Parametric Analysis of Greenhouse Gas Emissions of the Technical

Building System Alternatives in Detached Houses Retrofitted to

nZEB Level

László Zsolt Gergely

a,*

, and Tamás Csoknyai

b

Budapest University of Technology and Economics, Faculty of Mechanical Engineering, Department of Building Services

and Process Engineering, Műegyetem rkp. 3, Budapest 1111, Hungary

Keywords: nZEB, Near zero energy buildings, Climate change, Carbon footprint, Heat pump, Total equivalent warming

impact

Abstract: Buildings account for a significant part of greenhouse gas emissions. A reasonable way of mitigation is the

retrofit of the building stock, both from the perspective of the building envelope and the technical building

system. However, to maximize carbon emission savings, effects of these two measures shall be observed hand

in hand. This paper approaches the issue through the possible renovation of the detached houses of the

Hungarian residential building stock to a nearly zero energy building (NZEB) level. Three system layouts,

namely air-to-water heat pumps, air-to-air heat pumps with electric boilers and gas condensing boilers are

compared in terms of greenhouse gas emissions while covering heating and domestic hot water demands.

Results reflect that heat pumps offer the possibility of a remarkable reduction of carbon-dioxide emissions

compared to condensing gas boilers in case of the present electricity mix of Hungary. Furthermore, it appears

that after the NZEB renovation, air-to-water heat pumps represent the best solution for detached houses. In

the meanwhile, air-to-air heat pumps with electric boilers could remain eco-friendly for applications with

relatively low hot water needs.

1 INTRODUCTION

Buildings account for a significant part of both

primary energy consumption and carbon emissions

worldwide (Mayer, Szilágyi, and Gróf 2020). As a

result, building sector is often prioritised in policies

aiming the reduction of energy consumption and

greenhouse gas emissions. Performance requirements

of building structures and technical building systems

are getting more and more strict, which in Europe can

be traced trough Nearly Zero Energy Building

(NZEB) requirements, targeting both minimizing the

energy consumption and enhancing the use of

renewable energy sources (Balint & Kazmi, 2019).

For the latter, heat pumps are often considered as a

widely available and effective solution of renewable

based technical building system (Marinelli et al.,

2019).

a

https://orcid.org/0000-0001-9365-211X

b

https://orcid.org/ 0000-0003-0327-0316

Nevertheless, there are other factors to consider

besides energy consumption to estimate greenhouse

gas emissions of a system. Several calculation

methods aim to include such indicators. In case of

heat pumps the Total Equivalent Warming Impact

(TEWI) is widely used (Mota-Babiloni et al., 2020).

Despite the fact that both NZEB regulations and

TEWI calculations are widely known, they are rarely

observed together. This paper introduces and

calculates parameters to define the best performing

technical building system out of three up-to-date

layouts, namely gas condensing boiler, air-to-water

heat pump (AWHP) and air-to-air (AA) heat pump

with electric boiler for hot water generation. Section

2 reveals the parameters of the study, and that of the

carbon footprints (CF) of the three technical building

systems. Section 3 first presents the emission

calculations of the different systems for the specific

cases, then reveals the certain parameters, where air-

source heat pump-based systems perform better than

Gergely, L. and Csoknyai, T.

Parametric Analysis of Greenhouse Gas Emissions of the Technical Building System Alternatives in Detached Houses Retrofitted to nZEB Level.

In Proceedings of the 7th International Conference on Water Resource and Environment (WRE 2021), pages 231-239

ISBN: 978-989-758-560-9; ISSN: 1755-1315

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

231

the gas condensing boiler system. This is continued

with contrasting the air-source heat pump-based

systems. Finally, section 4 concludes the results.

2 PARAMETERS OF THE STUDY

2.1 Buildings Under Study

From the perspective of greenhouse gas emission,

residential sector of buildings is often considered a

more significant emitter than commercial sector (Ge

& Friedrich, 2020). In this paper therefore we

approach the problem from the residential buildings’

perspective. Data of the Hungarian building stock

was used, containing 19 types of residential buildings

to describe the national typology (Tamas, 2013), out

of which 9 types of detached houses (each named by

the reference typology) were considered as potential

sites for heat pump application. In terms of

construction date, selected types fall in the period

from the 1950’s to today’s constructions. In case of

the newest types, the original construction itself

guarantees NZEB parameters, for the former ones

NZEB retrofit actions are considered.

In this paper by NZEB-level buildings we assume

buildings with a building shell fulfilling NZEB

requirements, not considering if they fulfil additional

requirements, such as overall energy performance and

renewable energy share.

Figure 1: Typical meteorological year of Budapest, Hungary, generated from the data of years 2007-2016 (Poggi et al., 2008).

