Study on the Adsorption Technology of Chitosan to the Protein in

Tofu Yellow Slurry Water

Cili Li

1a

and Jianbo Cheng

2b

1

College of food engineering, Harbin University of Commerce, Harbin 150028, China

2

Heilongjiang Feihe Dairy Co., Ltd., Qiqihar 161005, China

Keywords: Tofu Yellow Slurry Water, Chitosan, Protein, Adsorption.

Abstract: In this paper, the protein removal rate was used as an indicator to study the effects of the amount of chitosan

added, reaction time, reaction temperature, and pH on the process of chitosan's adsorption of protein in tofu

yellow slurry water. Orthogonal experiments were used to determine the optimal reaction conditions. The

results show that, optimum conditions for chitosan to adsorb protein in tofu yellow slurry water: chitosan

added 1.0g/L, pH 7, temperature 20℃, the response time is 3h, the removaling rate is 51.64%. The results

show that chitosan can be utilized to the process of the recycling of soybean protein and Tofu yellow slurry

water.

1 INTRODUCTION

1

Soybean is one of the main food and oil crops in the

world. Processed products using soybeans as raw

materials are favored by consumers because

soybeans are rich in high-quality protein, calcium,

potassium, iron, copper, zinc and other trace

elements, vitamin B1 and B2, organic acids and

cellulose and other nutrients (Diao, 2015, Wang,

2019). The most popular food developed with

soybeans as a raw material by consumers is

traditional tofu. A large amount of yellow slurry

water is generated in the production of tofu. It is

estimated that 8-10 tons of wastewater will be

generated from processing 1 ton of soybeans (Du,

2008). Tofu yellow slurry water is produced in the

process of extracting tofu from soy milk and alkali-

dissolved supernatant. According to the current

research status (Che, 2017), yellow slurry water

contains a lot of organic matter, which contains

about 1700 mg/L of oil, 3800~4000mg/L of protein,

7000~20000 mg/L of total sugar, and 800~1700 mg

of total nitrogen (TN). /L, total phosphorus (TP)

100~200mg/L, BOD5 value is about

5000~10000mg, COD value is 20000~24000mg, it

is a kind of wastewater with high concentration and

high degree of biodegradability (Xie, 2009).

a

https://orcid.org/0000-0001-7519-7790

b

https://orcid.org/0000-0002-2481-7985

Therefore, if the protein in the fermented tofu yellow

slurry water can be effectively recovered, not only

the utilization of raw materials will be improved, but

the sewage will be purified, and the pressure of

subsequent sewage treatment will be reduced,

thereby realizing the unification of environmental

and economic benefits.

Chitosan is a natural biopolymer of basic amino

polysaccharides, which is the product of

deacetylation of chitin. Chitosan has excellent

biocompatibility, non-toxicity and easy chemical

modification (Xie, 2013, Chen, 2001). Studies have

found that chitosan can be used as a flocculant for

water treatment. It has good effects in the treatment

of food wastewater, papermaking wastewater and

urban domestic wastewater. This paper studies the

flocculation conditions of chitosan to adsorb protein

in tofu yellow slurry water, which can provide a

certain theoretical basis for the treatment of tofu

yellow slurry wate.

64

Li, C. and Cheng, J.

Study on the Adsorption Technology of Chitosan to the Protein in Tofu Yellow Slurry Water.

DOI: 10.5220/0011180500003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 64-69

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

2 MATERIALS AND METHODS

2.1 Materials and Reagents

Soybeans, Northeast soybeans are commercially

available. Chemical reagents such as sodium

hydroxide, hydrochloric acid, acetic acid, and

methyl orange are all analytically pure. Chitosan,

Zhejiang Golden Shell Biochemical Co., Ltd.;

Bovine Serum Protein, Jilin Boshen Biotechnology

Co., Ltd..

2.2 Instruments and Equipment

Model 752 UV-Vis Spectrophotometer, Shanghai

Spectrometer Co., Ltd.; HZS-H Water Bath

Oscillator, Harbin Donglian Electronic Technology

Development Co., Ltd.; PHS-25 Digital Display pH

Meter, Shanghai Precision Scientific Instrument Co.,

Ltd.; ALC-2100 electronic balance, Shanghai

Precision Instrument Co., Ltd.; DHG-9123A electric

heating constant temperature blast drying oven,

Shanghai Yuejin Medical Equipment Factory; DK-

98-II electric heating constant temperature water

bath, Shanghai Yuejin Medical Equipment Factory;

JB-1 timing two-way Magnetic stirrer, Jiangsu

JintanRonghua Instrument Manufacturing Co., Ltd.;

80-2 centrifuge, Shanghai Anting Instrument

Factory; HZQ-C air bath oscillator Harbin Donglian

Electronic Technology Development Co., Ltd.,

DHP-9162 electric heating constant temperature

incubator Shanghai Yiheng Technology Co., Ltd..

