Research of Food Supply Chain Safety Evaluation based on Fuzzy

Analytic Hierarchy Process

Yu Huang

a

International Business School Suzhou at XJTLU, Xi’an Jiaotong-liverpool University, Suzhou, China

Keywords: Food Supply Chain, Fuzzy Analytic Hierarchy Process, Safety Evaluation.

Abstract: Aiming at the food supply chain safety evaluation, this paper adopts a fuzzy hierarchy analysis method to

build a risk identification model of the food supply chain from strengthening five aspects: quality and safety

risk control, logistics safety risk control, cooperative safety risk control, market safety risk control and

environmental safety risk control. According to the calculation results of the model, the specific risk factors

affecting the safety of the food supply chain are analyzed. It is of specific reference value to study food quality

risk management based on the food supply chain level, take scientific measures to reduce food quality and

safety risks caused by various factors, and strengthen food safety risk prevention and control ability.

1 INTRODUCTION

Food safety risks always exist judging from the

emerging food safety problems, which will gradually

become the focus of social attention (Shaw and

Shaw,2019). With improving people's living

standards in modern times, the requirements and

standards for healthier food are also increasing. Food

raw materials feature variety, different places of

origin, seasonality, perishability, and there are many

factors such as physical, chemical, and biological

factors that may threaten food safety (Beulens et al.

2005). Thus, it is challenging to guarantee food safety

only by controlling one link in food operation. As an

essential part of food safety research, researchers at

home and abroad have studied the food safety

evaluation system from the perspective of food safety

management technology, consumer behaviour, and

overall food safety evaluation and other aspects (Dani

and Deep, 2010; Spink, 2019).

For the safety risk management of the food supply

chain, Fares and Rouviere (2010) adopted the

corresponding mechanism of food safety system as

the research object. From the food safety system and

mechanism perspective, identify and classify food

safety risk factors. Government departments play a

role in food safety research and management. This

management method reduces the possibility of

a

https://orcid.org/0000-0002-1402-1975

security risks in the supply chain. Wolfe and Lee

(2003) pointed out that it is necessary to find the

primary person responsible for food safety when

conducting food safety management. Finding out the

person responsible for the accident is of great

significance to the effective development of the

research. By finding the person in charge, we can deal

with safety accidents in a targeted way. Secondly, he

believes that a traceable food safety supervision and

management system should be established so that the

root cause of the problem can be found when the

problem occurs. The supply chain can reduce the

possibility of food safety events and establish an

excellent company's external image. Ahi and Searcy

(2013) established a supply chain network model,

focusing on the three central subjects of the food

supply chain, food retailers and food distributors. The

food safety risk management decision is divided into

multi-level, and the food safety risk is reduced

through multi-level decision-making. If the model

shows convergence when calculating the data, the

model is in equilibrium, and the safety risk is low.

When Hallikas and four other researchers (2004)

conducted supply chain management, he focused on

key supply chain network management and non-basic

supply chain network management methods. This

research method is more in-depth and practical. Carry

out in-depth supply chain management. It is found

that the more members in the supply chain, the more

Huang, Y.

Research of Food Supply Chain Safety Evaluation based on Fuzzy Analytic Hierarchy Process.

DOI: 10.5220/0011304400003437

In Proceedings of the 1st International Conference on Public Management and Big Data Analysis (PMBDA 2021), pages 113-118

ISBN: 978-989-758-589-0

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

113

risk-prone the supply chain is, and the non-primary

supply chain network management method can

manage the supply chain more effectively. Ray (2021)

took the perishable goods supply chain as the research

object and established the optimization model of the

perishable goods supply chain. The model improves

the expected profit of decision-makers under the

uncertainty of demand and price and manages the

supply chain to achieve the expected effect of risk

management. A case study is carried out to compare

the operation effects of the basic single strategic

scheme and the multi decision combination scheme.

A single approach is not enough to provide

solutions in all risk scenarios. Combining various

methods is the most effective and best goal of risk

management. Dharmalingam and the other four

experts (2021) the effective operation of the supply

chain depends not only on the solid competitiveness

of each node enterprise but also on the harmonious,

cooperative relationship and coordinated

development with other cooperative enterprises in the

supply chain. Therefore, facing the risks arising from

the supply chain, it is necessary for each enterprise to

carry out sufficient supervision and management and

need to manage together with other enterprises.

