Results from using an Automl Tool for Error Analysis in

Manufacturing

Alexander Gerling

1,2,3

, Oliver Kamper

4

, Christian Seiffer

1

, Holger Ziekow

1

,

Ulf Schreier

1

, Andreas Hess

1

and Djaffar Ould Abdeslam

2,3

1

Business Information Systems, Furtwangen University of Applied Science, 78120 Furtwangen, Germany

2

IRIMAS Laboratory, Université de Haute-Alsace, 68100 Mulhouse, France

3

Université de Strasbourg, France

4

SICK AG, 79183 Waldkirch, Germany

{alexander.gerling, djaffar.ould-abdeslam}@uha.fr, oliver.kamper@sick.de

Keywords: AutoML Tool, Manufacturing, Production Line.

Abstract: Machine learning (ML) is increasingly used by various user groups to analyze product errors with data

recorded during production. Quality engineers and production engineers as well as data scientists are the main

users of ML in this area. Finding a product error is not a trivial task due to the complexity of today’s production

processes. Products have often many features to check and they are tested in various stages in the production

line. ML is a promising technology to analyze production errors. However, a key challenge for applying ML

in quality management is the usability of ML tools and the incorporation of domain knowledge for non-

experts. In this paper, we show results from using our AutoML tool for manufacturing. This tool makes the

use of domain knowledge in combination with ML easy to use for non-experts. We present findings obtained

with this approach along with five sample cases with different products and production lines. Within these

cases, we discuss the occurred error origins that were found and show the benefit of a supporting AutoML

tool.

1 INTRODUCTION

In recent years machine learning (ML) has been

progressively used in manufacturing to predict errors

(Li et al., 2019; Caggiano et al., 2019; Hirsch et al.,

2019). Modern explainable ML approaches open new

possibilities to analyze a product error. The objective

is to use ML as support to find the origin of a

production error. There are already data-driven

approaches for complex production systems (Ren et

al., 2020). Data‑driven quality prediction methods are

growing in various areas (Kirchen et al., 2019;

Tangjitsitcharoen and Ratanakuakangwan, 2017; Liu

et al., 2019a; Li et al., 2019), thanks to the rapid

development of artificial intelligence (AI) technology

and tools. Quality engineers are the main users to

analyze a product error in the manufacturing domain.

However, this is often not a trivial task, as there are

many test stations in today’s complex production

lines and products have a large number of features to

be tested. Also, quality engineers are often having

deep knowledge in the manufacturing domain but

have no expertise in data science techniques. This

impedes to the exploitation of ML potential in error

analysis. In (Wilhelm et al., 2020), we can find a brief

overview of problems and challenges of data science

approaches for quality control in manufacturing.

Further, we can find a description of the use of ML in

production lines in (Gerling et al., 2020).

As ML techniques and tools keep maturing, we

see the opportunity to combine data science

techniques with domain expert knowledge to create

applications for non-experts in the field of ML. The

aim is to make the use of ML accessible to quality

engineers. The key concept to enable this use of ML

for error analysis is Automated Machine Learning

(AutoML). AutoML is used to create an application

of ML, which is more feasible for a user and reduces

the required level of expertise. Examples for AutoML

solutions can be found in (Candel et al., 2016;

Golovin et al., 2017; Kotthoff et al., 2019; Feurer et

al., 2019). Within these solutions, we already benefit

from automating several steps of the data science

pipeline, like hyperparameter tuning of an algorithm.

100

Gerling, A., Kamper, O., Seiffer, C., Ziekow, H., Schreier, U., Hess, A. and Abdeslam, D.

Results from using an Automl Tool for Error Analysis in Manufacturing.

DOI: 10.5220/0010998100003179

In Proceedings of the 24th International Conference on Enterprise Information Systems (ICEIS 2022) - Volume 1, pages 100-111

ISBN: 978-989-758-569-2; ISSN: 2184-4992

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

Figure 1: Cutout from Figure 7 (Seiffer et al., 2020).

One of the main tasks of a quality engineer is to

find faults in the production and eliminate them. This

task is very time-consuming and needs highly

specialized personnel, as a product often has many

features and is produced over several test stations.

Furthermore, an error could be caused by the

interaction of several features (e.g., overheating due

to current and voltage). A quality engineer must find

dependencies across several features, which is hardly

feasible for a human. Therefore, ML could be a great

help. To identify errors, we provide an AutoML tool

that creates various analyses and visualizations.

These are adjusted for the error analysis of a quality

engineer. The different types of visualizations can

further help to understand the error in-depth and get

more insights. Furthermore, automatic data analyses

can run along, which can indicate changes in

production. This can happen by an adjustment of the

production line or by the occurrence of a new error.

This information is particularly interesting, as it

contributes to detecting possible causes of errors

quickly.

In previous publications, we evaluated ML

techniques to reduce the dataset complexity, optimize

the results, or evaluated different visualizations for

the quality engineer. That is why, we want to

investigate in this paper if our ML tool provides the

important features for the analysis with the associated

visualizations which lead to the origin of the error.

Therefore, we would like to answer the following

research questions (RQ) through this paper:

• (RQ1) Can we provide important features for the

error analysis and derive target visualizations?

• (RQ2) Can a quality engineer find plausible

reasons for the errors?

The paper is organized as follows: Section 2

describes the potential of our AutoML tool. In Section

3 we provide an overview of similar applications or

approaches in production. The processing pipeline of

our AutoML tool is described in Section 4. We

discuss further information about domains

knowledge in Section 5. In Section 6 we describe five

investigated cases and the possible solutions for

identifying the error origin. We use Section 7 to

conclude our work.

2 USE CASE

With our AutoML tool PREFERML (Ziekow et al.,

2019b), we aim to support a quality engineer’s work.

The objective is that a quality engineer is able to work

autonomously without the help of a data scientist or

needs further ML knowledge to achieve results. We

accomplish this through the automation of processes

within our AutoML tool and the use of predefined

domain knowledge. Furthermore, our tool can be

integrated into the as-is process to reduce product

errors in the production line (Gerling et al., 2020) and

to support the quality engineer in his daily work.