2.3 Method

2.3.1 Preparation of Tofu Yellow Slurry

Water

Evenly take the tofu whey wastewater (yellow slurry

water) discharged when the traditional method is

used to produce tofu. 1 kg of raw soybeans produces

2.5 kg of tofu and discharges 8.95 kg of yellow

water.

2.3.2 Preparation of Chitosan Solution

The experiment uses glacial acetic acid to prepare

1% chitosan solution. Specific steps: (1) Configure

1% acetic acid solution. (2) Add an appropriate

amount of chitosan to 1% acetic acid solution, and

prepare 1% chitosan solution. A magnetic stirrer can

be used to help chitosan dissolve uniformly in acetic

acid.

2.3.3 Determination of the Degree of

Deacetylation of Chitosan

In the experiment, the degree of deacetylation of

chitosan was measured by acid-base titration. The

specific steps are as follows: accurately weigh

0.3~0.5g of chitosan dried to constant weight at

105℃, put it in a 250mL Erlenmeyer flask, add

30mL of 0.1mol/L hydrochloric acid standard

solution, and stir at 20℃~25℃ until it is completely

dissolved, Add 2~3 drops of methyl orange

indicator, titrate free hydrochloric acid with

0.1mol/L sodium hydroxide standard solution to the

end point (WU S H, 2009). Deacetylation degree

calculation formula:

Free amino content

(

−𝑁𝐻

)

%=

(

)

×.×%

Degree of deacetylation =

(

)%×%

.%

Where:

C1-Concentration of hydrochloric acid standard

solution, mol∕L

C2-Concentration of sodium hydroxide standard

solution, mol∕L

V1-The volume of hydrochloric acid standard

solution added, mL

V2-The volume of sodium hydroxide standard

solution consumed during titration, mL

G-Sample weight, g

0.016-The amount of amino group equivalent to

1mL 1 mol/L hydrochloric acid solution, g

9.94%-Theoretical amino content.

2.3.4 Single-factor Experiment of Protein

Adsorption in Tofu Yellow Slurry

Water

The Effect of Chitosan Addition on Protein

Removal Rate.

Take five 50mL colorimetric

tubes, and add 50mL tofu yellow slurry water,

labeled 1~5. Maintain the pH of the original

wastewater. Add 1% chitosan solution to No. 1~5

respectively, that is, the amount of chitosan added:

0.4g/L, 0.6g/L, 0.8g/L, 1.0g/L, 1.2g/L. The protein

removal rate is used as an indicator to determine the

optimal amount of chitosan added.