Therefore, supply chain risk needs to be managed in

the whole supply chain. In many traditional risk

management models, few people pay attention to the

importance of internal risk management culture. The

author believes that the risk of the whole supply chain

should be managed by introducing a revolutionary

supply chain risk management process and

emphasizes the importance of the company's risk

management strategy - the embedded risk

management culture. Shi (2020) believes that we

must build a new logistics and emergency supply

chain system to strengthen supply chain management.

The supply chain is quickly interrupted or inefficient

without a sound logistics system. The emergence and

use of intelligent logistics will avoid various

problems in traditional logistics, and intelligent

logistics will be more efficient, intelligent, fast,

border and flexible. The emergency supply chain

shows more agile characteristics, collaboration,

accuracy and green, which align with the current

supply chain demand (Liang and Yang, 2020). The

popularity of COVID-19 has strengthened the

requirements of food supply chain management. In

this environment, the food supply chain management

must first establish an information network platform

to facilitate all enterprises in the food supply chain.

Be able to timely understand the information of the

whole supply chain and make timely adjustments to

yourself. Understand the real-time unsalable products

of the enterprise in the production process, integrate

the source of products according to the real-time

demand of the market, and allocate products among

various markets. Secondly, build an intelligent supply

chain connecting buyers, sellers and logistics, and

build a three-dimensional distribution system to

ensure the smooth transportation and supply balance

of products in all markets.

In comparison, there is still no comprehensive and

unified evaluation of regional food safety. This study

seriously studies the management of food quality risk

and carries out a scientific evaluation from the food

supply chain and food safety perspective. The fuzzy

analytic hierarchy process is adopted to research the

food supply chain safety evaluation to provide a

scientific reference for further food safety research.

2 INTRODUCTION OF THE

FUZZY ANALYTICAL

HIERARCHY PROCESS

The fuzzy analytic hierarchy process is a systematic

analysis method that combines qualitative and

quantitative analysis and analyzes based on the fuzzy

number or fuzzy judgment matrix

(Nehme,2019). The

traditional analytic hierarchy process has certain

limitations on testing the judgment matrix, while the

fuzzy analytic hierarchy process overcomes this

defect. It is a more effective comprehensive

evaluation method of which the specific analysis

steps are as follows.