We define the automated parts of our AutoML

tool by the Cross-Industry Standard Process for Data

Mining (CRISP-DM) (Chapman et al., 2000).

CRISP-DM has six phases, and we automate four of

them. That is, we use an extended notion of AutoML

which comprises the subsequent phases. (1) Data

Understanding: Here we model the provided domain

knowledge from the quality engineer for later use.

Therefore, we set the predefined key attributes for the

AutoML tool based on the product information. (2)

Data Preparation: In this phase, we prepare the data

with the help of the predefined domain knowledge, so

that the data could be used by the ML model. Within

this phase, missing or not usable values are

automatically removed. Also, the product data gets

enriched with derived features, by using the

information from the domain knowledge. Sometimes

an error is related to other product errors, and it is

beneficial to analyze them as a group. Therefore, our

AutoML tool has the possibility to group error

messages and analyze them as one product error. This

is especially useful if a product has detected several

similar faults in a test station. (3) Modeling: We

automate the feature selection and hyperparameter

tuning part to train the final ML model. (4)

Results from using an Automl Tool for Error Analysis in Manufacturing

101

Evaluation: In this phase, we provide selected and

adjusted visualizations and statistics for the user,

which is done automatically. Therefore, we improve

the automation of the analysis pipeline.

In our earlier work (Seiffer et al., 2020), we

describe a process to investigate errors using ML

support with a detailed explanation (see Figure 7 in

(Seiffer et al., 2020)). The process task is divided into

four subtasks. In Figure 1 we show a cutout from the

investigation process. Especially the displayed

subtasks T6.3 and T6.4 should be highlighted to

support the quality engineer in the automatic error

evaluation. Within these two tasks, we provide the

automatically necessary information and

visualizations for the analysis. In task T6.4 we

distinguish two possibilities for the deeper analysis.

(I) Derivation of Rules: this can be done by ML

agnostic tools, to explain the decisions of a model.

Well known libraries like ANCHOR (Ribeiro et al.,

2018), SHAP Plots (Lundberg and Lee, 2017) or a

Surrogate Model (Pedregosa et al., 2011) are used

here. Also, a decision tree from the model or a rule

list based on derived decision rules could be provided

(II) Visualizations: adjusted visualizations for the

quality engineer like Scatter Plots and Histograms are

used to get an overview over the distribution of the

measured product values. Further, a Correlation

Diagram can help to understand the correlation

between a feature and the test result.

3 RELATED WORK

In Dogan and Birant (Dogan and Birant, 2021), a

comprehensive literature review is provided for an

overview of how machine learning techniques can be

utilized to comprehend manufacturing mechanisms

with smart actions. The objective of this review was

to provide an understanding of the main approaches

and which algorithms were used to improve

manufacturing processes in the last years. They group

previous ML studies and the latest research in

manufacturing in four main subjects: monitoring,

quality, failure, and scheduling. Further, existing

solutions to various aspects of algorithms, tasks,

performance metrics, and learning types are provided

by Dogan and Birant. Also, an overview from

different perspectives about the current literature is

provided. The advantages of utilizing machine

learning techniques are provided and how to tackle

challenges for the manufacturing. Additionally,

further research directions in this area were provided.

In Turetskyy (Turetskyy et al., 2021), a battery

production design to use multi-output machine

learning models was provided. Lithium-ion battery

(LiB) cell manufacturing has high production costs

and a great impact on the environment. This is due to

the expensive materials, the high process fluctuations

with high scrap rates. Also, the energy demand for

this is especially high. Moreover, it is difficult to plan,

control and execute the production in this area

because of the lack of profound knowledge of LiB

cell production processes and their influence on the

quality. The multi-output approach is based on data-

driven models, which predict the final product

properties. This was done by the intermediate product

features. A concept was utilized in a case study within

the pilot line of the Battery LabFactory

Braunschweig. For the case study, 155 lithium-ion

battery cells were used to build an artificial neural

network model. The final product properties from

intermediate product features were later predicted by

the trained model. Within the provided concept, they

showed how the approach could be deployed within

the framework of a cyber-physical production system.

This is targeting for continuous improvement of the

underlying data-driven model and further, the

decision support in production.

In Liu (Liu et al., 2019b), a real-time quality

monitoring and diagnosis scheme for manufacturing

process profiles based on a deep belief network

(DBN) was developed. This is based on the ability of

DBN to extract the essential features from the input

data. This is essentially needed because the

manufacturing process has a large number of real-

time quality data, which are collected through various

sensors. Further, most of the data are high-dimension,

nonlinear and high-correlated. Therefore, it is

difficult to model the process profile, which limits the

function of a typical statistical process control

technique. They used the collected profile from a

manufacturing process and mapped it into quality

spectra. In this paper, a novel DBN recognition model

for quality spectra was established for the offline

learning phase. This can be used to monitor and

diagnose the process profiles in the online phase. To

test how effective the DBN recognition model for

manufacturing process profiles was, a simulation

experiment and a real injection molding process

example were used to analyze the performance. As

result, the proposed DBN model could outperform

alternative methods.

Soto, Tavakolizadeh, and Gyulai (Carvajal Soto et

al., 2019) present a machine learning and

orchestration framework for fault detection in

manufacturing. In the context of surface mount

devices, they propose a system for real-time machine

learning application. A key component of their work

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

102

is the introduction of a discrete-event simulation that

allows failure detection approaches to be evaluated

without disrupting ongoing production operations.

The authors evaluate both random forests and

gradient boosting as alternatives for machine learning

algorithms. To avoid concept drift, ML models are

retrained at regular intervals. Both approaches show

convincing results in a case study. Their developed

approach fulfills the most important conditions of a

scalable, reconfigurable, adaptable, and re-

deployable solution. Scalability, acceptance,

however, have not been measured and generalization

and security still have to be proven.

