Design Optimization of PMSM with Temperature Effect using GSA

and GSA-PSO

Vinod Puri

1

, Yogesh K. Chauhan

2

1

Eectrical Engineering Department, BGSB University, Rajouri, India

2

Department of Electrical Engineering, KNIT, Sultanpur, UP, India

Keywords: Permanent magnet generator, Temperature effect, Optimization, Gravitational Search Algorithm and Parti-

cle Swarm Optimization.

Abstract: The design of the machine is complex and regrous process. There are many parameters which influence the

design of a machine. The manufacture has to keep an eye on these factors well in advance and consider their

effect on the geometrical parameters. The research work focused on the temperature effect while optimizing

the geometrical parameters of permanent magnet synchronous machine. The objective which is based on the

minimization of temperature of the machine has been formulated. The optimization of geometrical parame-

ters has been done using natured inspired Newtonian law based Gravitational Search Algorithm. This paper

focused on a comparative study which has been done on algorithms and their hybridization of Gravitational

Search Algorithm and Particle Swarm Optimization.

1 INTRODUCTION

World’s technology is moving at a faster rate with

lots of improvement in the manufacturing industries,

maintained of electrical equipment’s, use of electri-

cal equipment in space science, biomedical instru-

mentation, electrical vehicle, communication indus-

try, power utility etc. All this is possible because of

the different types of machine. These different con-

figuration of machine may be used in advance appli-

cation as stated above. In these advance applications

the machine is required to work in most extreme

conditions. The manufacturer before manufacturing

the machine consider all the factors which affects

the working of the machine for desired performance.

The factors which mostly affects the performance of

the machine is temperature, skin effect, skewing,

cogging torque, torque ripple etc. Among all the fac-

tors temperature is one of the major factor which af-

fects the machine’s performance. It has been seen

many cooling techniques adopted by the manufac-

ture to limit the temperature in the permissible limits

while working in the extreme conditions without

sacrificing the performance of the machine. The

cooling methods adopted are natural air cooling,

forced air cooling, gas cooling and oil cooling, etc.

Therefore it is important to find the minimum work-

ing temperature with optimal geometrical parameters

for set of desired performance of the machine.

There are several ways by which the temperature

analysis have been done as temperature affects all

parts from shafts to the frame of the machine the

heat mostly developed in armature windings due to

ohmic loss and in the core due to hysteresis and ed-

dy current constituted core loss, friction also consti-

tuted the development of heat in the machine. In

(Xyptras and Hatziathanassiou, 1999)the thermal

analysis have been performed where cross-section of

an asynchronous machine have been taken for eval-

uating the copper and iron loss at steady state and

deep bar effect under transient conditions. Similar

study have been performed while considering the to-

tally enclosed fan cooled electric motor where

steady state and transient conditions are used to es-

timate the temperature of the machine (Mellor et al.,

1991).The online temperature estimation has also

been done using thermo fluid model to predict the

temperature in an oil cooled machine . This method

has the accuracy up to 94% of the actual val-

ue(Camilleri et al., 2015). The temperature has also

been estimated using high frequency current injec-

tion method in Permanent Magnet Ma-

chines(Reigosa et al., 2016). Some dynamic analysis

have been performed for evaluating the real time

analysis of thermal field effect using Finite Element

Puri, V. and Chauhan, Y.

Design Optimization of PMSM with Temperature Effect using GSA and GSA-PSO.

DOI: 10.5220/0010562600003161

In Proceedings of the 3rd International Conference on Advanced Computing and Software Engineering (ICACSE 2021), pages 61-66

ISBN: 978-989-758-544-9

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

61

model(Wang et al., 2019). As it is evident that the

temperature affects the electrical machine in a way

where it affects the performance of the machine. In

(Husain et al., 2016; Le Guyadec et al., 2019) The

temperature effect have also been taken into consid-

eration in the design process. In (Madonna et al.,

2018) the management in regulating the temperature

of the electric machine have been done to find out

the effective cooling methods and their comparative

analysis. İn (Xue et al., 2018) an iron loss model for

the electrical machine have been reviewed which

helps in the temperature prediction of the machine.

