Prospects to Development of Green Technologies for Alternative

Motor Fuel’s Production

Larysa Gubacheva

1

, Darya Chizhevskaya

1

and Irina Makarova

2

1

Vladimir Dahl Lugansk National University, Lugansk, Ukraine

2

Kazan Federal University Naberezhnye Chelny, Russia

Keywords: Vehicle, Engine, Gas Generator, Environmental Friendliness, Carrying Capacity, Economy, Efficiency.

Abstract: Negative processes in ecosystems accompanying the rapid development of engineering and technologies dur-

ing the transition to the fourth industrial revolution necessitate a change in the economic paradigm - the tran-

sition to a circular economy. Ecosystem degradation is taking place when accelerating urbanization and mo-

torization. The search for global solutions to ensure comfortable living conditions on the planet is imple-

mented by minimizing the negative impact of solid industrial and domestic waste on the environment. Con-

sequently, on the one hand, it is necessary to solve the problem of reducing resource consumption, while

reducing industrial and household waste, on the other. "Greening" of transport reduces the negative load on

the environment and can be associated both with the search and use of alternative fuels, and with the reduction

of emissions due to new technical solutions. The article presents a new technology to improve energy effi-

ciency and environmental friendliness of road transport by processing wood and polyethylene waste as raw

materials for alternative fuels. The offered solution will reduce the content of harmful substances in the ex-

haust gases of internal combustion engines and the negative load on the environment from vehicles.

1 INTRODUCTION

In the message of the President of Russia to the Fed-

eral Assembly of 2019, it was determined that solving

problems in the field of ecology is both the primary

task of industry and science and the responsibility of

each citizen. One of the main directions for solving

the problem is the formation of "nature-like" technol-

ogies (meeting the requirements of the Fourth Indus-

trial Revolution). The set task is to form a civilized

and safe waste processing system by 2024, as well as

reclamation of all problem landfills in the country. At

the same time, waste processing should be increased

from the current 6-7 percent to 60 percent, and hous-

ing and communal services, energy, transport enter-

prises should be switched to cleaner environmental

solutions. Businesses should participate more ac-

tively, including in projects for the development of

the gas-motor market, invest in the creation of a net-

work of refueling stations and fuel systems that use,

in particular, liquefied natural gas (LNG) (On the

State…, 2007).

The necessity to develop this direction is due to

environmental problems, by increasing energy needs

of mankind, depletion of reserves of non-renewable

fossil fuels and, as a consequence, their rise in price.

The development of technologies for obtaining en-

ergy from local renewable sources is a topical direc-

tion for the Russian Federation, which has reserves of

biofuel from waste products of the woodworking and

forestry industries, as well as plant biomass. At the

same time, the main efforts are aimed at creating and

improving gas generating plants for internal combus-

tion engines and transport vehicles operating in re-

mote regions of the country (Bozhko, 2003).

Obtaining energy from secondary raw materials,

we simultaneously solve the problem of waste recla-

mation, receiving cheap, one might say, almost free

gas fuel that can be used in transport while simulta-

neously reducing the negative load on the environ-

ment in places where this waste is accumulated

through their utilization. The problem of providing al-

ternative fuel is especially acute in the event of man-

made disasters (natural disasters, military conflicts),

when there is no or difficult access to power sources

for transport (Automotive, 2019). The aim of the

work is to substantiate the improvement of environ-

mental friendliness and resource-saving work due to

the use of generator gas obtained in processing solid

household waste in a gas generator.

Gubacheva, L., Chizhevskaya, D. and Makarova, I.

Prospects to Development of Green Technologies for Alternative Motor Fuel’s Production.

DOI: 10.5220/0010530907750782

In Proceedings of the 7th International Conference on Vehicle Technology and Intelligent Transport Systems (VEHITS 2021), pages 775-782

ISBN: 978-989-758-513-5

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

775

2 STATE OF THE PROBLEM:

ALTERNATIVE FUELS FOR

ROAD TRANSPORT

In Japan, two oil crises in the 1970s triggered the in-

troduction of "next generation vehicles." Examples

include battery electric vehicles (BEVs), compressed

natural gas vehicles (CNGVs), and hydrogen fuel cell

electric vehicles (FCEVs). The study (Kimura, 2016)

looks at the next-generation fuel supply infrastruc-

ture, in particular, its technical objectives, challenges

and risks, as well as reviews of Japan's past ap-

proaches and efforts, as well as future prospects. Ob-

jective prerequisites for the growth of interest in the

use of gas as a motor fuel in recent years are higher

energy and environmental performance compared to

oil fuel. Natural gas provides the safest exhaust emis-

sions of all commonly used motor fuels and technol-

ogies, and has a noticeable effect on lubricating oils

(30-40%). In addition, the gas does not contain the

main gasoline pollutant - sulfur, so even the most re-

fined «Euro-5» gasoline cannot be compared with gas

fuel in clean combustion. Thus, according to the au-

thors of the article (Khan,2016), among all alternative

fuels, compressed natural gas (CNG) is considered

one of the best solutions for replacing fossil fuels due

to its availability throughout the world, clean com-

bustion, economy and adaptability to gasoline and

diesel engines.