In Olson and Moore (Olson and Moore, 2016), an

open-source genetic programming-based AutoML

system named TPOT is explained. This AutoML tool

automatically optimizes ML models and feature pre-

processors. An objective for the supervised

classification task is to optimize classification

accuracy. TPOT designs and optimizes the necessary

ML pipeline without any involvement of a human

being for a given problem domain (Olson et al.,

2016). TPOT uses a version of genetic programming

- an evolutionary computation technique to

accomplish this. It is possible to automatically create

computer programs (Banzhaf et al., 1998) with

genetic programming. For the supervised

classification, TPOT uses similar algorithms as we

do. However, our focus lies on tree-based algorithms

for understandable results, and we do not use e.g.,

logistic regression. After the usage of TPOT, the user

gets a file with code, which should help to execute the

ML process. In contrast, we do not deliver any files

with code but provide results with analyses and

supporting visualizations. Our AutoML tool further

provides a pre-processing and feature engineering

pipeline, which get automatically executed in the

process.

Maher and Sherif (Maher and Sakr, 2019) present

a meta learning-based framework for automated

selection and hyperparameter tuning for ML

algorithms (SmartML). The SmartML tool has a

meta-learning feature which mimics the role of a

domain expert in the area of ML. The meta learning

mechanism get used to select an algorithm to

minimize the parameter-tuning search space. Further,

the SmartML tool supply the user with a model

interpretability package to explain their results. In

contrast to SmartML, we pre-process the data with the

provided background information of a product. This

task could be done by a ML expert or a quality

engineer. Regarding the algorithm, we utilize a

decision tree-based algorithm to supply the user with

human recognizable and acceptable decisions. With

decision tree-based algorithms, we can improve the

confidence of the user in the given results. A main

distinction to SmartML is, that our tool is specialized

for the manufacturing domain. Highly unbalanced

data or the selection of a specific metric are not

supported by the SmartML tool.

Limits and possibilities of applying AutoML in

production are described by Krauß et al. (Krauß et al.,

2020). Their work provides an evaluation of available

systems. Further, it shows a comparison of a manual

implementation from data scientists and an AutoML

tool in a predictive quality use case. The result of this

comparison was that currently AutoML still requires

programming knowledge. Further, it was

outperformed by the implementation of the data

scientists. A critical point which led to this result was

the preparation of the needed data. For example, an

AutoML system cannot merge the data correctly

without predefined domain knowledge. Further, the

extraction from a database and the integration of the

data is problematic. An expert system could be the

solution for these problems. A further point was the

deployment of the results of the models. In summary,

it can be said that the AutoML system delivers a

chance to improve the efficiency of an ML project.

This could be achieved by automating the necessary

procedure within Data Preparation, Data Integration,

Modelling, and Deployment. Domain knowledge and

the expertise of a data scientist should be included in

this to obtain satisfying results. However, the newest

developments show evidence for upcoming

improvements towards the automation of specific

steps within the ML pipeline.

Our work represents an AutoML approach for

manufacturing that is aided by domain knowledge.

This helps to automate the ML pipeline and further

can narrow the error root cause analysis. With the

AutoML approach, data scientists are able to perform

error-oriented analyses without prior knowledge in

the field of ML. Further, feature importance statics

are providing hints to the important feature

visualizations, which are automatically created.

4 PROCESSING PIPELINE

In this section, we discuss the workflow of our

AutoML tool and the processing pipeline. The first

step is to merge the data from various test stations.

From the domain knowledge, we can derive the order

of the test stations and merge the data. As the next

step, we read and clean the data e.g., from missing

values. The next step is to prepare the data by

removing unnecessary features e.g., features with

Results from using an Automl Tool for Error Analysis in Manufacturing

103

only one value in the column and check the data

format. In the following step, we use domain

knowledge to create the derived features. Afterwards,

we split the data in a predefined percentage split into

a train and test set. The test set always contains 33%

of the errors from the dataset. The next step is the

training and optimization of the ML model. We use

the XGBoost classifier (eXtreme gradient boosting)

(Chen and Guestrin, 2016) as its ML core, as we value

comprehensibility in our model higher than

prediction accuracy. The optimization is performed

on a cost-based metric that maximizes business value.

To optimize the model training, the user can select

hyperparameter tuning and feature selection

separately or together if the user wants to improve the

model performance further. Feature selection is a

valid method to reduce the complexity of data and

reduces the search space for the error origin.

Therefore, feature selection can be used for the

analysis. Even if the users cannot achieve a better

result but can reduce the complexity of the data, they

can benefit from the reduction of features. After using

the feature selection method, only the most relevant

features for the model are left. Feature selection

requires time and computation power which varies

depending on the dimensionality of the dataset. Our

tool can perform feature selection strategies in

different ways (Gerling et al., 2021b).

Hyperparameter tuning of the model is a method

to optimize the model even more and benefit from

better results. However, hyperparameter tuning is not

a universal solution to improve the results and uses a

lot of computation resources. We are evaluating

possibilities to use highly parallel computation

methods to reduce the time needed for this step.

Next, we evaluate the results and check the

created visualizations. We create multiple adjusted

visualizations for the error root cause analysis for the

quality engineer. For example, a scatter plot can be

used to see in which value area an error appears and

if there are changes in the measured values over time.

Moreover, the scatter plot shows indirect the timeline

of the production and when a product error has

appeared. An evaluation of possible visualization to

use for the production can be found in (Gerling al.,

2021a). For the evaluation, we check the model

performance based on our cost-based metric. Based

on the model performance, we can identify beneficial

trained models. Here, a good-performing model can

indicate the origin of an error and can help to save

costs. We check the feature importance of each

feature. To do so, we use various model-dependent

and independent feature importance techniques e.g.,

total gain, gain, and SHAP Max Main Effect (Ziekow

et al., 2019a). Also, we check the correlation between

each feature and the test result with the Kendall's tau

correlation (Virtanen et al., 2020). Based on the

importance order of the features, we check

sequentially the created visualizations of each. A

further possibility to analysis the product error and to

inspect the decision from the model are provided by

a decision tree. The XGBoost classifier uses multiple

decision trees within the boosting approach.