The machine can work in high temperature using

super conductors with no insulation for the applica-

tion of electric propulsion of aircraft(Wang et al.,

2020).

There are following research which carried to in-

corporate the temperature effect while designing a

machine (Bramerdorfer et al., 2018; Kreuawan et al.,

2008; Mellor et al., 2014). In(Baker and Mellor,

2017)a design optimization have been done depend-

ing up on the split-ratio which balances stator iron

and winding losses. This optimized design is suc-

cessfully used for higher output power and higher

with available volume. There are many methods de-

veloped for thermal analysis(Ayat et al., 2016)and

considering the effects of degradation of the perma-

nent magnets due to temperature effect(Sumislawska

et al., 2016). New cooling method has also been re-

ported in the literature where effect of spray parame-

ters in heat dissipation have been effectively ana-

lyzed(Zhenguo et al., 2017).

The following points have been inferred while

doing a short literature review on the temperature ef-

fect:

Most of the research involved the analytical

study of post effect analysis of temperature on the

machine.

The mitigation of the temperature rise prob-

lem can be done using several cooling methods in-

cluding spray.

Design of machine has also been reported in

the literature while consideration different type of

materials which helps in reducing the losses in the

machine(Ismagilov et al., 2017; Persson and Jans-

son, 1995; Rahaman and Sandhu, 2019)

The literature review in the given domain has

been carried and salient points have been enumerat-

ed. The author also pointed out some of the un-

searched and dormant areas which are important in

the manufacturing and designing of electrical ma-

chine are:

The factors which affect the performance of the

machine must be considered before manufactur-

ing scare literature is reported in this direction.

There a need to find a heuristic approach in

finding the optimal geometrical parameters of

the machine such that the performance as well

as cost may not be compromised.

The machine may be design for limiting value

of the nonlinearities present like flux density,

temperature, current density, frequency etc.

In this research work the author solved the de-

sign problem with the help of a natured inspired-

Newtonian law based gravitational search algorithm

(GSA).GSA is based on the law of gravitational

forces and was enumerated by Rashedi in 2009

(Rashedi et al., 2009; Rashedi et al., 2011). In this

optimization technique the solutions are having dif-

ferent parameters called masses in term of GSA. The

obtained solution is a large aggregation of masses

which exerts forces on each other. The solution hav-

ing larger mass represents the optimal solution in the

search space and it cannot be attracted by others

small masses (Hassanzadeh and Rouhani, 2010).

The GSA has already been used in solving problems

like optimal power flow, economic dispatch and unit

commitment (Duman et al., 2012; Mondal et al.,

2013; Roy, 2013; Xing and Gao, 2014). In this re-

search work the GSA has been hybridized with PSO.

The temperature of the machine has been considered

in finding the optimal geometrical parameters of the

machine. These optimal geometrical parameters cor-

responds to the minimum temperature, maximum ef-

ficiency and minimum regulation. It seems to be

possible that the optimal geometrical parameters of

the machine is such that the temperature of the ma-

chine kept constant without affecting the perfor-

mance of the machine.

The article has been structured in such a way that

the objective function has been formulated while in-

corporating the possible geometrical parameters in

section II. The heuristic algorithm have been studied

in section III. In section IV the results pertaining to

optimal evaluation of geometrical parameters of

PMSM considering temperature effect using GSA

and GSA-PSO.

2 GSA AND ITS

HYBRIDIZATION WITH PSO

Here, the GSA and GSA-PSO are used to optimize

the temperature of the machine. Their algorithms

have been discussed here in the following section in

detail.

ICACSE 2021 - International Conference on Advanced Computing and Software Engineering

62

2.1 GSA Algorithm

Step1: Let a system with ‘n’ number of agents and

the position of the i

t

agent is given by,

𝑃

𝑝

,…….𝑝

,…….𝑝

).