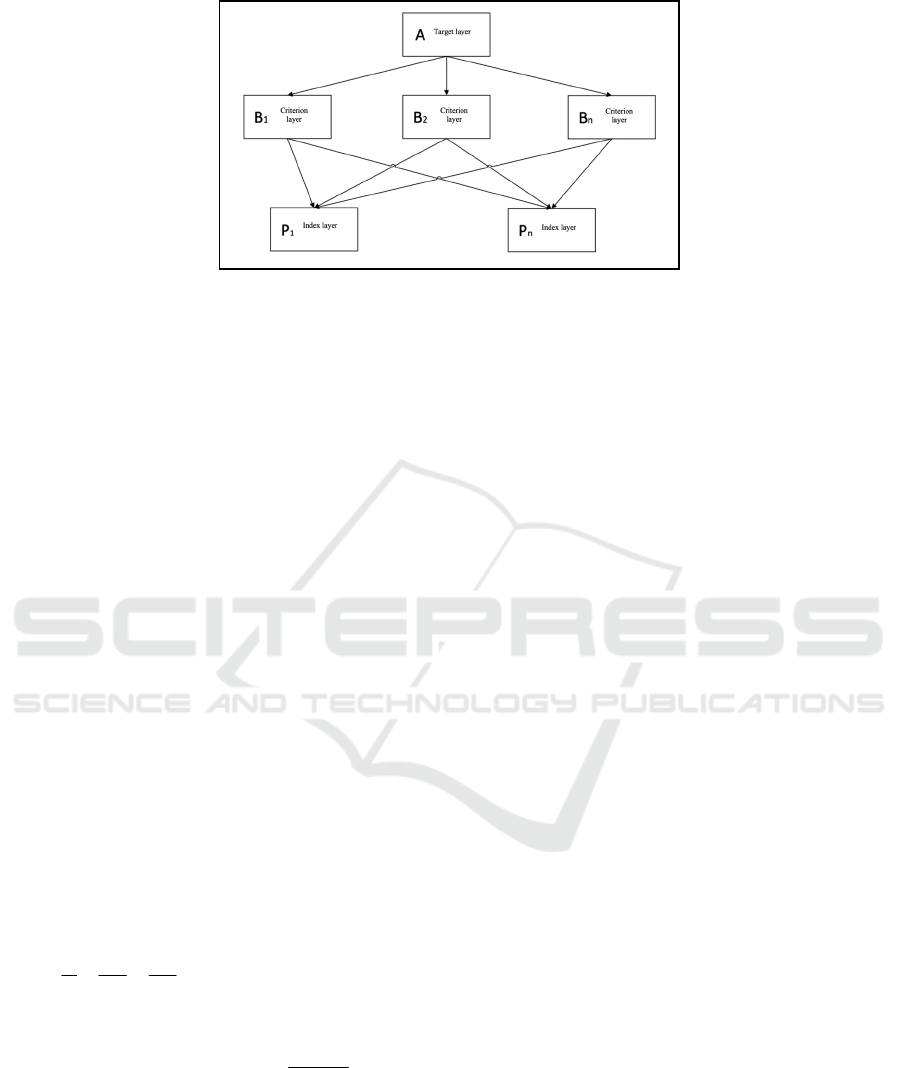

2.1 Fuzzy Hierarchical Structure

Model

First, all factors are divided into three layers and

arranged into the target layer, criterion layer, and

index layer from high to low, respectively, to establish

the fuzzy hierarchy model of this study, as shown in

Fig. 1 (Bakhtari et al. 2021).

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

114

Figure 1: Fuzzy hierarchical structure model.

2.2 Fuzzy Complementary Matrix

Compare the relative importance of relevant elements

between the upper layer element B and the current

layer element C to create a fuzzy complementary

matrix R, which is:

11 12 13 1

21 22 23 2

31 32 33 3

123

n

n

BC n

nn n nn

rrr r

rrr r

Rrrr r

rrr r

−

=

where

0.5, ( 1, 2, , )

ii

ri n==

;

1,(,1,2,,)

ji ij

rrij n=− =

.

2.3 Hierarchical Single Sorting

The importance of the factors on the current layer is

sorted, and the weight is determined according to the

calculation of the fuzzy complementarity matrix

(Li

and Xu,2021)

. That is, the single hierarchical sorting is

formed. The weight formula is:

1

11 1

,( , 1,2, , )

2

n

ikik

wrikn

nana

=

=− + =

where n is the order of R, and

(1)

2

n

a

−

=

.

2.4 Hierarchical Total Sorting

The hierarchical total sorting can be obtained by

calculating the weighted sum of the results of

hierarchical single sorting from top to bottom. The

importance vector of the element

n

k

on layer K to

the elements on layer k-1 is:

12 1

1

(, ,, )

k

kT

kknknkn

www w

−

−

−− −

=

.The synthetic

importance vector of the elements on the k-th layer to

the total target is:

11

1

kk-

kk-k

w=w w×

. The weight

matrix of index factor layer of the n-layer low-order

structure is:

1112332

12 21

2

in

nn n

kinnn

wwwwwww

=

−− −

−−

==

∏

.

2.5 Determine the Index Factor Set

Assign initial values to each index ≤ factor in the

above evaluation index system, and the index factor

set after dimensionless treatment is:

123

(, , )

T

n

XXXXX=

.

2.6 Calculation of the Evaluation Set

If the evaluation set of the target layer to be

determined is Y, then:

1

1

()

n

T

nii

i

Yw X wx

=

=×=

.