Therefore, we use a surrogate model to provide the

approximate decision rules from the model

represented by one decision tree. The decision rules

from the trained model can be further derived and

directly be used in form of a rule list. This can be done

by providing the associated rules for the analysis.

To start it is advisable to let the PREFERML

AutoML tool run through the complete process

without making any additional settings like activating

feature selection. Therefore, we use the standard

parameter settings for the initial process run. These

initial results may already highlight features that are

correlated to the error. Within the provided results,

the user can check the given statistics of the results

and features that were weighted most strongly by the

ML model. The benefit of this initial process is, that

feasible results can already be quickly achieved with

this procedure and bring insights into the origin of an

error.

5 DOMAIN KNOWLEDGE

The domain knowledge of a product is represented as

a simple ontology. An illustration of the ontology can

be found in (Gerling et al., 2020). To create the

ontology, the quality engineer is the most suitable

user. The ontology has pre-defined key attributes

from a product. The key attributes include

information about the product, test stations (Test

System), test specification, and production line.

Every test station in a production line can be defined

separately in the ontology and thus offers variable

adaptation options. For example, the user configures

the sequence of test stations and further necessary

information about the product. The ontology -

respectively a representation of the domain

knowledge - is crucial to automate the ML tool.

During the execution of a process, the defined key

attributes are accessed within the ontology and used

for specific process execution. One of the key

attributes is the name of the previous test station.

With this information, we can derive the order of the

test stations in the production line. Moreover, we can

derive and determine a unique product feature to track

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

104

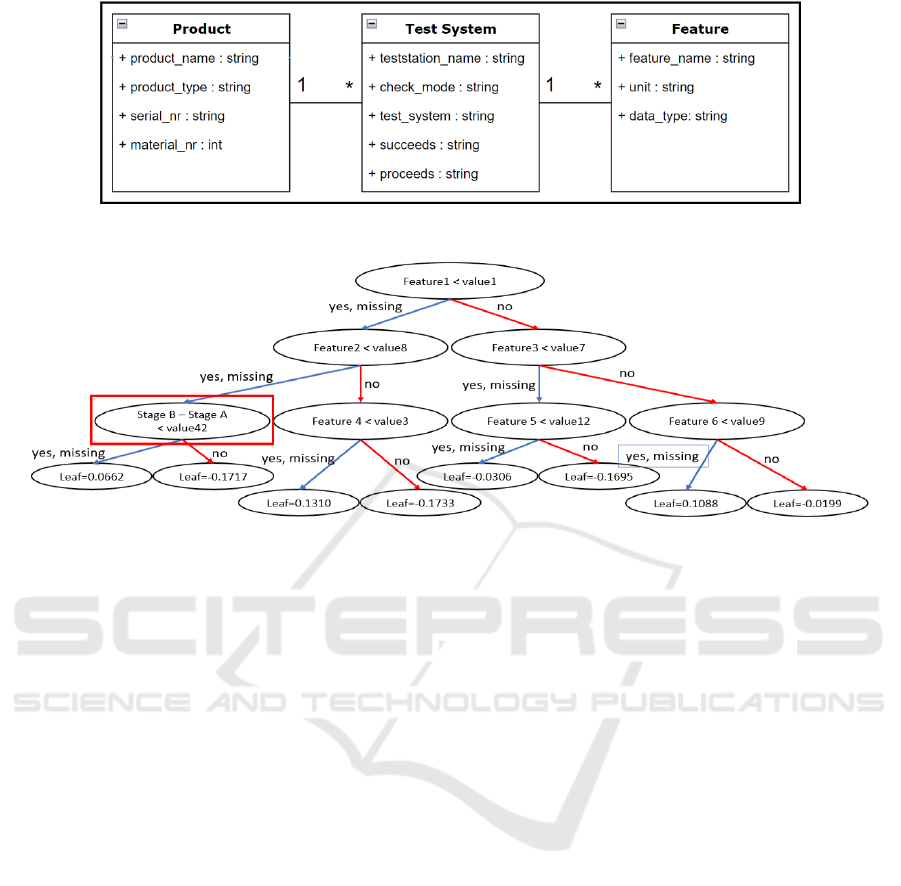

Figure 2: Simplified ontology (presented as entity relationship model).

Figure 3: Decision tree.

products across several test stations. With both

mentioned information, our tool can merge data from

various test stations and use it later for the analysis.

Further features to be defined are datetime and

categorical features. From the datetime feature, we

can derive time-relevant features. The categorical

features will be converted into usable information for

the classifier. Soon, we will extend information of a

future by additional information like the unit i.e., volt

or ampere. With this additional information, further

derivations can be carried out. Moreover, features

with similar units can be grouped and selected or

removed for later analyses. This allows a specific

error to be narrowed down even further and simplifies

the analysis.

In Figure 2 we illustrate a simplified UML

diagram for the ontology for our AutoML tool. We

show how the three classes are connected and their

specific attributes. In the Test System class, we have

the attributes succeeds and proceeds, which helps to

rebuild the production line structure. This represents

the Test System and Production Line from our

ontology (Gerling et al., 2020). In the Product class,

we have the attributes serial_nr and material_nr.

These two attributes may be combined and could

represent one value/attribute to create a unique

identifier. However, there may be cases in which

more than two features or even just one can serve as

a unique identifier. In the Feature class we can use the

unit attribute to afterwards create feature groups from

the production data. The unit attribute could

especially be used to narrow down the origin of an

error. The Feature class represents the Test

Specification from our ontology.

6 RESULTS

In this section, we show five specific cases from five

different products. We discuss the reasons for the

production error and show visualizations from our

AutoML tool which help to identify them. To protect

the confidential information of our partner company,

we only visualize important features with obfuscated

values and names.