(1)

Step2: Evaluate the fitness of the objective function.

𝐹𝑖𝑡𝑛𝑒𝑠𝑠

𝑓𝑝

,…….𝑝

,…….𝑝

). (2)

Step3: Both thegravitational and inertial mass de-

pends upon the fitness of theobjective func-

tion and are given by,

𝑀

𝑀

𝑀

𝑀

, (3)

𝑚

𝑡

, (4)

𝑀

𝑡

∑

, (5)

Here the fitness (t) is the fitness of the object

I at time t and worst and bestfitness is given

by,

𝑏𝑒𝑠𝑡𝑓𝑖𝑡𝑛𝑒𝑠𝑠

𝑡

min

∈…….

𝑓𝑖𝑡𝑛𝑒𝑠𝑠

𝑡 (6)

𝑤𝑜𝑟𝑠𝑡𝑓𝑖𝑡𝑛𝑒𝑠𝑠

𝑡

max

∈…….

𝑓𝑖𝑡𝑛𝑒𝑠𝑠

𝑡. (7)

Step 4: Calculate the force on mass I due to mass j.

𝐹

𝐺𝑡

𝑝

𝑡

𝑝

𝑡

, (8)

Here, M

aj

acts as active mass of object j; M

pi

is the passive mass of object i.

The R

ij

(t) is given by,

𝑅

𝑡 ⃦𝑃

𝑡,𝑃

𝑡 ⃦, (9)

Step 5: Calculate the total force acting on mas-

s

i

𝐹

𝑡

∑

𝑟𝑎𝑛𝑑

𝐹

∈,

𝑡, (10)

Here, Kbest is the set of initial objects with

the best fitness.

Step6: Calculate the acceleration of mass i in time t

in the d

th

dimension is given as follows,

𝑎

, (11)

Step7: Update velocity and position as,

𝑢

𝑡1

𝑟𝑎𝑛𝑑

𝑢

𝑡

𝑎

𝑡

, (12)

𝑝

𝑡1

𝑝

𝑡

𝑢

𝑡 1.

(13)

2.2 Algorithm for GSA-PSO

GSA-PSO combined the social thinking PSO with

local search capability of GSA.

The steps 1 to 6 have been same except the update

of velocity and position as,

𝑢

𝑡1

𝑤𝑢

𝑡

𝐶

𝑟𝑎𝑛𝑑𝑎

𝑡

𝑟𝑎𝑛𝑑 𝑋𝑔𝑏𝑒𝑠𝑡𝑋

(14)

𝑝

𝑡1

𝑝

𝑡

𝑢

𝑡1

. (15)

3 PROBLEM FROMULATION OF

PARAMETER ESTIMATION

OF PMG

In this proposed research work, temperature is con-

sidered as main objective. The objective is to mini-

mize the temperature of the machine while optimiz-

ing the values of the selected design variables i.e.D

o

,

D, L, h

s

.

𝐹𝑡 𝑚𝑖𝑛𝑇𝑒𝑚𝑝 (16)

Formulatedmain objective function as,

𝑇𝑒𝑚𝑝

𝐷

,𝐷,𝐿,ℎ

,

..

.

.ℎ

.

.

.

.

(17)

Where, D

o

is outer diameter; D is air gap diame-

ter; L is length of the machine; h

s

is height of the sta-

tor slot.

Subjected to constraints as per given equations,

𝜂

𝜂

𝜂

(18)

𝑅𝑒𝑔

𝑅𝑒𝑔

𝑅𝑒𝑔

(19)

The performance parameters have been calculat-

ed using optimal values,

Efficiency is calculated as per equation

,

𝜂

(20)

Regulation is calculated as per equation,

𝑅𝑒𝑔

100 (21)

4 RESULTS AND DISCUSSION

A 3.3kV, 500KVA, 3-phase, 50 Hz, 600

rpm,PMSM. The design parameters (D

o

, D, L, h

s

,)

are evaluated while considering the temperature of

machine as main objective. The function of tempera-

ture is optimized using GSA and GSA-PSO. The

Table 1 shows the optimal results evaluated using

both the algorithms.