3 FUZZY ANALYTIC

HIERARCHY PROCESS

RESULTS

By reading a large number of relevant literature on

supply chain risk, based on the expert survey method,

and through detailed index sorting and screening, the

following 20 secondary risk elements are finally

determined: (1) five secondary indexes of quality

risk: the use of pesticides, hormones, food additives,

Research of Food Supply Chain Safety Evaluation based on Fuzzy Analytic Hierarchy Process

115

and other chemicals; poor hygienic environment in

food production, processing, and sales; improper food

storage; imperfect food safety supervision

mechanism; imperfect enterprise food quality

management system (Fung, Guo and Wang,2021); (2)

three secondary indexes of logistics risk: damage in

the process of food circulation; mixed transportation

of food and other commodities; delayed arrival of

food; (3) five secondary indexes of cooperation risk:

information asymmetry; unreasonable distribution of

interests; distrust among enterprises; inconsistent

strategic objectives; corporate culture differences; (4)

five secondary indexes of market risk: market

demand uncertainty; insufficient product supply; food

price fluctuation; industry competition risk; changes

in economic policies; (5) two secondary indexes of

environmental risk: natural environment risk;

economic environment risk.

To determine ratios to construct a relevant

judgment matrix of indexes on each layer,

comparisons between each factor on the same layer

and a particular factor on the higher layer are carried

out by referring to a large number of relevant research

literature and using the expert assignment scaling

method. MATLAB software is used to calculate the

judgment matrices (Regattieri, Gamberi and Manzini,

2007). Results are shown in Table I below.

Table 1: Criterion Layer F Judgment Matrix.

F F1 F2 F3 F4 F5 W

F1

a

1.00 3.00 2.00 1.00 .50 0.2255

F2

b

0.33 1.00 1.00 0.33 0.33 0.0936

F3

c

0.50 1.00 1.00 0.50 0.50 0.1194

F4

d

1.00 3.00 2.00 1.00 3.00 0.3227

F5

e

2.00 3.00 2.00 0.33 1.00 0.2388

a. F1 is for quality risk; b. F2 logistics risk; c. F3 cooperation risk;

d. F4 market risk; e. F5 environmental risk.

Table 2: Supply Chain Quality Risk F1 Judgment Matrix.

F1 F11 F12 F13 F14 F15 W

F11

a

1.00 0.50 2.00 2.00 0.50 0.1815

F12

b

2.00 1.00 3.00 2.00 1.00 0.2984

F13

c

0.50 0.33 1.00 1.00 0.33 0.1018

F14

d

0.50 0.50 1.00 1.00 0.50 0.1198

F15

e

2.00 1.00 3.00 2.00 1.00 0.2984

a. F11 is for the use of pesticides, hormones, food additives, and other chemicals;

b. F12 poor hygienic environment in food production, processing, and sales;

c. F13 refers to improper food storage; d. F14 imperfect food safety supervision

mechanism;

e. F15 imperfect food quality management system.

Table 3: Supply Chain Logistics Risk F2 Judgment Matrix.

F2 F21 F22 F23 W

F21

a

1.00 1.00 2.00 0.416

F22

b

1.00 1.00 1.00 0.3275

F23

c

0.50 1.00 1.00 0.2599

a. F21 is for the damage during food circulation;

b. F22 mixed transportation of food and other commodities;

c. F23 delayed arrival of food.

Table 4: Supply Chain Cooperation Risk F3 Judgment

Matrix.

F3 F31 F32 F33 F34 F35 W

F31

a

1.00 0.33 0.50 0.50 0.50 0.0943

F32

b

3.00 1.00 2.00 2.00 2.00 0.3368

F33

c

2.00 0.50 1.00 3.00 1.00 0.2222

F34

d

2.00 0.50 0.33 1.00 0.50 0.1244

F35

e

3.00 0.50 1.00 2.00 1.00 0.2222

a. F31 refers to information asymmetry; b. F32 unreasonable benefit distribution;

c. F33 distrust among enterprises; d. F34 inconsistent strategic objectives;

e.F35 corporate cultural differences.

Table 5: Supply Chain Market Risk F4 Judgment Matrix.

F4 F41 F42 F43 F44 F45 W

F41

a

1.00 1.00 1.00 0.50 1.00 0.1626

F42

b

1.00 1.00 0.33 0.50 0.50 0.1134

F43

c

1.00 3.00 1.00 3.00 2.00 0.3070

F44

d

2.00 2.00 0.50 1.00 3.00 0.2673

F45

e

1.00 2.00 0.50 0.33 1.00 0.1476

a. F41 refers to market demand uncertainty; b. F42 insufficient product supply;

c. F43 food price fluctuation; d. F44 industrial competition risk; e. F45 changes in

economic policies.