6.1 Case 1

In the first case, we analyzed the general error

probability in four consecutive production steps. The

production setup for this product is already highly

optimized, so no quick results could be found by the

quality engineers anymore. Also, most of the features

that could possibly correlate to any common error

were investigated before. In this situation, quality

engineers approached us with the need to further

reduce the generally low error probability. This is

why we did not focus on a specific error.

Results from using an Automl Tool for Error Analysis in Manufacturing

105

We could achieve a good result for error

prediction but - at the first glance - no clear

correlation between the errors with any specific

feature could be identified. However, a naive

approach of analyzing the first decision tree of the

XGBoost model, a user with domain knowledge

background was able to identify a specific feature. In

Figure 3 we can see the first decision tree of the model

and at the lower-left corner the identified feature. This

visualization is automatically created by our AutoML

tool and shows the rules that are used by the ML

Model. Moreover, a decision tree shows multiple

chains of rules that can be utilized for independent

error analysis. In this case, the feature identified by a

quality engineer was generated during data

preprocessing and was not part of the initial dataset.

This shows why good feature engineering can

significantly improve the results and create insights

that are hard to achieve by a human.

Figure 4: Time difference stage B – stage A.

As the next step, we took a closer look at the

histogram of the time difference feature. In Figure 4

we can see that this error held further hidden

information. On the x-axis of the histogram, the value

range is divided into several buckets which represent

the number of days. The columns are colored darker

depending on the percentage of corrupt products. As

an aid, the number of absolute and the percentage of

corrupt products within the separated value range is

shown above the column. The y-axis shows the

number of instances in a natural logarithm to provide

a better visual representation. In this figure, we can

recognize that the percentage of corrupt parts is

significantly too high if the time difference is smaller

than 5 hours. This means that the product must rest

longer between to stations to reduce the number of

errors.

After a discussion with the quality engineer, we

found that the product parts are treated with glue at

the first station. This means, that we possibly

identified the error root cause and are now evaluating

a rule to let the product rest longer between the

stations. The results of this evaluation are still

pending. In this specific case, the time difference was

not the origin of the error but provided a direct hint.

By identifying this feature, a quality engineer was

able to perform more in-depth and targeted analyses.

6.2 Case 2

In the second case, we analyzed the specific error

message “Measurement Accuracy Distance Value too

high”. This error cause could be found through

analyzing the feature importance. Based on the

feature importance, the “Material number” was the

most important feature.

Figure 5: Error frequency depending on material number.

In Figure 5 we can see that all errors correspond

to the value range of 15 to 18 of the material number.

As the material number corresponds to a certain type

of subproduct, we can specify further analyses with

these. It has turned out that the subproduct types with

the material number 15 - 18 have different

specifications regarding range and accuracy.

Figure 6: Measurement accuracy maximum distance

value 1.

Figure 6 shows the second most important feature

for this case. The device accuracy is measured on

different targets (e.g., reflectors or 5%-black) in

different distances ranging from very close to very

far. Measurement 1 is done on a reflecting foil in a

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

106

very close range, so the detector is near its saturation.

Measuring with too high accuracy here leads to bad

results in long range measurements on less reflective

targets. It might very well be, that the device is

electrically overcompensating, or emitter and

detector are not adjusted in a perfect manner.

Nearly all occurred errors are in the value range

of approximately 27-29. Whereas good parts range

from 64 to 68 approx. This information can further

strengthen the analysis of the product error and lead

us to a specific feature respectively product part. We

suggested that, as a first step, all product parts that are

unique to the material numbers 15+ and that may

influence the accuracy of the measurements to be

investigated further.

6.3 Case 3

In our third case, we analyze another product error, in

which we did not optimize the model for one specific

error but for a general error prediction. We retrieved

data from a chain of test stations from a production

line. The following visualizations belong to a specific

test station. In this case, the most important feature

was the modulation feature. Modulation is the process

of adding information to an electrical or optical

carrier signal. The modulation can change the signal’s

frequency (frequency modulation, FM) or its

amplitude (amplitude modulation, AM). In Figure 7

we can see this feature and the increasing error rate in

the higher value range.

Figure 7: Error frequency depending on modulation.

We further create a SHAP dependence plot

(Lundberg and Lee, 2017) for the modulation feature

in Figure 8.

At the x-axis the modulation feature with the

value range. On the left side of the y-axis, we see the

associated SHAP value for the modulation feature.

The right side of the y-axis shows the feature with the

highest interaction with the modulation feature and

the associated values of this feature. High feature

values are colored in red and low feature values are

Figure 8: Modulation SHAP dependence plot.

colored in blue. Therefore, we know that the

modulation feature has the most interaction with the

amplitude feature, which is also the second most

important feature by the feature importance. The error

probability (high SHAP value) is increased with an

increasing value of modulation. Furthermore, an

interaction between modulation and amplitude can be

seen. A high modulation value goes together with a

high amplitude value. This correlation between

modulation and amplitude is already known by a

quality engineer but the provided visualization

strengthens the trust in our AutoML tool because it

shows the real behavior of product features.

Figure 9: Error frequency depending on amplitude.

Next, the amplitude feature is shown in Figure 9.

This feature was the second most important based on

the feature importance list. This visualization shows

that products with a high amplitude tend to make

errors more often. If technically possible and

economically rational, it might be a good idea to

switch from amplitude to frequency modulation,

which is a lot more robust against amplitude changes

of the base signal.

Based on Figure 8 and Figure 9 it became clear

that a solution correcting the root cause will not be

achieved quickly. In the meantime, one could

implement a control function within the testing

equipment to detect error-prone combinations of the

mentioned features. Modules with high amplitudes

Results from using an Automl Tool for Error Analysis in Manufacturing

107

and / or modulation could be sorted out in the

production line as early as possible. Even if the error

will not disappear completely in this case, the

situation will improve as our tool is optimizing the

model towards an economic optimum and not 0%

error rate.