Compressed natural gas is widely used as a vehi-

cle fuel in countries with their own natural gas re-

serves. CNG vehicles are already in use all over the

world, and the technology for its producing, storing

and using has already been developed. Due to that

these fuels have a high-octane number, and also a

small amount of carbon dioxide is emitted during

combustion. In recent years, China has made signifi-

cant strides in promoting natural gas vehicles (NGV).

The article (Hao, 2016) discusses the development of

natural gas vehicles in China based on a technical and

economic framework with a triple perspective (fuel-

vehicle-infrastructure). The authors of the article be-

lieve that local governments should develop a strat-

egy to support the further deployment of the CNG /

LNG refueling infrastructure. The document (Wang,

2015) analyzes the favorable factors and barriers for

the development of NGV in China. The following

strategies are proposed for the further development of

NGV in China: (1) to improve the infrastructure for

the delivery of natural gas throughout the country; (2)

of a reasonable reduction in the relative price of nat-

ural gas versus gasoline; (3) preference to small and

medium-sized cities where gas refueling stations are

easier to locate;(4) promoting the use of NGV in the

private sector. In some countries, researchers (Mehra,

2017) are trying to reduce pollution by using medium

and heavy vehicles powered by hydrogen-rich com-

pressed natural gas (HCNG). Under certain parame-

ters, the thermal efficiency of the HCNG engine is

much better than the CNG engines, while the emis-

sions are relatively low. The document (Khan, 2015)

presents the global prerequisites, prospects and prob-

lems of using natural gas as a vehicle motor fuel, as

well as the environmental and economic aspects of

such a transformation. The main indicators chosen for

the comparative assessment of natural gas as a vehicle

fuel are: economic indicators, emission efficiency and

safety. Of particular relevance is the use of transport

vehicles running on natural gas in Latin America and

Asia, where a significant part of megacities is located.

Article (Ogunlowo, 2015) examines the approaches

to the problem of converting vehicles to natural gas

in seven countries with different backgrounds. It is re-

quired to gain an understanding of the barriers to the

development of the NGV market in Nigeria.

The authors of the article (Wang, 2015) believe

that political support and special measures are needed

in European countries to stimulate the use of natural

gas as a fuel for vehicles. Looking at the UK LNG

van market, the authors of (Kirk, 2014) identified a

number of barriers, the most important of which is the

lack of refueling facilities, but the authors also point

to the opportunities, namely fuel costs and the poten-

tial for reducing pollution. The authors of the article

(Rosenstiel, 2015) note that the measures being taken,

the market share of gas transportation vehicles (NGV)

in Germany lags far behind expectations and market

trends in other countries. The authors conclude that

lack of co-ordination, market monopoly and undevel-

oped infrastructure hinder the development of the

NGV market. The authors of the article (Makarova,

2012) believe that the main weak point for LNG as a

fuel in Italy is its distribution and, in particular, the

supply process. It is important to solve this problem

together with the problem of the lack of rules and

standards on the places for the development of new

alternative fuels and support for the introduction of

LNG in the Italian market.

One of the main parts of the exhaust gases pro-

duced by internal combustion engines are solid par-

ticulate matter. CNG is a potentially profitable fuel as

particulate matter emissions are significantly reduced

by using natural gas fuels because natural gas does

not contain aromatic and poly-aromatic compounds,

and contains less dissolved sulfur compounds than

oils fuel. The authors of the study (Goyal, 2003) com-

pared the pollution levels in Delhi before and after the

iMLTrans 2021 - Special Session on Intelligent Mobility, Logistics and Transport

776

implementation of the project to convert public road

transport in 2002 to compressed gas. A decrease in

the number of suspended particles by 14%, CO by

10%, SO

2

by 22% and NO

x

by 6% was found. In

(Huang, 2016), the authors also conducted a study of

CO, HC and NOx emissions from 9 vehicles under 8

operating conditions. Based on the data obtained, the

influence of operating conditions and types of fuel on

the level of pollution was analyzed. Thus, the contri-

bution of CNG to smog generation may be less than

that of vehicles with gasoline and diesel engines. But

there are studies (Dondero, 2005) in which CNG re-

sults were unsatisfactory or even worse than gasoline

vehicles due to inadequate maintenance of CNG ve-

hicles. With the obvious advantages of NGV fuel, as

we see, the problem of its implementation is the un-

developed infrastructure, in particular, deficiency of

refueling stations and services. Therefore, in our

opinion, a good alternative is the application of gas

generating plants, which, in addition, contribute to the

rational use of waste.