Table 6: Environmental Risk F5 Judgment Matrix.

F5 F51 F52 W

F51

a

1.00 0.50 0.3333

F52

b

2.00 1.00 0.6667

a. F51 is the natural environment risk; b. F52 is the economic environment risk.

Through the above judgment matrices, the index

weight set vectors of the target layer and the criterion

layer are obtained respectively, which are:

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

116

W

F

=(0.2255,0.0936,0.1194,0.3227,0.2388);

W

F1

=(0.1815,0.2984,0.1018,0.1198,0.2984);

W

F2

=(0.4126,0.3275,0.2599);

W

F3

=(0.0943,0.3368,0.2222,0.1244,0.2222);

W

F4

=(0.1626,0.1134,0.3070,0.2673,0.1496);

W

F5

=(0.3333,0.6667).

According to the index, weight set vectors of the

target and criterion layers are combined with the

evaluation matrices of the five criterion layers of

quality risk, logistics risk, cooperation risk, market

risk, and environmental risk

(Wei and Song,2018). The

fuzzy comprehensive evaluation can bring the data

into the fuzzy analytic hierarchy process for fuzzy

operation.Then, it can be obtained that W1= (0.1519,

0.1743, 0.2592, 0.2140, 0.2006); W2= (0.1804,

0.1840, 0.1740, 0.2493, 0.2124); W3= (0.1598,

0.1925, 0.2266, 0.2269, 0.2078); W4= (0.1616,

0.1770, 0.2728, 0.2019, 0.1865); W5= (0.1300,

0.2567, 0.2533, 0.1867, 0.1733). By recombining the

W1, W2, W3, W4, and W5 as a criterion layer to

evaluate the matrix R, the final fuzzy evaluation of

this supply chain is:

𝑊=𝑊

×𝑅

= (0.2255,0.0936,0.1194,0.3227,0.2388)

×

⎣

⎢

⎢

⎢

⎡

0.1519 0.1743 0.2592 0.2140 0.2006

0.1804 0.1840 0.1740 0.2493 0.2124

0.1598 0.1925 0.2266 0.2269 0.2078

0.1616 0.1770 0.2728 0.2019 0.1865

0.1300 0.2567 0.2533 0.1867 0.1733

⎦

⎥

⎥

⎥

⎤

= (0.1534,0.1979,0.2503,0.2084,0.1915)

Combine the final fuzzy evaluation results with

the Likert five-level scale for further matrix

multiplication. The final evaluation score of food

supply chain risk is 2.5179, which shows that the

overall quality safety of the food supply chain is at the

medium level.

4 CONCLUSIONS

Food is a necessity of our life, and from the most

primitive state of food to the subsequent transmission

to consumers, any mistake in any link may cause

quality and safety risks, which will directly affect

people's life and health, so society has paid great

attention to it for a long time. In order to better ensure

food safety and make consumers feel at ease and

enterprises operate comfortably, unilateral

investigation of the reasons of enterprises or

consumers often does not play a key role. Exploring

and evaluating comprehensive factors has become an

important issue. Scholars have less research on the

safety risk of the food supply chain, and only analyze

it from the internal and external or subjective and

objective single level of the food supply chain, lack

the combination of qualitative and quantitative

analysis, and do not comprehensively analyze the

deep-seated reasons affecting the safety risk of food

supply chain from multiple angles. Aiming at this

problem, this paper first comprehensively analyzes

the safety risk from the perspective of the food supply

chain, combined with the internal, external,

subjective and objective aspects of food supply chain

enterprises, and finds out the factors that affect the

safety risk of food supply chain in essence.

To sum up, from the perspective of food supply

chain supervision, this paper establishes a

quantitative evaluation model based on a fuzzy

analytic hierarchy process. It provides a quantitative

evaluation tool for food supply chain safety

supervision, which realizes the overall safety and

practical evaluation of the food supply chain and

provides decision support for refining the food supply

chain safety evaluation

(Yeung and Morris,2013).

