Incentive-driven Safety Performance Appraisal Strength of

Municipal New-energy Industry

Junan Ruan

1a

, Mengqiang Duan

2b

and Yuan Gao

2c

1

Hangzhou City Water Facilities and River Protection Management Center, Hangzhou, China, Hangzhou 310012, China

2

Huadong Engineering Corporation Limited, Hangzhou 311100, China

Keywords: Incentive Model, Safety Performance, Incentive Strength, Comparative Study.

Abstract: Performance management and appraisal is an important part of enterprise safety management system. This

article takes typical companies in the municipal new-energy industry as representatives, and conducts

statistics and analysis on how to evaluate the strength of safety performance management or incentives-based

incentive model. Through a comparative study of negative incentives of resulting performance indicators in

single municipal new-energy industry as well as varied industries including construction engineering and

metallurgy, the paper summarizes the characteristics of performance appraisal strength in enterprises from the

three industries. The statistical and analysis results are able to provide a reference for the implementation of

reward and punishment measures, which may further enhance the safety awareness of employees at all levels

of the municipal new-energy industry, and also raise a useful guide for companies to improve safety

management.

1 INTRODUCTION

Incentive is a process in which the organization

stimulates, guides, maintains and standardizes the

behavior of the members by means of communication

through appropriate reward forms as well as certain

codes of conduct and punitive measures with the aim

of achieving the established goals of the organization

and the individual (Wang 2013). Incentive measures

are generally divided into two types. One is positive

incentive measures, including honor incentive, goal

incentive, demonstration incentive, material

incentive. The other is negative incentive, which is

mainly to give warning, economic punishment,

demotion, dismissal, probation, dismissal and other

penalties to employees or departments who commit

mistakes, violate enterprise rules and regulations,

delay work, damage equipment and facilities, cause

economic losses to the enterprise and damage the

reputation of the enterprise.

Safety incentive refers to the management of

safety production for enterprise organizations and

individuals through incentive theory to improve the

a

https://orcid.org/0000-0002-9038-6618

b

https://orcid.org/0000-0003-3386-8757

c

https://orcid.org/0000-0002-2929-4693

overall safety level of the enterprise. In the work of

safety production and disaster prevention, the

establishment of incentive mechanism for personnel

and departments at all levels has become one of the

most direct and effective methods of safety

management (Gao 2018). At present, the commonly

used safety incentive theories mainly include X-Y

theory and two-factor theory, and the detailed

description of the basic ideas of the two theories is

shown in Figure 1.

Figure 1: Theory of safety incentive.

In modern enterprise production process, safety

incentive has become fully mobilize employees to the

96

Ruan, J., Duan, M. and Gao, Y.

Incentive-driven Safety Performance Appraisal Strength of Municipal New-energy Industry.

DOI: 10.5220/0011162400003437

In Proceedings of the 1st International Conference on Public Management and Big Data Analysis (PMBDA 2021), pages 96-100

ISBN: 978-989-758-589-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

core of production safety measures. In the process of

municipal new-energy safety, fully motivated

employees attach great attention to safety problems

and have much interest in seeking solutions. From the

safety production results, the frequency and severity

of accidents in companies with better implementation

of safety incentives are highly reduced. To sum up,

the role of safety incentive in enterprises is four

aspects (Duan 2007).

In order to achieve safe production of municipal

new-energy engineering project with high quality,

enterprises must have a clear driving force and

constraints. To realize this, we always need to

introduce incentive mechanism to fully arouse the

enthusiasm and subjective initiative of each

production safety practitioners, that is, motivating

employees to do a good job of safety by means of

economic and administrative strategies. In this

respect, the realization of the goal for safe production

is closely related to each person's economic interests.

For those who has achieve the target, they will get

some rewards. While for those who fails to reach the

target, they will definitely get a punishment. In this

way, incentive intensity, indicating the strength of

safety performance appraisal, is highly vital for

bringing about safety behaviors consistent with the

safety production goal pursued by the enterprise

(Zhang 2015). Thus, in this work, a novel method is

raised based on motivation theory to measure the

safety performance appraisal strength, which is aimed

at helping to promote safety management and stay

away from disasters throughout the new-energy

enterprise.