3 RESULTS AND DISCUSSION

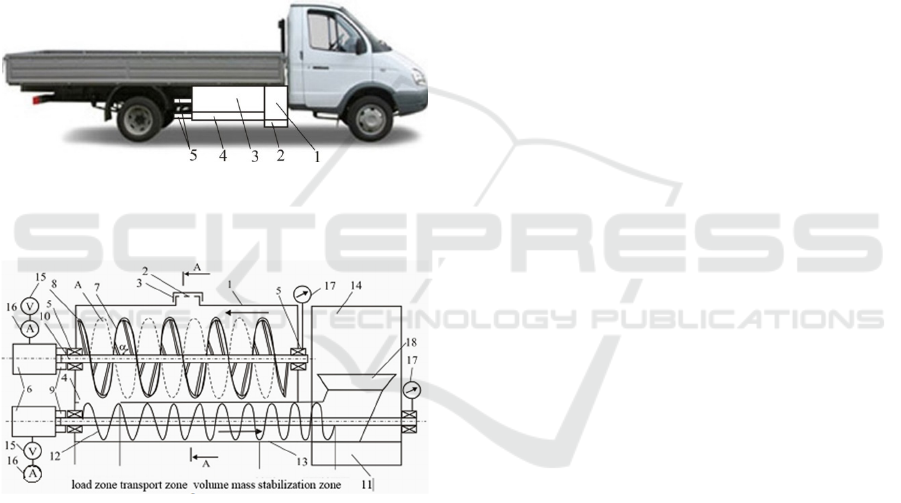

The designs of the produced automobile gas genera-

tor units have not changed significantly since the mid-

dle of the last century. Specific requirements for

transport gas generators (small dimensions, stability

of the gasification process, variable mode and the ne-

cessity for more thorough purification and cooling of

gas) require a comprehensive analysis of modern gas

generator plants and further optimization of transport

gas generators by improving their design (Makarova,

2019). It is known that one of the most successful

technical solutions of the last century is a gas genera-

tor of the Imbert and Volkswagen Type 82. Such gas

generators were produced by many automobile com-

panies, including GM, Ford, Mercedes-Benz. Cur-

rently, the companies of France, VOLVO (Sweden),

“Attik” Ukraine, “Nasha-Energiya” LLC, Ukraine,

the “Adaptika” group of companies, Russia produce

automobile gas generators that do not require any ma-

jor vehicle alteration, which are installed: on a trailer;

inside the body; between the body and the cab (Fig.

1). The use of synthetic combustible gas based on

generator gas obtained from solid industrial and do-

mestic wood waste, including with the addition of

polyethylene-containing waste can be accepted as a

promising direction as a motor fuel both on mobile

and stationary plants. Fig. 2 presents a gas generator

set (general view), which can be both stationary and

mobile.

Figure 1: Layouts of gas generating plants: a, b - gas gener-

ator tractor with a gas generator set of the “Imbert” type

(Sweden, 1976), (France, 2004); c - trailed gas generator set

of the “Imbert” type of the VOLVO company (Sweden,

2002); d - gas generator vehicle Volkswagen Type 82

(Volkswagen AG, 1944).

The processes for producing generator gas from

wood waste are represented by the suggested formu-

las for the composition of the gas generated from

wood with an initial moisture content of 20% per 1

m

3

– (97 g of moisture); 3.5 g - dust; 0.5 g - resin:

0.054(С

6

H

10

O

5

+2,2H

2

O) + 0.097(O

2

+4N

2

)=

=0.161H

2

+0.209CO+0.092CO

2

+0.023CH

4

+0.388N

2

+0.009O

2

+0.117 H

2

O+Q

3

where Q

3

is the heat released as a result of the reaction

of obtaining generator gas from wood.

Figure 2: General view of the gas-generator: 1-hopper,

2– coarse filter, 3– cooler, 4– fine filter, 5– mixer;

6– air-leaner. 7 - fan, 8 - ash pan.

Gas generator vehicles are divided into two

groups: (1) running on liquid fuel, converted for

temporary operation on generator gas; (2) specially

manufactured for continuous operation on generator

gas. The first group of liquid-fueled vehicles

converted for temporary operation on generator gas

was selected for the research. So, a widely used

vehicle of the Gazelle 3302 brand was chosen, with

a ZMZ - 4063.10 engine, running on AI 92 gasoline,

having the following technical characteristics:

carburetor engine, in-line, 4-cylinder, 4-stroke, 16-

Prospects to Development of Green Technologies for Alternative Motor Fuel’s Production

777

valve; rated power at 4500 rpm 110 hp (kW); maxi-

mum torque 19.5 kgcm (Nm) at 2500 rpm; carrying

capacity 1500 kg with a gross vehicle weight of

3500 kg; minimum specific fuel consumption up to

195 g / hp from 2000 to 3000 rpm; maximum speed

115 km / h and maximum power 125 hp at a shaft

speed of 5000 rpm; transmission: mechanical, five-

speed, three-shaft, fully synchronized, gear ratios:

4.05 - 2.34 - 1.395 - 1.0 - 0.849 (GAZEL, 2005).

One of the ways to increase fuel efficiency during

the operation of a Gazelle vehicle is its converting

from gasoline to compressed gas methane CH

4

,

which is accompanied by a decrease in engine power

(by 15% or more) when a calorific value of combus-

tible gas is reduced, the filling of cylinders and the

combustion rate of fuel-air mixtures are decreased

(Zolotnitskiy, 1997). In addition, the actual Gazelle

vehicle carrying capacity, when 6 cylinders with

compressed methane (total weight 360 kg) are in-

stalled, decreases from 1500 kg to 1140 kg, i.e. by

14%. Also, the average speed of cargo delivery and

vehicle performance are reduced. For most vehicle

owners, the determining factor is the difference in

price between gas engine fuel and gasoline, which is

two to three times lower (the cost of 1 liter of AI-92

gasoline in the central region of Russia is 42 rubles

/ liter or more, and gas - about 14 rubles. / l.). The

cost of re-equipping a Gazelle vehicle with a gas in-

stallation will amount to 15 thousand rubles. Pay-

back, with a fuel consumption in the urban cycle of

17 l / 100 km, will be achieved in 2-3 months - and

this is without taking into account the reduction in

oil costs and an increase in engine distance between

overhauls.

