Design and Deployment of Digital Twins

for Programmable Logic Controllers in Existing Plants

Stephan Sch

¨

afer

1

, Dirk Sch

¨

ottke

1

, Thomas K

¨

ampfe

1

, Kiril Ralinovski

1

,

Bernd Tauber

2

and Ralf Lehmann

2

1

Hochschule f

¨

ur Technik und Wirtschaft (HTW) Berlin, Berlin, Germany

2

EAW Relaistechnik GmbH, Berlin, Germany

Keywords:

Digital Twin, Asset Administration Shell, Middleware BaSys 4.

Abstract:

Digitization and network integration of production environments are two core prerequisites for changeable

production environments according to a digital factory. In addition, consistent and cross-system descriptions of

the equipment and abilities are required over the entire life cycle of plants. This descriptions can be done with

Asset Administration Shells, which are a useful tool for the design of new facilities and their system components.

Currently, industrial plants usually use programmable logic controllers, which are programmed with domain-

specific programming languages. The use of these programming languages leads to an inflexible coupling of

programmable logic controllers and their sensors and actuators with the process. If the plant configuration is

changed later, a new engineering process with extensive reprogramming is required. However, in many cases,

clarity and completeness of changes are not sufficiently addressed in the accompanying documentation. The

paper discusses the results of the project ”OpenBasys 4.0”. A project goal is to retrofit a conventional existing

plant with programmable logic controllers into a reconfigurable plant design by using the BaSys 4 middleware.

A method was developed and exemplarily implemented on a prototype. The focus of the method is on the

automated generation of Asset Administration Shells and their use.

1 INTRODUCTION

In the Reference Architecture Model Industrie 4.0

(RAMI4.0), the concept of the Asset Administration

Shell (Bader et al., 2020) is presented as an essen-

tial basis for interoperability. The Asset Administra-

tion Shell (AAS) is the digital representation (Digital

Twin) of an asset in the Industry 4.0 (I4.0) environment

and enables communication with other assets. Among

other things, machines, products or control systems

are regarded as assets. An AAS consists of several

submodels in which information and functionalities

of an object are described. The information provided

by AAS consists of documents, properties, parameters

and other functions. (Kuhn et al., 2020)

Programmable logic controllers (PLC) are assigned

to the lowest RAMI level and have a close relation-

ship to production system equipment. (Cavalieri and

Salafia, 2020) This results in significant advantages

in the description of the commissioning and in the

process of reconfiguration of the plant components.

Despite the close association, there are gaps in the use.

(Bedenbender et al., 2021)

On the one hand, it lacks consistent self-description

and representation to neighboring systems and objects.

On the other hand, there are gaps in the consistent

preparation and use of information in the engineering

phase. In addition, there is currently no established pro-

cedure for integrating existing solutions within PLCs

in I4.0 system environments, but rather a variety of

proprietary methods. (DIN e. V., 2020) Some gaps

can be compensated for by using BMBF-funded re-

search project Basys 4.0 middleware. (Grothoff, 2018)

Fig. 1 shows how the Basys 4 middleware fits into the

plant context and will be explained later for a specific

scenario in the paper.

In order to reduce the deficits described above, a

methodical approach is required in order to be able to

generate a high benefit from the available data. For

this purpose, it is first necessary to consider the gen-

eral state of the art in the project planning of control

environments.

In various papers, the use cases are based on the ini-

tial configuration of equipment and required structures.

For example, in the modeling of a reference plant (Pick

& Place - Station) and its components (Belyaev et al.,

Schäfer, S., Schöttke, D., Kämpfe, T., Ralinovski, K., Tauber, B. and Lehmann, R.

Design and Deployment of Digital Twins for Programmable Logic Controllers in Existing Plants.

DOI: 10.5220/0010711000003062

In Proceedings of the 2nd International Conference on Innovative Intelligent Industrial Production and Logistics (IN4PL 2021), pages 145-150

ISBN: 978-989-758-535-7

Copyright

c

2021 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

145

Server

Edge

Gateway

PLC*²

Registry

AAS*¹

Ethernet

OPC-UA

Fieldbus

BaSys 4 - Middleware

Device Level

Field Level

Plant Level

Submodel

Submodel

* *¹ ²Asset Administra!on Shell, Programmable Logic Controller

Figure 1: Integration of BaSys 4 middleware.

2021) extensive descriptions were made. The mod-

eling of abilities as sub models was also discussed

there. The migration/transition of existing plants to an

I4.0 environment presents a different situation and a

challenge.