2 SAFETY PERFORMANCE

ASSESSMENT SYSTEM AND

INCENTIVE INTENSITY

DIVISION

2.1 Concept

Safety performance assessment refers to using

scientific standards, methods and procedures to

evaluate the behaviours, achievements and final

actual performance of the organization, department or

staff as accurately as possible. There are four basic

performance appraisal methods, namely key

performance indicators, balanced scorecard, 360-

degree performance appraisal and management by

objectives. According to relevant literature review

(Hu 2008), this paper defines safety performance as

the combination of safety construction state and the

final consequences of safety accidents. The

comprehensive results of contents of the above two

can more completely and accurately reflect the state

of enterprise safety performance.

2.2 Safety Performance Appraisal

System

To adopt scientific and reasonable evaluation

methods to more accurately evaluate the safety

performance of different enterprises, it is necessary to

start from the process of safety production and the

consequences of accidents. In the whole evaluation

process, the safety of municipal new-energy

engineering projects is the key point emphasized by

the enterprise. Reasonable design, control and

adjustment of the safety production process are

necessary means of realization. Enterprise safety

performance assessment is a complete operation

process, which generally should include five

procedures, that is, the establishment of enterprise

safety objectives and indicators, the determination of

index weight, safety production performance

evaluation, and the feedback of assessment results.

When the process of safety performance assessment

of an enterprise is completed, it will proceed to the

establishment and determination of enterprise

objectives in the next stage, thus forming an

assessment cycle (Duan and Chen 2010).

Based on the idea of strengthen source prevention,

pay attention to process management and give

consideration to result control, it makes the scope and

nature of enterprise safety production management

work more clear, so that enterprises are able to take

corresponding measures to prevent the occurrence of

accidents and ensure the safety production (Sun

2019). Considering the authority and universality of

accident classification in China, we take the accident

occurrence degrees (ordinary accident, larger

accident, major accident and extraordinarily serious

accident), which belongs to the category of result

control, as indicator of safety performance evaluation

in this paper, as shown in Table 1.

Incentive-driven Safety Performance Appraisal Strength of Municipal New-energy Industry

97

Table 1: Accident classification.

Degree Classification Standard

Extraordinarily

serious

accident

(ESA)

More than 30 deaths, or more

than 100 serious injuries, or more

than 100 million yuan of direct

economic loss

Major accident

(MA)

10-30 deaths, or 50-100 serious

injuries, or 50-100 million yuan of

direct economic loss

Larger

accident (LA)

3-10 deaths, or 10-50 serious

injuries, or 10-50 million yuan of

direct economic loss

Ordinary

accident (OA)

Less than 3 deaths, or less than

10 serious injuries, or less than 1000

million yuan of direct economic loss

2.3 Incentive Intensity Division

According to the model of incentive theory put

forward by the famous North American psychologist

and behavioral scientist Victor Froom in <Work and

Incentive> in 1964, we can effectively quantify the

incentives within the enterprise:

Incentive force = Expected value × Valence (1)

Expected value can be understood as a tendency

of an organization or an individual to achieve a goal,

that is, an expectation level for different degrees of

accidents in safety management. Valence indicates

the satisfaction of individual for achieving goals.

During typical safety work, valence means incentive

measures (economic and administrative incentives).

Through the intuitive assignment calculation of these

two concepts, we would have a straightforward

understanding of incentive intensity. Combining with

the research content of this article, we set the

expected value of the formula to be negative, that is,

the expected level of avoiding different degrees of

accidents. While for valence, we decide to calculate it

using the weight integration with negative incentive

means prescribed by the enterprise.

Specifically, we have to determine the degree of

accidents first according to the number of deaths and

economic losses. In order to make the final results

more intuitive, the grading method is adopted to

assign the score of each accident. The accident degree

rating table is shown below.

Table 2: Rating rule for accident degrees.

De

g

ree Score

Extraordinarily serious accident (ESA)

8

Major accident (MA)

4

Larger accident (LA)

2

Ordinary accident (OA)

1

After determining the degree of the accident, we

need to conduct a further quantitative analysis of the

negative incentive by the incentive mechanism after

accident, which makes the final summary and

comparative analysis clearer. To unify the process of

negative incentive evaluation, this paper scores the

level of punishment measures of different enterprises

in the municipal new-energy industry and other

mainstream industries. Based on the punishment

measure level, the score from light to heavy can be

assigned with 1 to 10, in which 1 represents the

lightest punishment measure while 10 denotes the

heaviest one. The grading standard of punishment is

shown in Table 3.

Table 3: Rating rule for punishment measures.