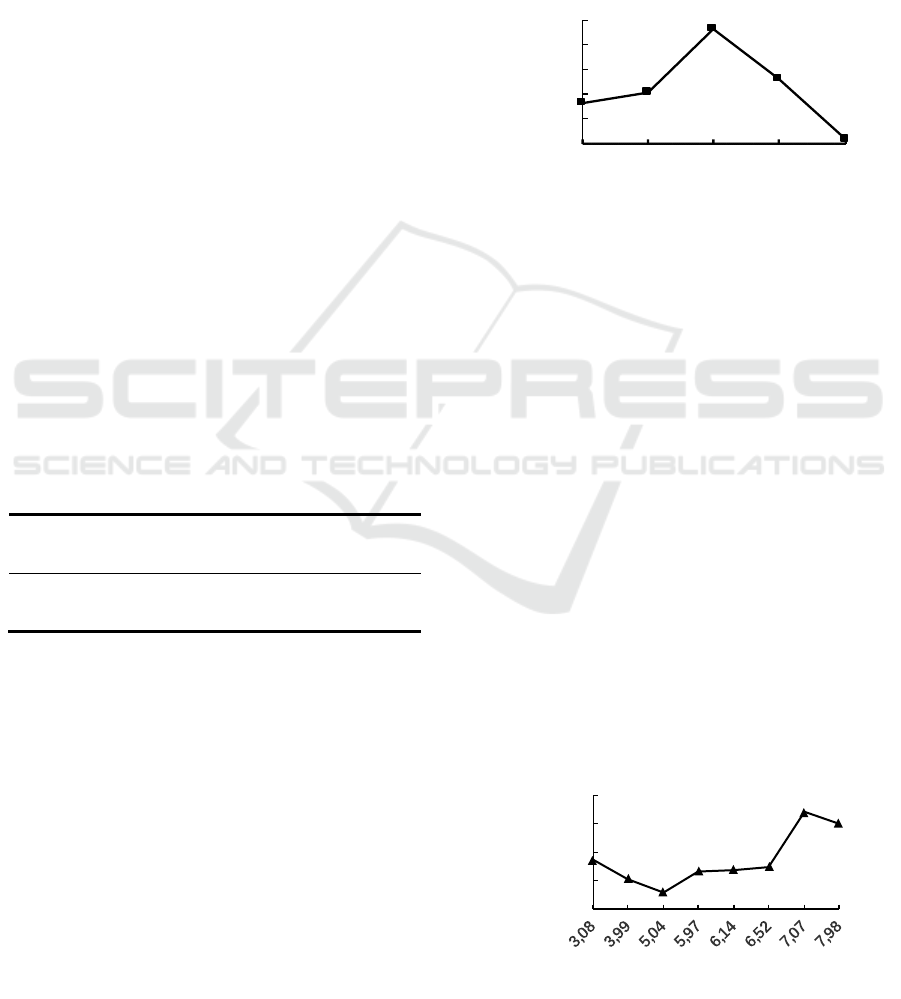

The Effect of pH on Protein Removal Rate.

Take eight 50mL colorimetric tubes, add 50mL of

tofu yellow slurry water, labeled 1~8, add chitosan

to 0.8 g/L, and adjust the pH to 3.08, 3.99, 5.04,

5.97, 6.14, 6.52, 7.07, 7.98, respectively. The protein

removal rate is an indicator to determine the optimal

pH.

Study on the Adsorption Technology of Chitosan to the Protein in Tofu Yellow Slurry Water

65

0

10

20

30

40

Protein removal rate/%

pH

0

5

10

15

20

25

0,4 0,6 0,8 1 1,

2

Protein removal rate/%

Chi tosan addition/g.L-1

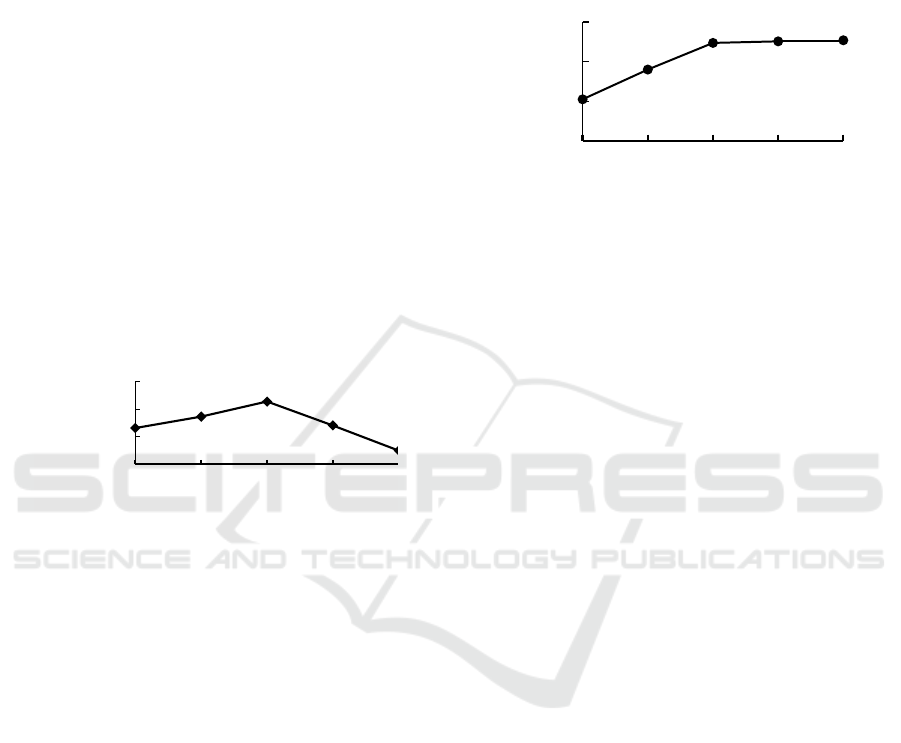

The Effect of Temperature on Protein

Removal Rate.

Take five 50mL colorimetric

tubes, label 1~5 and add 50mL tofu yellow water.

The amount of chitosan added was 0.8 g/L, the pH

was 7.07, and the reaction temperature was

controlled at 5°C, 17°C, 25°C, 35°C, and 45°C. The

protein removal rate was used to determine the

optimal reaction temperature.