Because the implementation phase of functions of

a production line involves a significant engineering

effort, a review of the necessary requirements and ex-

isting reference implementations should be performed

in advance. It is possible that the requirements and the

design of the system environment have changed during

the plant life cycle, so that system components have to

be adapted.

On the one hand, not all realized requirements were

documented or functions were implemented or that

functions have been implemented in the life cycle that

were not specified in the requirements phase. This

situation can lead to unpredictable side effects when

redesigning the plant functionality. If, on the other

hand, existing and tested function modules (templates)

are already used in the modeling of the plant behavior,

this results in a large number of synergies for future

adaptations. This aspect should not be underestimated

when transferring existing plants with programmable

logic controllers to modern I4.0 structures.

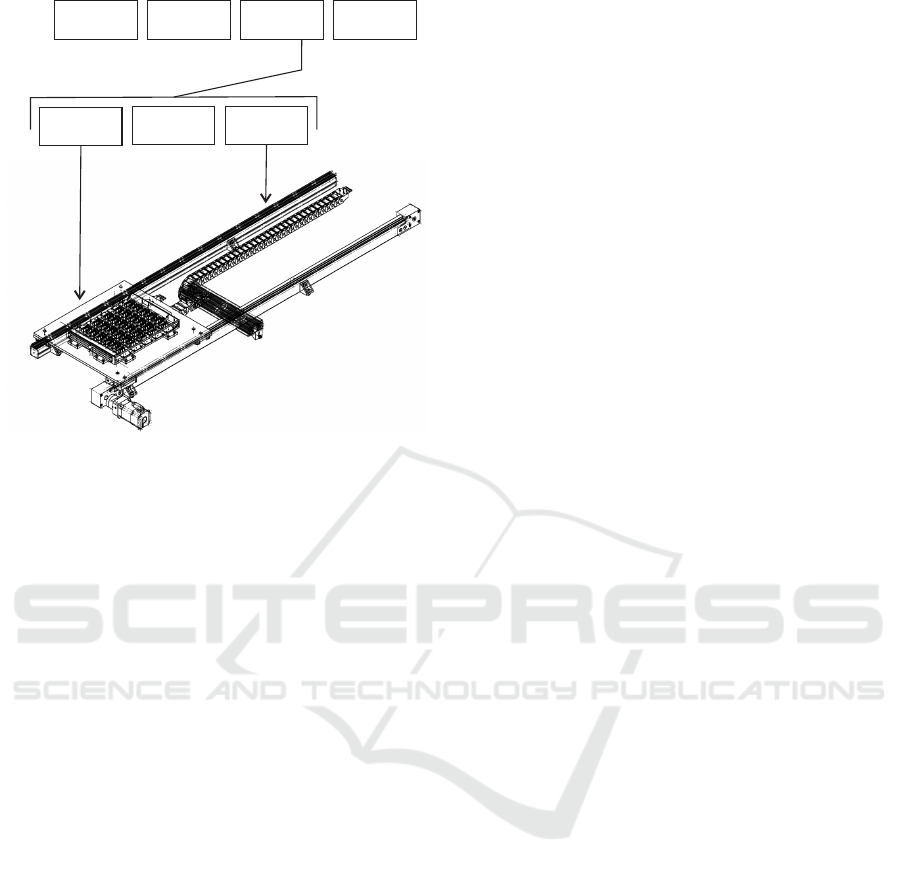

2 USE CASE: SORTING

In the specific use case of high-quality thermal

switches, products are tested in an industrial environ-

ment during production or after the manufacturing pro-

cess. Fig. 2 shows an overview of the environment

as an example. The products are placed on a special

pallet carrier and made available for further processes.

In this environment, each product runs through prede-

fined test scenarios. At the test stations, the required

test scope, sequence and time vary according to the

product batch. The following processes are handled in

the existing environment:

• Bring and Pick up service

• Pallet handling

• Pallet delivery

• Sorting of the thermal switches

The existing classic automation solution is to be

gradually converted into an I4.0-based solution with

Asset Administration Shell (AAS) in order to achieve

synergies with the use of production data at a manage-

able cost.

In the use case, different abilities or groupings of

abilities are required for the processes, which can be

described as assets via metamodels. For example, the

”pallet delivery” process includes the ability to fix and

transport objects. The technological components are

shown in excerpts in Fig. 3.

The abilities can be seen in isolation or as a com-

bination of abilities. In the first case, the communica-

tion relationships and dependencies for higher-level

coordination must be known. In the second case, the

grouping can be based on the totality of abilities, so

that the relationships can already be implemented on

the programmable logic controller (PLC).