Thus, the absence of dissolving and flushing

properties in the gas contributes to an increase in the

service life of engine oil by 1.5 - 2 times and a de-

crease in its consumption by 10 ÷ 15%. At the same

time, the engine distance between overhauls is in-

creased by 1.5 - 2 times. The operation of the igni-

tion system also is improved, the service life of the

spark plugs increases by 40%. The toxicity of carbon

monoxide (CO) is significantly reduced - by 2-3

times, for nitrogen oxide (NO) - by 1.3-1.9 times.

No resinous deposits build up in the fuel system and

combustion chamber. Gas is a high-quality fuel with

an octane rating of about 105, therefore knocking

knocks in the engine are completely eliminated. If

the vehicle is equipped with a catalytic converter, its

safety when running on gas is guaranteed. In addi-

tion, the noise level is reduced by 2-3 dB, and the

engine itself runs smoother. However, it should be

taken into account that when converting from gaso-

line to gas, the engine power decreases under the

same operating modes. The reason is a decrease in

the filling factor of the cylinders and a 6-8% de-

crease in the release of heat by gas per unit volume

of the combustible mixture, despite the fact that a

unit of gas mass releases more heat (propane gas -

10972 Kcal / kg; butane gas 10845 Kcal / kg, gaso-

line - 10500 Kcal / kg).

For engines, two types of gas fuel are mainly

used: liquefied petroleum gas (propane-butane) and

compressed natural gas (methane). The highest dis-

tance between overhauls without refueling is pro-

vided by a system running on liquefied gas, for ex-

ample, with the same volume of cylinders, about 3

times more than on compressed methane. And

thanks to the latest developments of specialists, it

can be assumed that the future belongs to installa-

tions powered by methane. Methane is significantly

cheaper than liquefied propane-butane obtained

from oil. In addition, methane is 1.6 times lighter

than air, and in case of a leak it instantly evaporates

(propane-butane is 1.5 - 2 times heavier than air and,

if it leaks, can accumulate in rooms, forming an ex-

plosive mixture with air.). Methane is less explo-

sive: for an explosion to occur, it must accumulate

2.5 times more than propane. Servicing gas is no

more dangerous than handling gasoline, but requires

other rules to be followed.

The research and production company “SAGA”

(Moscow) and JSC “INKAR” (Perm) have devel-

oped and have already launched the production of

the automobile gas fuel system (AGFS) “SAGA-7”

for compressed natural gas (CNG) - methane. It is

installed as the additional equipment on any models

of passenger vehicles, light trucks and minibuses of

domestic and foreign production with an engine ca-

pacity of up to 4 liters. The system compares favor-

ably with similar systems, design and technological

solutions and quality of manufacturing.

Integrated use of the SAGA-7 gas fuel system

(AGTS) device and a new arrangement of gas gen-

erating equipment under the body will eliminate the

shortcomings of the experimental model of the gas

generating vehicle. This decision, in our opinion,

opens up the possibility of creating a universal vehi-

cle on alternative fuels for use in agriculture and for-

estry, as well as in remote villages, both in everyday

life and in emergency situations, since it does not

need fuel and financial injections from the side of

state budget. One, two or three cylinders can be in-

stalled depending on the vehicle brand, size and

weight of the cylinders. The metal cylinder body is

covered with a fiberglass reinforcement layer, which

increases strength and reduces weight. The inner

surface is coated to protect against corrosion. The

iMLTrans 2021 - Special Session on Intelligent Mobility, Logistics and Transport

778

gas reserve in three cylinders is designed for about

250 km. In (Makarova, 2019), an approach to the

layout of an automobile gas generator shown in Fig.

3, which is fundamentally new and has not been de-

scribed in the well-known literature on gas-generat-

ing vehicles. The layout of the proposed automobile

gas generator is based on the principle of its division

into bunker and reaction zones (Fig. 4). In this case,

the bunker, the gasification chamber and the ash pan

are installed under the truck body. The bunker is in-

stalled horizontally, while the gasification chamber

and ash pan are installed vertically (Gubacheva,

2012). Since the bunker is installed separately from

the gasification chamber, an automated stoker burner

must be used for continuous and metered fuel supply

from the bunker to the gasification chamber.

Figure 3: GAZ-330202 GAZel vehicle with the elongated

base: 1 – gasification chamber; 2 – ash-bin; 3 - agitating

tank; 4 – pellet burner; 5 – reductor engine.

Figure 4: Automobile gas generator feeder construction:

1 - bunker-turner; 2 - loading hatch; 3 - hatch cover;

4 - unloading window; 5 - bearing units; 6 - drives of the

screws of the pellet burner and bunker - turner; 7 - rib-blade;

8 - tape auger; 9 - clutch; 10 - the shaft of the tape auger 8;

11 - ash pan; 12 - continuous auger of a pellet burner; 13 -

pellet burner; 14 - gasification chamber.

At the same time, any measures aimed at increas-

ing the environmental efficiency of vehicles are ac-

companied by changes in their operational and tech-

nical indicators, and not always for the better.