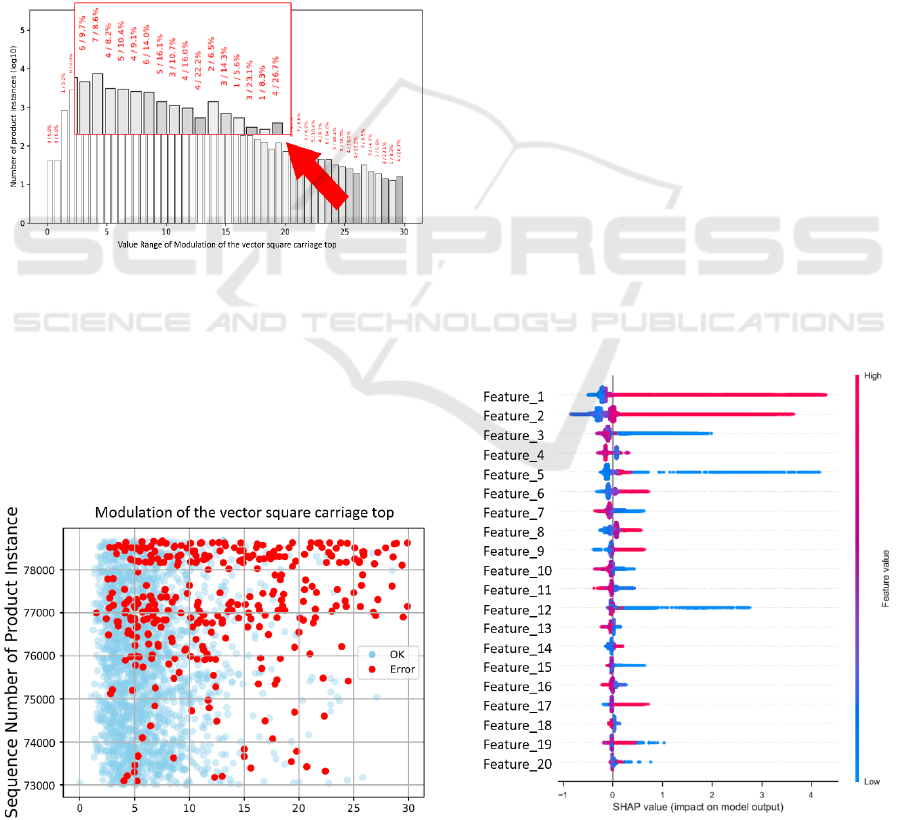

6.4 Case 4

For the fourth case, we analyze the specific product

error “Cosine trace too high”. In this case, we took

features from one test station to predict errors at the

subsequent test station in the production line. The

most important feature here is “vector square carriage

top”. We first take a look at the histogram of this

feature in Figure 10.

Figure 10: Modulation of vector square carriage top.

We can see that the highest error probability is

related to the value of the feature ranging from 21 to

29. Here we could restrict the tolerance or only let

through products with the maximum value of 20. At

first glance, this amount of error might be acceptable

if the error is not extremely expensive. However, in

this case we want to show another relevant factor in

manufacturing.

Figure 11: Modulation of the vector square carriage top

scatter plot.

In Figure 11 we show the time progression of the

error as it occurred. In this visualization, the latest

products are represented by a high product instance

number. It can be seen that the error caused by this

feature has occurred in two waves and was relevant at

the time of analysis. Note, that not all good products

are shown in this visualization to reduce overplotting.

Specifically, we randomly selected 2000 data points

of good products and visualized them alongside all

errors that occurred. Nevertheless, due to the actuality

of the occurred errors, we could consult with the

responsible employees about recent changes in the

production. This could create further conclusion of

the occurred product error. Through this discussion, a

solution to the error could be found and as a

consequence, the production could be corrected. We

suggested to investigate the change before the start of

the second wave of errors and the change that led to

the end of the first wave.

6.5 Case 5

In this case, we want to highlight the advantage to use

model agnostic techniques within our AutoML tool.

These techniques help to comprehend the model

decisions and provide an additional way to analyze

the error cause further. We take advantage of this to

automatically provide customized visualizations for

the user. For this purpose, we show two visualizations

that demonstrate the learned decision of the trained

ML model. For the sake of demonstration, we

obfuscated the feature names and values.

Figure 12: SHAP summary plot.

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

108

For a deeper investigation of the origin of an

error, a SHAP Summary Plot (Lundberg and Lee,

2017) is automatically generated by our AutoML

tool. Here, the features learned from the model are

sorted from top to bottom in order of feature

importance. With this plot, we can visualize various

information to the quality engineer. First, the

importance of the features and their order. Further,

the different dots are colored according to the value

of each instance. Moreover, the SHAP value on the x-

axis shows a tendency if a product instance could be

good (negative SHAP value) or corrupted (positive

SHAP value). In Figure 12 we can see that Feature_1

and Feature_2 both tend to an error when the

measured value is high with a SHAP value over 3.

Also, feature Feature_3, Feature_5, and Feature_12

tend to an error when the measured value is low.

Feature_5 represents a time difference between two

test stations, which was derived with the help of

domain knowledge. As can be seen in the SHAP

Summary Plot, the product has a higher tendency to

fail when the value is low. For the explanation, at test

station A a heat test was performed on a product.

After that, the product was cooled down in the

subsequent test station B. If the internal components

of the product are still too hot, this product will not

pass the followed check at test station B. In a further

investigation, we saw that the product should

approximately cool down about 8 minutes, or else the

ratio to fail the test station check at test station B will

be much higher.

Figure 13: SHAP dependence plot of Feature_3.

In Figure 13 we show the SHAP Dependence Plot

of Feature_3 from the previous visualization. We

found the strongest interaction between Feature_3

and Feature_2. In this visualization, we can see in-

depth, how the values of this feature are distributed in

three distinguishable regions. One region spanning

from values of -4.5 to approx. -1.8 and another one in

range of approx. -1.8 to approx. 5.0. It should be

investigated what the cause for this behavior is

especially in the last region of values in the range

from -4.0 to -4.5 where a high SHAP values are given.