Figure 2: Technological scheme (excerpt).

IN4PL 2021 - 2nd International Conference on Innovative Intelligent Industrial Production and Logistics

146

* excerpt

Bring-/

Pick up

Pallet

handling

Pallet

delivery

Sor!ng

Pallet

fixing

Posi!oning

unit

Pallet

carrier

Figure 3: Subscheme - pallet delivery (excerpt).

In the use case, the functions have already been

encapsulated on the PLC, so that the functions are

used as assets on the AAS. All abilities or groupings

of abilities are also to be synchronized at the AAS

level. For this purpose, a Pack ML state machine is

to be established for each controller and process or

subprocess. In the case that several subprocesses are

implemented on one controller, an additional higher-

level Pack ML state machine is used.

3 APPROACH

3.1 Existing Plant & Asset

Administration Shells

In order to successfully convert a plant into an I4.0-

based solution, the plant description and the programs

used must be documented in a proper manner. In the

use case, the project planning of the existing plant was

carried out with PLCs, which were programmed with

domain-specific programming languages such as IEC

61131-3. The ”Codesys” platform was used, which is

popular and is based on a PLCopen compliant notation.

In this platform, a large number of libraries and vari-

ous communication protocols can be used. (Rayment,

2004) However, there are still no solutions that allow

easy integration into an I4.0 environment via Asset

Administration shells (AAS).

The challenge is the effort-reduced realization of

Digital Twins (Koulamas and Kalogeras, 2018) as I4.0

components. These can be designed as Asset Adminis-

tration shells (AAS). AASs can be separated into three

types based on a unified information metamodel. (Bun-

desministerium f

¨

ur Wirtschaft und Energie (BMWi),

2020) Type 1 AAS represents a passive AAS, which

consists of an asset description. Type 2 AAS repre-

sents a reactive AAS, which in addition to the asset

description, also contains a communication channel.

Only Type 3 AAS is a proactive AAS and is capable of

independently communicating with other AAS. Sub-

model templates are provided for modeling frequently

used asset aspects. They are equivalent to the profiles

for fieldbuses.

One tool for the description of AAS is the AASX

Package Explorer. (Belyaev et al., 2021) This enables

a structured description to be implemented using sub-

models and other structural elements. The AASX Pack-

age Explorer supports extensive export/import func-

tions. The entire asset descriptions or individual sub-

models can be exported for further processing in an

XML or JSON format, and node sets for the assets can

be imported. Detailed and further information can be

found on the AASX Package Explorer GitHub website.

(Github Repository - AASX Package Explorer, 2021)

3.2 Challenge

The SDK BaSyx 4.2 (Eclipse BaSyx Platform, 2021)

was used in the project to implement the representa-

tive. It offers the possibility of implementing AAS in

different programming environments (Java, C++, C#).

AASs can be configured manually by using SDK

according to the general description of the structure

and its submodels in the C#. However, this means that

an IT expert has to take over the engineering sector

in the company. In many cases, however, appropriate

employees with the required knowledge are not avail-

able in the company. However, automation engineers

are already employed for the existing machinery and

equipment, who are responsible for the support of the

plant. Their knowledge and skills can be drawn upon

with regard to the design of solutions.

The mentioned method of manual project engineer-

ing of AAS is established and will not be considered

further. The question arises of how the user of indus-

trial control is enabled to use AAS in the industrial

environment. A solution is the generic preparation of

AAS without knowledge of the SDK. For this, only the

description of the Type 1 AAS asset and the modifica-

tion of the PLC program should be as requirements.

In the research project ”OpenBasys 4.0” (Bun-

desministerium f

¨

ur Bildung und Forschung (BMBF),

2019), an environment for generic generation of AAS

was implemented. Type 2 AAS can be implemented

in this environment without knowledge of the SDK.

Design and Deployment of Digital Twins for Programmable Logic Controllers in Existing Plants

147

Start components

<< AAS[i] >>

<< PLC[i] >>

<< Registry >>

<< AAS-Generator >>

Figure 4: Minimum environment in I4.0.

The company’s employees only need to make minor

corrections and additions to their PLCs. These changes

include for example the global variable list (GVL) and

the login data (AAS ID, ip address, etc.) as http request

with a JSON structure. In most cases a http requests

(GET) are supplied by libraries of PLC manufacturer.