2.1.1 Energy Needs and Heat Loads

Hungary, located in central Europe, has a temperate

seasonal climate. In these circumstances, the role of

the technical building system is usually to cover the

heating and domestic hot water needs of the houses.

Cooling needs are relatively low due to the climatic

characteristics and the national building code (TNM

7/2006 Decree) regarding NZEB buildings, aiming to

minimize or even exclude active cooling in case of

the residential sector, with proper building design

(Ministry Without Portfolio of Hungary, 2020).

Having a look at Figure 1, representing a typical

meteorological year (TMY) of Budapest (European

Commission, 2017), it is seen that for a significant

part of the year the average external temperature by

day is below under 12°C, which is usually considered

as the heating threshold temperature.

On the other hand, the number of days with the

average above 23°C (which is determined as a cooling

threshold temperature with a maximum internal

temperature of 26°C and subtracting the maximum

allowed overheating temperature difference of 3°C) is

much fewer. Considering occupancy schedule as well,

it is seen that the number of hours where the external

temperature is above 26°C in the period of 17:00 –

07:00 is only 18 hours a year. For the present study

cooling, therefore, is not considered.

The design heat load for heating is determined

according to the national building code (Ministry

Without Portfolio of Hungary, 2020), as well as the

net energy needs of heating and DHW production.

DHW net energy need is determined as 30

kWhth/m

2

year, therefore is the same before and after

the building reconstructions. On the contrary, net

energy needed for heating, calculated with an internal

temperature of 20°C, reduces significantly with

NZEB level refurbishment. For the various types of

buildings, decrease of the sum of the net energy needs

comes with different extent but in general for building

types 1-5, demand after reconstruction is

approximately the third to fourth of the original state,

while in case of types 6 and 7 it is 70%.

Table 2

reveals, that the extent of it is highly influenced by

‐10

‐5

0

5

10

15

20

25

30

1 21 41 61 81 101 121 141 161 181 201 221 241 261 281 301 321 341 361

Temperature[°C]

DayofTMY(2007‐2016)

Avg.externaltemperaturebyday 23°C 12°C

WRE 2021 - The International Conference on Water Resource and Environment

232

the ratio of 𝑄

and 𝑄

, as only the latter changes

by the retrofit.

2.2 Appliances

Two types of air-source heat pumps were considered

in the calculations, as their application comes with a

lower limit in terms of the source side, compared to

ground-source or water-source heat pumps. One type

is the air-to-water heat pump that itself can cover both

heating and DHW net energy needs.

The other air-source heat pump type is air-to-air

heat pump. For DHW generation electric boilers are

assumed. As a reference, emissions of gas condensing

boiler systems are calculated as well. Carbon

footprint of the listed systems are calculated in the

followings.

2.2.1 TEWI of Heat Pump Systems

For the heat pump systems, TEWI calculations are

used to approximate the greenhouse gas emissions for

the lifetime of the appliance. TEWI considers two

types of emissions. Direct emissions are related to the

refrigerant used in the heat pump (described with the

first two terms of equation 1), while indirect

emissions are corresponding to the electricity used by

the heat pump (described with the third term) (Mota-

Babiloni et al., 2020).

𝑇𝐸𝑊𝐼

𝐺𝑊𝑃 ∗ 𝑚 ∗ 𝐿

∗𝑛

𝐺𝑊𝑃 ∗ 𝑚 ∗

1𝛼

𝐸

∗𝛽

∗𝑛

(1)

In TEWI, 𝐺𝑊𝑃 stands for the Global Warming

Potential (kgCO

2

eq./kg), 𝑚 (kg) represents the mass

of the refrigerant charge. 𝐿

(% / year) is the

annual loss of refrigerant charge through leakages and

𝛼

(%) stands for the amount of charge that can be

potentially recovered at the end of life. Factor 𝑛

(years) appearing is the estimated lifespan of the heat

pump.

The indirect emissions part is characterised with

𝐸

(kWh

e

/year), annual electricity consumption,

multiplied with the lifespan and applying the carbon

intensity factor 𝛽

(kgCO

2

eq./kWh

e

) of the

electricity, that describes the greenhouse gas

emissions that the generation of 1 kWh

e

of power is

accounted for.

2.2.2 Parameters of TEWI Calculation

In practice, TEWI is calculated for the heat pump that

is subject of the specific calculation. However, to

draw conclusions about the emissions of the different

heat pump-based systems under various conditions,

generalization of these values is necessary. In case of

the refrigerant parameters, and therefore the GWP

value, it is reasonable to define a type of refrigerant

for the study that is widely used. For that reason,

refrigerant R32 is taken into consideration, with a

global warming potential of 675 kgCO2eq./kg (Choi

et al., 2017).