So, to assess the indicators, a Gazelle 3302 vehi-

cle with a ZMZ 4063.10 engine was chosen, using

various types of fuel: gasoline AI 92 (total weight of

the vehicle is 3400 kg, carrying capacity - 1500 kg);

methane СН4 (the total weight of the vehicle is 3400

kg, the reduction in carrying capacity due to the in-

stallation of 6 compressed methane cylinders with a

total weight of 360 kg - up to 1140 kg); gas obtained

in the modernized installation of a horizontal type

gas generator (the total weight of the vehicle is 3400

kg, a decrease in carrying capacity due to the instal-

lation of a gas generator with a total weight of 260

kg - up to 1240 kg).

The assessment was carried out according to the

methodology for calculating the traction and speed

qualities of vehicles, taking into account the distinc-

tive features. This is especially important for the de-

teriorating quality of the road surface, which after

each autumn - winter period turns into a direction

covered with holes for moving vehicles.

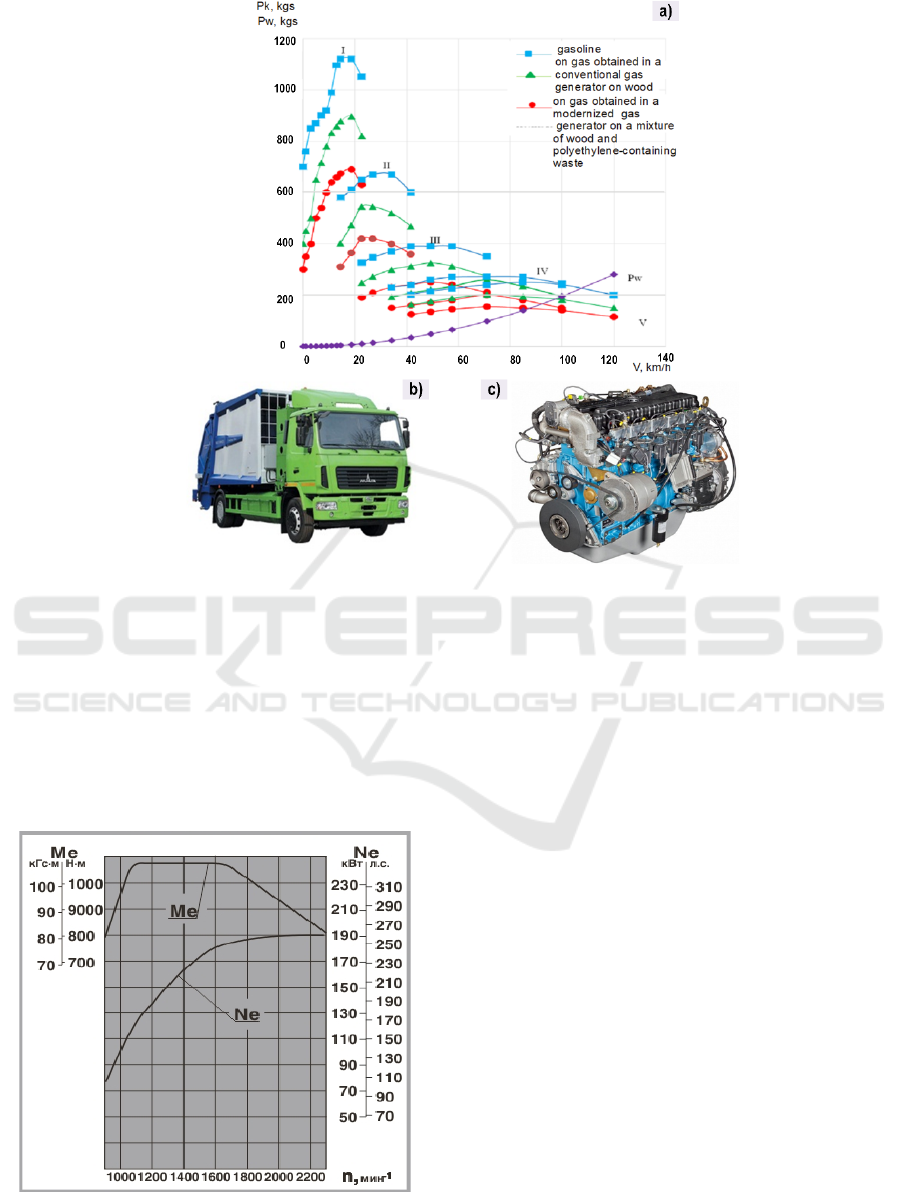

Fig. 5a shows the comparative calculated trac-

tion and speed characteristics of a Gazelle vehicle

with an engine of the ZMZ - 4063.10 type, which

operates on: a) gasoline; b) on gas obtained in a con-

ventional gas generator on wood; c) on gas obtained

in a modernized gas generator on a mixture of wood

and polyethylene-containing waste (modernized en-

gine ZMZ - 4063.10). Analysis of the obtained char-

acteristics shows that the calculated maximum trac-

tion force when operating on conventional gas-gen-

erating gas falls from 1120 kgf to 690 kgf, i.e. by

39%, as in the case of experimental trips of the Ga-

zelle 3302 vehicle with a ZMZ engine - 4063.10.