This means that a Type 2 AAS can be generated and

stored in a container largely automatically on request,

e.g. by the PLC. The approach involves the generic

generation of AAS for a variety of use cases using

established controls.

The potential user should be able to design AASs

relatively easily with the help of this approach and

transfer it into an I4.0 compliant environment. A ma-

chine interpretation of the contents/abilities is not yet

given due to the different use of the terminology. In

the project, a separate structure was created for the use

case. In the future, each generated AAS will receive a

GUI generated to match the AAS. At the current stage

of the project, the Pack ML state machine data (Mu

ˇ

si

ˇ

c,

2015) is transferred from the PLC and synchronized

with the AAS. With the Pack ML state machine and

the GUI, pre-testing of the components used with any

end devices is possible.

4 DESIGN OF GENERATION

PROCESS

A functioning I4.0 system requires at least a minimal

environment (Fig. 4). In the use case, this consists of a

registry and an AAS generator, which converts Type

1 AAS into Type 2 AAS. The registry is a directory

where the Type 2 AAS can register with their sub-

models. The AAS generator has a database in which

Type 1 AASs have already been stored for later use.

The sequence diagram (Fig. 5) explains the generation

process for an AAS and a required communication

interfaces. In order to convert Type 1 AAS into Type

2 AAS, the required AAS generator was developed.

:PLC

:AAS-Generator

Mongo

DB

Generate

configura"on data

Create

container (Docker)

Init

Check

fieldbus interface

from container ()

Check

availability()

Send

parameter list()

Validate

parameter list()

Validate Fieldbus

e()interfac

Validate Fieldbus

e()interfac

Wait for

registra"on

URI

present?()

URI

present!()

Read AAS

()entries

Fieldbus interface

()available?

Generate

AAS structure

Append

submodels

Figure 5: Sequence of generation process.

The structure of the AAS generator itself is a Type

3 AAS. PLCs use the generator’s RESTful interface.

(Eclipse BaSyx Wiki, 2021) It also has knowledge of

the submodels and their properties for communication.

PLCs first check the availability of the generator

by sending a request. If the generator is reachable, the

PLC then sends essential information for identifica-

tion. Furthermore, additional information is sent to the

AAS generator for later fieldbus communication be-

tween the industrial controller and the assigned AAS.

These are, for example, IP address, port number and

IN4PL 2021 - 2nd International Conference on Innovative Intelligent Industrial Production and Logistics

148

:PLC

:AAS-1

(Container)

Register

AAS()

Check fieldbus

interface

()availability

Get

configura"on

from AAS

generator()

Init

:Registry

Change to

„Ready“ state()

Check

state()

Ready

Await

request

Figure 6: Sequence of registry process.

communication protocol to be used.

The AAS generator reads corresponding Type 1

AAS from the MongoDB database. If an AAS with a

matching ID exists, the AAS generator reads the en-

tries for the AAS and submodels from MongoDB and

creates an instance. Now the AAS generator checks

the availability of the fieldbus communication. For ex-

ample, in the case of OPC UA communication, the

AAS generator creates a session and establishes a con-

nection to the PLC. The AAS generator now creates

a configuration file, which contains all information

of the Type 1 AAS and the submodels together with

fieldbus interfaces.

The configuration file also contains the information

needed for the communication between the AAS and

the registry. Then the AAS generator creates a Docker

container. Inside the Docker container, a Type 2 AAS

is created and filled with information.

5 DEPLOYMENT OF AAS

The following sequence diagram (Fig. 6) represents

the communication between AAS, registry and the

respective PLC.

First, a process is started which reads the previ-

ously created configuration file. The process checks

the fieldbus communication again from the Docker

container. This renewed communication test is neces-

Produc!v components

<< Coordinator >>

<< AAS-Management >>

<< AAS[1] >>

<< PLC[1] >>

<< AAS[2] >>

<< PLC[2] >>

Figure 7: Productive environment (excerpt).

sary to ensure that the Docker container can establish

fieldbus communication to the PLC. If the fieldbus

communication was successful, the AAS logs on to

the registry and transfers the descriptions to the reg-

istry. The descriptions of the AAS, its submodules and

their communication endpoints are now known and the

AAS is now available as an active resource.

The resources (AAS) can then be booked for use

in the productive environment (Fig. 7) in accordance

with the use case. In the current phase, their overall

coordination is still being handled by a coordinator.

The relationships between the AAS are currently still

being established manually.