The mass of the charge, though, is also dependant

on the specification of the heat pump and is in

accordance with the capacity of the appliance.

Usually, the specific charge mass is between 0.24 – 1

kg/kW (Poggi et al., 2008). In the study, 0.3 kg/kW is

used, just as applied in (Johnson, 2011). Leakage

rates vary on a wide scale in different studies,

however it is believed that they have a modest effect

on the results (Johnson, 2011). In case of the annual

leakage rate the value is usually around 6% (Greening

& Azapagic, 2012; Johnson, 2011). For recovery rate

also many different values can be found in literature.

Calculations of this paper assume 80% of recovery

rate, which is quite general (Greening & Azapagic,

2012). The expected lifespan of the appliances in the

following calculations is 15 year (Mota-Babiloni et

al., 2020).

Carbon intensity factor in TEWI is an average

value for the electricity used throughout the lifetime.

However, when calculating in advance, only

estimations could be used. Though carbon intensity is

believed to continuously decrease in the future, in this

study, carbon intensity of the installation year is used

through the lifetime, to rather err on the side of

caution.

2.2.3 Energy Consumption of the Heat

Pumps

It is often highlighted that the dominating part of

greenhouse gas emissions is the indirect part of

TEWI, energy consumption related parameters

(Greening & Azapagic, 2012; Mota-Babiloni et al.,

2020). Annual electricity consumption of this term

can be determined various ways. The most precise

would be measuring the consumption, however the

carbon emission estimation is carried out in advance,

therefore it is not possible in our case. Another option

could be a detailed dynamic modelling of the heat

pumps’ performance for the specific cases, which is

resource and time demanding. A simpler, though for

Parametric Analysis of Greenhouse Gas Emissions of the Technical Building System Alternatives in Detached Houses Retrofitted to nZEB

Level

233

annual calculations still sufficiently appropriate

option is estimating the consumptions with the

Seasonal Coefficient of Performance (SCOP) of the

heat pumps (Huang & Mauerhofer, 2016), that is

applied further on in the paper. 𝐸

is therefore

determined as the ratio of the net energy need of

heating (𝑄

), net energy need of DHW production

(𝑄

) and the specific SCOP.

In case of the AWHP this approach is used for

estimating the electricity consumption of heating and

DHW production, and in case of air-to-air heat pump

to determine electricity consumption of heating.

SCOP values are considered according to the guide of

the Danish Energy Agency for these cases

(Energistyrelsen, 2018).

In case of the air-to-water heat pump, the annual

energy consumption 𝐸

,

appears as:

𝐸

,

𝑄

𝑆𝐶𝑂𝑃

,

𝑄

𝑆𝐶𝑂𝑃

,

(2)

where 𝑆𝐶𝑂𝑃

,

stands for the seasonal coefficient

of performance of heating with AWHP and similarly,

𝑆𝐶𝑂𝑃

,

is for the characterization of the

efficiency of DHW production with AWHP.

Electricity consumption of heating with air-to-air heat

pump, 𝐸

,

is expressed with the denominator of

𝑆𝐶𝑂𝑃

,

that stands for the seasonal coefficient of

performance of heating. The electricity consumption

of DHW production in case of an electric boiler (EB)

is estimated similarly, with using of the efficiency of

the boiler, η

that is considered 100% in the

calculations. The annual electricity consumption of

the air-to-air heat pump-based system is denoted with

𝐸

,

𝐸

,

.

𝐸

,

𝐸

,

𝑄

𝑆𝐶𝑂𝑃

,

𝑄

η

(3)

The carbon intensity factor also has a high impact

on the results. For this reason, this value should

consider future trends in power generation and

geographic location. In this study, yearly averages of

the present (the same as for the year 2020), 2030 and

2050 electricity mix are considered for the Hungarian

electricity grid (Kiss, Kácsor, and Szalay 2020).

2.2.4 Carbon Footprint of the ASHP-based

Systems

Knowing the energy consumption of the ASHP based

systems, CF of the systems can be expressed. In case

of air-to-water heat pump TEWI and the carbon

footprint of the system equal:

𝐶𝐹

𝑇𝐸𝑊𝐼

𝐺𝑊𝑃 ∗ 𝑚 ∗ 𝐿

∗𝑛

𝐺𝑊𝑃 ∗ 𝑚 ∗

1𝛼

𝐸

,

∗𝛽

∗𝑛

(4)

For further calculations notation 𝐷 is introduced

for the direct emission part.

