. 3, pp. 257-279.

SAP 2005. RFID-Enabled Supply Chain Execution

powered by SAP NetWeaver™ - Using SAP Auto-ID

Infrastructure 2.1 Document Version 1.2 – March 15,

2005. Material Number 50071075.

Shamsuzzoha, A. and Helo, P., 2012. Tracking and tracing

of logistics networks: perspective of real-time business

environment. International Journal of Industrial

Engineering: Theory, Applications and Practice, Vol.

19, No. 3.

Shamsuzzoha, A., Ehrs, M., Addo-Tenkorang, R., Nguyen,

D. and Helo, P., 2013. Performance evaluation of

tracking and tracing for logistics operations.

International Journal of Shipping and Transport

Logistics, Vol. 5, No. 1, pp. 31-54.

Toyryla, I., 1999. Realising the potential of traceability – a

case study research on usage and impacts of product

traceability. PhD thesis, Acta Polytechnica

Scandinavica. Mathematics, Computing and

Management in Engineering Series. No. 97, Finnish

Academy of Technology, Espoo.

Zhu, X., Mukhopadhyay, S. and Kurata, H. 2012. A review

of RFID technology and its managerial applications in

different industries. Journal of Engineering and

Technology Management, Vol. 29, No. 1, pp. 152-167.

Tracking and Tracing of Global Supply Chain Network: Case Study from a Finnish Company

125