Design Optimization of PMSM with Temperature Effect using GSA and GSA-PSO

63

Table 1: Effect of temperature on design parameters and

performance of Machine

Design

parameters

Range of

parame-

ters and

Initial de-

sign pa-

rameters

Optimal

design pa-

rameters

using

GSA

Opti-

mal

design

pa-

rame-

ters

us-

ingGS

A-

PSO

Outer di-

ameters (m)

1.142-

1.04

1.0780 1.0752

Air gap di-

ameters (m)

0.9-0.8 0.8981 0.8986

Length (m) 0.45-0.35 0.3515 0.3533

Depth of

stator slots,

(m)

0.0475-

0.0411

0.0466 0.0456

6

Perfor-

mance

Indices

Initial Performance

Indices

Tempera-

ture (

o

C)

33.266 24.355 24.266

8

Regulation 32.12 31.745 31.723

7

Efficiency 93.49 95.425 95.418

6

Max flux

density in

the stator

teeth.

(

wb/m

2

)

1.92-2.1 1.5082

(a)

(b)

(c)

(d)

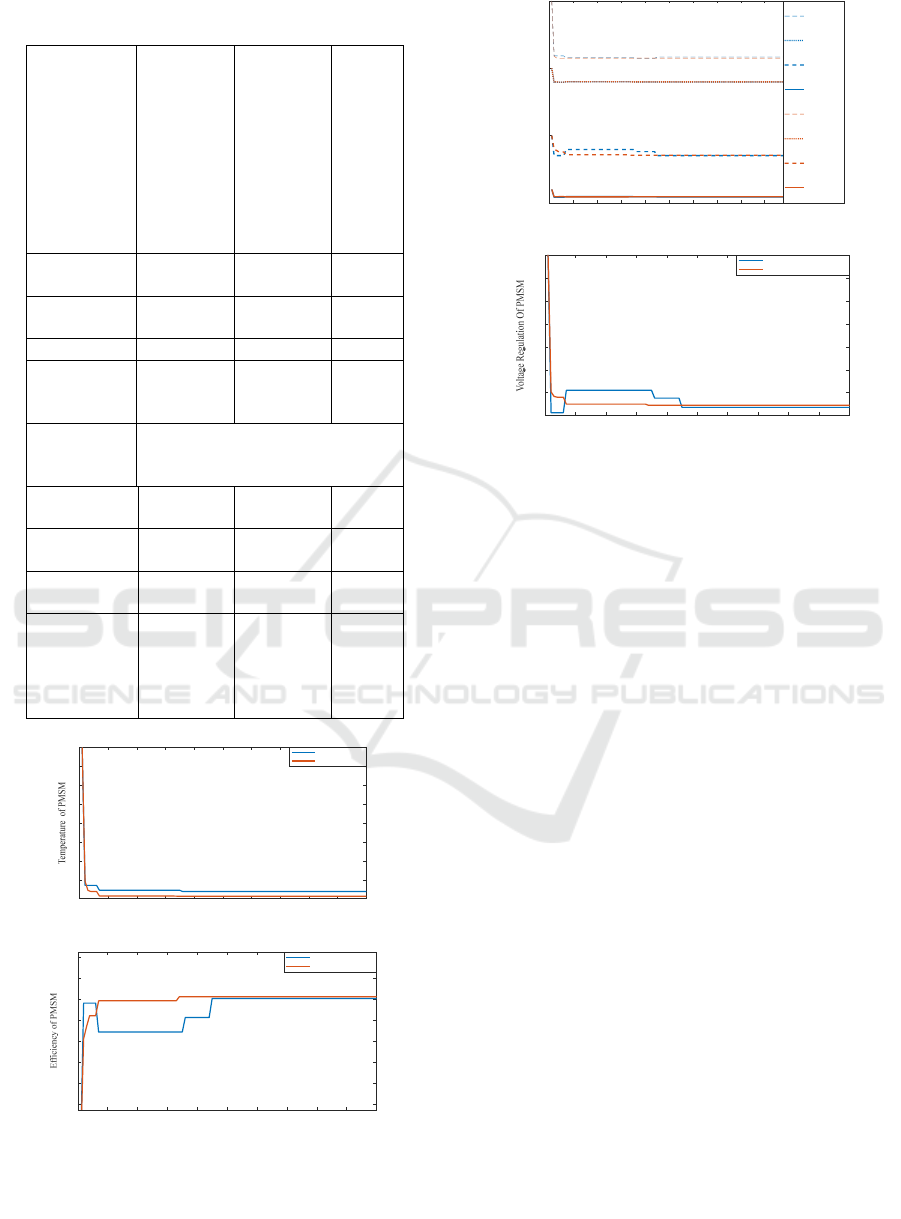

Figure 1: Performance optimized curves of temperature

minimization function of PMSM using GSA and GSA-

PSO: (a) Optimization curve of temperature using GSA

and GSA-PSO. (b)Variation of efficiency as performance

parameter of PMSM using GSA and GSA-PSO.

(c)Variation of design parameters of temperature using

GSA and GSA-PSO. (d) Variation of regulation as per-

formance parameter of PMSM using GSA and GSA-PSO.

It is seen from table 1, the design variables are in

their specified range and the performance of ma-

chine improves from initial design parameters. The

temperature of the machine has been reduced by

26.78% and 27.05% using GSA and GSA-PSO re-

spectively. The GSA-PSO has improved the reduc-

tion of temperature from GSA by 0.274%.

It has been reported in earlier results and in the

optimizing curves that the GSA-PSO improves the

results and quickly converges towards the optimal

values than GSA. The regulation of the machine has

been improved by 1.167% and 1.27% respectively.