The Effect of Reaction Time on Protein

Removal Rate.

Take five 50mL colorimetric

tubes, and add 50mL tofu yellow slurry water,

labeled 1~5. The amount of chitosan added was 0.8

g/L, the pH was 7.07, the temperature was 25°C, the

reaction time was controlled to 1h, 2h, 3h, 4h, 5h,

and the protein removal rate was used to determine

the optimal reaction time.

2.3.5 Orthogonal Experiment on the

Absorption of Protein in Tofu Yellow

Slurry Water

According to the results of the single factor

experiment, the reaction time is controlled to 3h, and

the addition amount of chitosan, pH, and reaction

temperature are selected as factors for L9 (34)

orthogonal test. The protein removal rate is used as

an indicator to determine the best process

conditions. The experimental design is shown in

Table 1.

Table 1: Test factor level table.

Level

A

pH

B

the addition amount of

chitosan/g﹒L

-1

C

T/℃

1

2

3

6.5

7

7.5

0.6

0.8

1.0

20

25

30

3 RESULTS AND ANALYSIS

3.1 Determination of the Degree of

Deacetylation of Chitosan

The degree of deacetylation of chitosan was

determined according to 1.3.3, and the degree of

deacetylation of chitosan used in the test was 72.4%.

3.2 Single-factor Experiment of Protein

Adsorption in Tofu Yellow Slurry

Water

3.2.1 The Effect of Chitosan Addition on

Protein Removal Rate

The relationship between the amount of chitosan

added and the protein removal rate is shown in

Figure 1:

Figure 1: The effect of chitosan addition on protein

removal rate.

It can be seen from Figure 1 that as the amount

of chitosan added increases, the protein removal rate

shows a trend of first increasing and then decreasing.

When the added amount reaches 0.8g/L, the protein

removal rate reaches the maximum, indicating that

the adsorption and separation effect of chitosan on

protein is the best at this time. The analysis believes

that when the amount of chitosan added is small, the

protein cannot fully bind to the chitosan, so it cannot

completely react to form a protein-chitosan

complex; when the amount of chitosan added is too

high, it will inhibit the formation of the protein-

chitosan complex, and the reaction consumes too

much chitosan, which is a waste of resources, so the

optimal addition amount of chitosan is 0.8g/L.

3.2.2 The Effect of pH on Protein Removal

Rate

The relationship between the pH of tofu yellow

slurry water and the protein removal rate is shown in

Figure 2:

Figure 2: The effect of pH on protein removal rate.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

66

It can be seen from Figure 2 that when the pH is

3~5, as the pH of the protein increases, the protein

removal rate decreases. This is because the protein is

positively charged at this time, and the chitosan is

also positively charged, and the two repel each

other, so when the pH is 5, the protein removal rate

reaches the lowest. When the pH is between 5 and 7,

the protein removal rate increases as the pH

increases. This is because when the pH of the

protein is greater than the isoelectric point, the

protein is negatively charged and attracts the

positive charge of chitosan to form a protein-

chitosan complex. When the pH is 7.04, the protein

removal rate reaches the maximum. Therefore, the

optimal pH value is 7.04.

3.2.3 The Effect of Temperature on Protein

Removal Rate

The relationship between temperature and protein

removal rate of tofu yellow slurry water is shown in

Figure 3:

0

10

20

30

5 1725354

Protein removal

rate/%

Temperature/℃

Figure 3: The effect of temperature on protein removal

rate.

It can be seen from Figure 3 that too high

temperature will inhibit the formation of chitosan-

protein complexes. As the reaction temperature

increases, the protein removal rate gradually

increases, which proves that the increase in

temperature is beneficial to the adsorption and

separation of proteins by chitosan. When the

temperature reaches 25°C, the protein removal rate

reaches the maximum, and chitosan has the best

effect on protein adsorption and separation. After

that, the protein removal rate decreases with the

increase of temperature. Excessive temperature

affects the adsorption and separation effect.

Therefore, the optimal reaction temperature is 25°C.

3.2.4 The Effect of Time on Protein

Removal Rate

The relationship between time and the protein

removal rate of fermented bean curd syrup is shown

in Figure 4:

0

10

20

30

12345

Protein removal rate/%

Time/h

Figure 4: The effect of time on protein removal rate.

It can be seen from Figure 4 that the prolonged

reaction time can promote the contact and reaction

between chitosan and protein. In 1~3h, the protein

removal rate increased obviously. In3~5h, the

increasing trend of protein removal rate was not

obvious, indicating that the adsorption and

separation of protein by chitosan was basically

completed at this time. Therefore, the optimal

reaction time is 3h.