𝐶𝐹

𝐷

𝐸

,

∗𝛽

∗𝑛

In case of the air-to-air heat pump-based system,

TEWI, however, would only represent the emissions

related to heating with the air-to-air heat pump, but

not the DHW generation with the electric boiler. For

that reason, GHG emission of the electric boiler is

approximated with the electricity consumption of the

boiler and the carbon intensity factor of the grid.

Production phase is neglected (just like in TEWI in

case of the heat pumps). As a result, CF of this system

can be expressed as:

𝐶𝐹

&

𝐷

𝐸

,

𝐸

,

∗𝛽

∗𝑛

(5)

Assuming the same leakage rates, charge capacity

and refrigerant type, direct emissions ( 𝐷 of the

different heat pump systems are considered equal.

2.2.5 Gas Condensing Boiler Emissions

Emissions of the condensing boiler are used as a

reference case, to allow distinguishing the effect of

the NZEB construction and the selection of heat

pumps for technical building system. Greenhouse gas

emissions of the gas condensing boiler system are

calculated with the help of Ecoinvent database, that is

a widely used database for LCAs (Ecoinvent, 2014).

Based on that, a carbon intensity factor, 𝛽

is

introduced to determine the carbon emissions of the

natural gas condensing boiler as

𝐶𝐹

𝛽

∗𝐸

,

∗𝑛

(6)

where 𝐶𝐹

(kgCO2eq) refers to the carbon footprint

of the heat generation with gas condensing boiler,

𝐸

,

is the final energy consumption of the gas

condensing boiler, which, similarly to the other

appliances is the sum of energy needed for heating

and DHW production divided by the efficiency of the

boiler, η

, that is considered 95% in the

calculations

.

WRE 2021 - The International Conference on Water Resource and Environment

234

2.2.6 Sizing the Appliances

As greenhouse gas emissions are dependent on the

size of the heat pump (through the introduced scaling

factor for the refrigerant charge amount), capacity of

the different appliances should be determined. In our

research we assumed the capacity of the heat pumps

according to the heat load of the analysed buildings.

In case of the AWHP it is presumed that this

capacity is sufficient for covering the DHW needs as

well. When electric boiler is used for DHW

generation, the capacity of the equipment is irrelevant,

as in this case, only electricity used has impact on

carbon emissions, production of the equipment is

excluded from CF calculation (as suggested in section

2.2.4,). sums up all the parameters of the technical

building systems used in the study.

Table 1: Values used is Carbon Footprint calculations of the technical building system.

3 RESULTS AND DISCUSSION

3.1 Carbon Emissions for the Different

Technical Building Systems

In case of the gas condensing boiler system, carbon

dioxide emissions are directly proportional to the

energy needs of the specific cases, as heating and

DHW production are not distinguished from this

perspective (equation 6). It provides a representation

of a technical building system that is though up-to-

date, comes with a limit in terms of reducing GHG

emissions as lacks the integration of renewable

energy sources.

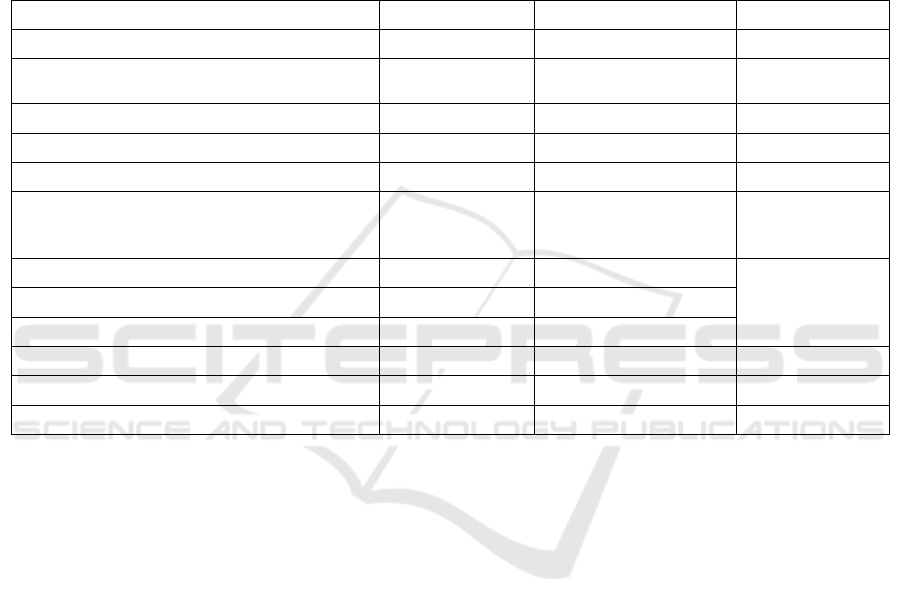

In Figure 2, it is recognisable, that the gas boiler

system represents larger emissions than the ASHP

based systems, even with the electricity mix of 0.1234

kgCO2eq./kWh

e

, that is suggested by a study as the

carbon intensity factor of the 2020 electricity mix of

Hungary (Kiss, Kácsor, and Szalay 2020).