It has been seen in the table 1 that there is increase

in efficiency of the machine by 2.06 %, using both

algorithms.

The fig 1 (a) shows the temperature optimiza-

tions curve. The curve shows the initial variation but

soon after approximately 45 iterations the curve set-

tled to its optimal value. The variation of design pa-

rameters which are dependent upon the temperature

has been shown in fig 1 (b). The improvement in the

performance parameters of the machine like effi-

ciency and regulation have been shown in fig 1 (c)

and fig 1 (d)

0 102030405060708090100

Iterations

24

26

28

30

32

34

36

38

40

Temp GSA

Temp GSA-PSO

0 102030405060708090100

Iterations

94.4

94.6

94.8

95

95.2

95.4

95.6

95.8

Efficiency GSA

Efficiency GSA-PSO

0 102030405060708090100

Iterations

0

0.5

1

1.5

Variation Of Design Parameters (m)

(PMSM)

Do (GSA)

D (GSA)

L (GSA)

hs (GSA)

Do (GSA-PSO)

D (GSA-PSO)

L (GSA-PSO)

hs (GSA-PSO)

0 102030405060708090100

Iterations

31.5

32

32.5

33

33.5

34

34.5

35

Volt. Regulation GSA

Volt. Regulation GSA-PSO

ICACSE 2021 - International Conference on Advanced Computing and Software Engineering

64

5 CONCLUSION

In this research work an objective function pertain-

ing to the design of PMSM has been formulated.

The objective function is formulated taking into con-

sideration the temperature effect. The geometrical

parameter so obtained corresponds to minimum

temperature, maximum efficiency and minimum

regulation. Following important points have been in-

ferred from this research work:

The GSA and GSA-PSO both are capable of op-

timizing the objective function shows the versa-

tility in optimizing different set of problems.

While optimizing the problem using GSA the

temperature is 24.35, efficiency is 95.4%, regu-

lation is 31.7%.