Form of

Punishment

Punishment Measures Score

Economic

punishment

10000-20000 yuan

3

20000-40000 yuan

5

More than 40000 yuan

7

Administrative

punishment

Warning

1

Demerit recording

2

Major demerit recording

3

Demotion

5

Dismissal

7

Expulsion

9

In order to facilitate the comparison and statement

of the calculated incentive intensity, we define the

value of incentive force with the corresponding level

after expert brainstorming and the investigation of

employees in the enterprise.

3 SAFETY PERFORMANCE

APPRAISAL STRENGTH IN

DIFFERENT INDUSTRIES

3.1 Safety Performance Appraisal

Strength in Municipal New-energy

Industry

Municipal new-energy enterprises are different from

general production enterprises. They have the

characteristics of large investment, long cycle and

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

98

high professional integration. To get rid of

backward management system and implement correct

strategies, it is necessary for municipal new-energy

enterprises to establish their own performance

assessment system (Zou 2016). Under this

circumstance, we scored the both economic and

administrative punishments of domestic mainstream

municipal new-energy enterprises A, B, C and D, and

weighted the average according to the equally

important weights. The average score is exactly

regarded as the valence. After multiplying the

expected value and valence, the final scores of

incentive force (incentive intensity) are obtained and

shown in Table 4.

Table 4: Safety performance appraisal strength in municipal new-energy industry.

Object of

Punishment

Enterprises

Accident Classification

OA LA MA ESA

Person mainly

responsible for the

accident

A 4.75

11

32

68

B 5

13

30

64

C 5

11

32

68

D 4.5

13

32

68

Average 4.8125

12

31.5

67

Secondary person

responsible for the

accident

A 4

10

32

64

B 4

11

30

60

C 4.5

10

28

60

D 4.5

11

30

68

Average 4.25

10.5

30

63

Head of

department

responsible for the

accident

A 4

10

24

64

B 3.5

12

26

60

C 4

8

22

52

D 3.5

10

26

64

Average 3.75

10

24.5

60

Principal of the

enterprise

A 3.5

10

22

52

B 3.5

11

28

64

C 2.5

5

20

40

D 3

8

22

44

Average 3.125 8.5

23

50

From the results above, it can be seen that among

the negative incentives for the main responsible

person, secondary responsible person and department

responsible person of the accident, the incentive force

of enterprise D is relatively large compared with the

other three enterprises. Among the negative

incentives for main responsible persons (principal),

enterprise B has the largest incentive force. After the

accident, the municipal new-energy industry has

different motivation for different responsible people,

in which the order from large to small: the main

responsible person of the accident, the secondary

responsible person of the accident, the head of the

department responsible for the accident, principal of

the enterprise (project).