It is also notable that the amount of carbon

emissions saved with NZEB reconstruction of the

buildings and of the technical building systems with

ASHPs is the same orders of magnitude (applying the

2020 electricity mix).

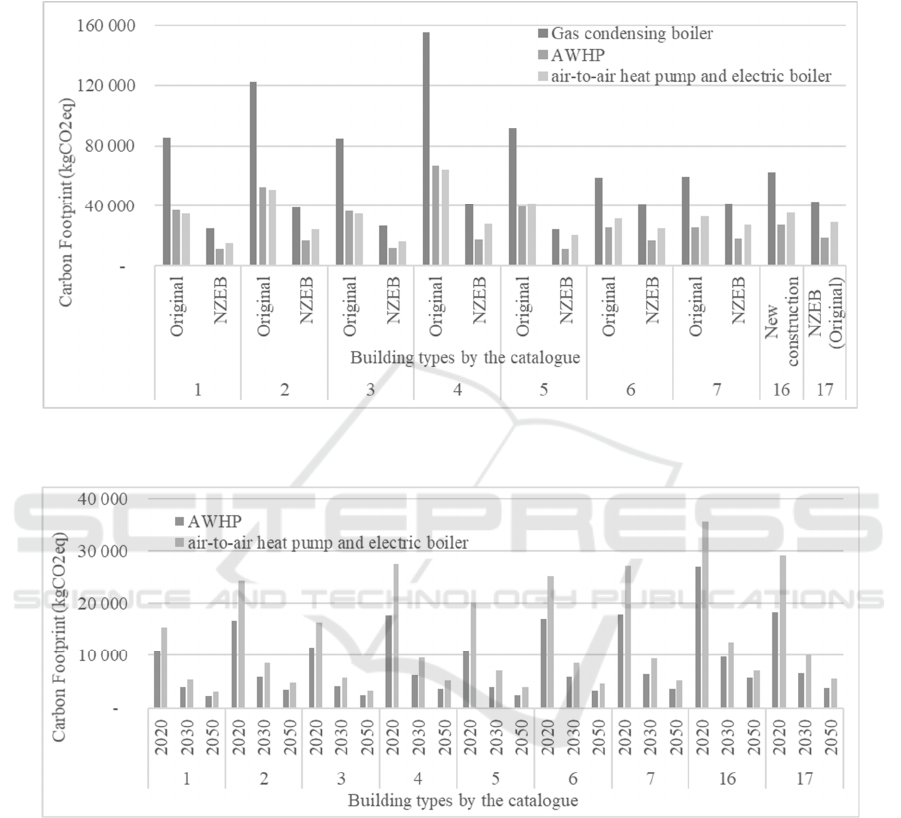

Potential emission savings, however, are pushed

even further with the future electricity mixes of 2030

and 2050 as seen in Figure 3. As more and more

renewables are foreseen to be integrated in power

production, carbon intensity factor of the power grid

𝛽

gradually reduces from 0.3769 kgCO

2

eq./kWh

e

of 2020 to somewhere around 0.1234 and 0.0637

kgCO

2

eq./kWh

e

by the years 2030 and 2050

respectively, as a study reveals (Kiss, Kácsor, and

Szalay 2020).

3.2 Determining the Best Performing

Equipment for an Application

Carbon intensity factor of the electricity consumed by

the appliances is an important factor of GHG

Name Symbol Value Unit

Global Warming Potential of refrigerant R32 𝐺𝑊𝑃 675 kgCO

2

eq./kg

mass of refrigerant charge 𝑚

0.3 kg/kW * capacity of

the ASHP

kg

annual leakage rate of charge 𝐿

6 %/year

estimated lifespan 𝑛 15 years

recovered refrigerant amount at end-of-life 𝛼

80 %

carbon intensity factor of the Hungarian power

grid for 2020, 2030 and 2050 respectively

𝛽

0.3769

0.1234

0.0637

kgCO

2

eq./kWh

e

SCOP of air-to-water HP, DHW production 𝑆𝐶𝑂𝑃

,

3.35

kW/kW

SCOP of air-to-water HP, heat production 𝑆𝐶𝑂𝑃

,

3.55

SCOP of air-to-air HP, heat production 𝑆𝐶𝑂𝑃

,

4.9

natural gas burning factor 𝛽

248.6 gCO

2

/kWh

th

gas-condensing boiler efficiency

η

95 %

electric boiler efficiency

η

100 %

Parametric Analysis of Greenhouse Gas Emissions of the Technical Building System Alternatives in Detached Houses Retrofitted to nZEB

Level

235

emissions and as a result also plays a decisive role

when it comes to the selection of the system with the

lowest carbon equivalent. Noting that ASHP systems

appeared with less carbon emissions for all the cases,

brings up the question of the conditions where

condensing gas boiler technology could result better

emission values.