The results obtained from the GSA-PSO has al-

so been similar like the temperature is 24.26, ef-

ficiency is 95.4% and regulation is 31.7%.

While comparing both the algorithms the GSA-

PSO although gives similar results but it con-

verges faster as compared to GSA.

The GSA and GSA-PSO opens up the scope of de-

signing a machine with desire performance.

6 FUTURE SCOPE OF WORK

The current research restricted up to the evaluation

of geometrical parameters while considering the

temperature effect. Further studies can be carried on

the factors that affect the performance of the PMSM

like demagnetization of permanent magnets, skin ef-

fect, skewing effect and cogging torque etc. Re-

search can be extended while changing the material

for manufacturing the machine which uses magnets

of high magnetic flux density, hybrid materials to

reduce the weight of the machine.

ACKNOWLEDGEMENTS

The current research is a part of project sanction by

the Baba Ghulam Shah Badshah University under

RGS Scheme.

REFERENCES

Ayat, S., Wrobel, R., Goss, J. and Drury, D.,

2016.Experimental calibration in thermal analysis of

PM electrical machines. In 2016 IEEE Energy Con-

version Congress and Exposition (ECCE) (pp. 1-8).

IEEE.

Baker, J.L. and Mellor, P.H., 2017. Influence of stator

split-ratio upon the thermally limited power-envelope

of a permanent-magnet electrical machine. In 2017

IEEE International Electric Machines and Drives

Conference (IEMDC) (pp. 1-8). IEEE.

Bramerdorfer, G., Tapia, J.A., Pyrhönen, J.J. and

Cavagnino, A., 2018. Modern electrical machine de-

sign optimization: techniques, trends, and best practic-

es. IEEE Transactions on Industrial Electron-

ics, 65(10), pp.7672-7684. IEEE.

Camilleri, R., Howey, D.A. and McCulloch, M.D., 2015.

Predicting the temperature and flow distribution in a

direct oil-cooled electrical machine with segmented

stator. IEEE Transactions on Industrial Electron-

ics, 63(1), pp.82-91. IEEE

Duman, S., Güvenç, U., Sönmez, Y. and Yörükeren, N.,

2012. Optimal power flow using gravitational search

algorithm. Energy conversion and management, 59,

pp.86-95.

Hassanzadeh, H.R. and Rouhani, M., 2010. A multi-

objective gravitational search algorithm. In 2010 2nd

international conference on computational intelli-

gence, communication systems and networks (pp. 7-

12). IEEE.

Hussain, S., Ghorbanian, V., Benabou, A., Clénet, S. and

Lowther, D.A., 2016. A study of the effects of temper-

ature on magnetic and copper losses in electrical ma-

chines. In 2016 XXII International Conference on

Electrical Machines (ICEM) (pp. 1277-1283). IEEE.

Ismagilov, F.R., Khayrullin, I.K., Vavilov, V.Y., Bekuzin,

V.I. and Ayguzina, V.V., 2017. Minimization of ener-

gy losses in ultra-high-speed electrical rotating ma-

chines. Elektrotehniski Vestnik, 84(1/2), p.56.

Kreuawan, S., Gillon, F. and Brochet, P., 2008. Optimal

design of permanent magnet motor using multidisci-

plinary design optimization. In 2008 18th Internation-

al Conference on Electrical Machines (pp. 1-6). IEEE.

Le Guyadec, M., Gerbaud, L., Vinot, E. and Delinchant,

B., 2019. Sensitivity analysis using Sobol indices for

the thermal modelling of an electrical machine for siz-

ing by optimization. COMPEL-The international

journal for computation and mathematics in electrical

and electronic engineering.

Madonna, V., Walker, A., Giangrande, P., Serra, G.,

Gerada, C. and Galea, M., 2018. Improved thermal

management and analysis for stator end-windings of

electrical machines. IEEE Transactions on Industrial

Electronics, 66(7), pp.5057-5069. IEEE.