6.6 Lessons Learned

With the above-described cases, we demonstrated the

benefit to use our AutoML tool. First, we can support

the tasks of a quality engineer with meaningful

visualizations and further information about the error

root cause analysis. This speeds up the time between

the error’s first occurrence and the implementation of

a solution.

We provide further visualization technics with the

help of ML-like in the test case. A further advantage

is, that a quality engineer can use our tool without any

knowledge in the field of ML while at the same time

the data scientist does not need specific domain

knowledge because this can be easily formalized and

provided in a single file by the quality engineer. By

automating the data merging, processing, and

enhancement, we save the quality engineer time and

bring helpful information to the analysis like the time

differences between test stations. The user is provided

with the most important features for the analysis,

which often lead to the origin of an error.

Furthermore, the visualized feature can point to

hidden causes of errors like in Case 1. Therefore, it is

important to include as much relevant data for

analysis as possible. Often, even trivial reasons such

as the temperature in the production hall or the time

of production can bring decisive advantages to the

analysis.

7 CONCLUSION

In this paper, we investigate the benefit of AutoML

for error analysis in manufacturing along with real-

world cases. We describe the difficulties that arise in

a complex production environment and provide a

brief overview of the workflow. In five real-world use

cases, we could provide respectively assist in

identifying the error origin using AutoML. In these

five cases, we found clear correlations to a possible

error origin. Further, we provide domain experts the

possibility to combine domain knowledge of a

product or production line with an easy-to-use

AutoML tool. This leads to a synergy that would

otherwise be unused. Therefore, we offer a data

science layperson the possibility, without prior

knowledge in the field of ML, to use our AutoML tool

and benefit from the advantages for an analysis.

Results from using an Automl Tool for Error Analysis in Manufacturing

109

Through this paper, we now can answer the

research questions from the introduction. First, we

demonstrated that the PREFERML AutoML tool

provided useful visualization and further information

to analyze the origin of an error (RQ1). Even if a

visualization could not show the direct cause of an

error, it could point out an important feature that led

to a possible reason, as in case 1 (RQ2). Furthermore,

we found that, if the root cause was not found or could

not be solved, our tool gives easy guidelines on how

to implement a function or process to sort out

products with a high error probability.

In the near future, we want to use domain

knowledge more efficiently by establishing an

advantage product ontology. Further, we want to test

our AutoML tool with more products and gather

feedback from different user groups to improve it

even more. We also want to improve the Explainable

ML part of the AutoML tool to provide further

analysis to quality engineers and support the ML

decision with various visualizations.

ACKNOWLEDGEMENTS

This project was funded by the German Federal

Ministry of Education and Research, funding line

“Forschung an Fachhochschulen mit Unternehmen

(FHProfUnt)“, contract number 13FH249PX6. The

responsibility for the content of this publication lies

with the authors. Also, we want to thank the company

SICK AG for the cooperation and partial funding.

REFERENCES

Banzhaf, W., Nordin, P., Keller, R. E., and Francone, F. D.

1998. Genetic programming: an introduction: on the

automatic evolution of computer programs and its

applications. Morgan Kaufmann Publishers Inc.

Caggiano, A., Zhang, J., Alfieri, V., Caiazzo, F., Gao, R.,

and Teti, R. 2019. Machine learning-based image

processing for on-line defect recognition in additive

manufacturing. CIRP Annals 68, 1, 451–454.

Candel, A., Parmar, V., LeDell, E., and Arora, A. 2016.

Deep learning with H2O. H2O. ai Inc, 1–21.

Carvajal Soto, J. A., Tavakolizadeh, F., and Gyulai, D.

2019. An online machine learning framework for early

detection of product failures in an Industry 4.0 context.

International Journal of Computer Integrated

Manufacturing 32, 4-5, 452–465.

Chapman, P., Clinton, J., Kerber, R., Khabaza, T., Reinartz,

T., Shearer, C., Wirth, R., and others. 2000. CRISP-DM

1.0: Step-by-step data mining guide. SPSS inc 9, 13.

Chen, T., & Guestrin, C. (2016). XGBoost: A Scalable Tree

Boosting System. In Proceedings of the 22nd ACM

SIGKDD International Conference on Knowledge

Discovery and Data Mining (pp. 785–794). New York,

NY, USA: ACM.

https://doi.org/10.1145/2939672.2939785

Dogan, A. and Birant, D. 2021. Machine learning and data

mining in manufacturing. Expert Systems with

Applications 166, 114060.

Feurer, M., Klein, A., Eggensperger, K., Springenberg, J.

T., Blum, M., and Hutter, F. 2019. Auto-sklearn:

efficient and robust automated machine learning. In

Automated Machine Learning. Springer, Cham, 113–

134.

Gerling, A., Schreier, U., Heß, A., Saleh, A., Ziekow, H.,

Abdeslam, D. O., Nandzik, J., Hannemann, J., Flores-

Herr, N., and Bossert, K. 2020. A Reference Process

Model for Machine Learning Aided Production Quality

Management. In ICEIS (1), 515–523.

Gerling, A., Seiffer, C., Ziekow, H., Schreier, U., Hess, A.

and Abdeslam, D. 2021a. Evaluation of Visualization

Concepts for Explainable Machine Learning Methods

in the Context of Manufacturing. In Proceedings of the

5th International Conference on Computer-Human

Interaction Research and Applications, pages 189-201.

Gerling, A., Ziekow, H., Schreier, U., Seiffer, C., Hess, A.,

and Abdeslam, D. O. 2021b. Evaluation of Filter

Methods for Feature Selection by Using Real

Manufacturing Data. In DATA ANALYTICS 2021:

The Tenth International Conference on Data Analytics,

October 3-7, 2021, Barcelona, Spain, 82–91.

Golovin, D., Solnik, B., Moitra, S., Kochanski, G., Karro,

J., and Sculley, D. 2017. Google vizier: A service for

black-box optimization. In Proceedings of the 23rd

ACM SIGKDD international conference on knowledge

discovery and data mining, 1487–1495.