Figure 2: Carbon Footprint of the different technical building systems of the Hungarian detached houses, before and after

NZEB-level reconstruction, considering the 2020 carbon intensity factor for the lifetime.

Figure 3: Carbon Footprint of the ASHP based technical building systems of the Hungarian detached houses after NZEB-

level reconstruction, considering the 2020, 2030 and 2050 carbon intensity factors.

3.2.1 Comparing ASHP Systems with Gas

Condensing Boilers

Both ASHP based technologies are compared with

the gas condensing boiler system. For that, equations

(4,5,6) describing the CF of the different systems are

examined. Comparing the ASHP based systems with

the condensing boiler system it is remarkable, that

from the perspective of the equipment only the carbon

intensity factor 𝛽

represents a variable as other

values are set by the specifications of the appliances (

and the energy needs of the cases (Table 2). This

allows to express the equations to the carbon intensity

factor, that represents a threshold for the ASHP based

technical building systems, when compared to the gas

condensing boilers. Carbon intensity values above

this threshold would mean that gas condensing boilers

are preferred, below this carbon intensity ASHP

based systems would result less carbon dioxide

emissions for the lifetime of the technical building

WRE 2021 - The International Conference on Water Resource and Environment

236

system. Mathematically, this is expressed with

equality between (4) and (6), rearranged to express

the carbon intensity, that comes as follows:

𝛽

,,

𝛽

∗𝐸

,

∗𝑛𝐷

∗

1

𝐸

,

∗𝑛

(7)

where 𝛽

,,

represents the carbon intensity which

would result the same carbon-dioxide emissions for

the AWHP system and the gas condensing boiler

system. For the 9 building types observed, this

𝛽

,,

varies around the value of 0.9

kgCO2eq./kWh

e

, seen in Table 2. As the carbon

intensity of the Hungarian electricity mix is notably

lower than this, AWHP provides a better choice than

gas condensing boiler for all the observed residential

detached houses.

The case of air-to-air heat pump-based system is

similar. Direct emission part of TEWI equals with the

AWHP system’s. However, the indirect part differs as

electricity consumption of the air-to-air heat pump

and of the electric boiler are both included. Carbon

intensity factor to decide whether condensing boiler

or air-to-air heat pump, combined with electric boiler

performs better is expressed as follows (after

rearranging the equality of (5) and (6)).

𝛽

,

&

,

𝛽

∗𝐸

,

∗𝑛𝐷

𝐸

,

𝐸

,

∗𝑛

(8)

𝛽

,&,

values appear on a much wider range

than that of 𝛽

,,

, from 0.963 kgCO2eq./kWh

e

to

as low as 0.462 kgCO2eq./kWh

e

, for types 1 and 7

respectively (seen in Table 2).

As only energy consumption of the appliances

change, compared to the previous case, the reason for

the alteration of the values has to be in reliance with

that. It is notable, that the greater the ratio of the net

energy demand of DHW production 𝑄

and

heating 𝑄

is, the higher the emissions of the

ASHP based systems will be, as DHW production

comes with lower efficiency for both ASHP based

systems. Furthermore, in case of the electric boiler,

the efficiency of DHW generation ( η

is

significantly lower compared to the heat generation

with heat pump ( 𝑆𝐶𝑂𝑃

,

, resulting larger

alterations in 𝛽

,&,

.

This also explains why 𝛽

,,

varies in a

remarkably more moderate range. Seasonal

coefficient of performance of DHW production

(𝑆𝐶𝑂𝑃

,

) and space heating (𝑆𝐶𝑂𝑃

,

comes

with notably lower difference for that case.

Table 2 sums up the different carbon intensity

thresholds for the examined cases of the Hungarian

residential building stock. If the carbon intensity is

below the threshold of 𝛽

,,

and 𝛽

,&,

of

the specific cases, ASHP-based systems offer a more

favourable way of heating and domestic hot water

production, from the perspective of carbon emissions.

On the contrary, if carbon intensity factor exceeds

these thresholds, then condensing boilers are the

preferable.

Table 2: Carbon intensity limits and net energy need ratios for the different detached houses of the Hungarian building

typology with the 2020 carbon intensity.