3.3 Orthogonal Experiment on the

Adsorption of Protein in Tofu

Yellow Slurry Water

Table 2 shows the orthogonal experiment results of

chitosan adsorbing protein in tofu yellow slurry

wate.

Study on the Adsorption Technology of Chitosan to the Protein in Tofu Yellow Slurry Water

67

Table 2. Orthogonal test results.

Number

A

pH

B

Chitosan

addition/g.

L

-1

C

Temperature/

℃

D

Empty

column

Protein

removal

rate/%

1 1 1 1 1 32.74

2 1 2 2 2 20.29

3 1 3 3 3 24.96

4 2 2 3 1 27.51

5 2 3 1 2 49.87

6 2 1 2 3 24.18

7 3 3 2 1 38.97

8 3 1 3 2 24.96

9 3 2 1 3 21.84

K

1

77.99 81.88 104.45 99.22

K

2

101.56 69.64 83.44 95.12

K

3

85.77 113.80 77.73 70.98

k

1

25.997 27.293 34.817 33.073

k

2

33.853 23.213 27.813 31.707

k

3

28.590 37.933 25.910 23.660

R 23.57 44.16 26.72 28.24

Major factors→Secondary factors BCA

Optimal schemeA

2

B

3

C

1

From the range R value in Table 2, it can be seen

that the primary and secondary order of the three

factors affecting the protein removal rate is: B>C>A,

that is: chitosan added amount>reaction

temperature>pH, according to the orthogonal

experiment statistical calculations show that the

superior level is A

2

B

3

C

1

. Therefore, a verification

test was carried out, and the protein removal rate of

the combination A

2

B

3

C

1

was measured three times.

The results are shown in Table 3.

Table 3. Protein removal rate of experimental combination A

2

B

3

C

1

Number 1 2 3 Average value

Protein removal rate/% 50.93 52.33 51.65 51.64

From Table 3, the optimal process conditions for

chitosan to adsorb protein in tofu yellow syrup were

determined: chitosan was added at 1.0 g/L, pH was

7, temperature was 20°C, reaction time was 3h, and

protein removal rate was 51.64%.

4 CONCLUSIONS

In this paper, tofu yellow slurry wate is used as the

raw material, The effect of chitosan on the protein

removal rate of tofu yellow syrup was investigated

through single factor experiment, and the optimal

process conditions for chitosan to adsorb protein in

tofu yellow slurry water were determined through

orthogonal experiment design. Get the following

conclusions: (1) The degree of deacetylation of

chitosan was determined by chemical analysis. The

degree of deacetylation of chitosan used in the test

was 72.4%. (2) Using chitosan as a flocculant, we

studied in detail the influence of pH, chitosan

addition, reaction temperature, and reaction time on

the protein removal rate in tofu yellow slurry wate.

(3) We adopted an orthogonal experiment design

and used the protein removal rate as an indicator to

determine the best conditions for chitosan to adsorb

protein in tofu yellow slurry water: pH is 7, the

addition amount of chitosan is 1.0g/L, reaction

temperature is 20℃, The reaction time is 3h. At this

time, the removal rate of protein in the tofu yellow

slurry water was 51.64%.

REFERENCES

Che Y J. (2017). Study on the production of single cell

protein by fermentation of yellow water D. Shangxi

Agricultural University, Jinzhong.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

68

Chen Liang. (2001). Research progress of chitosan

adsorption in wastewater treatment[J]. Sichuan

Environment, 20(3):19-23.

Diao N N. (2015). The utilization research of soybean

wastewater [J]. Food andFermentation Technology,

51(1): 20-24.

Du Ming. (2008). Research progress of soybean whey

protein[J]. Food industry technology, (2):302-305.

Wang Y. (2019). Sustainability of dairy and soy

processing: a review on wastewater recycling[J].

Journal of Cleaner Production, 237: 117821.

WU S H. (2009). Research of Common Indicator of

Degree of Deacetylation of Chitosan by

Alkalimetry[J]. Food Science and Technology. (4):

262-265,275.

Xie Guopai. (2009). Exploration on comprehensive

utilization of yellow pulp water[J], China brewing,

Chinabrewing, (04),129-130.

Xie Jiayi. (2013). Research Progress on characteristics and

application of Chitosan Flocculant[J]. Guangzhou

Chemical, 41(IS):45-47.

Study on the Adsorption Technology of Chitosan to the Protein in Tofu Yellow Slurry Water

69