Hirsch, V., Reimann, P., and Mitschang, B. 2019. Data-

driven fault diagnosis in end-of-line testing of complex

products. In 2019 IEEE International Conference on

Data Science and Advanced Analytics (DSAA), 492–

503.

Kirchen, I., Vogel-Heuser, B., Hildenbrand, P., Schulte, R.,

Vogel, M., Lechner, M., and Merklein, M. 2017. Data-

driven model development for quality prediction in

forming technology. In 2017 IEEE 15th international

conference on industrial informatics (INDIN), 775–

780.

Krauß, J., B. M. Pacheco, H. M. Zang, and R. H. Schmitt.

“Automated Machine Learning for Predictive Quality

in Production.” Procedia CIRP 93 (2020): 443–48.

https://doi.org/https://doi.org/10.1016/j.procir.2020.04.

039.

Kotthoff, L., Thornton, C., Hoos, H. H., Hutter, F., and

Leyton-Brown, K. 2019. Auto-WEKA: Automatic

model selection and hyperparameter optimization in

WEKA. In Automated Machine Learning. Springer,

Cham, 81–95.

Li, Z., Zhang, Z., Shi, J., and Wu, D. 2019. Prediction of

surface roughness in extrusion-based additive

ICEIS 2022 - 24th International Conference on Enterprise Information Systems

110

manufacturing with machine learning. Robotics and

Computer-Integrated Manufacturing 57, 488–495.

Liu, G., Gao, X., You, D., and Zhang, N. 2019a. Prediction

of high power laser welding status based on PCA and

SVM classification of multiple sensors. Journal of

Intelligent Manufacturing 30, 2, 821–832.

Liu, Y., Zhou, H., Tsung, F., and Zhang, S. 2019b. Real-

time quality monitoring and diagnosis for

manufacturing process profiles based on deep belief

networks. Computers & Industrial Engineering 136,

494–503.

Lundberg, S., & Lee, S. I. (2017). A unified approach to

interpreting model predictions. arXiv preprint

arXiv:1705.07874.

Maher, Mohamed Mohamed Maher Zenhom Abdelrahman,

and Sherif Sakr. 2019. SmartML: A Meta Learning-

Based Framework for Automated Selection and

Hyperparameter Tuning for Machine Learning

Algorithms. EDBT: 22nd International Conference on

Extending Database Technology, Mar.,

doi:10.5441/002/edbt.2019.54.

Olson, R. S. and Moore, J. H. 2016. TPOT: A tree-based

pipeline optimization tool for automating machine

learning. In Workshop on automatic machine learning,

66–74.

Olson, R. S., Urbanowicz, R. J., Andrews, P. C., Lavender,

N. A., La Kidd, C., and Moore, J. H. 2016. Automating

biomedical data science through tree-based pipeline

optimization. In European conference on the

applications of evolutionary computation, 123–137.

Pedregosa, F., Varoquaux, G., Gramfort, A., Michel, V.,

Thirion, B., Grisel, O., Blondel, M., Prettenhofer, P.,

Weiss, R., Dubourg, V., Vanderplas, J., Passos, D.,

Brucher, M., Perrot, M., & Duchesnay, E. (2011).

Scikit-learn: Machine Learning in Python. Journal of

Machine Learning Research, 12, 2825–2830.Ribeiro,

M. T., Singh, S., & Guestrin, C. (2016). "Why

Should I Trust You?". Proceedings of the 22nd ACM

SIGKDD International Conference on Knowledge

Discovery and Data Mining.

https://doi.org/10.1145/2939672.2939778

Ren, L., Meng, Z., Wang, X., Zhang, L., and Yang, L. T.

2020. A data-driven approach of product quality

prediction for complex production systems. IEEE

Transactions on Industrial Informatics.

Seiffer, C., Gerling, A., Schreier, U., & Ziekow, H. 2020.

A Reference Process and Domain Model for Machine

Learning Based Production Fault Analysis. In

International Conference on Enterprise Information

Systems (pp. 140-157). Springer, Cham.

Seiffer, C., Ziekow, H., Schreier, U., and Gerling, A. 2021.

Detection of Concept Drift in Manufacturing Data with

SHAP Values to Improve Error Prediction. In DATA

ANALYTICS 2021: The Tenth International

Conference on Data Analytics, October 3-7, 2021,

Barcelona, Spain, 51–60.

Tangjitsitcharoen, S., Thesniyom, P., and

Ratanakuakangwan, S. 2017. Prediction of surface

roughness in ball-end milling process by utilizing

dynamic cutting force ratio. Journal of Intelligent

Manufacturing 28, 1, 13–21.

Turetskyy, A., Wessel, J., Herrmann, C., and Thiede, S.

2021. Battery production design using multi-output

machine learning models. Energy Storage Materials 38,

93–112.

Virtanen, Pauli; Gommers, Ralf; Oliphant, Travis E.;

Haberland, Matt; Reddy, Tyler; Cournapeau, David et

al. (2020): SciPy 1.0: Fundamental Algorithms for

Scientific Computing in Python. In: Nature Methods

17, S. 261–272. DOI: 10.1038/s41592-019-0686-2.

Wilhelm, Y., Schreier, U., Reimann, P., Mitschang, B., and

Ziekow, H. 2020. Data Science Approaches to Quality

Control in Manufacturing: A Review of Problems,

Challenges and Architecture. In Symposium and

Summer School on Service-Oriented Computing, 45–

65.

Ziekow, H., Schreier, U., Gerling, A., & Saleh, A. 2019a.

Technical Report: Interpretable machine learning for

quality engineering in manufacturing-Importance

measures that reveal insights on errors.

Ziekow, H., Schreier, U., Saleh, A., Rudolph, C., Ketterer,

K., Grozinger, D., and Gerling, A. 2019b. Proactive

error prevention in manufacturing based on an

adaptable machine learning environment. In Artificial

Intelligence: From Research to Application: Proc. of

the Upper-Rhine Artificial Intelligence Symposium

UR-AI, 113–117.

Results from using an Automl Tool for Error Analysis in Manufacturing

111