Building type 1 2 3 4

Original NZEB Original NZEB Original NZEB Original NZEB

Heat load kW 8.97 2.35 12.13 3.37 8.87 2.41 15.96 3.17

Q

H

kWh

th

/year 20 132 4 707 28 433 7 116 19 780 5 007 36 282 7 148

Q

DHW

kWh

th

/year 1 680 1 680 2 727 2 727 1 782 1 782 3 294 3 294

𝛽

,

,

kgCO

2

eq./kWh

e

0.903 0.896 0.904 0.896 0.903 0.896 0.903 0.896

𝛽

,

&

,

kgCO

2

eq./kWh

e

0.963 0.620 0.935 0.604 0.947 0.621 0.946 0.565

Q

DHW

/Q

H

limit [-] 0.111

Q

DHW

/Q

H

[-] 0.083 0.357 0.096 0.383 0.090 0.356 0.091 0.461

Building type 5 6 7 16 17

Original NZEB Original NZEB Original NZEB New constr. NZEB

Heat load kW 9.06 2.70 6.14 2.08 5.84 3.36 5.98 3.35

Q

H

kWh

th

/year 20 702 3 529 12 144 7 405 12 028 7 409 12 431 7 378

Q

DHW

kWh

th

/year 2 748 2 748 2 853 2 853 3 174 3 174 3 525 3 525

𝛽

,

,

kgCO

2

eq./kWh

e

0.902 0.883 0.897 0.903 0.898 0.896 0.897 0.896

𝛽

,

&

,

kgCO

2

eq./kWh

e

0.861 0.462 0.719 0.608 0.691 0.580 0.674 0.557

Q

DHW

/Q

H

limit [-] 0.111

Q

DHW

/Q

H

[-] 0.133 0.779 0.235 0.385 0.264 0.428 0.284 0.478

Parametric Analysis of Greenhouse Gas Emissions of the Technical Building System Alternatives in Detached Houses Retrofitted to nZEB

Level

237

3.2.2 Selection between ASHP based

Systems

Comparing the ASHP based systems in Figure 2,

reveals that in most of the cases AWHP guarantees

better results. Although, there are certain conditions

where air-to-air heat pump with the electric boiler

prove to result lower emissions. It is notable that it

only appears for the original state and never for the

NZEB option. In case of these examples (building

types 1-4) the NZEB option leads to a technological

shift in the terms of the system with the lowest CF.

The equations only differ in the amount energy

consumed (as a result of the different efficiencies of

the specific equipment used). As for the observance,

the equality of CF of the ASHP based systems is

expressed for the ratio of the net energy needs (9).

This therefore defines the circumstances that results

in equal emissions for the systems. Above this ratio,

AWHP performs better as a result of more efficient

DHW production, below this ratio higher SCOP of

air-to-air heat pump makes the latter system a more

favourable choice.

𝑸

𝑫𝑯𝑾

𝑸

𝑯

𝑺𝑪𝑶𝑷

𝑯,𝑨𝑨

𝑺𝑪𝑶𝑷

𝑯,𝑨𝑾

𝑺𝑪𝑶𝑷

𝑯,𝑨𝑨

∗𝑺𝑪𝑶𝑷

𝑯,𝑨𝑾

∗

𝑺𝑪𝑶𝑷

𝑫𝑯𝑾,𝑨𝑾

∗

𝛈

𝒆𝒃

𝑺𝑪𝑶𝑷

𝑫𝑯𝑾

,

𝑨𝑾

𝛈

𝒆𝒃

(9)

The present efficiency values result in a ratio of

approximately 0.11 [-] of DHW net energy need and

the net energy needed for space heating (SH). For

building types 1-4 the same ratios are remarkably

lower for the original state, represented in Table 2,

which can be explained with the significant decrease

of space heating demand as a result of the NZEB

retrofit, while the DHW demand remains the same.

As seen, the ratio of the net energy consumption

(of types 1-4) prior to the renovation is below the

threshold limit of 0.11, while after the renovation is

above. This explains why air-to-air heat pumps with

electric boilers emit less carbon dioxide before the

retrofit, and AWHPs after the NZEB retrofit. The

technological swift can be traced in Figure 2.

4 CONCLUSIONS AND

OUTLOOK

In this paper three technical building systems were

compared to reveal the conditions where a specific

system could minimize carbon dioxide emissions.

Comparison of carbon footprints justified that heat

pump-based systems could provide lower emissions

compared to gas condensing boiler system. However,

there could be certain applications, with high carbon

intensity factors, where the latter is still preferable. In

comparison with AWHP, this limit is high, about 0.9

kgCO2eq./kWh

e

. Comparing with air-to-air heat

pump and electric boiler, the limit could appear even

as low as 0.462 kgCO2eq./kWh

e

in case of the

Hungarian residential building stock. The

significance of the DHW-to-SH demand ratio of the

houses is also highlighted when heat pump-based

building technical systems are compared to

condensing boiler technology.

