Effect of Dehydration Process Conditions on Oily Sludge in a Fenton

Advanced Oxidation System

Hongpan Liu

1,2,3

, Yongting Chen

1

, Yulin Zheng

1

, Zhongqing Yang

2,*

, Jiangtao Yu

3,*

and Heshan Yang

1

1

Chongqing Key Laboratory of Environmental Materials & Remediation Technologies, College of Chemistry and

Environmental Engineering, Chongqing University of Arts and Sciences, Chongqing, 402160, China

2

School of Energy and Power Engineering, Chongqing University, Chongqing, 400044, China

3

China Power Investment of Yuanda Environmental Protection Engineering Co. Ltd, Chongqing, 401122, China

1543557532@qq.com

Keywords: Oily Sludge, Fenton, Dehydration, Orthogonal Experiment.

Abstract: Oily sludge is the main solid waste produced by the petrochemical industry and has attracted increasing

attention due to its complex composition, containing a large number of heavy metals and organic toxic

substances. Advanced oxidation technology has attracted much attention as an oily sludge treatment method

as it can be used to reduce the harmful organic matter content and improve the dewatering performance of

oily sludge. Taking oily sludge as the research object, this study adopted an orthogonal experimental design

to investigate the water content and specific resistance of oily sludge by controlling the pH, reaction time

and the mass ratio of hydrogen peroxide to ferrous sulfate (m

H2O2

/m

FeSO4

) of the reaction system. Results

showed that the water content of oily sludge treated using the Fenton reagent was optimal under reaction

conditions of pH 3, with a reaction time of 40 min and m

H2O2

/m

FeSO4

of 10/1. In contrast, the specific

resistance of oily sludge treated using the Fenton reagent was optimal under the conditions of pH 3, with a

reaction time of 50 min and m

H2O2

/m

FeSO4

of 14/1. Among the three factors assessed, the m

H2O2

/m

FeSO4

mass

ratio had the greatest influence on both the water content and specific resistance of oily sludge.

1 INTRODUCTION

Oily sludge is an oily solid waste produced during

the process of oil exploitation, transportation,

refining and oil field oily wastewater treatment in

the petrochemical industry. It generally consists of a

stable suspension emulsion of oil in water (O/W),

water in oil (W/O) and suspended solids. The

composition of oily sludge is highly complex,

containing a large amount of water and numerous

refractory organic substances, heavy metals and

other toxic substances, causing it to be classified as

hazardous waste (Hu 2013). The high moisture

content results in oily sludge having a large volume,

while the untreated heavy metal residues can

accumulate to dangerous concentrations which

endanger human health. Extracellular polymeric

substances (EPS) and metal ions are important

components of oily sludge (Liu 2016). EPS accounts

for about 80% of the sludge content, contributing to

the formation of highly hydrated biofilms

comprising various microorganisms, which adsorbs

a large amount of water and constitutes the sludge

floc skeleton. The EPS content has been reported to

be the most important factor affecting sludge

dewatering (Xiao 2017).

Previous studies have investigated the

mechanism of sludge conditioning using the Fenton

reaction. Hydroxyl radicals (·OH) are produced by a

chain reaction in Fenton systems and have a very

high redox potential (up to 2.8V), which can quickly

oxidize EPS, changing the sludge structure and

achieving sludge conditioning. Zhang et al. studied

the changes in EPS and sludge morphology during

the process of Fenton sludge conditioning via three-

dimensional fluorescence electron microscopy,

finding that oxidation is more important than

flocculation in the process of Fenton sludge

conditioning. After the oxidation of ·OH, the EPS

composition and the morphology of sludge changed,

resulting in a change of floc structure and particle

size (Zhang 2015, Yang 2017). Xu et al. showed that

Liu, H., Chen, Y., Zheng, Y., Yang, Z., Yu, J. and Yang, H.

Effect of Dehydration Process Conditions on Oily Sludge in a Fenton Advanced Oxidation System.

DOI: 10.5220/0011182700003443

In Proceedings of the 4th International Conference on Biomedical Engineering and Bioinformatics (ICBEB 2022), pages 79-83

ISBN: 978-989-758-595-1

Copyright

c

2022 by SCITEPRESS – Science and Technology Publications, Lda. All rights reserved

79

fulvic acids disappear and that EPS was destroyed

after sludge was treated using a Fenton-like system,

while SEM exhibited that stable sludge flocs were

destroyed using a Fenton-like system and

acidification, with the water in flocs more easily

released and therefore, the sludge dewatering

performance improved. The floc structure of sludge

changes, allowing the bound water to be released

and the polymer to become smaller after EPS

oxidation and degradation (Xu 2016).