Although this paper accurately, scientifically, and

timely reflects the food safety situation from the

fundamental problems of food source and food

consumption from the aspects of quality risk, logistics

risk, cooperation risk, market risk, and environmental

risk of the food supply chain, improvement is still

needed for specific research.

REFERENCES

Ahi, P. and Searcy, C., 2013. A comparative literature

analysis of definitions for green and sustainable supply

chain management. Journal of Cleaner Production, 52,

329-341.

Bakhtari, A. R., Waris, M. M., Sanin, C. and Szczerbicki,

E., 2021. Evaluating Industry 4.0 Implementation

Challenges Using Interpretive Structural Modeling and

Fuzzy Analytic Hierarchy Process. Cybernetics and

Systems, 52(5), 350-378.

Beulens, A. J., Broens, D., Folstar, P. and Hofstede, G. J.,

2005. Food safety and transparency in food chains and

networks Relationships and challenges. Food Control,

16(6), 481-486.

Dani, S. and Deep, A., 2010. Fragile food supply chains:

reacting to risks. International Journal of Logistics

Research and Applications, 13(5), 395-410.

Dharmalingam, B., Giri Nandagopal, M., Thulasiraman, V.,

Kothakota, A. and Rajkumar, 2021. Short food supply

chains to resolve food scarcity during COVID 19

Research of Food Supply Chain Safety Evaluation based on Fuzzy Analytic Hierarchy Process

117

pandemic—An Indian model. Advances in Food

Security and Sustainability, [online] 6, 35-63. Available

at:

<https://www.sciencedirect.com/science/article/pii/S24

52263521000070> [Accessed 21 December 2021].

Fang, K., Guo, J. and Wang, Q., 2021. Evaluation of Air

Material Support Capability Based on Fuzzy Analytic

Hierarchy Process. Logistics Sci-Tech, (11), 139-141.

Fares, M. and Rouviere, E., 2010. The implementation

mechanisms of voluntary food safety systems. Food

Policy, 35(5), 412-418.

Hallikas, J., Karvonen, I., Pulkkinen, U., Virolainen, V. and

Tuominen, M., 2004. Risk management processes in

supplier networks. International Journal of Production

Economics, 90(1), 47-58.

Li, P. and Xu, G., 2021. Safety Condition Assessment of

Bridge Crane Based on Improved Fuzzy Analytic

Hierarchy Process. Machine Design and Research,

37(5), 219-223.

Liang, P. and Yang, P., 2020. Discussion on

countermeasures of promoting circulation of

agricultural products in response to the epidemic

situation. Commercial Economics Research, 18, 132-

134.

Nehme, S., 2019. Governmentally Controlled Supply

Chains in Areas Facing Food Security Challenges: The

Case of Baladi Bread Supply Chain in Egypt and the

Policy Transition After the 2011 Uprising. Springer

International Publishing,2019.11.

Ray, P., 2021. Agricultural Supply Chain Risk

Management Under Price and Demand Uncertainty.

International Journal of System Dynamics

Applications, 10(2), 17-32.

Regattieri, A., Gamberi, M. and Manzini, R., 2007.

Traceability of food products: General framework and

experimental evidence. Journal of Food Engineering,

81(2), 347-356.

Shaw, H. J. and Shaw, J. J. A., 2019. Corporate Social

Responsibility and the Global Food Supply Chain.

Taylor and Francis, 2019.05.

Shi, X., 2020. Impact of COVID-19 on China's logistics and

global supply chain and countermeasures. Logistics

Research, 01, 11-16.

Spink, J. W., 2019. Supply Chain Management (Part 2 of

2): Application Applied to Food Fraud Prevention.

Springer. New York,2019.10.

Wei, X. and Song, Y., 2018. Comprehensive benefit

evaluation for of PV building based on fuzzy analytic

hierarchy process. Acta energiae solaris sinica, 39(2),

544-549.

Wolfe, M. and Lee, H., 2003. Supply Chain Security

Without Tears. Supply Chain Management Review,

7(3), 12-20.

Yeung, R. W. W. and Morris, J., 2013. Food safety risk.

British Food Journal, 103(3), 170-186.

PMBDA 2021 - International Conference on Public Management and Big Data Analysis

118