When comparing the air-source heat pump-based

systems it can be concluded that in contrast only the

DHW-to-SH demand ratio matters. The threshold of

this net energy need

ratio is low, around 0.11,

meaning that for residential NZEBs air-to-water heat

pumps are more favourable. Nevertheless, under

certain circumstances, for instance in case of building

functions with low domestic hot water

demand,

resulting in a lower ratio, air-to-air heat pumps with

electric boilers could be preferable.

Results of the study could be essential for

environmentally conscious decision-making in

legislation on a building cluster level. However, it

should be highlighted that the presence of significant

cooling needs could modify the threshold of the net

energy ratios, therefore further research is needed to

extend the parameters with the presence of cooling

needs.

ACKNOWLEDGEMENTS

The work has been carried out at BME within the

research project entitled “Large Scale Smart Meter

Data Assessment for Energy Benchmarking and

Occupant Behavior Profile Development of Building

Clusters”. The project (no. K 128199) has been

implemented with the support provided from the

National Research, Development and Innovation

Fund of Hungary, financed under the K_18 funding

scheme.

The research has also been supported by the NRDI

Fund (TKP2020 IES, Grant No. BME-IE-MI) based

on the charter of bolster issued by the NRDI Office

under the auspices of the Ministry for Innovation and

Technology.

WRE 2021 - The International Conference on Water Resource and Environment

238

REFERENCES

Balint, A., & Kazmi, H. (2019). Determinants of Energy

Flexibility in Residential Hot Water Systems. Energy

and Buildings, 188–189, 286–96.

Choi, S. Y., Oh, J. W., Hwang, Y. H., & Lee, H. S. (2017).

Life Cycle Climate Performance Evaluation (LCCP) on

Cooling and Heating Systems in South Korea. Applied

Thermal Engineering, 120, 88–98.

Ecoinvent. (2014). Ecoinvent 3.4. www.ecoinvent.com.

Energistyrelsen. (2018). Technology Data for Heating

Installations.

European Commission. (2017). JRC Photovoltaic

Geographical Information System (PVGIS) - European

Commission. Photovoltaic Geographical Information

System: 1.

https://re.jrc.ec.europa.eu/pvg_tools/en/tools.html#PV

P.

Ge, M. P., & Friedrich, J. (2020). Greenhouse Gas

Emissions by Countries and Sectors. World Resources

Institute, 2–11.

Greening, B., & Azapagic, A. (2012). Domestic Heat

Pumps: Life Cycle Environmental Impacts and

Potential Implications for the UK. Energy, 39(1), 205–

17.

Huang, B. J., & Mauerhofer, V. (2016). Life Cycle

Sustainability Assessment of Ground Source Heat

Pump in Shanghai, China. Journal of Cleaner

Production, 119, 207–14.

Johnson, E. P. (2011). Air-Source Heat Pump Carbon

Footprints: HFC Impacts and Comparison to Other

Heat Sources. Energy Policy, 39(3), 1369–81.

Kiss, B., Kácsor, E., & Szalay, Z. (2020). Environmental

Assessment of Future Electricity Mix – Linking an

Hourly Economic Model with LCA. Journal of Cleaner

Production, 264, 121536.

Marinelli, S., Lolli, F., Gamberini, R., & Rimin, B. (2019).

Life Cycle Thinking (LCT) Applied to Residential Heat

Pump Systems: A Critical Review. Energy and

Buildings, 185, 210–23.

Mayer, M. J., Szilágyi, A., & Gróf, G. (2020).

Environmental and Economic Multi-Objective

Optimization of a Household Level Hybrid Renewable

Energy System by Genetic Algorithm. Applied Energy,

269(May), 115058.

Ministry Without Portfolio of Hungary. (2020). Regulation

7/2006 Determining the Energy Performance of

Buildings.

Mota-Babiloni, A., Barbosa, J. R., Makhnatch, P., &

Lozano, J. A., (2020). Assessment of the Utilization of

Equivalent Warming Impact Metrics in Refrigeration,

Air Conditioning and Heat Pump Systems. Renewable

and Sustainable Energy Review, 129, 109929.

Poggi, F., Macchi-Tejeda, H. Leducq, D., & Bontemps. A.

(2008). Refrigerant Charge in Refrigerating Systems

and Strategies of Charge Reduction. International

Journal of Refrigeration, 31(3), 353–70.

Tamas, C. (2013). Building Typology for Energy Modelling

of the Domestic Housing Stock of Hungary.

Parametric Analysis of Greenhouse Gas Emissions of the Technical Building System Alternatives in Detached Houses Retrofitted to nZEB

Level

239