3.2 Safety Performance Appraisal

Strength in Varied Industries

In order to better provide suggestions and ideas for

the establishment of safety performance incentive

mechanism for enterprises in municipal new-energy

industry, we select enterprises which are

representative in metallurgical and construction

industries in China to further conduct comparative

analysis of incentive intensity. The numerical results

of safety performance appraisal strength are shown in

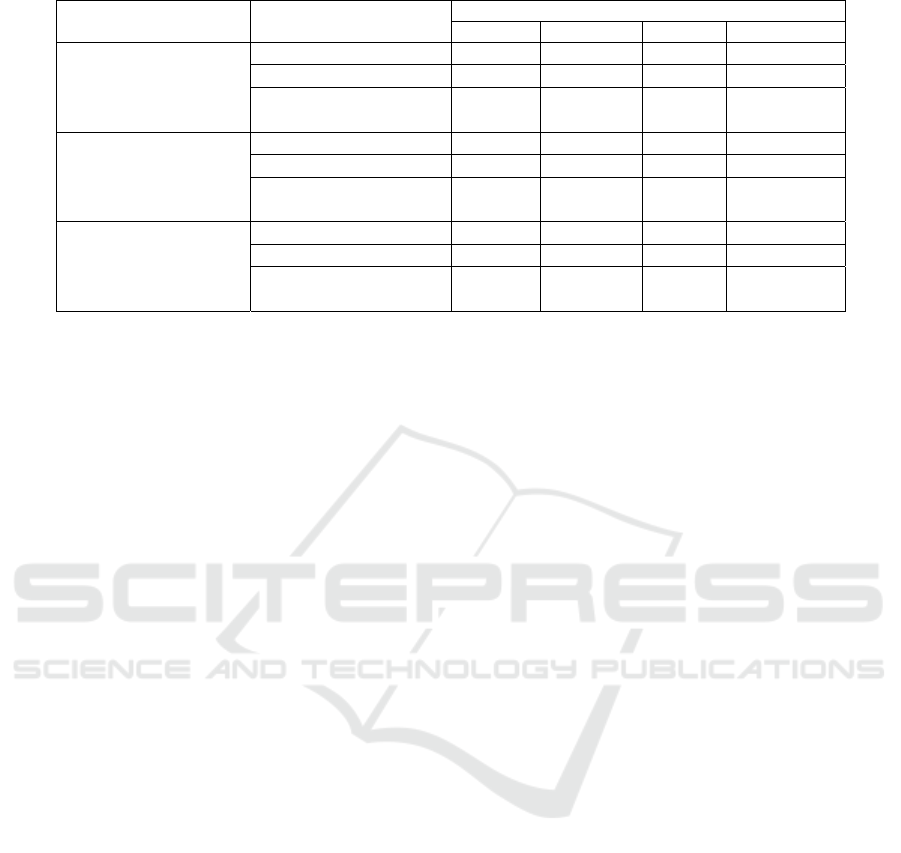

Table 5.

As can be seen from the above data, in OAs and

LAs, the incentive force of metallurgy industry and

construction industry to different responsible persons

is obviously greater than that of municipal new-

energy industry, but all of them has a same ordinary

incentive level. Thus, taking the analysis as a key

reference, municipal new-energy enterprises should

increase the level of economic and administrative

punishments for varied responsible persons with

respect to ordinary and larger accidents while

reducing the expectation of accident occurrence, so as

to arouse the crisis awareness of principals for

continuously improving the enterprise safety

performance.

Incentive-driven Safety Performance Appraisal Strength of Municipal New-energy Industry

99

Table 5: Safety performance appraisal strength in varied industries.

Object of Punishment Industries

Accident Classification

OA LA MA ESA

Person mainly

responsible for the

accident

Municipal new-energy 4.8125 12 31.5 67

Metallurgy 4.92 11.67 36 72

Construction

engineering

4.9 14 28.67 64

Head of department

responsible for the

accident

Municipal new-energy 3.75 10 24.5 60

Metallurgy 4.17 10.67 35 70

Construction

engineering

4.75 14.5 28 62.67

Principal of the

enterprise

Municipal new-energy 3.125 8.5 23 50

Metallurgy 4.53 11.30 34 68

Construction

engineering

4.5 14 28 53.15

4 CONCLUSIONS

In this paper, the incentive strength of safety

performance was measured and analyzed subjected to

different new-energy enterprises in municipal new-

energy industry as well as different industries

including metallurgy and construction engineering. It

is found that the incentive level of municipal new-

energy industry to different responsible persons is not

sufficiently high so that the economic and

administrative punishments should be strengthened.

In addition, appropriate implementation of safety

incentives based on varied degrees of accidents is

really needed for standardizing the safety behavior of

employees and ensuring the stable enterprise

development.

ACKNOWLEDGEMENTS

The authors would like to thank all participants of the

engineering enterprises and projects in Hangzhou.

REFERENCES

Duan, M. (2007). Discussion on new enterprise safety

evaluation and incentive mechanism, 4, 11–14.

Duan, W. Chen, G. (2010). The modelling of enterprises

performance evaluation in work safety responsibility as

main body and its application, China Safety Sci. J., 20,

53–61.

Gao, J. (2018). Research on the safety incentive mechanism

of logistics operation based on principal - agent

theory. Log. Eng. Manage., 40, 125–128.

Hu, C. (2008). Discussion on the application of incentive

and reward and punishment mechanism of safety

production goal in municipal new-energy production.

Hunan Hydro. Municipal new-energy, 5, 81–82.

Sun, S. (2019). Problems existing in incentive mechanism

of state-owned enterprises and optimization measures.

Ability and Wisdom, 4, 250.

Wang, C. (2013). Enterprise safety production performance

evaluation system and incentive constraint policy

research, Beijing, CN: Capital University of Economics

and Business.

Zhang, F. (2015). Study on the model and propelling

method of small and medium-sized enterprises work

safety standardization safety performance, Guangzhou,

CN: South China University of Technology.

Zou, J. (2016). The design of safety production

performance appraisal system of XINHUA municipal

new-energy generation company based on the incetive

mechanism, Zhengzhou, CN: North China University

of Water Resources and Electric Power.

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

100