According to the requirements listed above, it is

most advisable to install gas generators on trucks

that have a large power reserve when operating on

gasoline and diesel fuel. These can be medium and

large-capacity vehicles. Re-equipment of these ve-

hicles with gas generators is carried out with mini-

mal power loss (up to a maximum of 30% if the en-

gine is petrol) and without any chassis changes. In

diesel engines (especially in turbocharged engines),

the convert of a vehicle to generator gas can be car-

ried out without any noticeable power loss at all. Let

us consider as an object of research another vehicle,

a MAZ-Sapphire garbage truck powered by a gas en-

gine - YaMZ-53644 CNG (Fig.5b). The garbage

truck is designed to remove garbage from the terri-

tory of towns and settlements to landfills, waste

transfer stations or garbage incineration plants (Gar-

bage, 2018). This 6-cylinder gas engine (CNG), 4-

stroke, in-line cylinder, liquid cooling system, tur-

bocharging and charge-air cooling in an air-to-air

heat exchanger was mounted on a vehicle. Compres-

sion ratio 12. The YaMZ 53644 CNG engine is 90%

unified with diesel, but transferred to the Otto cycle.

Prospects to Development of Green Technologies for Alternative Motor Fuel’s Production

779

Figure 5: a) Сomparative design traction and high-sheed characteristics of Gazellevcar 3302 with the ZMZ engine- 063.10;

b) Vehicle MAZ-Sapphire on a gas engine- YaMZ- 53644CNG (Sapphire-eco, 2018); Gas engine- YaMZ- 53644C

(YaMZ,2015).

The YaMZ-53644 CNG engine - in terms of

emissions of harmful substances, corresponds to

environmental class 5: UN Regulation

No. 49-05B2

(G) Euro 5 (Fig. 5c). Figure 6 shows the speed char-

acteristics (rotational speed (n, min

-1

)) for the YaMZ-

536 CNG engine, depending on the net engine power

(N

e

, hp) and torque (M

e

, Nm).

Figure 6: Speed characteristics for the YaMZ-53644 engine

(YaMZ,2015).

The technologies under consideration for the use

of polyethylene containing solid waste may be of in-

terest for further improving the systems when using

alternative generator gas to increase the environmen-

tal level of gas-diesel transport vehicles. The Mer-

cedes-Benz engine is refitted and can operate in both

diesel and gas-diesel modes. In gas-diesel mode, the

engine simultaneously consumes both diesel fuel,

which acts as an igniter, and gas, which contributes to

better combustion of the mixture, while all the power

characteristics of the engine are preserved. The power

reserve of the KAMAZ-5490 NEO in gas-diesel

mode is 450 km. If the gas runs out of cylinders, the

vehicle automatically enters diesel mode and can

drive another 950 km until the next gas station. The

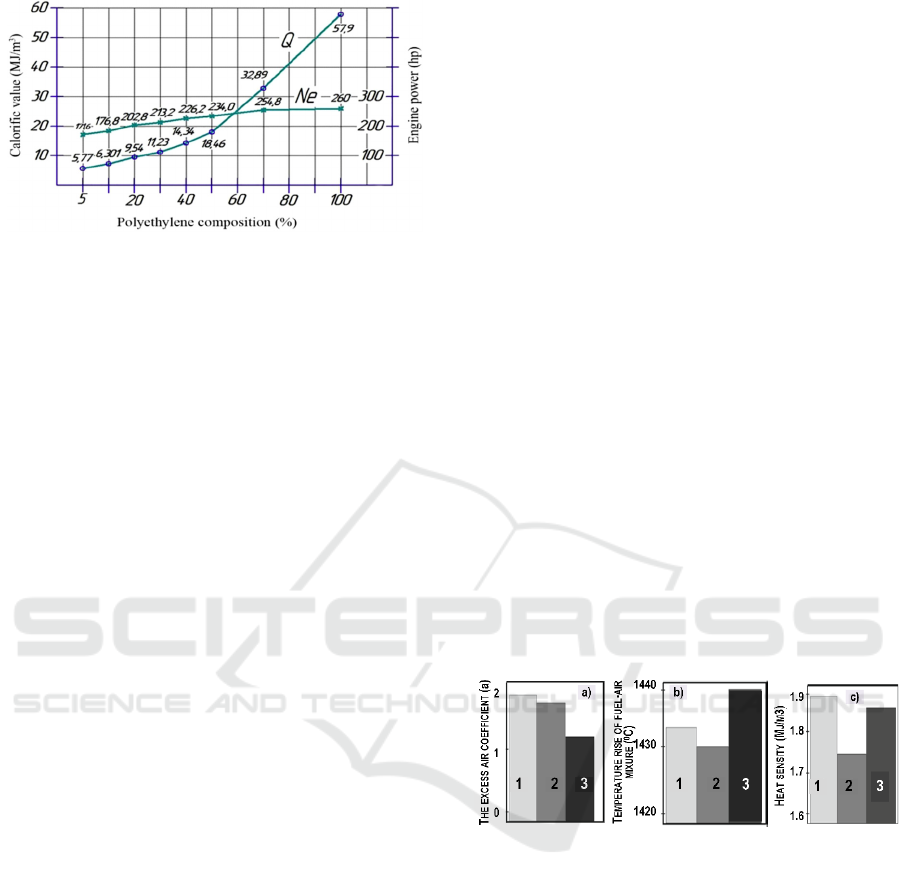

figure 7 also presents the estimated power of the gas-

diesel engine Mercedes-Benz in the case of conver-

sion to generator gas produced from the mixture of

wood with plastic waste.