Previous reports on sludge dewatering using

Fenton advanced oxidation systems, have mainly

focused on urban sludge, while few reports have

investigated oily sludge from specific industries and

there is no general consensus on the optimal Fenton

reagent dosage, or conditions for the dehydration

and reduction of oily sludge. This paper

comprehensively analyzes the dehydration

performance of oily sludge after conditioning using

a Fenton advanced oxidation system. The

influencing factors and optimal conditions for

Fenton reaction conditioning of oily sludge were

determined by investigating the changes in moisture

content and specific resistance of sludge after

conditioning. These findings lay a foundation for the

practical application of Fenton advanced oxidation

technology in the oil sludge industry.

2 MATERIALS AND METHODS

2.1 Materials

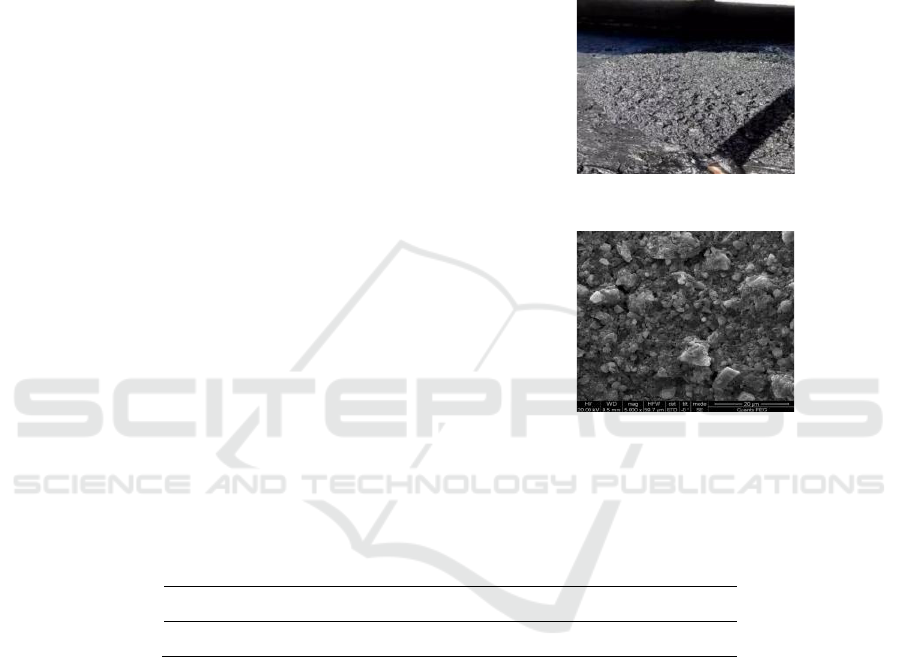

The oily sludge used in this experiment originated

from Sichuan province and was produced during

shale gas exploitation. The sludge was gray black

with a moisture content of 30-85%, as shown in Fig.

1 and Fig. 2. According to the results of XRF

analysis, the main components of the oily sludge

were found to be inorganic minerals such as BaSO

4

,

CaO and Al

2

O

3

, as shown in Table 1. FeSO

4

, H

2

O

2

and HCl were all of analytical purity.

Figure 1: Sample of oily sludge

Figure 2: SEM of oily sludge.

Table 1: Composition analysis of XRF oily sludge containing oily sludge.

Components SiO

2

CaO Al

2

O

3

BaO SO

3

Fe

2

O

3

Others

Wt (%) 39.26 15.32 11.45 10.69 8.26 5.65 9.37

2.2 Methods

Oily sludge was poured into a beaker and combined

with the Fenton reagent, with continual agitation

using a magnetic stirrer and the reaction maintained

under different temperatures and different durations.

The conditioned oily sludge was then poured into a

Brinell funnel equipped with quantitative filter paper

for vacuum suction filtration and dehydration. The

amount of filtrate in the measuring cylinder was

recorded at specific times, allowing the sludge

specific resistance (SRF) to be calculated. The

moisture content of sludge was determined using the

gravimetric method.

3 RESULTS AND ANALYSIS

In order to establish the effect of varying pH,

reaction time and m

H2O2

/m

FeSO4

, each factor was

compared at three levels, using the L

9

(3

4

) orthogonal

table, in which A indicates pH (A

1

(pH=2), A

2

(pH=3) and A

3

(pH=4)); B indicates reaction time

(B

1

(30 min), B

2

(40 min) and B

3

(50 min); C

indicates the mass ratio of hydrogen peroxide to

ferrous sulfate (m

H2O2

/m

FeSO4

) (C

1

(m

H2O2

/m

FeSO4

=10/1), C

2

(m

H2O2

/m

FeSO4

=12/1) and C

3

(m

H2O2

/m

FeSO4

=14/1)). Factors A, B and C are listed

in columns 1, 2 and 3 of L

9

(3

4

), respectively.