Mellor, P.H., Roberts, D. and Turner, D.R., 1991. Lumped

parameter thermal model for electrical machines of

TEFC design. In IEE Proceedings B (Electric Power

Applications) (Vol. 138, No. 5, pp. 205-218). IET Dig-

ital Library.

Mondal, S., Bhattacharya, A. and nee Dey, S.H., 2013.

Multi-objective economic emission load dispatch solu-

tion using gravitational search algorithm and consider-

ing wind power penetration. International Journal of

Design Optimization of PMSM with Temperature Effect using GSA and GSA-PSO

65

Electrical Power & Energy Systems, 44(1), pp.282-

292.

Persson, M. and Jansson, P., 1995. Advances in powder

metallurgy soft magnetic composite materials for elec-

trical machines.

Rahaman, M.M. and Sandhu, K.S., 2019. Energy Efficient

magnetic materials for Electrical Machines. In 2019

5th International Conference on Advanced Computing

& Communication Systems (ICACCS) (pp. 642-646).

IEEE.

Rashedi, E., Nezamabadi-Pour, H. and Saryazdi, S., 2009.

GSA: a gravitational search algorithm. Information

sciences, 179(13), pp.2232-2248.

Reigosa, D., Fernandez, D., Tanimoto, T., Kato, T. and

Briz, F., 2016. Comparative analysis of BEMF and

pulsating high-frequency current injection methods for

PM temperature estimation in PMSMs. IEEE Transac-

tions on Power Electronics, 32(5), pp.3691-3699.

IEEE.

Roy, P.K., 2013. Solution of unit commitment problem us-

ing gravitational search algorithm. International Jour-

nal of Electrical Power & Energy Systems, 53, pp.85-

94.

Sumislawska, M., Gyftakis, K.N., Kavanagh, D.F.,

McCulloch, M.D., Burnham, K.J. and Howey, D.A.,

2016. The impact of thermal degradation on properties

of electrical machine winding insulation materi-

al. IEEE Transactions on Industry Applications, 52(4),

pp.2951-2960. IEEE.

Wang, X., Gu, Y., Gao, P. and Li, X., 2019. The Research

on Temperature Effect for Dynamic Performance of

High-Speed Permanent-Magnet Synchronous Ma-

chines Rotors. In 2019 22nd International Conference

on Electrical Machines and Systems (ICEMS) (pp. 1-

6). IEEE.

Wang, Y., Weng, F., Li, J., Šouc, J., Gömöry, F., Zou, S.,

Zhang, M. and Yuan, W., 2020. No-Insulation High-

Temperature Superconductor Winding Technique for

Electrical Aircraft Propulsion. IEEE Transactions on

Transportation Electrification, 6(4), pp.1613-1624.

IEEE.

Xing, B. and Gao, W.J., 2014. Innovative computational

intelligence: a rough guide to 134 clever algorithms,

62 (2), pp. 22-28). Cham: Springer international pub-

lishing.

Xue, S., Zhu, Z.Q., Wang, Y., Feng, J., Guo, S., Li, Y.,

Chen, Z. and Peng, J., 2018. Thermal-loss coupling

analysis of an electrical machine using the improved

temperature-dependent iron loss model. IEEE Trans-

actions on Magnetics, 54(11), pp.1-5. IEEE.

Xyptras, J. and Hatziathanassiou, V., 1999. Thermal anal-

ysis of an electrical machine taking into account the

iron losses and the deep-bar effect. IEEE Transactions

on Energy Conversion, 14(4), pp.996-1003. IEEE.

Zhenguo, L., Shaoyan, L. and Lin, R., 2017. The effect of

spray parameter on heat dissipation in spray evaporat-

vie cooling high power density motors. In 2017 20th

International Conference on Electrical Machines and

Systems (ICEMS) (pp. 1-4). IEEE.

ICACSE 2021 - International Conference on Advanced Computing and Software Engineering

66