As a design of the gas-diesel process is considered

when using wood generator gas at 90% of engine

power and 10% of power on diesel fuel with an air

excess coefficient α = 1.4.

iMLTrans 2021 - Special Session on Intelligent Mobility, Logistics and Transport

780

Figure 7: Graph of the generator gas calorific value Q and

engine power Ne versus the polyethylene content in MSW.

The balance equation represents approximate

composition of the generator gas produced from

wood with 20% initial humidity and containing in 1

m3 97 g of moisture, 3.5 g of dust, 0.5 g of resin.

0,054(С

6

H

10

O

5

+2,2H

2

O) + 0,097(O

2

+4N

2

) =

0,161H

2

+ 0,209CO + 0,092CO

2

+0,023CH

4

+0,388N

2

+0,009O

2

+0,117 H

2

O+Q

3

where Q

3

— the heat generated by the reaction of pro-

ducing the generator gas from wood.

After cooling and cleaning, the generator gas in a

mixture with air enters the ICE cylinders and is ig-

nited by diesel fuel injection.

The approximate equation of combustion of the

fuel-air mixture with an excess air coefficient α = 1.4

in the engine cylinders can be

0,161H

2

+0,209CO+0,092CO

2

+0,023CH

4

+0,388N

2

+

0,009O

2

+0,117H

2

O+1,40,222(O

2

+ 4N

2

)

+1.40.0444(O

2

+4N

2

)+0.00165C

14

H

30

=0.349H

2

O+0.

357CO

2

+0.116O

2

+1.888N

2

+Q

3

where Q

3

the released heat can be determined by the

formula

Q

3

= 3.8ꞏ1.2ꞏ0.222ꞏ112 = 113 MJ.

The estimated volume of the burnt fuel-air mix-

ture is determined by the formula:

V

2

= 22.4ꞏ(0.349 + 0.357 + 0.116 + 1.888) = 60.5 m

3

The estimated mass of the gas mixture is deter-

mined by the formula:

m3 = m3CO

2

+ m3H

2

O + m3N

2

+ m3O

2

= 6,29 +

15,7 + 53 + 3,7 = 78,69 kg.

The estimated increase in gas temperature in the

ICE cylinders after combustion of the fuel-air mixture

is determined by the formula

t3 – t0 = Q3/m3 = 113ꞏ106/78.69ꞏ103 = 1440°C,

and the full temperature will reach 1652°C.

The estimated heat density in the engine cylinders

is determined by the formula

Q31 = Q3/V3 = 113/60.5 = 1.87 MJ/m3.

The estimated coefficient of diesel engine power

reduction after conversion to diesel plus generator gas

will be

Kne31 = Q31/Q1 = 1.87/1.90 = 0.982.

Figure 8 presents comparative diagrams: of the

coefficients of excess air α (figure 8a), temperature

rise of the fuel-air mixture (t3 – t0)°C (figure 8b), and

the heat density of the gas working mixture Qpci

(MJ/m3) (figure 8с).The diagrams respect various op-

tions of engine power supply systems when operating

in the mode of a conventional diesel engine (1), gas-

diesel engine (2) and generator gas-diesel engine (3).

The estimated coefficient α1 = 2 for a conven-

tional diesel engine and α2 = 1.9 for a gas-diesel en-

gine running on methane CH

4

was taken proceed

from combustion of the hydrocarbon components.

For option 3, the estimated coefficient α3 = 1.4 was

taken based on the combustion of hydrocarbons,

CnHm, carbon monoxide CO and hydrogen H

2

.

The estimated values of the temperature rise of the

fuel-air mixture in ICE cylinders during combustion

reach values of 1640-1730°C. Heat density varies be-

tween 1.90-1.74 MJ/m3.

Figure 8: Comparative diagrams for various options of

engine power supply system’s when operating in the mode

of a conventional diesel engine (1), gas-diesel engine (2)

and generator gas-diesel engine (3): а — air excess coeffi-

cients αi; b — temperature rise of the fuel-air mixture;

с — heat density of the gas working mixture.

The analysis shows that when converting the die-

sel engine of option 1 to the gas-diesel mode of option

2 with the consumption of methane CH4, a power

drop of 8-9% occurs due to losses of combustion and

evaporation of the H2O being formed. For gas-gener-

ator with a diesel engine, a lower power drop will oc-

cur due to the presence in the generator gas of a large

amount of carbon monoxide CO, the combustion tem-

perature of which in air is

2300°C.

Prospects to Development of Green Technologies for Alternative Motor Fuel’s Production

781

4 CONCLUSIONS

1. One of the ways to solve the problem of environ-

mental pollution with polyethylene-containing waste is

proposed. It consists in processing their mixture with

wood solid waste into generator gas.

2. Maintaining the transport infrastructure and the vi-

tal activity of small villages and remote settlements

requires additional expenditures from the budget for

energy carriers, including liquid motor fuel, the deliv-

ery of which is difficult in the absence of transport

infrastructure and seasonal operation of river

transport.