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

80

Table 2: Orthogonal experimental design.

Level

Factors

pH(A)

Reaction time

(B)

Mass ratio(C)

1

2(A

1

) 30(B

1

) 10/1(C

1

)

2

2(A

1

) 40(B

2

) 14/1(C

3

)

3

2(A

1

) 50(B

3

) 12/1(C

2

)

4

3(A

2

) 30(B

1

) 12/1(C

2

)

5

3(A

2

) 40(B

2

) 10/1(C

1

)

6

3(A

2

) 50(B

3

) 14/1(C

3

)

7

4(A

3

) 30(B

1

) 14/1(C

3

)

8

4(A

3

) 40(B

2

) 12/1(C

2

)

9

4(A

3

) 50(B

3

) 10/1(C

1

)

3.1 Apparent Analysis of Orthogonal

Experimental Results

Results show that the appearance of oily sludge was

a black solid block prior to treatment, changing to a

dissolved state after pH adjustment treatment. The

oily sludge expanded during treatment, with gas

escaping during the reaction process. Under different

reaction conditions the intensity of oily sludge

expansion varied, with the resulting dried oily

sludge being a black gray loose block. As shown in

Fig. 2, the oily sludge is in a mass shape with an

uneven surface, containing a high mass of

extracellular polymer micelles which contain a large

amount of bound water, which is not conducive to

the dehydration of oily sludge. As shown in Fig. 4,

the extracellular polymer structure was destroyed by

the Fenton reaction, improving the dewatering

performance of oily sludge.

Table 3 Orthogonal experimental results of oily sludge dewatering under Fenton advanced oxidation system

NO. m

1

(g) m

2

(g) m

3

(g) w

j

(%) c

j

(%) SRF (s

2

/g)

1 28.8968 48.9740 46.2095 13.77 86.23 7.53×10

14

2 28.9030 49.0111 46.3609 13.18 86.82 1.18×10

14

3 28.8980 49.3161 46.6438 13.09 86.91 5.12×10

14

4 28.8556 49.0637 46.1923 14.21 85.79 6.87×1014

5 28.6968 48.7183 46.1493 12.83 87.17 7.13×10

14

6 28.8584 48.8695 45.9478 14.60 85.40 1.01×10

14

7 28.8651 48.9668 46.2897 13.32 86.68 3.28×10

14

8 31.6662 51.7520 49.0044 13.68 86.32 4.60×10

14

9 28.8564 48.9887 46.1100 14.30 85.70 4.04×10

14

Effect of Dehydration Process Conditions on Oily Sludge in a Fenton Advanced Oxidation System

81

Figure 3: Oily sludge after treatment.

Figure 4: SEM of oily sludge after treatment.

3.2 Analysis of Water Content of Oily

Sludge under Fenton Advanced

Oxidation System

Analysis of orthogonal experimental results showed

that the water content of treated oily sludge varied

between 12-15% depending on the level of different

experimental factors. The lowest treated sludge

specific resistance had the highest water content of

14.60%, which was achieved under reaction

conditions of pH 3, with a 50 min reaction time and

m

H2O2

/m

FeSO4

ratio of 14/1. The lowest moisture

content of 12.83% was achieved under reaction

conditions of pH 3, with a reaction time of 40 min

and m

H2O2

/m

FeSO4

of 10/1, which were the optimal

experimental conditions in terms of moisture content

according to the orthogonal experimental results.

Table 4 Variance analysis of moisture content.

Source Class III sum

of squares

Freedom Mean square F Significance

Modified model 1.409

a

6 0.235 0.301 0.893

Interce

p

t 1680.453 1 1680.453 2156.240 0.000

pH

(

A

)

0.474 2 0.237 0.304 0.767

Reaction time

(

B

)

0.929 2 0.464 0.596 0.627

Mass ratio

(

C

)

0.007 2 0.003 0.004 0.996

Erro

r

1.559 2 0.779

Total 1683.421 9

Analysis of variance showed that among the

influencing factors, pH, reaction time and

m

H2O2

/m

FeSO4

ratio had a significant impact on the

water content of oily sludge. The primary and

secondary relationships among the three factors was

ranked in the order of m

H2O2

/m

FeSO4

(C) > pH(A) >

reaction time(B). The optimum level of each factor

was: pH 3, reaction time of 40 min and m

H2O2

/m

FeSO4

of 10/1.