6 CONCLUSION AND OUTLOOK

Programmable logic controllers (PLCs) can be inte-

grated into an I4.0 environment if they have a digital

twin as a representative. The paper discussed ways of

simplifying the design by a methodical approach and

the use of a generic approach. This approach was im-

plemented on a prototype and will be released as open

source once the project is completed. An essential pre-

requisite of the approach is that the documentation is

as complete and free of contradictions as possible.

Templates can now be generated with the ASS gen-

erator using the transformation models shown. Auto-

matically generated AAS as digital twins of their PLCs

enable plant operators to implement easier modifica-

tions in the plant. This helps to reduce the engineering

workload.

With the embedding of the ISA-88 state machine

(Pack-ML state machine) per AAS and PLC, higher-

level commands can be assigned to the processes and

described as an ability in the future. In addition, data

from the pack tags are automatically transferred to the

information model of the digital twin. This ensures

Design and Deployment of Digital Twins for Programmable Logic Controllers in Existing Plants

149

consistent and standardized process control and docu-

mentation.

With the prototype, an interface is made available

via AAS, which provides further information with stan-

dardized calls (RESTful, OPC-UA).

In the future, automatically generated web inter-

faces can enable the pre-testing of the components.

This will simplify the asset commissioning process

and process coordination.

To further reduce engineering processes, automated

derivation of abilities from requirements and their re-

lationship to each other will be necessary in the future.

This requires the transferability of information models

at the necessary levels.

ACKNOWLEDGEMENT

This research work called ”OpenBasys 4.0” has been

funded by the federal ministry of education and re-

search BMBF (01IS1900A) and is a BaSys 4 satellite

project for application-oriented projects. The effort of

this work was made possible by the Basys 4 frame-

work. The authors thank for the support of the BaSys

4 team.

REFERENCES

Bader et al., S. (2020). Details of the Asset Administration

Shell : Part 1: The exchange of information between

partners in the value chain of Industrie 4.0. Technical

report, Berlin.

Bedenbender et al., H. (2021). Industrie 4.0 Plug-and-

Produce for Adaptable Factories: Example Use Case

Definition, Models, and Implementation. Technical

report, M

¨

unchen.

Belyaev et al., A. (2021). VWS-Referenzmodellierung :

Exemplarische Modellierung einer fertigungstechnis-

chen Anlage mit AASX Package Explorer auf Basis

des VWS-Metamodells 2021. Technical report, Berlin.

Bundesministerium f

¨

ur Bildung und Forschung (BMBF)

(2019). BaSys 4.0 in der Anwendung - Verbundprojekt

OpenBasys 4.0.

Bundesministerium f

¨

ur Wirtschaft und Energie (BMWi)

(2020). Verwaltungsschale in der Praxis.

Cavalieri, S. and Salafia, M. G. (2020). Asset administration

shell for plc representation based on iec 61131–3. IEEE

Access, 8:142606–142621.

DIN e. V. (2020). DIN and DKE Roadmap - German Stan-

dardization Roadmap Industrie 4.0, Version 4. Techni-

cal report, Berlin.

Eclipse BaSyx Platform (2021). Ready-to-use compo-

nents and extendable software development kits (SDK).

https://www.eclipse.org/basyx/.

Eclipse BaSyx Wiki (2021). Accessing Asset Ad-

ministration Shells - AAS communication).

https://wiki.eclipse.org/BaSyx / Documentation /

AssetAdministrationShell.

Github Repository - AASX Package Explorer (2021).

A viewer / editor for the asset administration

shell. https://github.com/admin-shell-io/aasx-package-

explorer.

Grothoff, J. A. (2018). BaSys 4.0: Metamodell der Kom-

ponenten und Ihres Aufbaus; 1st ed. Technical report,

Aachen.

Koulamas, C. and Kalogeras, A. (2018). Cyber-physical

systems and digital twins in the industrial internet of

things [cyber-physical systems]. Computer, 51(11):95–

98.

Kuhn, T., Schnicke, F., and Oliveira Antonino, P. (2020).

Service-based architectures in production systems:

Challenges, solutions experiences. In 2020 ITU Kalei-

doscope: Industry-Driven Digital Transformation (ITU

K), pages 1–7.

Mu

ˇ

si

ˇ

c, G. (2015). A low-cost packml-based control solution

for a modular production line. IFAC-PapersOnLine.

Rayment, M. (2004). Flexible motion control using iec

61131-3. In 2004 Mini Symposia UKACC Control,

pages 27–36.

IN4PL 2021 - 2nd International Conference on Innovative Intelligent Industrial Production and Logistics

150