Under these conditions, in remote areas, it is ad-

visable to re-equip vehicles of the type: "Gazelle

3302", with a ZMZ 4010.63 engine, for dual power:

ordinary gasoline and generator gas obtained from

both wood waste and a mixture of wood and polyeth-

ylene-containing waste.

3. The advantages of gas engines include minimal

emissions of harmful substances and the absence of

soot emissions. The engine has less noise compared

to diesel one. As a result, it will significantly improve

the environmental situation in big cities, when it is in-

stalled on a transport.

REFERENCES

Automotive Parts Remanufacturing Market: Global Indus-

try Analysis and Forecast 2016–2024. URL:

http://www.persistencemarketresearch.com/market-

research/automotive-parts-remanufacturing-market.asp

(accessed 12.05.2019)

Bozhko, O.A. 2003. There is an alternative to conventional

fuel. New of heat supply. Vol. 10 (38). p. 28-30.

Dondero, L. et al., 2005. Environmental implications of

converting light gas vehicles: the Brazilian experience.

Energy Policy, vol. 33, pp. 1703–8.

GAZEL 2705, 3302 and modifications with ZMZ-40524,

UMZ-4216 and Chrysler engines. Mir Avtoknig, 2005.

331 p.

Goyal, P. et al., 2003. Present scenario of air quality in

Delhi: a case study of CNG implementation. Atmos En-

viron, vol. 37, pp. 5423–5431.

Gubacheva, L.O. et al., 2012. Patent 67440 Ukraine, IPC

F23K 3/00 Device for supplying solid fuel to combus-

tion plants. patent owner Volodymyr Dahl East Ukrain-

ian National University. № 201107909; application on

23.06.2011; published. 27.02.2012, Bulletin No. 4.

Hao, H. et al., 2016. Natural gas as vehicle fuel in China: A

review. Renewable and Sustainable Energy Reviews

62, p.521–533.

Huang, X. et al., 2016. Emission factors of air pollutants

from CNG-gasoline bi-fuel vehicles: Part II. CO, HC

and NOx. Science of the Total Environment, vol. 565,

pp. 698–705.

Khan M.I. et al., 2015. Technical overview of compressed

natural gas (CNG) as a transportation fuel. Renewable

and Sustainable Energy Reviews 51, p.785–797.

Khan, M.I. et al., 2016. Research progress in the develop-

ment of natural gas as fuel for road vehicles: A biblio-

graphic review (1991–2016). Renewable and Sustaina-

ble Energy Reviews 66, p. 702–741.

Kimura, S. and MatsumotoY, H. Infrastructure for Next-

Generation Vehicles, 2016. Energy Technology

Roadmaps of Japan. Springer Japan, p. 217-235.

Kirk, J.L. et al., 2014. Exploring the market for Compressed

Natural Gas light commercial vehicles in the United

Kingdom. Transportation Research Part D, vol. 29, pp.

22–31.

Makarova, I. et al., 2012. Dealer-service center competi-

tiveness increase using modern management methods.

Transport Problems, vol. 7 (2), pp. 53-59.

Makarova, I. et al., 2019. Improving transport system envi-

ronmental friendliness and energy efficiency due to us-

ing the gas generator as an alternative fuel. Develop-

ments in eSystems Engineering (DeSE), pp. 789-793.

Makarova, I. et al., 2019. Industry 4.0 in production and

household waste processing. Developments in eSys-

tems Engineering (DeSE), pp. 794-799.

Mehra, R.K. et al., 2017. Progress in hydrogen enriched

compressed natural gas (HCNG) internal combustion

engines - A comprehensive review. Renewable and

Sustainable Energy Reviews 80, p. 1458–1498.

Ogunlowo, O.O. et al., 2015. Developing compressed nat-

ural gas as an automotive fuel in Nigeria: Lessons from

international markets. Energy Policy 76, p. 7–17

On the State Program for the Development of Agriculture

and Regulation of Agricultural Products, Raw Materials

and Food Markets for 2008 – 2012. 2007. Decree of

the Government of the Russian Federation N 446.

Rosenstiel, D. et al., 2015. Why has the introduction of nat-

ural gas vehicles failed in Germany? Lessons on the

role of market failure in markets for alternative fuel ve-

hicles. Energy Policy, vol. 78, pp. 91–101.

Sapphire-eco - the garbage truck. 2015. URL:

http://maz500.com.ua/p368-sapfir-eko-muso-

rosborschik-ot-maz.html. (accessed: 15.04.2018).

Wang, H. et al., 2015. Development of natural gas vehicles

in China: An assessment of enabling factors and barri-

ers. Energy Policy 85, p. 80–93.

Wikipedia. Garbage truck. URL: https://ru.wikipe-

dia.org/wiki/Мусоровоз/ (accessed: 13.06.2018).

YaMZ-53644. Gas engine CNG. 2015. URL:

http://maz500.com.ua/p368-sapfir-eko-muso-

rosborschik-ot-maz.html (accessed: 15.04.2018).

Zolotnitskiy, V. et al., 1997. Methane in the motor. Behind

the wheel, vol. 11, pp.162-163.

iMLTrans 2021 - Special Session on Intelligent Mobility, Logistics and Transport

782