3.3 Analysis of Sludge Specific

Resistance of Oily Sludge under

Fenton Advanced Oxidation

System

It was found that the specific resistance of oily

sludge after treatment varied from 1.00×10

14

-

8.00×10

14

s

2

/g, with the analysis of orthogonal

experimental results showing that the specific

resistance of oily sludge under different factor

conditions varied according to both the factor and

the factor level. The highest specific resistance of

oily sludge (difficult to filter sludge) was

7.53×10

14

s

2

/g under reaction conditions of pH 2,

with a reaction time of 30 min and a m

H2O2

/m

FeSO4

of

ICBEB 2022 - The International Conference on Biomedical Engineering and Bioinformatics

82

10/1. In contrast, the lowest sludge specific

resistance was 1.01×10

14

s

2

/g under the reaction

conditions of pH 3, with a reaction time of 50 min

and a m

H2O2

/m

FeSO4

of 14/1, which were the optimal

experimental conditions for specific resistance

according to the orthogonal experimental results.

Table 5 Variance analysis of sludge specific resistance.

Source Class III sum of

s

q

uares

Freedom Mean square F Significance

Modified

model

4.50×10

29a

6 7.505×10

28

7.235 0.126

Interce

p

t 1.85×10

30

1 1.846×10

30

177.998 0.006

pH

(

A

)

1.62×10

28

2 8.106×10

27

0.781 0.561

Reaction time

(B)

9.64×10

28

2 4.822×10

28

4.648 0.177

Mass ratio

(C)

3.38×10

29

2 1.688×10

29

16.276 0.058

Erro

r

2.07×10

28

2 1.037×10

28

Total 2.32×10

30

9

Analysis of variance showed that among the

influencing factors, pH, reaction time and

m

H2O2

/m

FeSO4

ratio had a significant impact on the

specific resistance of oily sludge. The primary and

secondary relationships among the three factors

were ranked in the order pH(A) > reaction time(B) >

m

H2O2

/m

FeSO4

(C). The optimum level of each factor

was: pH 3, with a 50 min reaction time and

m

H2O2

/m

FeSO4

(C) of 14/1.

4 CONCLUSION

Orthogonal experimental results for oily sludge

treatment using the Fenton advanced oxidation

system show that the optimal moisture content of

12.83% was achieved under the experimental

conditions of pH 3, with a reaction time of 40 min

and m

H2O2

/m

FeSO4

of 10/1. The optimal specific

resistance of 1.01×10

14

s

2

/g was achieved under

experimental conditions of pH 3, with a reaction

time of 50 min and a m

H2O2

/m

FeSO4

of 14/1. These

results confirm that the Fenton advanced oxidation

system can effectively destroy the extracellular

polymer structure of oily sludge, releasing some of

the bound water and converting it into free water,

improving the dewatering performance of sludge.

ACKNOWLEDGEMENTS

This work was financially supported by National

Natural Science Foundation of Yongchuan

(Ycstc,2019nb0803), Science and Technology

Research Program of Chongqing Municipal

Education Commission (Grant No.

KJQN201901310) and Natural Science Foundation

of Chongqing (cstc2020jcyj-msxmX0833).

REFERENCES

Hu G J, Li J B, Zeng G M. (2013). Recent development in

the treatment of oily sludge from petroleum industry:

A review. J. Hazard. Mater. 261(13):470-490.

Liu J B, Wei Y S, Li K, et al. (2016). Microwave-acid

pretreatment: A potential process for enhancing sludge

dewaterability. Water Res. 90:225-234.

Xiao K, Chen Y, Jiang X, et al. (2017). Microwave-acid

pretreatment: A potential process for enhancing sludge

dewaterability. Water Res. 90:225-234.

Xu H, Shen K, Ding T, et al. (2016). Dewatering of

drinking water treatment sludge using the Fenton-like

process induced by electro-osmosis. Chem. Eng. J.

293: 207-215.

Yang Q, Sun J, Wang D B, et al. (2017). Effect of nickel

on the flocculability, settleability, and dewaterability

of activated sludge. Bioresource Technol. 224: 188-

196.

Zhang W, Yang P, Yang X, et al. (2015). Insights into the

respective role of acidification and oxidation for

enhancing anaerobic digested sludge dewatering

performance with Fenton process. Bioresource

Technol. 181:247-253.

Effect of Dehydration Process Conditions on Oily Sludge in a Fenton Advanced Oxidation System

83